Tire burst safety suspension system, control method and vehicle

A suspension system and tire blowout technology, applied in suspension, elastic suspension, vehicle components, etc., can solve the problem of inability to ensure the balance of body height and roll stiffness, and achieve increased stiffness, reduced cost, and reduced lateral The effect of tilted risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

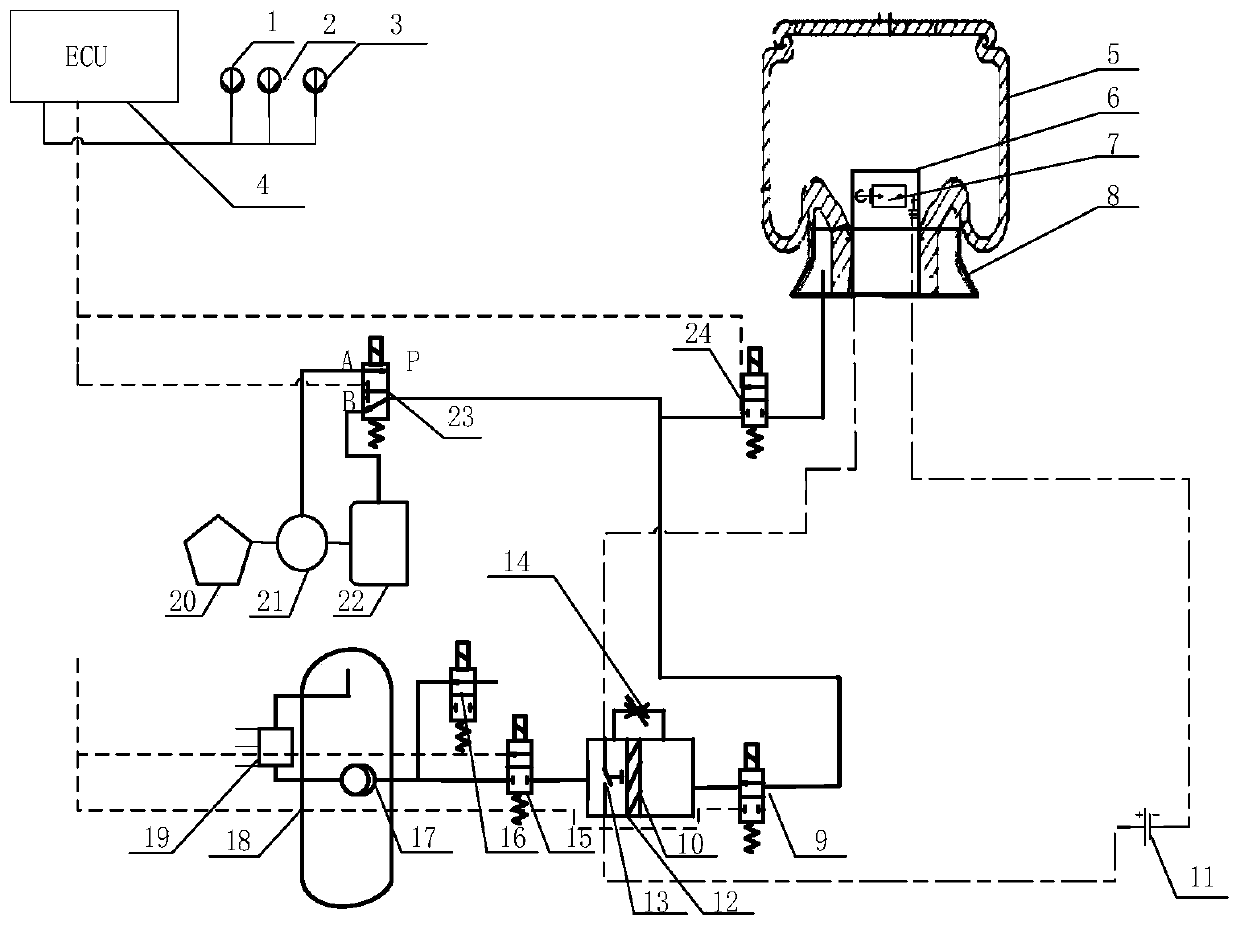

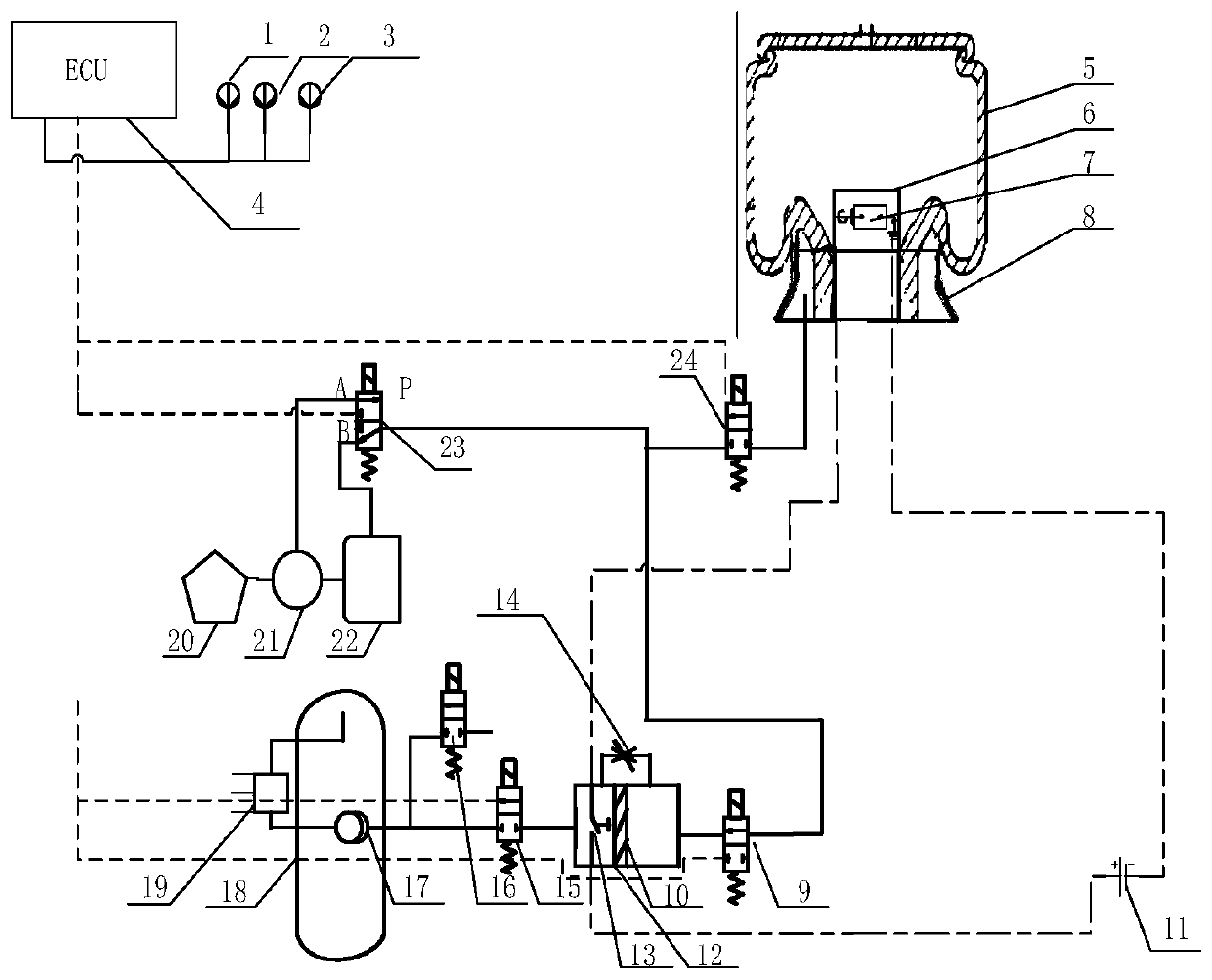

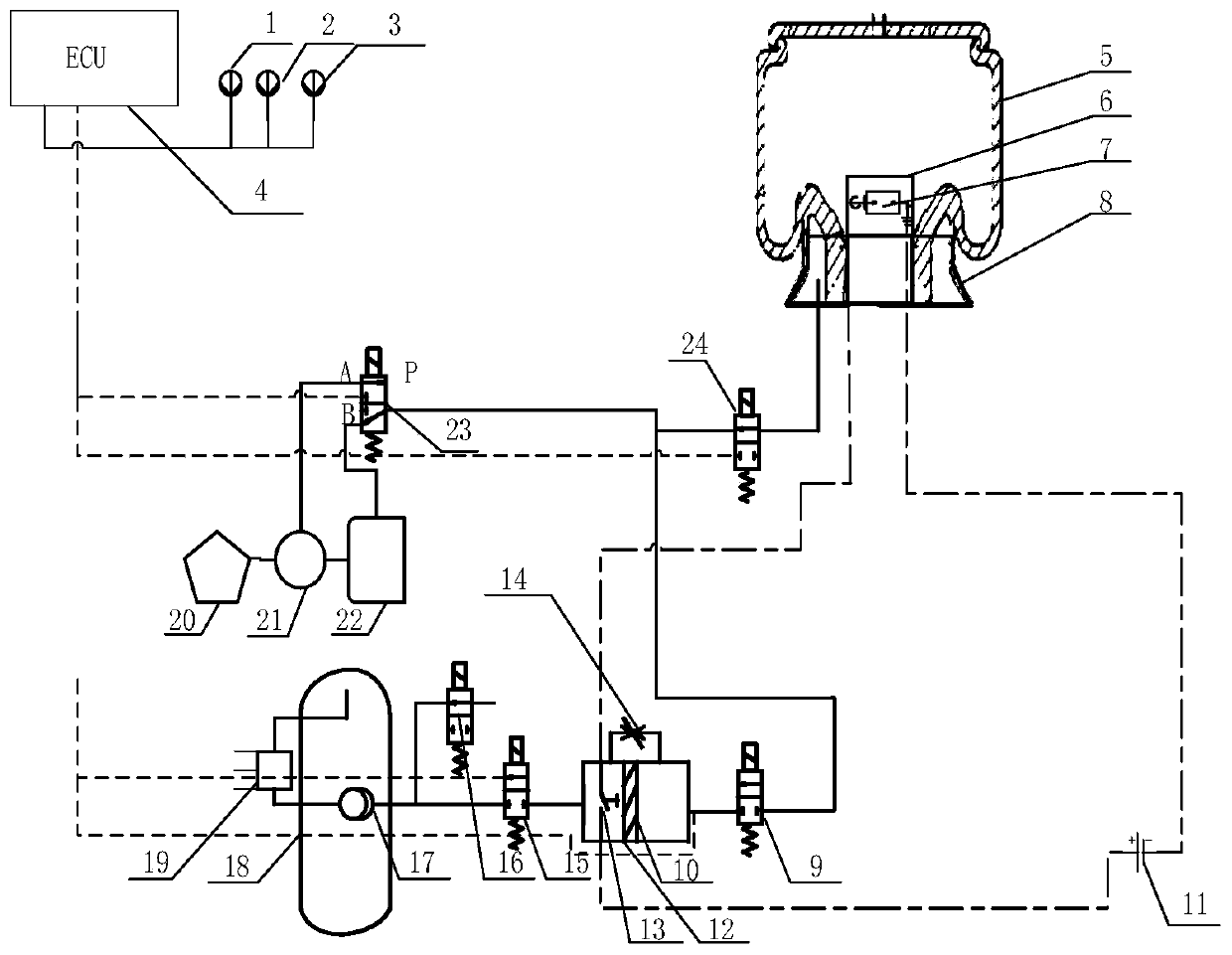

[0054] Such as figure 1 Shown is a tire burst safety suspension system, including an air spring 5, an air supply device, a tire pressure detection device, a high-pressure gas generating device, a detection device and a control unit 14. The high-pressure gas generating device is connected to the air chamber of the air spring 5; the tire pressure detecting device is connected to the tire and the high-pressure gas generating device respectively; the control unit 4 is connected to the tire pressure detecting device and the like.

[0055] The air spring 5 is preferably a bladder-type air spring; the interior includes a piston 8 and a high-pressure gas generating device 6; the bottom of the air spring can be installed on the suspension of the vehicle, and the top can be installed on the vehicle frame. The high-pressure gas generating device 6 is installed above the piston 8, and is used to generate high-pressure gas when a tire blows out, thereby increasing the vehicle body height o...

Embodiment 2

[0065] A vehicle, comprising the tire burst safety suspension system described in Embodiment 1. Therefore, it has the beneficial effects of Embodiment 1, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com