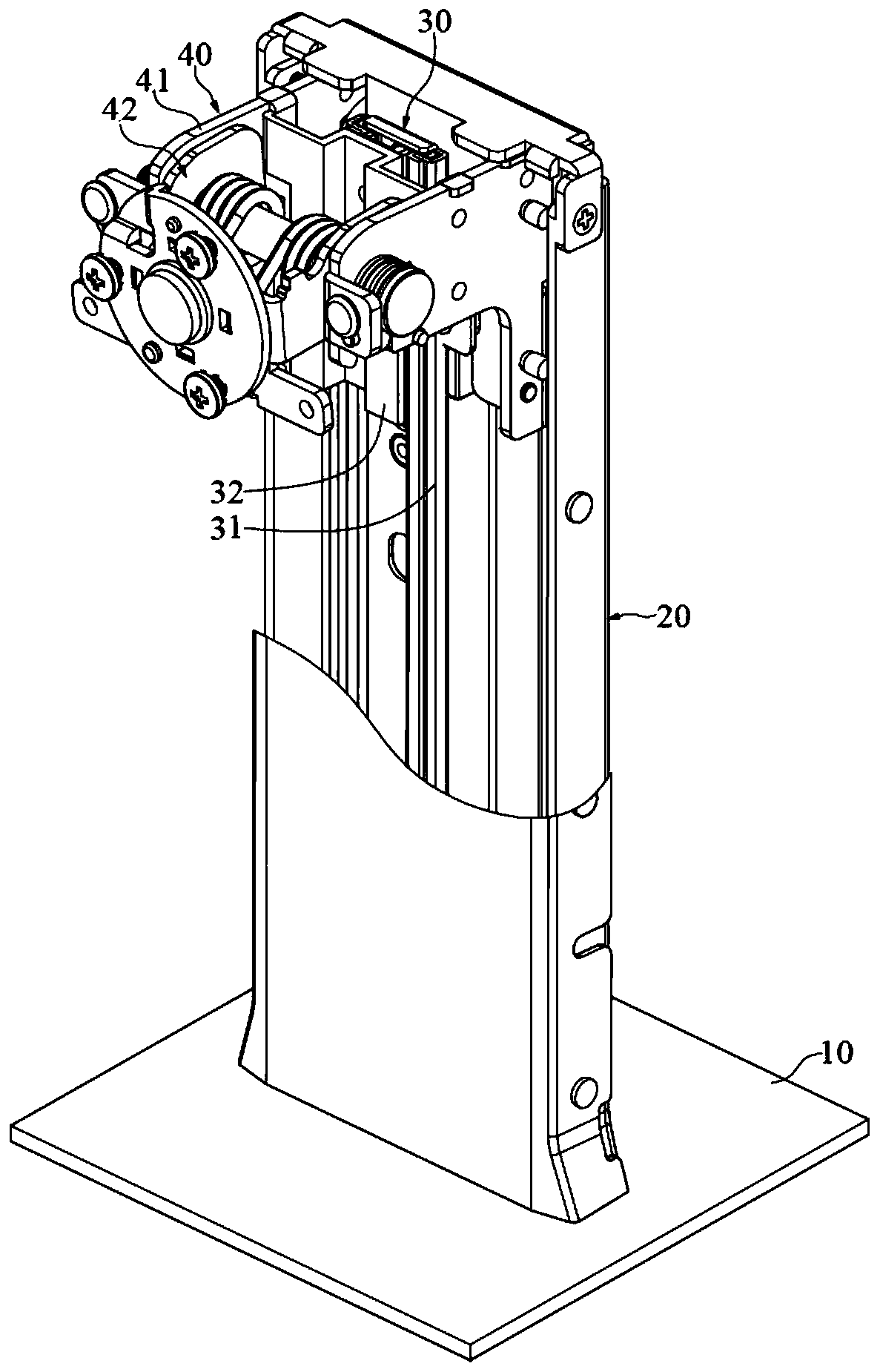

Display support mechanism

A technology for a support mechanism and a display, applied in the field of support frames, can solve the problem that the thickness cannot be effectively reduced, and achieve the effects of reducing materials, reducing costs, and reducing overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

