Method for mounting and alignment device for aligning a guide rail of an elevator system

A technology for guide rails and equipment, applied in the field of aligning devices for aligning guide rails, can solve the problems of poor riding comfort, misalignment of guide rails, and high wear and tear, and achieve the effects of precise alignment, correct alignment, and easy alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

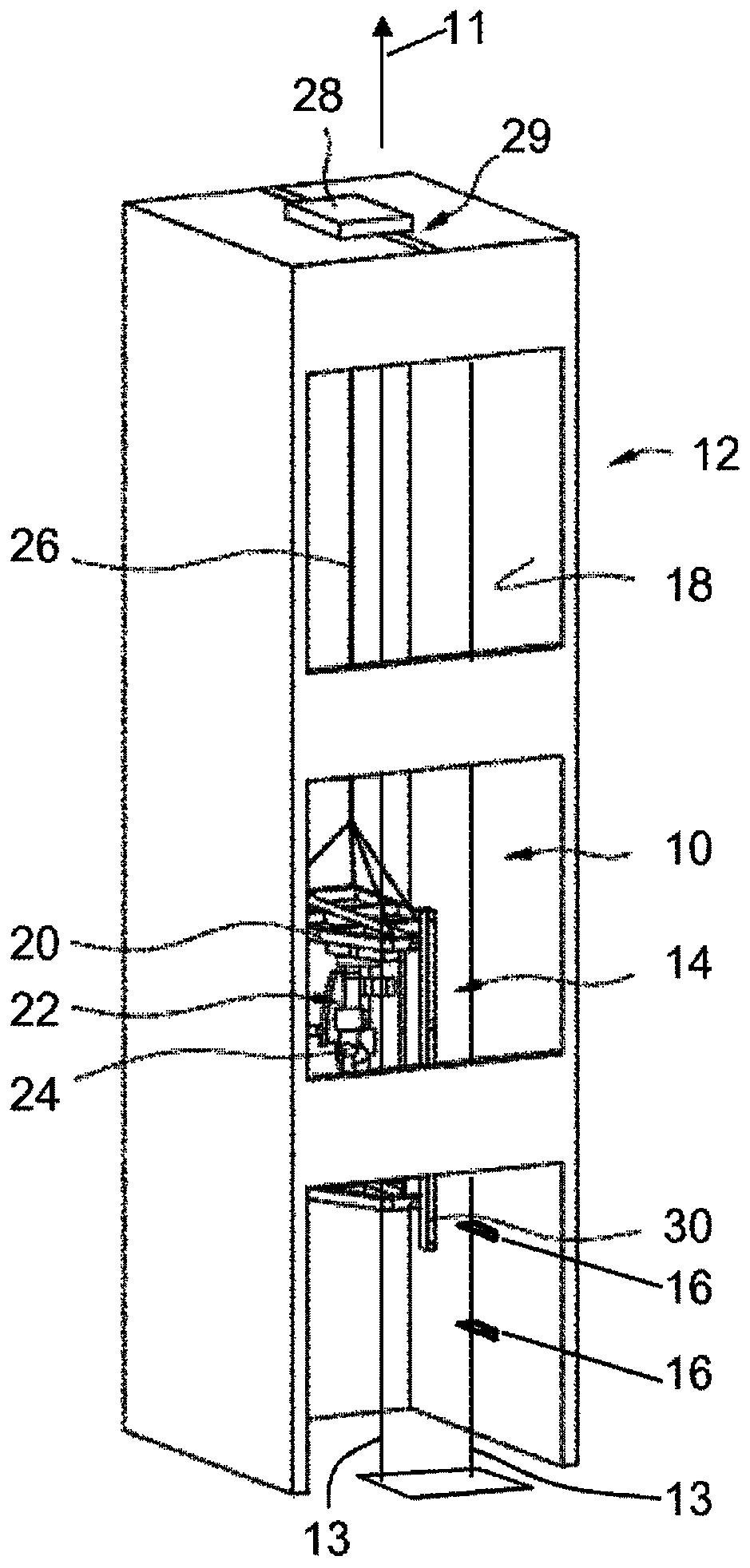

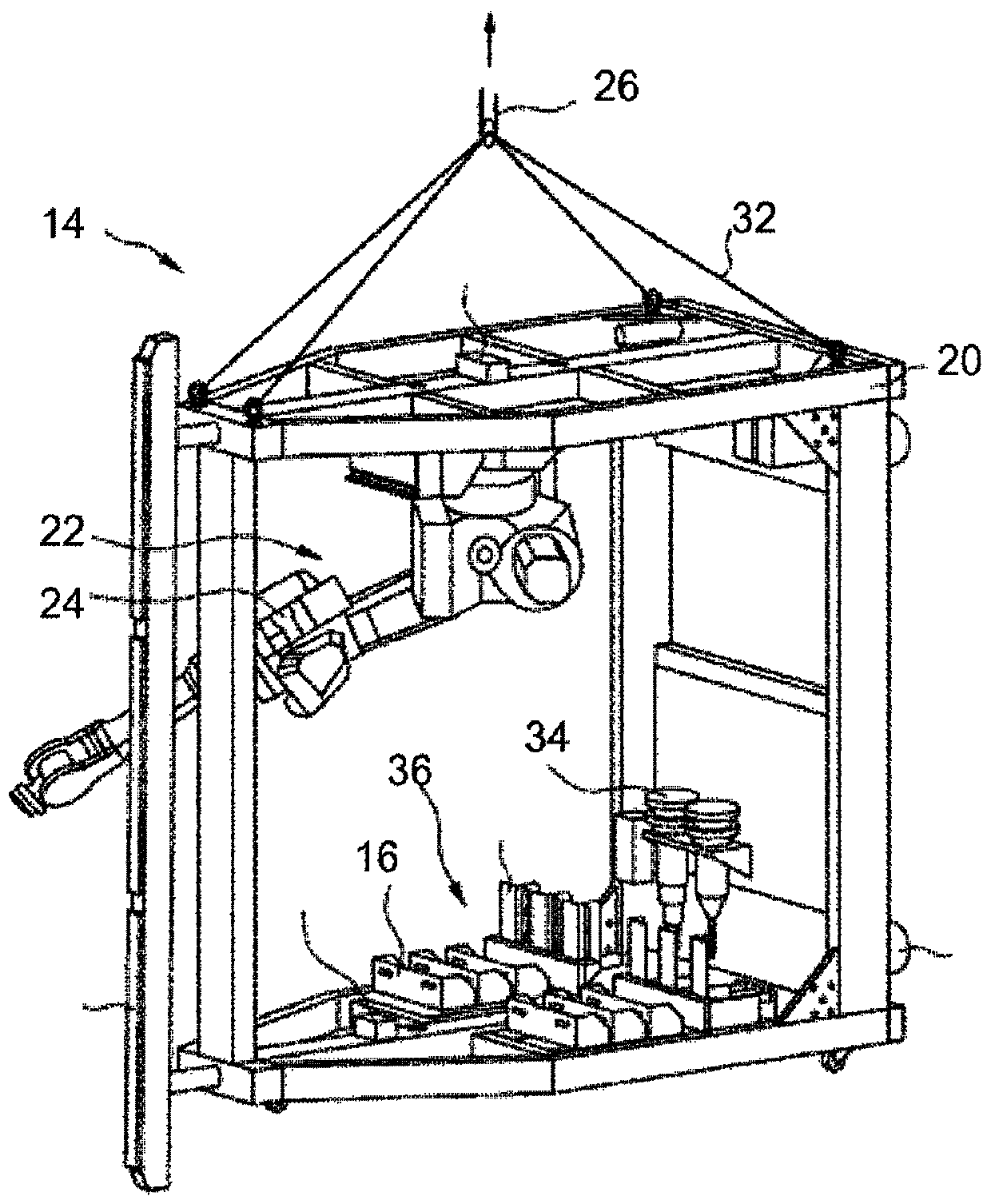

