Robot debugging platform

A robot and platform technology, applied in the field of robotics, can solve problems such as slowing down the progress of product development, affecting debugging efficiency, and time-consuming, and achieve the effects of shortening the consumption of manpower and material resources, solving the lack of platform resources, and facilitating debugging and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

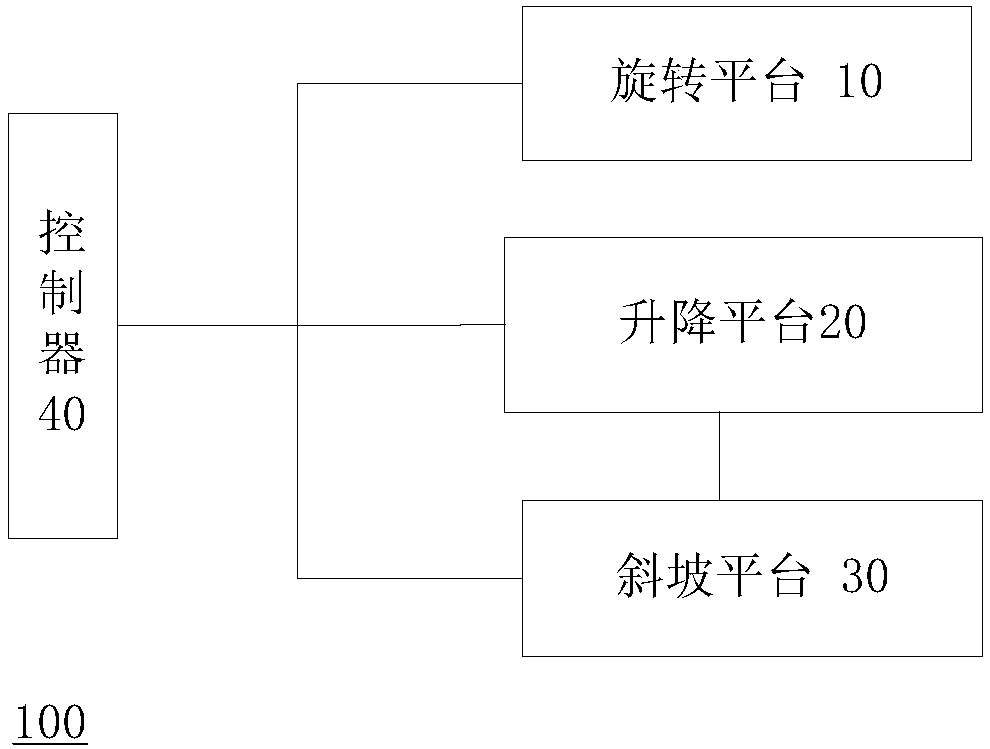

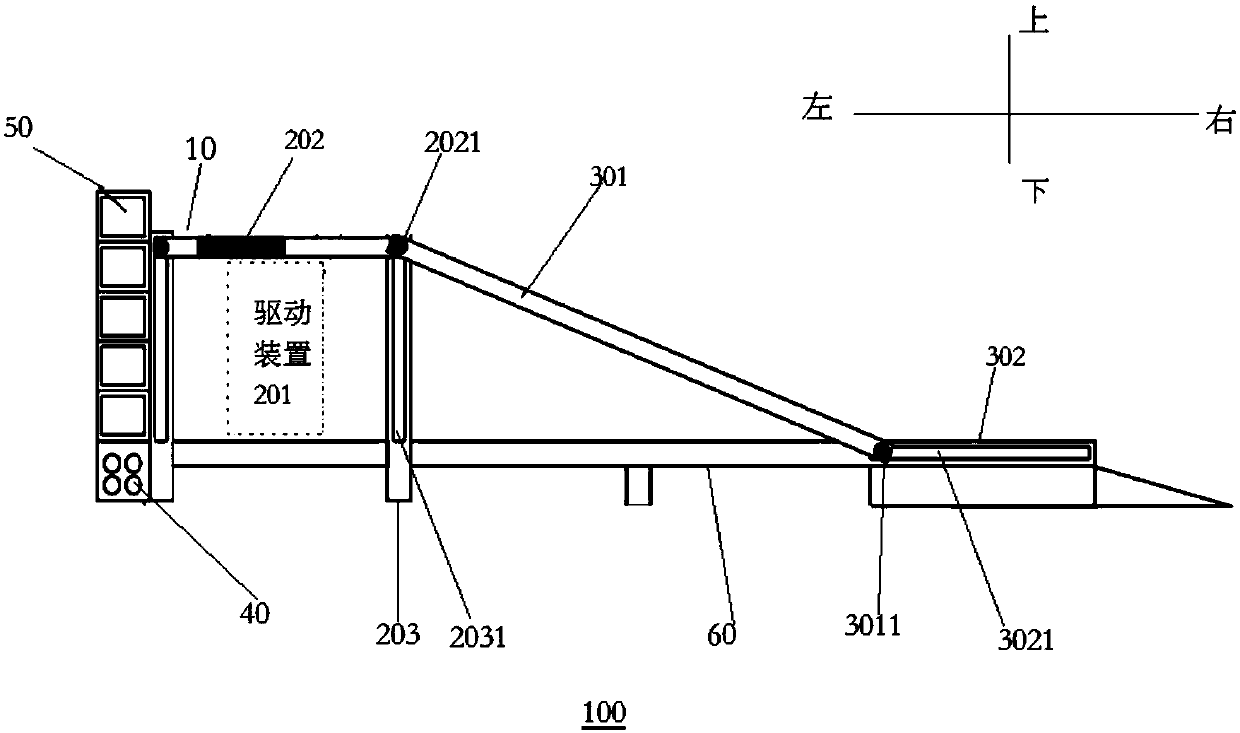

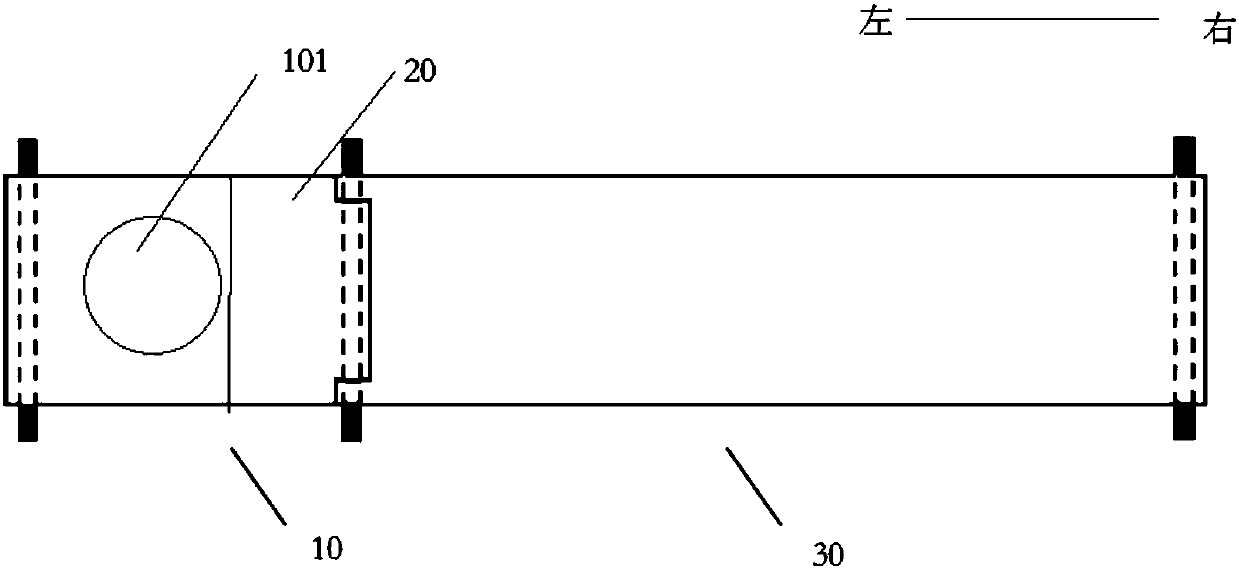

[0040] like Figure 4 In the illustrated embodiment, a robot debugging platform 100 is provided as an embodiment of the present invention. The robot debugging platform 100 includes: a lifting platform 20 and a slope platform 30 connected together with the lifting platform 20; the slope platform 30 can form a slope with a horizontal plane; the lifting platform 20 can go up and down, and the lifting platform A rotating platform 10 is arranged on the platform 20 ; the rotating platform 10 is arranged on an end of the lifting platform 20 away from the slope platform 30 , and the rotating platform 10 can rotate relative to the lifting platform 20 . In this embodiment, the angle range of the slope may be 0-30 degrees.

[0041] The slope platform 30 and the lifting platform 20 are connected together, and the slope platform 30 forms different slopes as the lifting platform 20 moves up and down. The lifting device 201 is an electric jack, and the slope platform 30 is linked with the ...

Embodiment 2

[0044] like Figure 5 In the illustrated embodiment, a robot debugging platform 100 is provided as an embodiment of the present invention. The robot debugging platform 100 includes: a lifting platform 20 and a slope platform 30 connected together with the lifting platform 20; the slope platform 30 can form a slope with a horizontal plane; the lifting platform 20 can go up and down, and the lifting platform A rotating platform 10 is arranged on the platform 20 ; the rotating platform 10 is arranged on an end of the lifting platform 20 away from the slope platform 30 , and the rotating platform 10 can rotate relative to the lifting platform 20 .

[0045] The slope platform 30 and the lifting platform 20 are connected together, and the slope platform 30 forms different slopes as the lifting platform 20 moves up and down. The lifting device 201 is a hydraulic cylinder. The slope platform 30 is linked with the lifting platform 20, so when the lifting platform 20 is operated to ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com