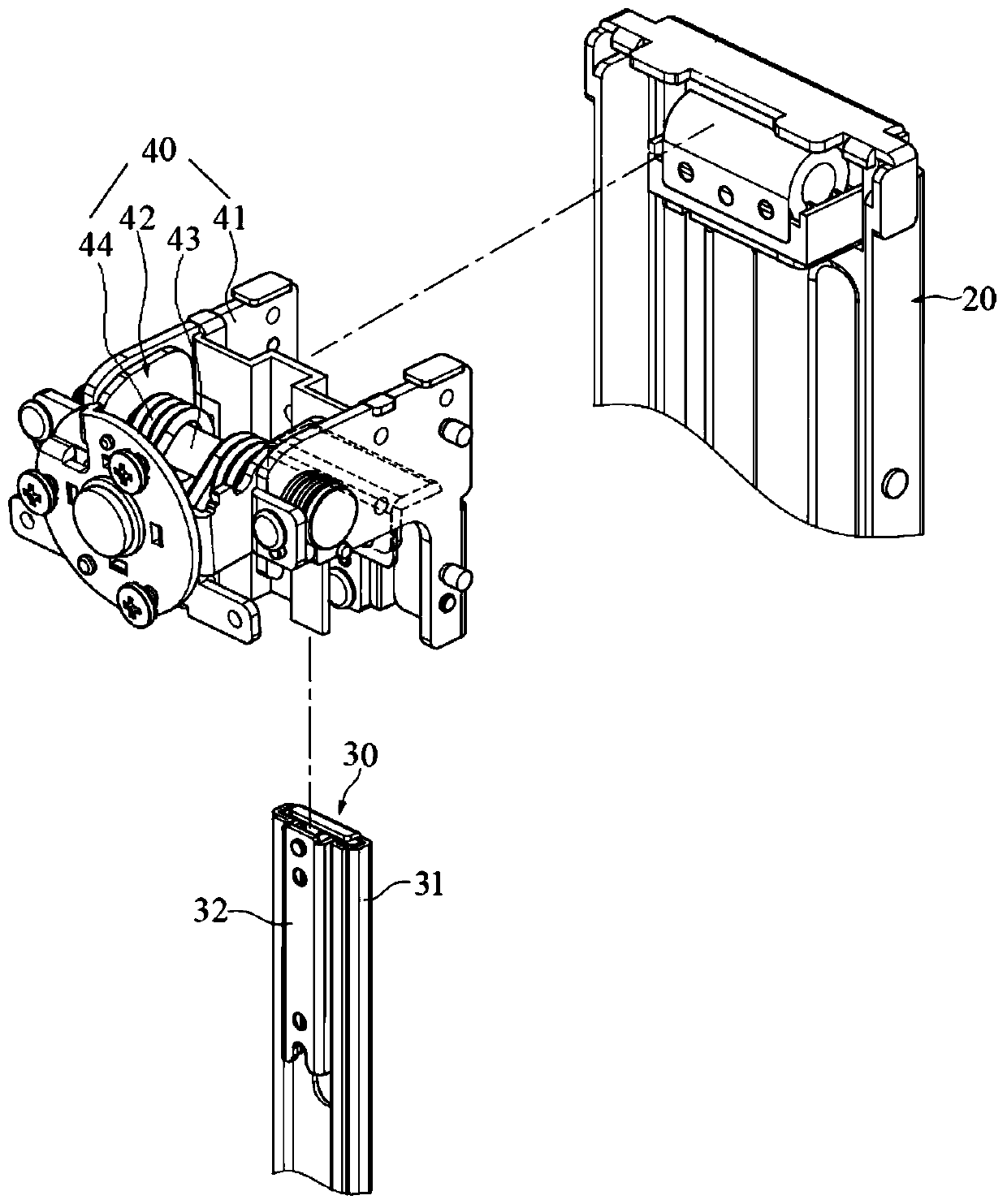

Method used

Image

Examples

Example Embodiment

[0057] Embodiment 2

[0058] see Figure 5 , this figure is a cross-sectional view of the slide rail module in the second embodiment; the difference between this embodiment and the first embodiment is that the first extension block 3122 of the pressing block structure 312 can be formed in a manner different from that of the first embodiment. In this embodiment, the connection surface between the first extension block 3122 and the pressure block structure 312 is larger, and the first extension block 3122 can be directly formed integrally with the pressure block structure 312 .

