Rolling machine for forming a threading on a cylindrical body, and method for mutually synchronising forming rollers of a rolling machine

A technology for forming rollers and cylinders is applied in the field of roller presses that form threads on cylinders and their forming rollers are synchronized with each other. standardization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

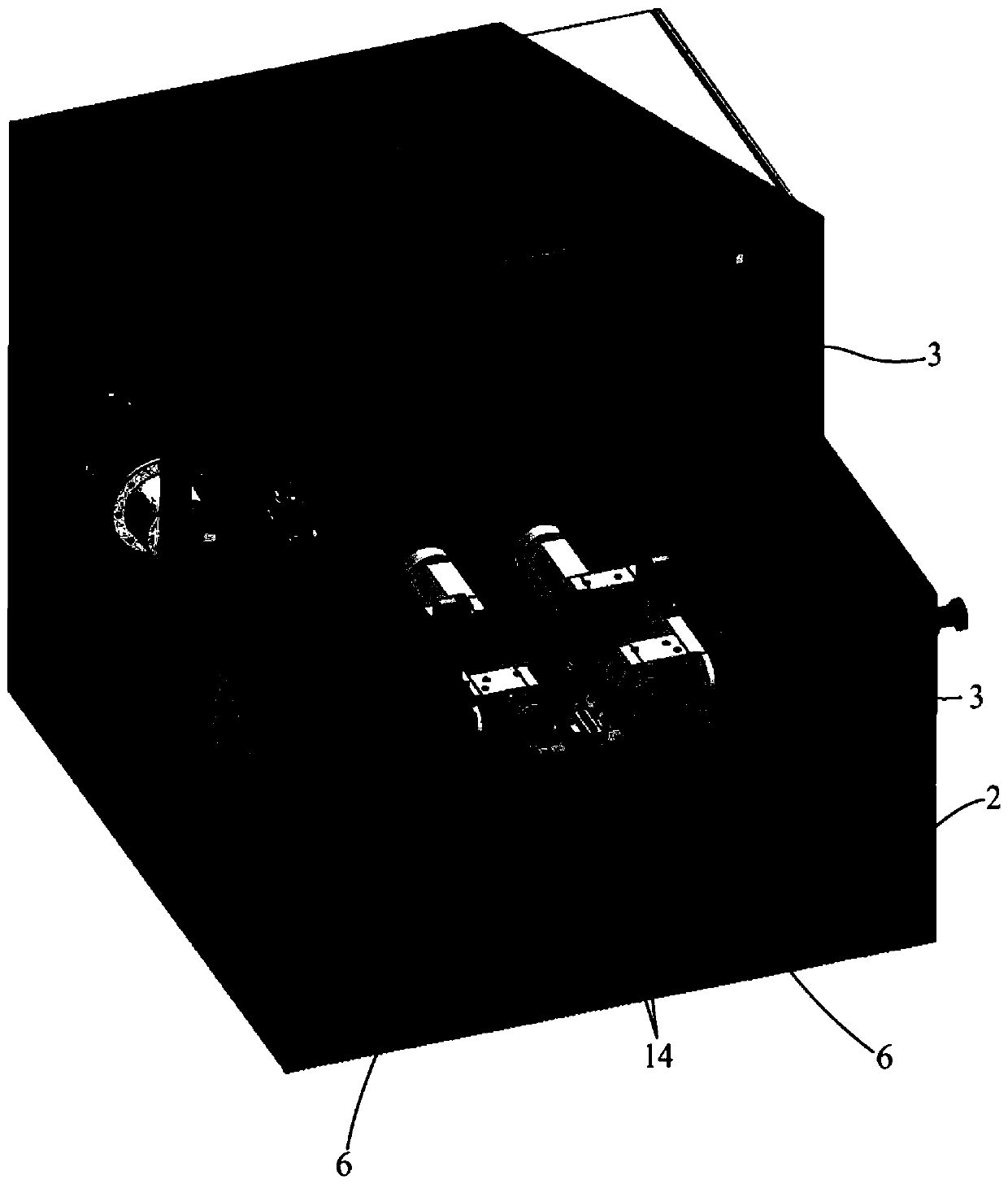

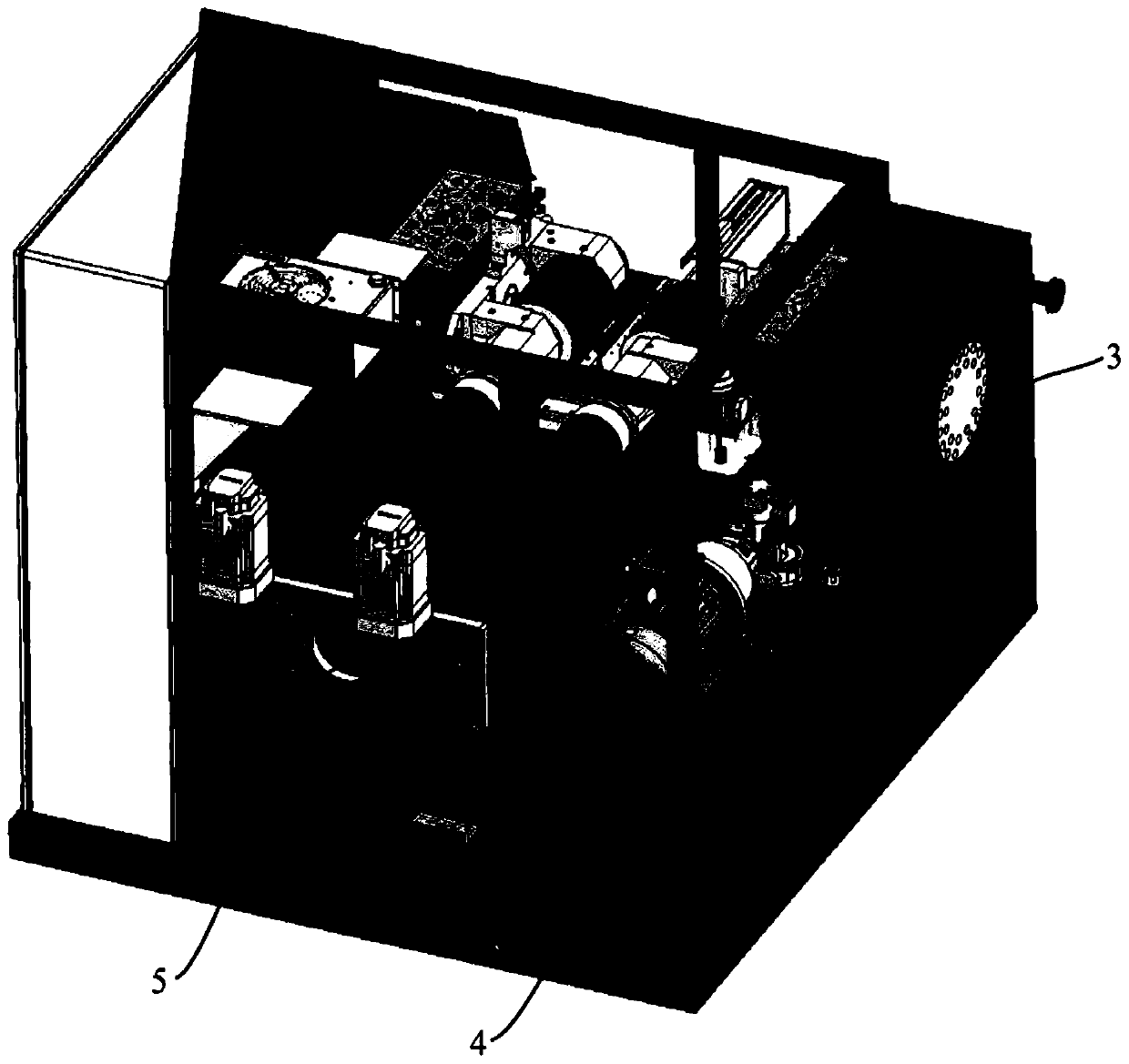

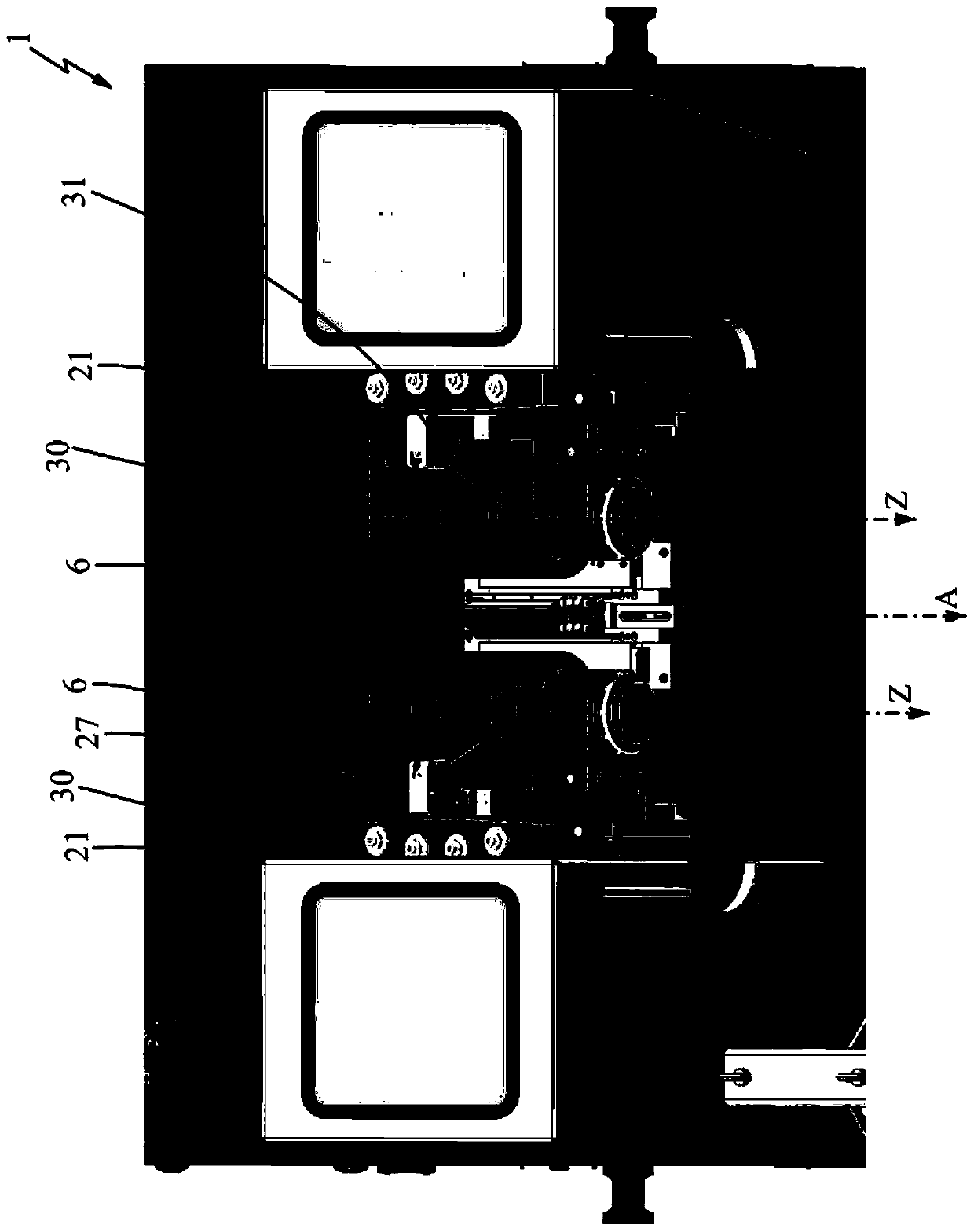

[0039] Referring to the accompanying drawings, a roller press for forming threads on a cylinder according to the present invention is generally indicated at 1 .

[0040] The roller presses discussed in this invention have a wide range of applications and are generally designated for producing the aforementioned threads on cylindrical parts of mechanical parts such as shafts, rods and rods.

[0041] Therefore, a mechanical part or piece of machinery, such as a shaft, rod, rod or any other cylindrical part, on which the threading is performed, is hereinafter referred to as a "cylinder".

[0042] This sleeve is obtained in a manner known per se or conventionally: cold plastic deformation is carried out on the surface of the cylinder to be formed by placing the cylinder in compression between several forming rollers 6 arranged around the circumference of the cylinder, wherein The cylinder is centered relative to the plurality of forming rolls.

[0043] In more detail, the rolling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com