A kind of anti-crack and anti-corrosion marine concrete prepared by using machine-made sand with high stone powder content

A technology of stone powder content and machine-made sand, which is applied in the field of building materials, can solve the problems of inconspicuous anti-corrosion effect of concrete, short service life, and easy aging, so as to improve work performance and mechanical properties, improve durability, and avoid steel bars or The effect of steel fiber corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

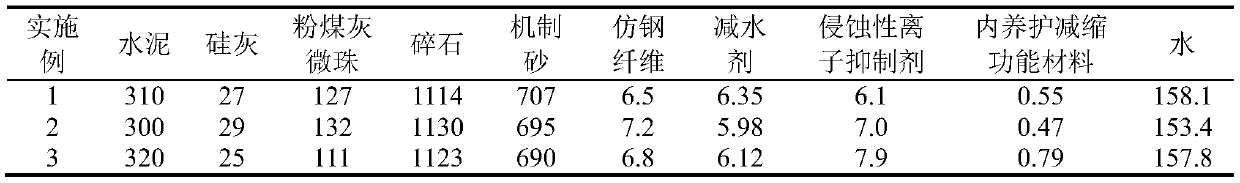

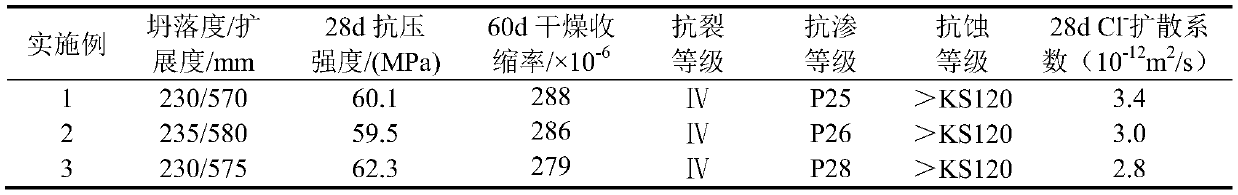

Embodiment 1~3

[0031] A crack-resistant and corrosion-resistant marine concrete (C50) prepared by utilizing machine-made sand with high stone powder content. The preparation method includes the following steps:

[0032] 1) Take each raw material by weighing the proportioning described in Table 1-1;

[0033] 2) Pour the weighed gravel and machine-made sand into the concrete mixer for dry mixing for 1 minute, then evenly add imitation steel fibers, then pour cement, silica fume, fly ash microbeads and internal curing shrinkage reduction functional materials into the mixer for 2 minutes. , then add water, polycarboxylate superplasticizer and aggressive ion inhibitor, and continue to stir for 6 minutes; finally, after mold loading, vibration, and molding, the surface is covered with an impermeable film, and the mold is removed after 1 day for standard maintenance. The anti-crack and corrosion-resistant marine concrete prepared by using machine-made sand with high stone powder content, the perfor...

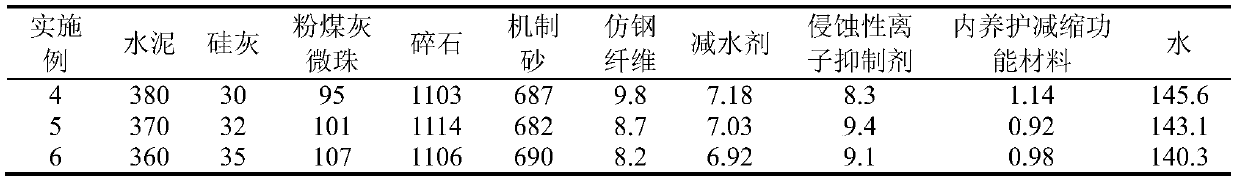

Embodiment 4~6

[0041] A crack-resistant and corrosion-resistant marine concrete (C60) prepared by utilizing machine-made sand with high stone powder content. The preparation method includes the following steps:

[0042] 1) Weigh each raw material according to the ratio described in Table 2-1;

[0043] 2) Pour the weighed gravel and machine-made sand into the concrete mixer for dry mixing for 1 minute, then evenly add imitation steel fibers, then pour cement, silica fume, fly ash microbeads and internal curing shrinkage reduction functional materials into the mixer for 2 minutes. , then add water, polycarboxylate superplasticizer and aggressive ion inhibitor, and continue to stir for 6 minutes; finally, after mold loading, vibration, and molding, the surface is covered with an impermeable film, and the mold is removed after 1 day for standard maintenance. The crack-resistant and corrosion-resistant marine concrete prepared by using machine-made sand with high stone powder content, the perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com