Waveform testing method of detonation waves

A waveform test and detonation wave technology, applied in the field of wireless high-speed dynamic process test, to achieve the effect of facilitating popularization and application, easy operation and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

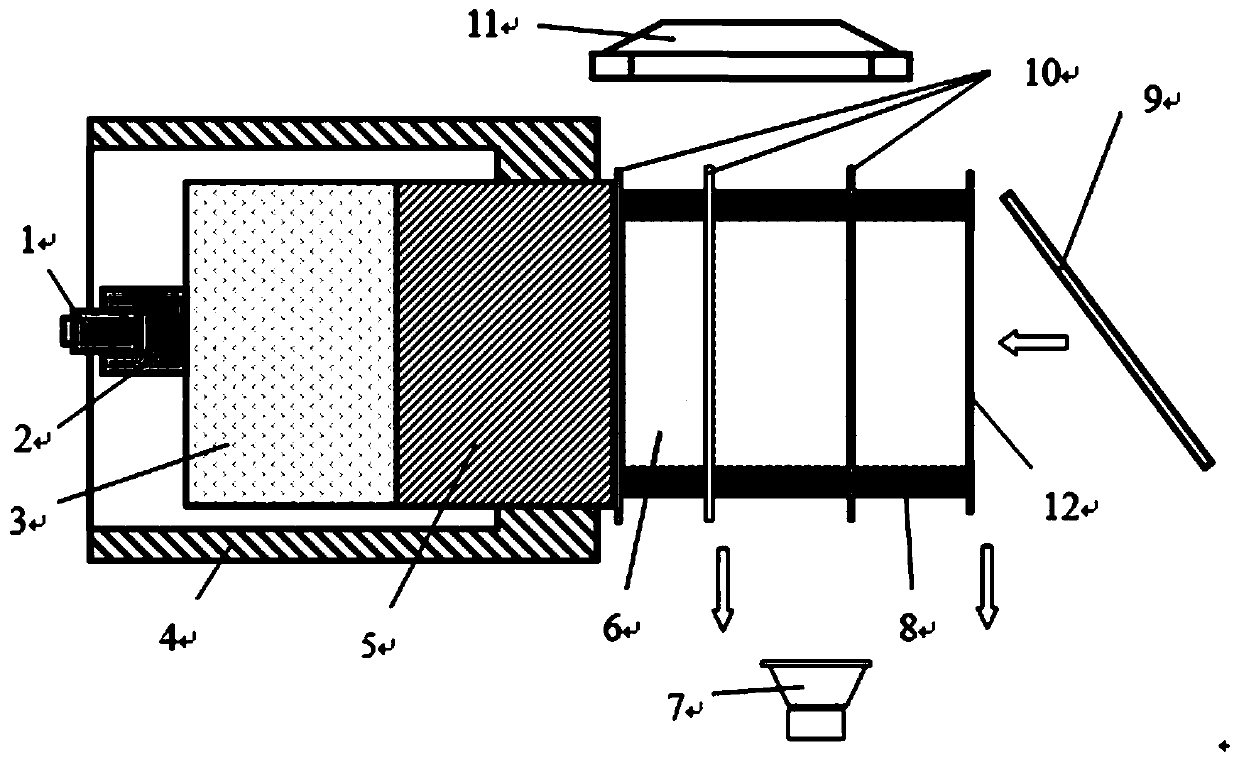

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

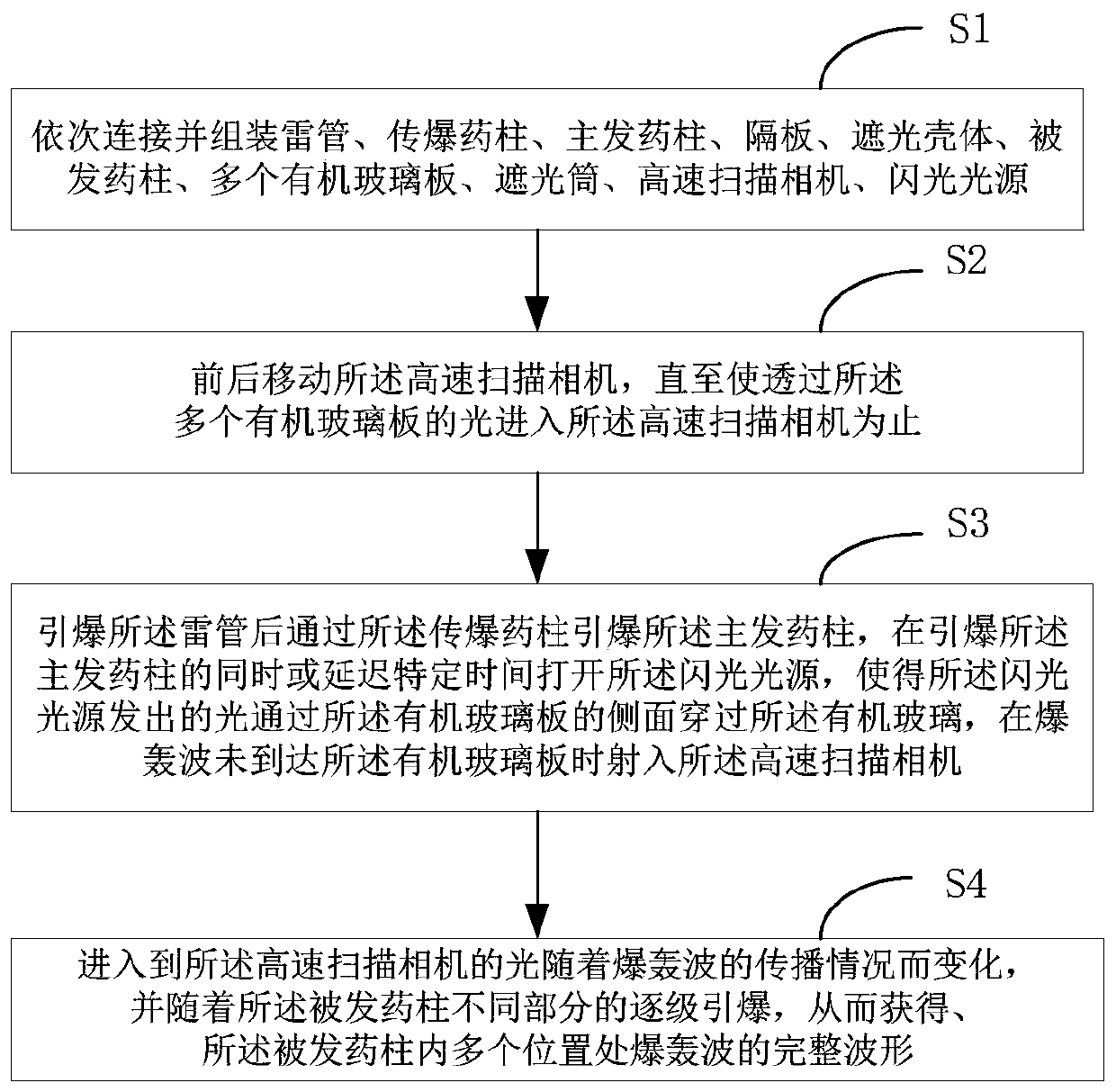

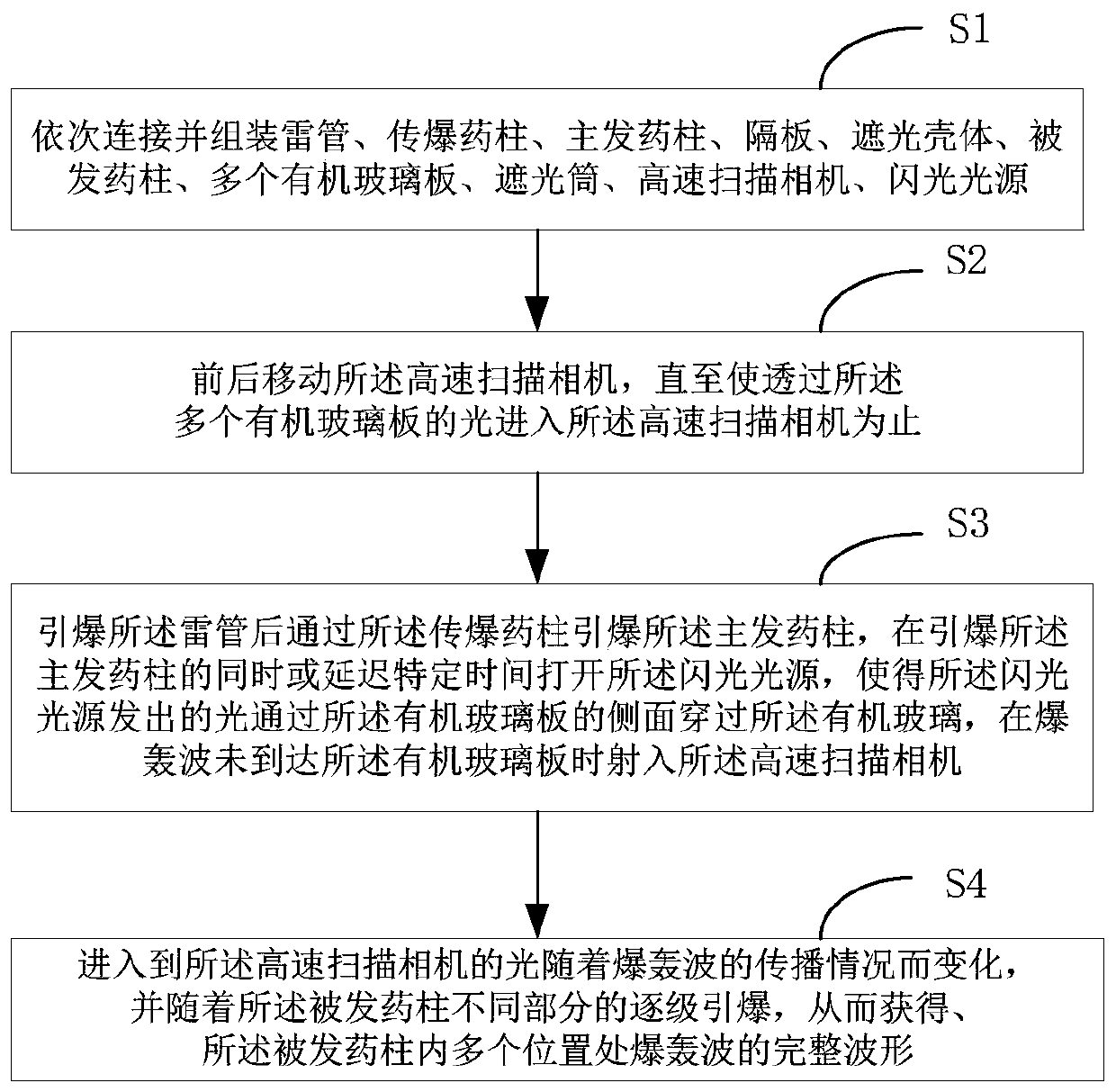

[0030] A specific embodiment of the present invention, such as figure 1 shown, combined with figure 2 , discloses a detonation wave waveform test method, comprising the following steps:

[0031] S1, sequentially connect and assemble the detonator 1, the booster charge 2, the main charge 3, the light-shielding shell 4, the partition 5, the fired charge 6, the high-speed scanning camera 7, the light-shielding cylinder 8, and multiple plexiglass plates 10. Flash light source 11;

[0032] S2, moving the high-speed scanning camera 7 back and forth until the light passing through the plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com