Desktop-type dual-spraying-head wax printing wax application machine with high resolution ratio

A high-resolution, desktop technology, applied in the processing of textile materials, partial treatment of textile materials, textiles and papermaking, etc., can solve the problem of affecting the whiteness of the cloth, not having the effect of anti-dyeing, and the effect of anti-dyeing is not good and other problems to achieve the effect of good precision and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

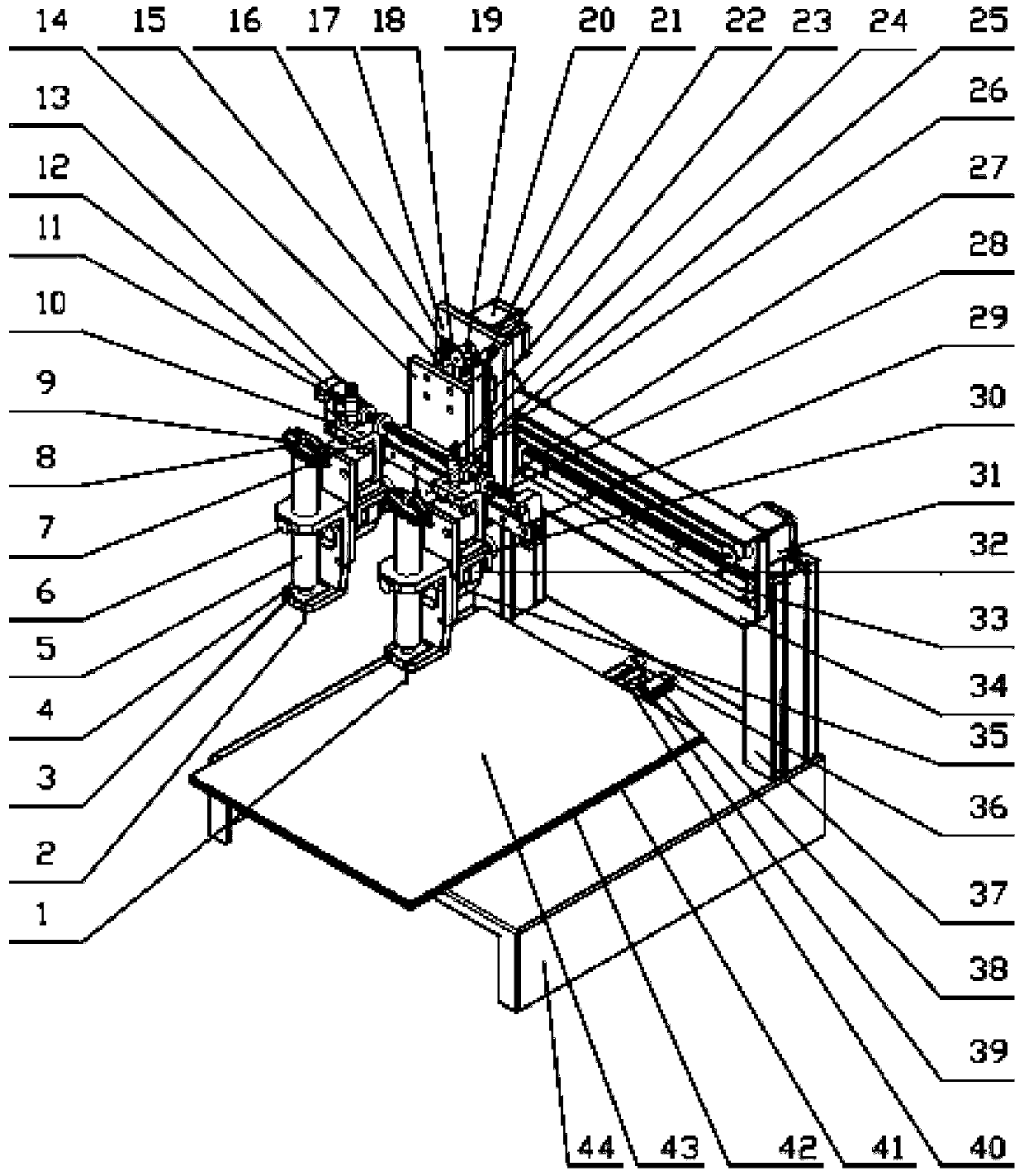

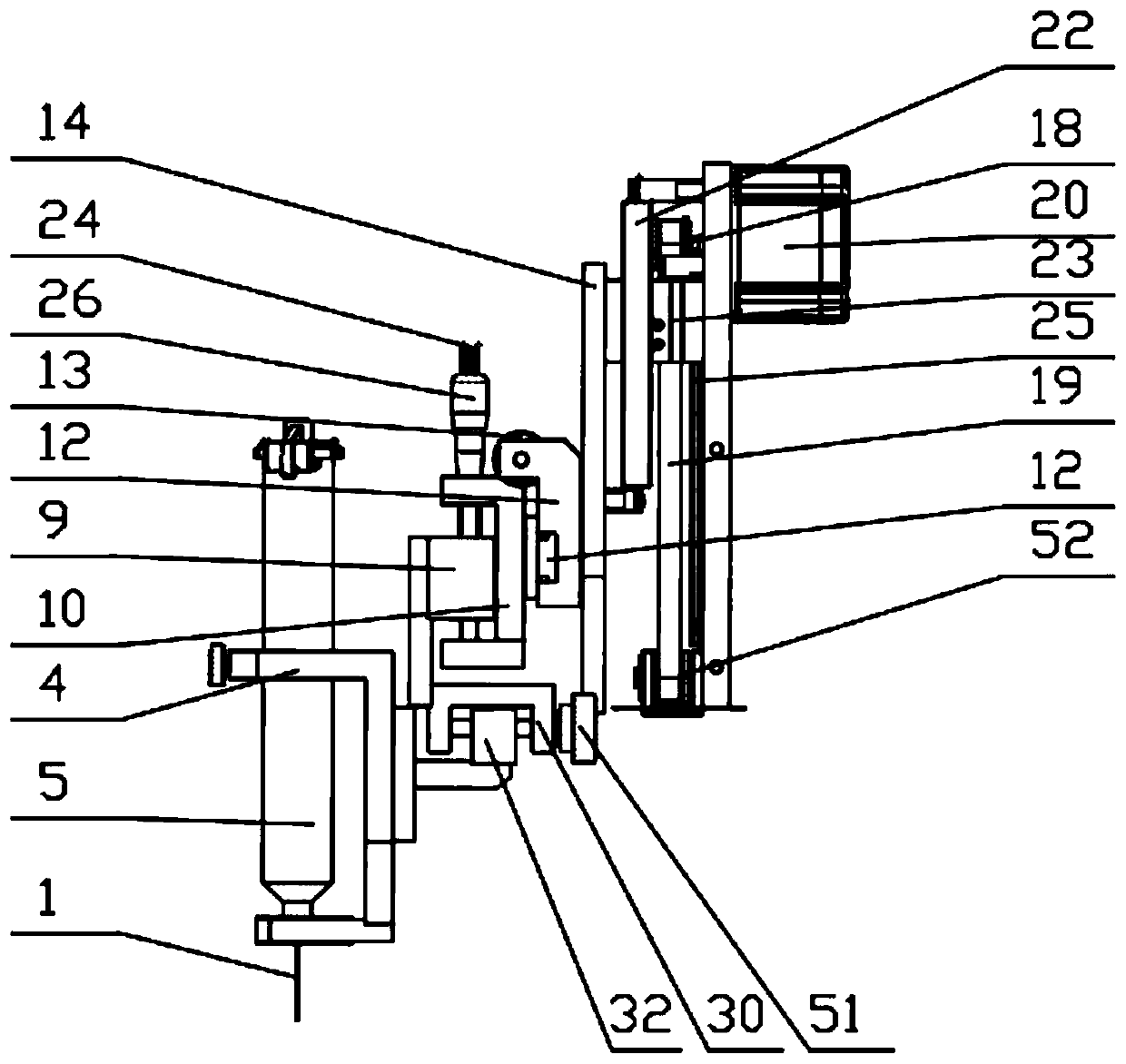

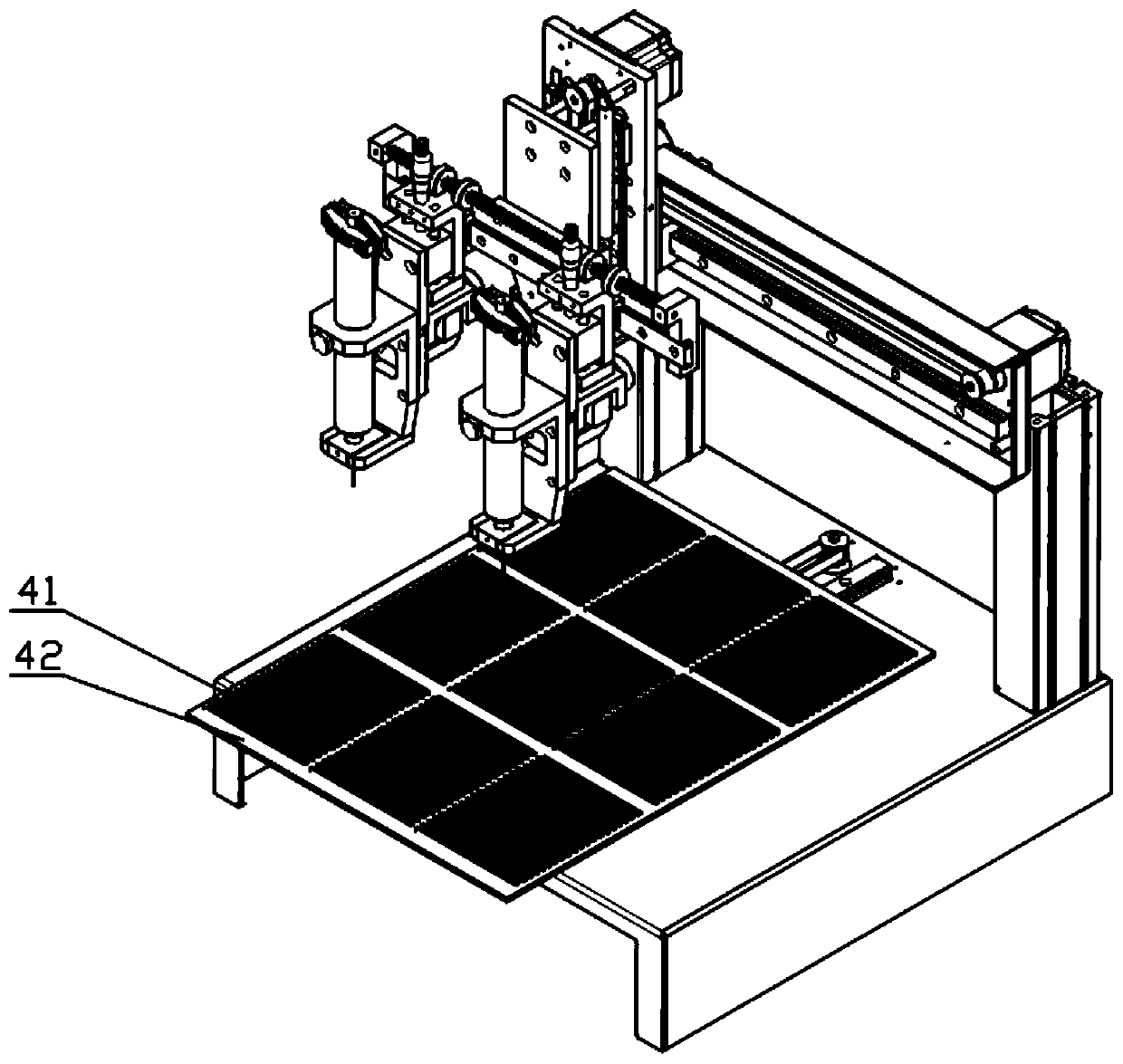

[0014] Embodiments of the present invention: a high-resolution desktop double-nozzle batik wax spotting machine, as shown in the accompanying drawings, an X slide rail 38 is set above the desktop support frame 44, and a stepping motor is set at one end of the desktop support frame 44. 39, a synchronous pulley 36 is set above the stepping motor 39, a synchronous belt 40 is meshed with a synchronous pulley 36, a slide block 47 is set above the X slide rail 38, and a sliding bracket 49 is set on the top of the slide block 47 , the supporting plate 41 is arranged successively above the sliding bracket 49, the heating wire layer 42, the workbench top plate 43, the support column one 37 and the support column two 53 are respectively arranged on the left and right edges of the desktop support frame 44, and above the support column one 37 Stepper motor two 31 are set, Y-axis frame 34 is set at stepper motor two 31 front ends, Y-axis slide rail 33 is set on Y-axis frame 34 inner surface...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap