Low-voltage centralized collecting fault and potential safety hazard troubleshooting simulation training device

A technology for troubleshooting and failure safety, which is applied to the simulation device of space navigation conditions, transportation and packaging, instruments, etc., can solve the hidden dangers of power safety, the lack of correct understanding of safety risks, and the inability to really improve the safety awareness of low-voltage centralized copying employees. Problems such as technical inadequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

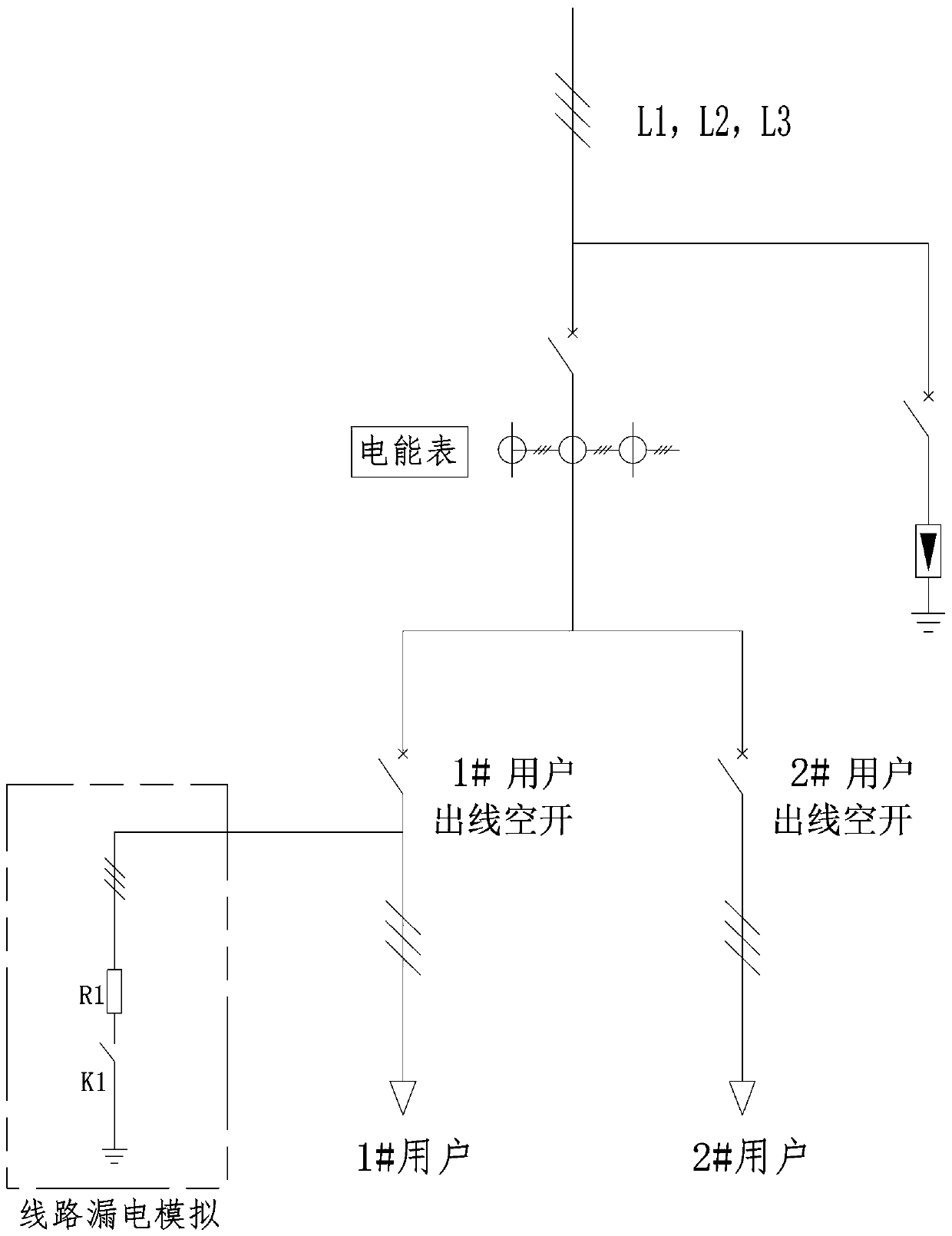

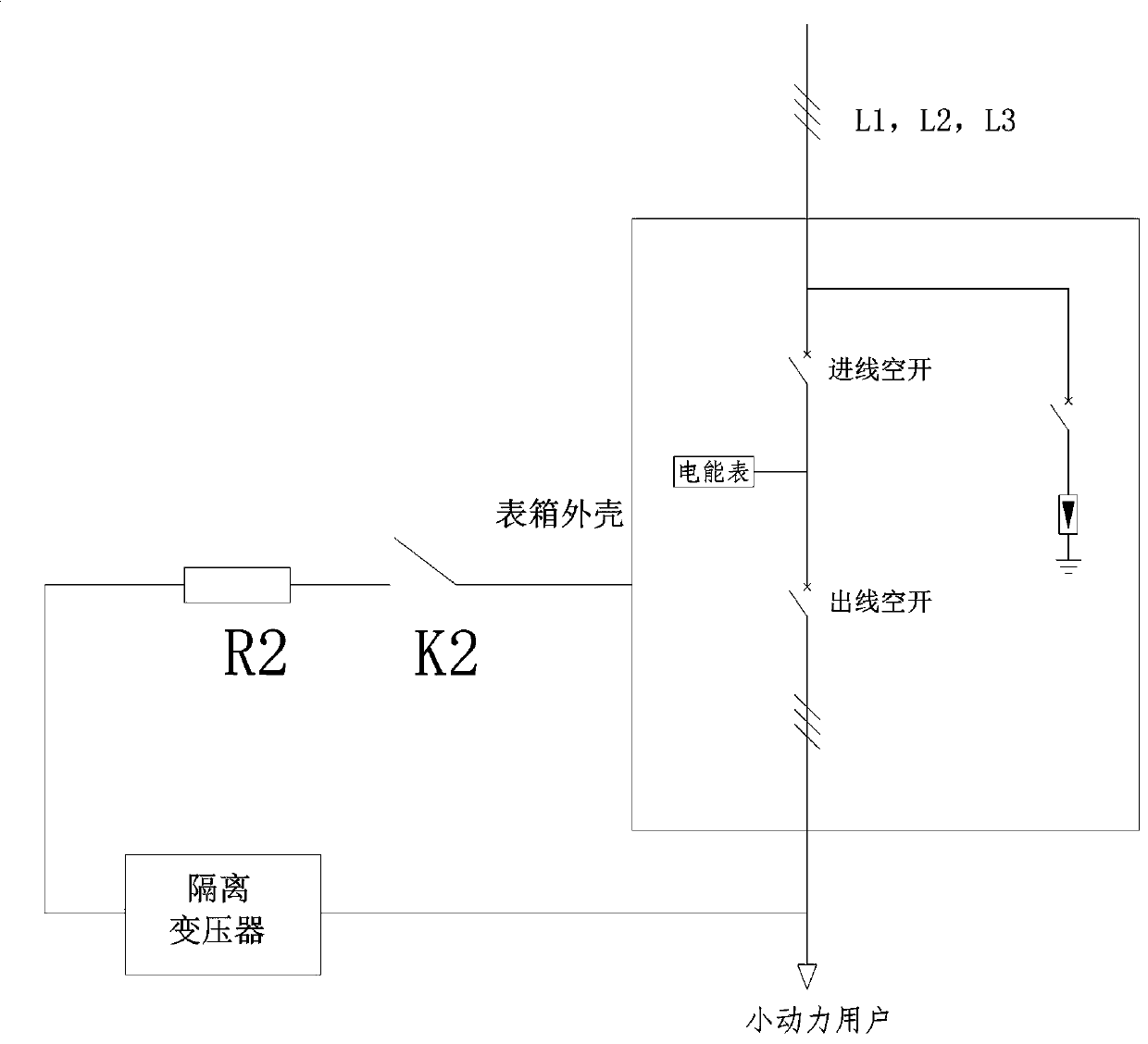

[0024] Such as Figure 1-7 As shown, a low-voltage centralized reading fault safety hidden trouble investigation simulation training device