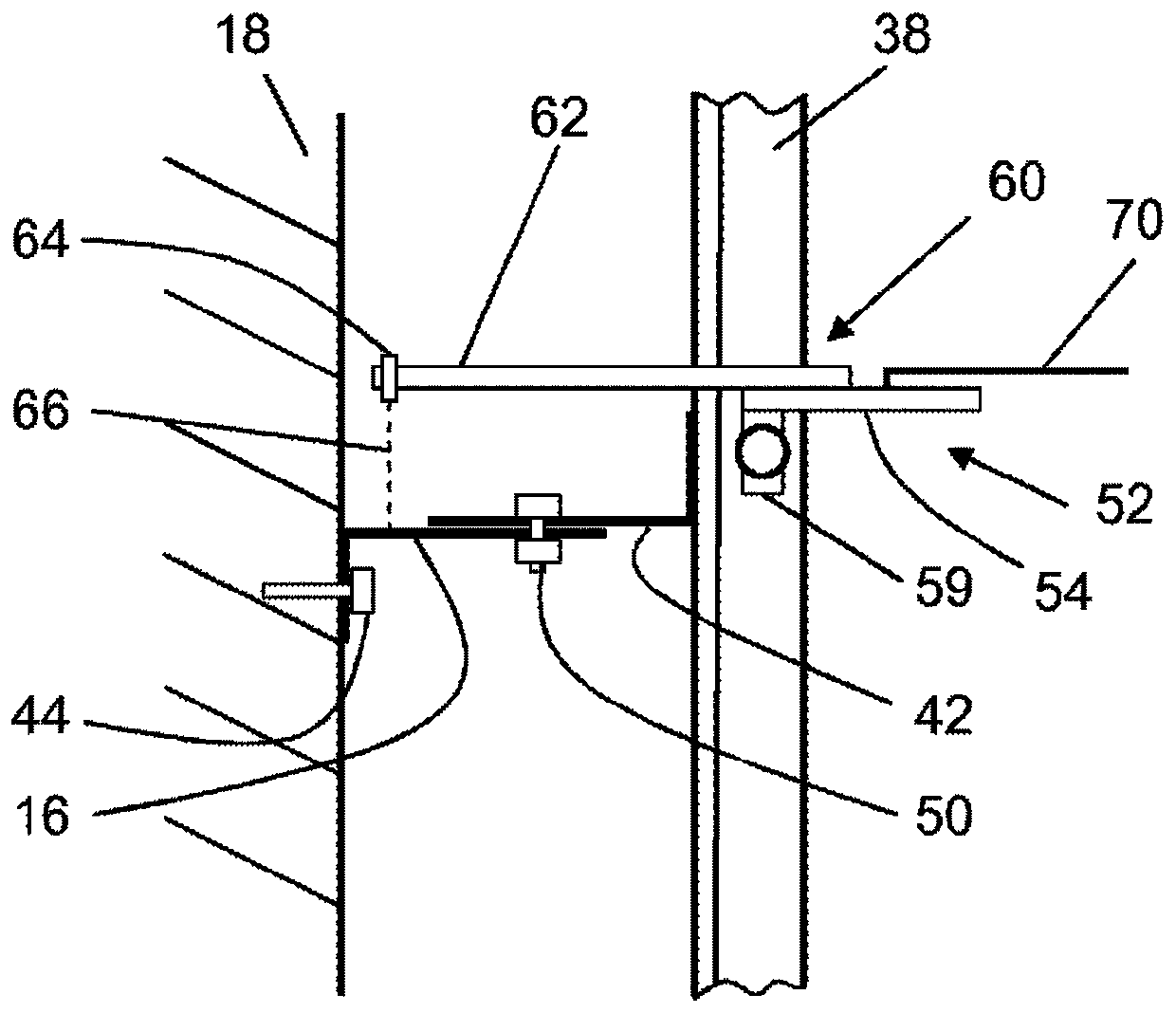

[0040] exist figure 1 FIG. 3 shows a mounting device 14 arranged in the elevator shaft 10 of the elevator installation 12 , by means of which mounting device the lower rail guide part 16 can be fastened to the shaft wall 18 . The elevator shaft 10 extends along a main direction of extension 11, which is at figure 1 Orientated vertically. With the aid of the lower part 16 of the rail guide frame, in a later assembly step the parts of the elevator installation 12 are figure 1 Rail not shown in ( image 3 and Figure 4 38) is fixed on the shaft wall 18. The mounting device 14 has a carrier part 20 and an electromechanical mounting part 22 . The carrier part 20 is designed as a frame, on which the electromechanical mounting part 22 is mounted. The frame has dimensions such that the carrier part 20 can be moved vertically within the elevator shaft 10, ie, for example, to different vertical positions on different floors within the building. In the example shown, the electrome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com