Control method for air-cooled maglev unit

A control method and magnetic levitation technology, applied in the control input related to air characteristics, space heating and ventilation control input, application, etc., can solve the problem of unit cost increase, unit failure shutdown, multiple fixed-frequency fans cannot be flexibly adjusted, etc. problems, to achieve the effect of avoiding downtime, low cost, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0022] It should be noted that, in the description of the present invention, the terms "first" and "second" are only used for description purposes, and cannot be understood as indicating or implying relative importance.

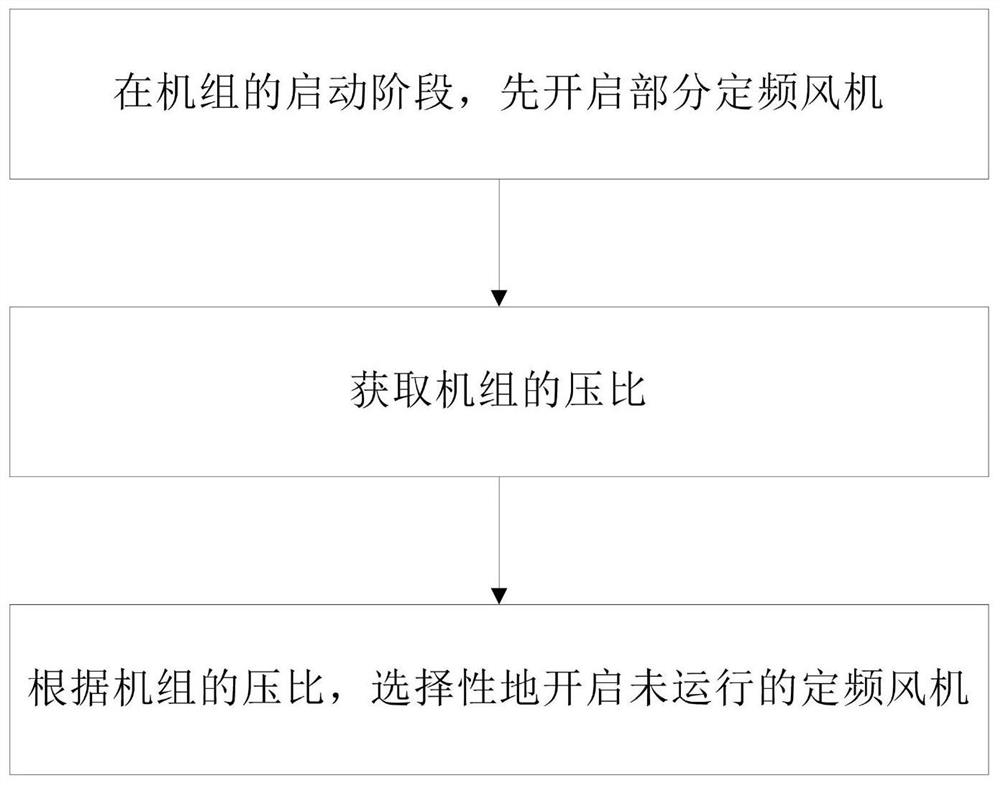

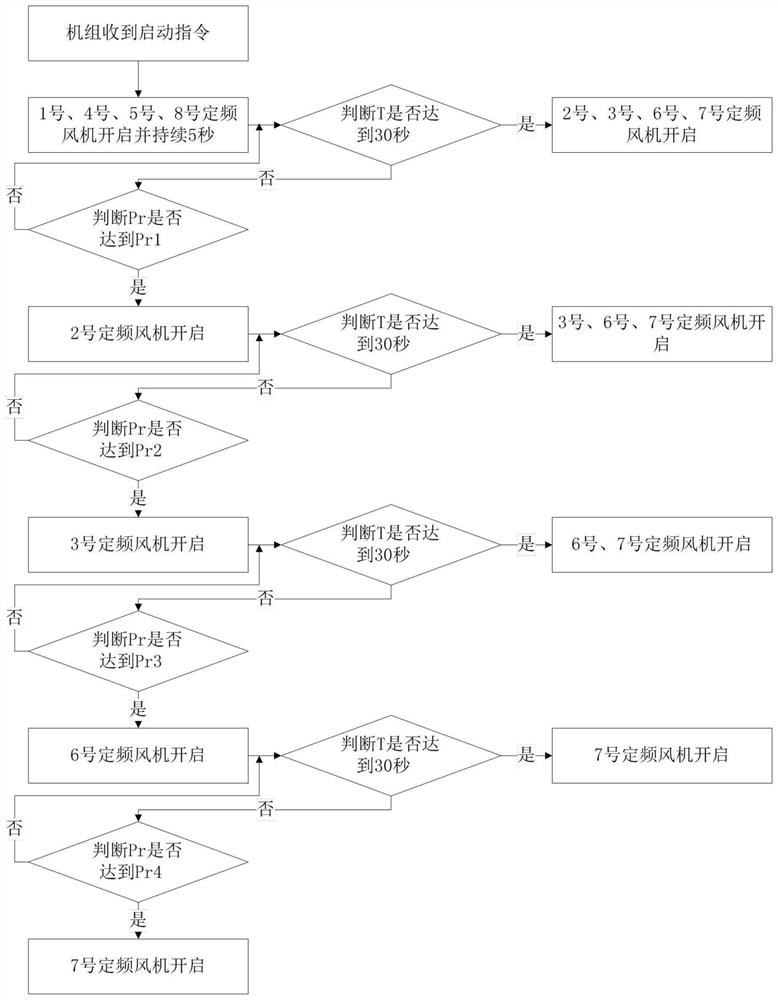

[0023] Based on the problems pointed out by the background technology that the existing air-cooled maglev unit adopts the structure of multiple fixed-frequency fans, the pressure ratio of the unit cannot be flexibly adjusted, which will easily lead to the failure of the unit and the use of multiple variable-frequency fans will greatly increase the cost of the unit. The invention provides a control method for an air-cooled mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com