includes a low-voltage distribution box and a fault simulation module; the low-voltage distribution box is used to supply power for the fault simulation module;

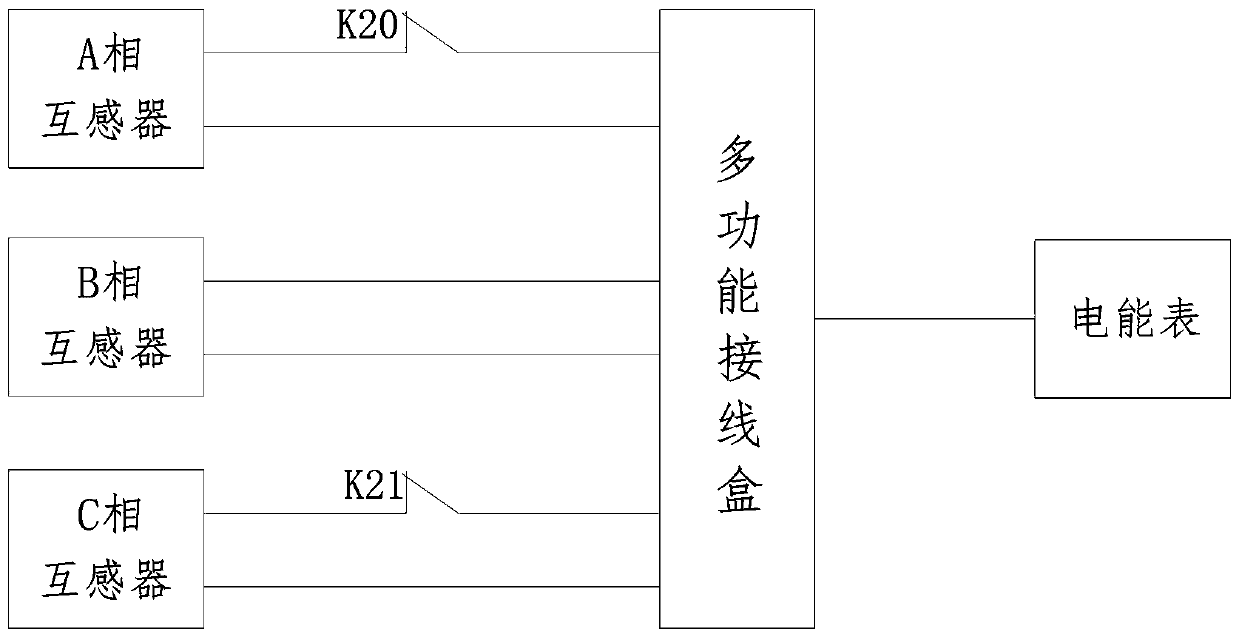

[0025] The fault simulation module includes a line leakage simulation module 1, and the line leakage simulation module includes a three-phase inductor type meter box, and a leakage point is set on the power supply circuit of the three-phase inductor type meter box, and the three-phase inductor type meter box The load of the type meter box is a power resistor, and the leakage point is grounded through the current limiting resistor R1 and the control switch K1; the three-phase current transformer in the three-phase inductor type meter box is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com