Example Embodiment

[0059] Embodiment 3

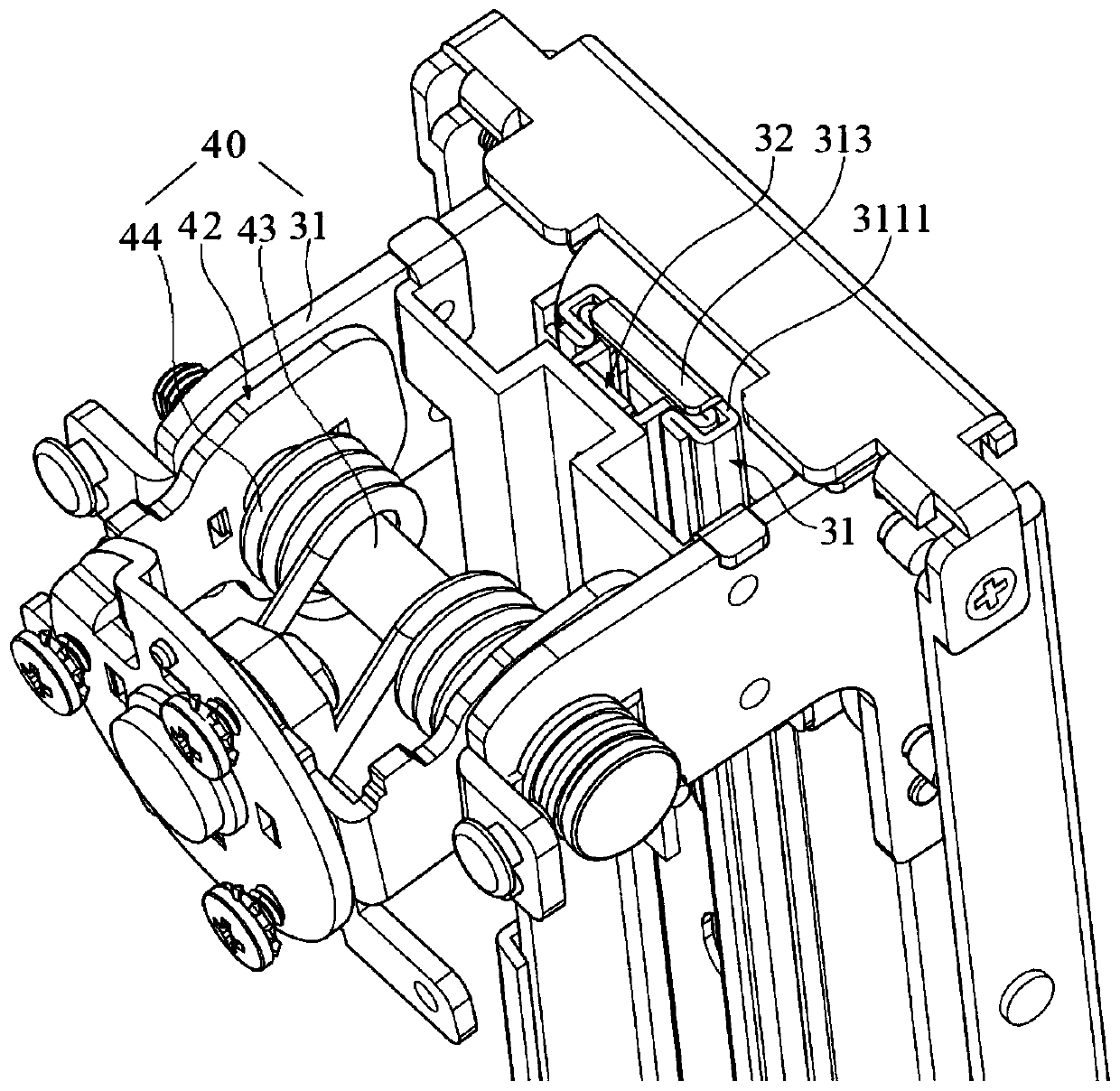

[0060] see Image 6 and Figure 7 ,in Image 6 is the assembly drawing of the slide rail module in the third embodiment, Figure 7 It is a cross-sectional view of the slide rail module in the third embodiment; the slide rail body 311 includes at least four connecting blocks 3112, and the connecting blocks 3112 are equally divided into two rows and are arranged on the side of the base member 3111 facing the pressing block structure 312, and each row is The plurality of connecting blocks 3112 are arranged at equal intervals; the two columns of connecting blocks 3112 are respectively detachably installed with pressing block structures 312 .

[0061] Wherein, the first extension block 3122 of the pressing block structure 312 can be obtained by extending and bending as in the first embodiment, or by direct integral molding as in the second embodiment; it can be understood that the two The pressure block structure 312 and the slide rail main body 311 adopt ...

Example Embodiment

[0063] Embodiment 4

[0064] see Figure 8 , this figure is a cross-sectional view of the slide rail module in the fourth embodiment; as shown in the figure, the slide rail module 30 in this embodiment, its slider 32 also includes two second extension blocks 324, two second The extension blocks 324 are respectively connected to the two inner slides 323; the two second extension blocks 324 are formed by extending and bending the two inner slides 323 opposite to the connecting arm 322 in a direction away from the connecting arm 322, Moreover, the second extension block 324 and the inner sliding piece 323 are mutually formed with a first arc-shaped protrusion 3241 . When the sliding block 32 slides relative to the guide rail 31 , the first arc-shaped protrusion 3241 abuts against the connecting block 3112 .

[0065] Specifically, the second extension block 324 is bent toward the base member 3111, that is, the second extension block 324 is in contact with the base member 3111, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap