All-working-condition efficient fresh air ventilator for multi-stage heat pump heat recovery

A technology of heat recovery and full working conditions, which is applied in heat recovery systems, space heating and ventilation, and compression machines with reversible cycles, etc. It can solve the problems of limited applicable working conditions, increased costs, and high energy consumption of dehumidifiers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

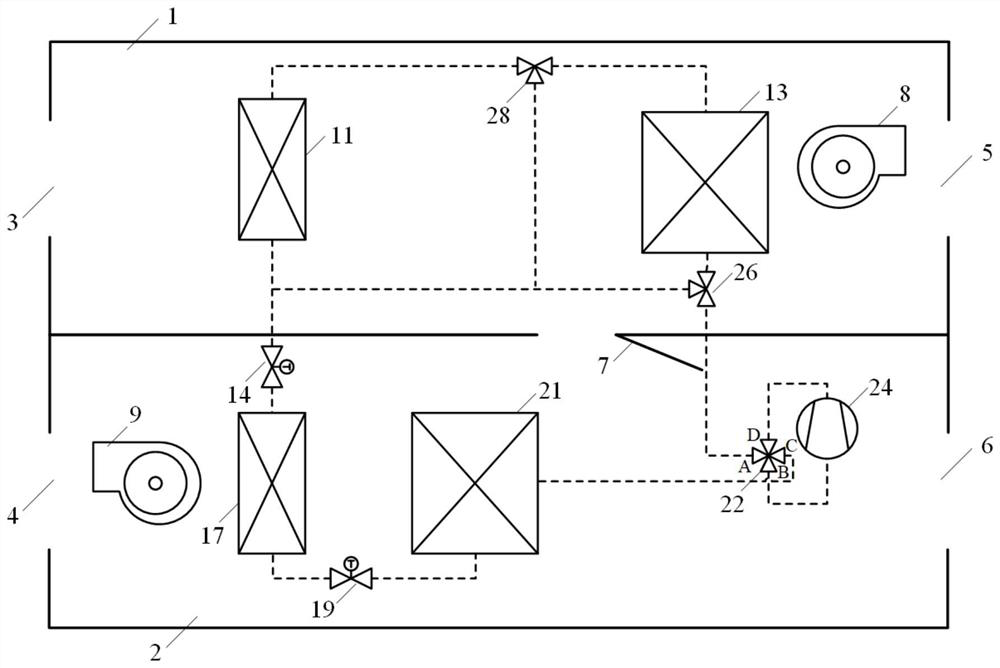

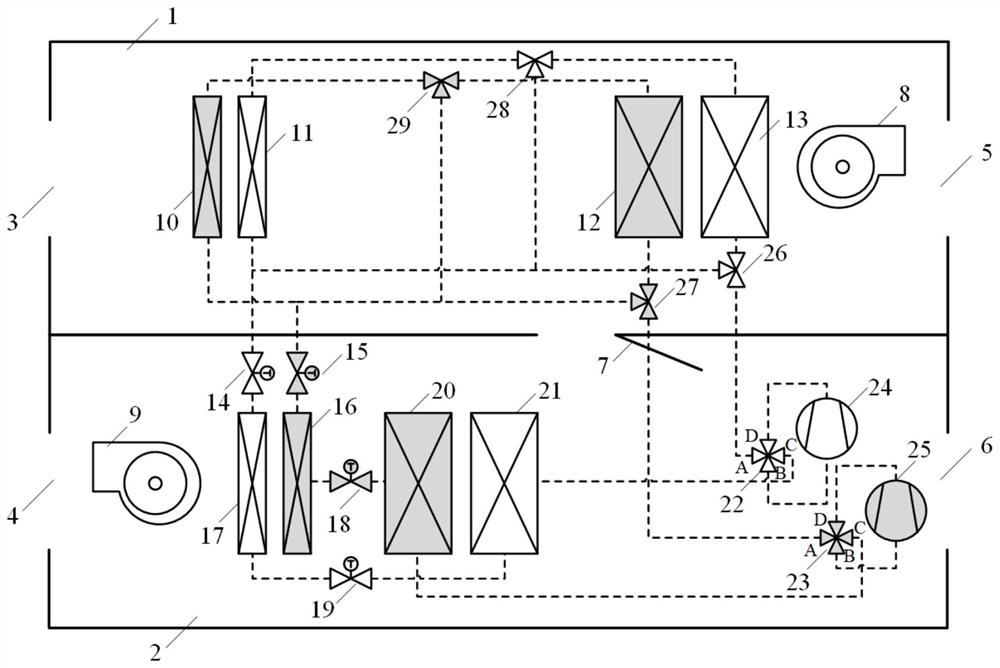

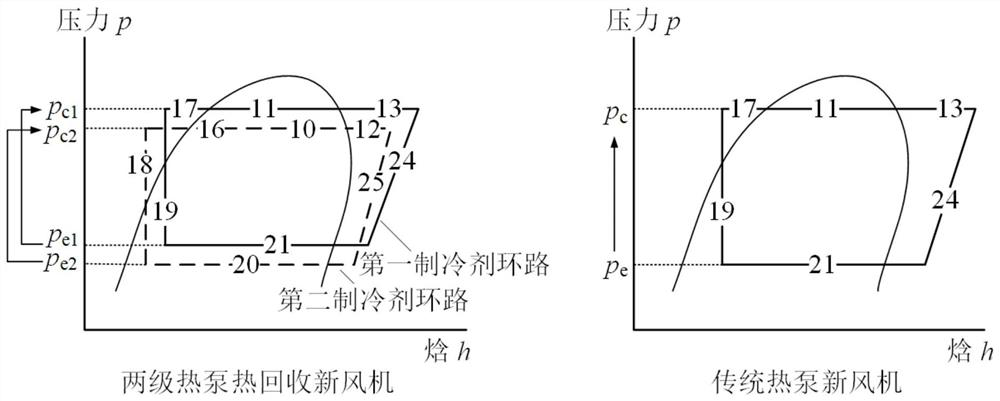

[0066] refer to figure 2 , a multi-stage heat pump heat recovery high-efficiency fresh air fan in this embodiment, the main structure includes a first air duct 1, a second air duct 2, a return air outlet 3, a supply air outlet 4, and an exhaust air outlet 5 , fresh air outlet 6, mixed air damper 7, exhaust fan 8, supply fan 9, subcooling coil 10, 11, exhaust coil 12, 13, first throttling device 14, 15, reheat coil 16 , 17, second throttling devices 18, 19, air supply coils 20, 21, four-way reversing valves 22, 23, compressors 24, 25, first bypass valves 26, 27, second bypass valve 28 , 29.

[0067] This embodiment includes two independent refrigerant loops (more than two refrigerant loops can be selected in the same way), a compressor 24 (25), a four-way reversing valve 22 (23), and a first bypass valve 26 (27), the refrigerant flow path of the exhaust coil 13 (12), the second bypass valve 28 (29), the refrigerant flow path of the subcooling coil 11 (10), the first throttli...

Embodiment 2

[0078] refer to Figure 10 , the system principle of this embodiment is similar to the operating mode and embodiment 1, the difference is that only one stage of reheating coil 17 is set, so that the subcooling section in the reheating coil 17 can be used in the cooling and dehumidification mode in summer and the heating / transition in winter The same air temperature gradient is matched in the intraseasonal circulation mode, and the temperature matching in different modes is more balanced.

[0079] refer to Figure 11 , this embodiment also provides a two-stage heat pump heat recovery fresh air fan, the air supply coil 21 (20) is provided with a two-stage heat exchanger, and the exhaust coil 13, the subcooling coil 11 and the reheating coil 17 are combined A single-stage heat exchanger. The system gives priority to the cooling and dehumidification mode in summer, and the air supply coil 21 (20) assumes the role of the evaporator, and the double evaporation temperature of the t...

Embodiment 3

[0082] refer to Figure 12 , the system principle and operating mode of this embodiment are similar to that of Embodiment 1, the difference is that it shows the general construction form of multi-stage heat pump heat recovery (2-stage and above). Theoretically speaking, increasing the number of heat recovery stages of the heat pump can continuously reduce the pressure ratio of the heat recovery of the heat pump at all levels, thereby improving energy efficiency. In practical applications, the number of series used is determined after comprehensive consideration of structural complexity and system cost.

[0083] This example is cited to show that in the multi-stage nested refrigerant loop of the present invention, any increase or decrease in the number of heat recovery stages of the heat pump does not change its technical essence and should belong to the protection scope of this patent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com