Plasma processing system and operation method thereof

A processing system and plasma technology, applied in the field of semiconductor processing, can solve the problems of the difference between the internal space and external dimensions of the processing chamber, the inability to use the task requirements of the manipulator, and the different spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

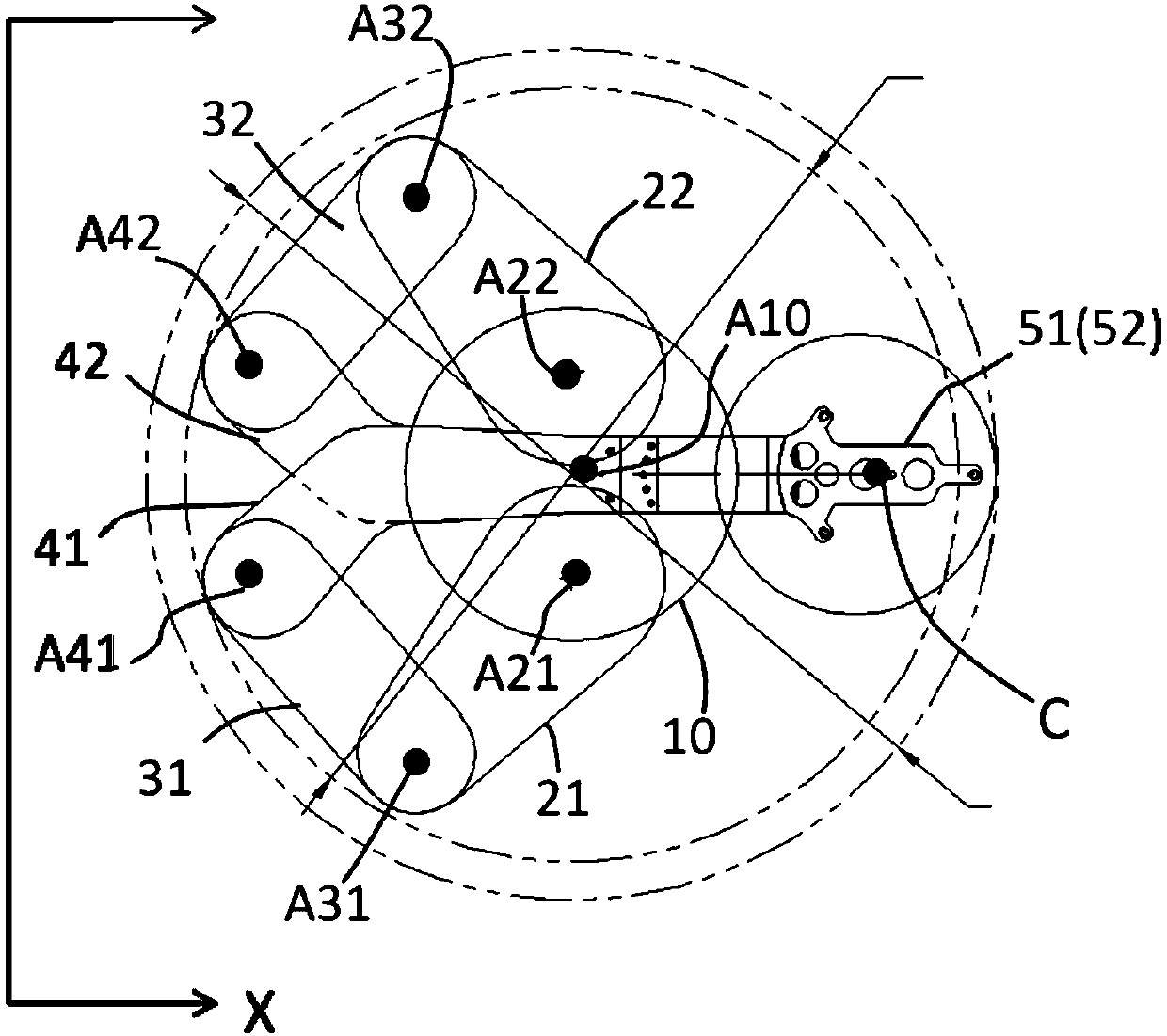

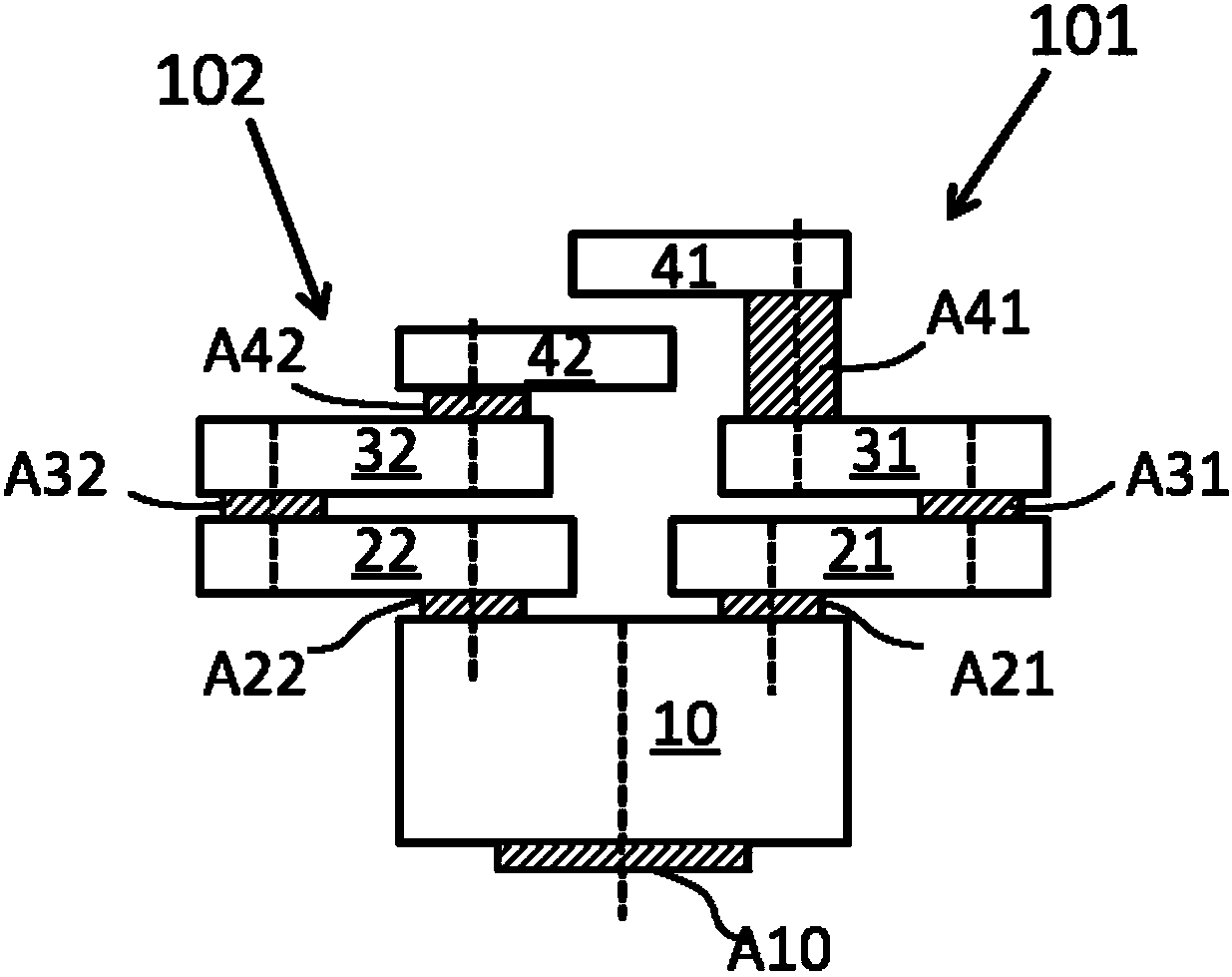

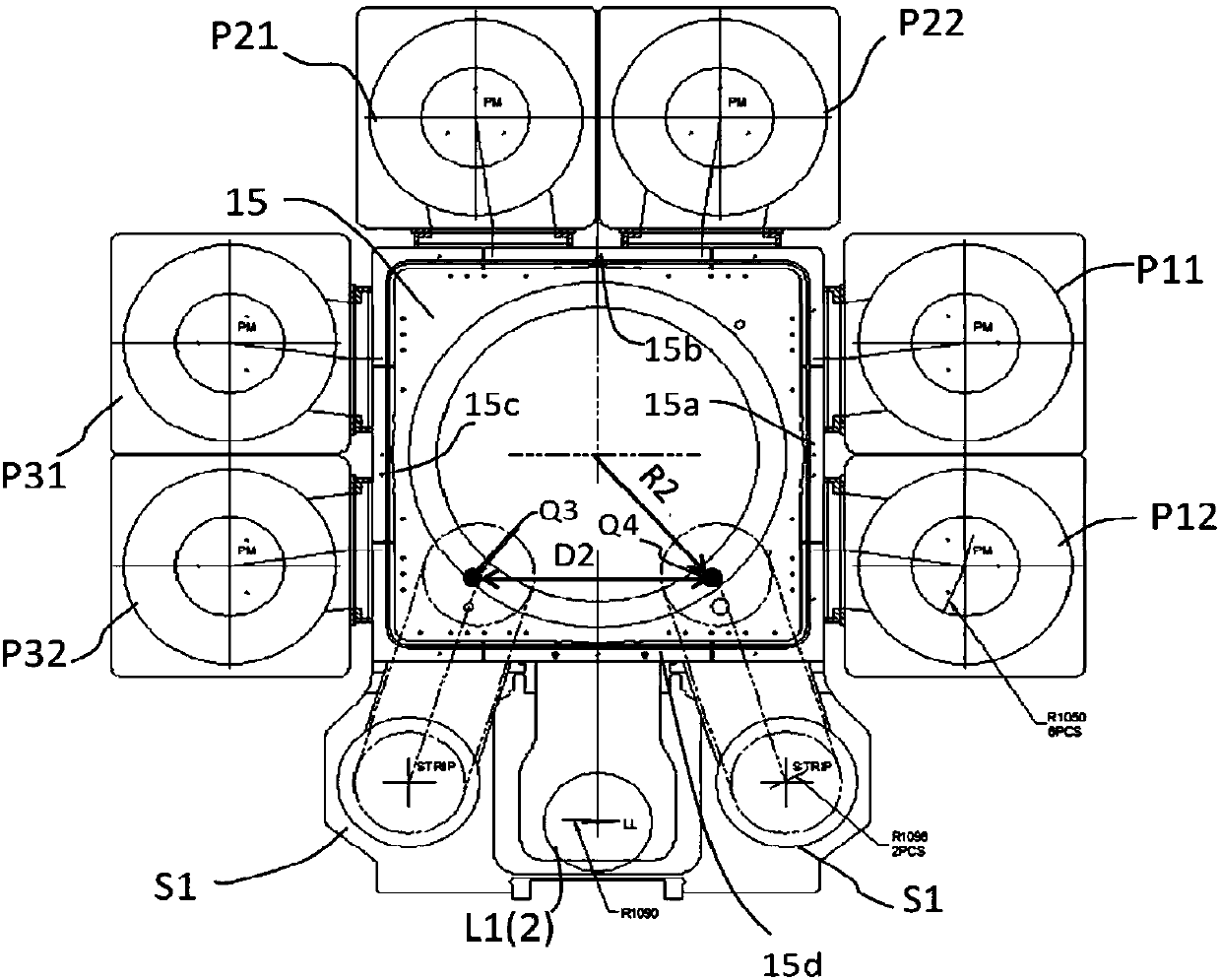

[0019] The specific embodiments of the present invention will be further described below in conjunction with accompanying drawings 1-3.

[0020] like Figure 1a As shown, the mechanical transmission device of the present invention includes a rotating base 10 , and the rotating base 10 can controllably rotate around a lower rotating axis A10 . The rotating base 10 includes two rotating axes A22 and A21 symmetrically distributed along the center line and located on two sides of the rotating axis A10. A first end of the rotating arm 22 is connected to the rotating base 10 through a rotating shaft A22, and a first end of the rotating arm 21 is connected to the rotating base 10 through a rotating shaft A21. The second end of the rotating arm 22 includes a rotating shaft A32, the first end of the rotating arm 32 is connected to the second end of the rotating arm 22 through the rotating shaft A32, and the second end of the corresponding rotating arm 21 includes a selection shaft A31,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap