Method for cold rolling ferritic stainless steel strip

A stainless steel strip and system technology, applied in metal rolling, contour control, etc., can solve problems such as poor production efficiency and low productivity of cold-rolled steel sheets, and achieve the effects of increasing productivity and inhibiting fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

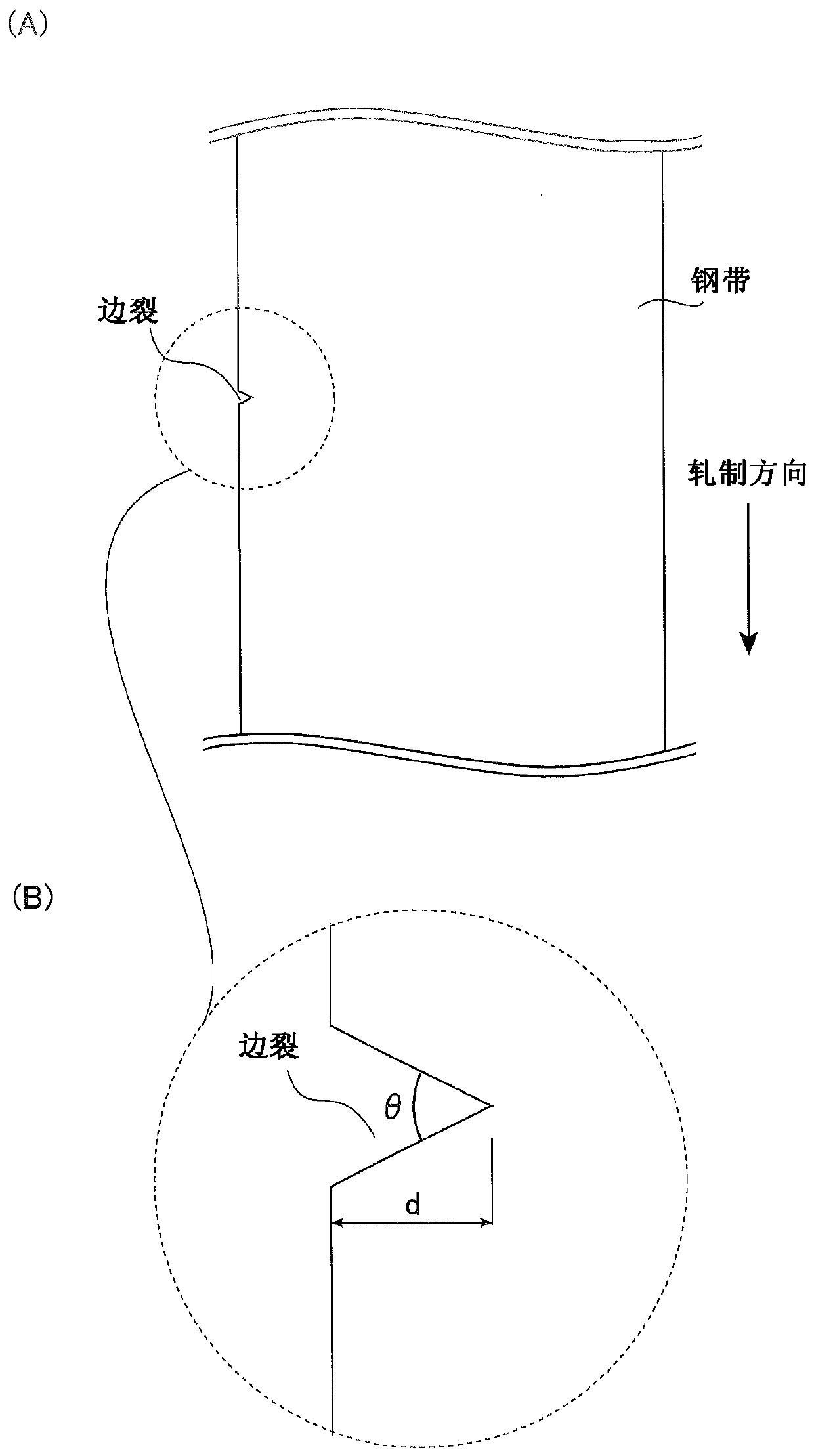

[0076] The above-described cold rolling was performed on a SUS430 ferritic stainless steel hot-rolled annealed pickled sheet with a plate thickness of 4.0 mm. At this time, before the cold rolling of each pass, the edge of the steel strip was visually checked for the presence or absence of edge cracks, and when edge cracks occurred, the depth and angle of the edge cracks were investigated.

[0077] Before implementing the fourth pass of cold rolling (thickness 2.4 mm), although it was confirmed that edge cracks with a depth of 2 mm and an angle of 60° had occurred in the steel strip, they were not specific edge cracks. Carry out the cold rolling of the 4th pass under the rolling condition (rolling speed 400mpm), then, also implement under the predetermined rolling condition (rolling speed 400mpm) from the cold rolling of the 5th pass to the 8th pass, manufacture A cold-rolled steel plate with an end plate thickness of 1.0mm is produced. In addition, after manufacture, the dep...

Embodiment 2

[0079] The above-described cold rolling was performed on a SUS430 ferritic stainless steel hot-rolled annealed pickled sheet with a plate thickness of 4.0 mm. At this time, before the cold rolling of each pass, the edge of the steel strip was visually checked for the presence or absence of edge cracks, and when edge cracks occurred, the depth and angle of the edge cracks were investigated.

[0080] Before implementing the cold rolling of the first pass, although it was confirmed that edge cracks with a depth of 3mm and an angle of 120° had occurred in the steel strip, since they were not specific edge cracks, the cold rolling condition (rolling speed) 200mpm), the cold rolling of the first pass is implemented, and then the cold rolling from the second pass to the eighth pass is also carried out under the predetermined cold rolling conditions (rolling speed 400mpm), and the final thickness of the plate is 1.0mm. of cold-rolled steel plates. In addition, after manufacture, the ...

Embodiment 3

[0082] The above-described cold rolling was performed on a SUS430 ferritic stainless steel hot-rolled annealed pickled sheet with a plate thickness of 4.0 mm. At this time, before the cold rolling of each pass, the edge of the steel strip was visually checked for the presence or absence of edge cracks, and when edge cracks occurred, the depth and angle of the edge cracks were investigated.

[0083] Before the cold rolling of the first pass, it was confirmed that a specific edge crack with a depth of 4 mm and an angle of 60° had occurred in the steel strip, so the rolling speed was reduced from the predetermined rolling condition (rolling speed 200 mpm) The cold rolling of the first pass is carried out to 100 mpm, and then the cold rolling from the second pass to the eighth pass is also carried out by reducing the rolling speed to 200 mpm from the predetermined rolling condition (rolling speed 400 mpm), A cold-rolled steel sheet having an end sheet thickness of 1.0 mm was produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com