Drive device and exhaust heat recovery device

A technology of exhaust heat recovery and driving device, which is applied in the direction of transmission device, gear transmission device, friction transmission device, etc., and can solve problems such as component damage and abnormal sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

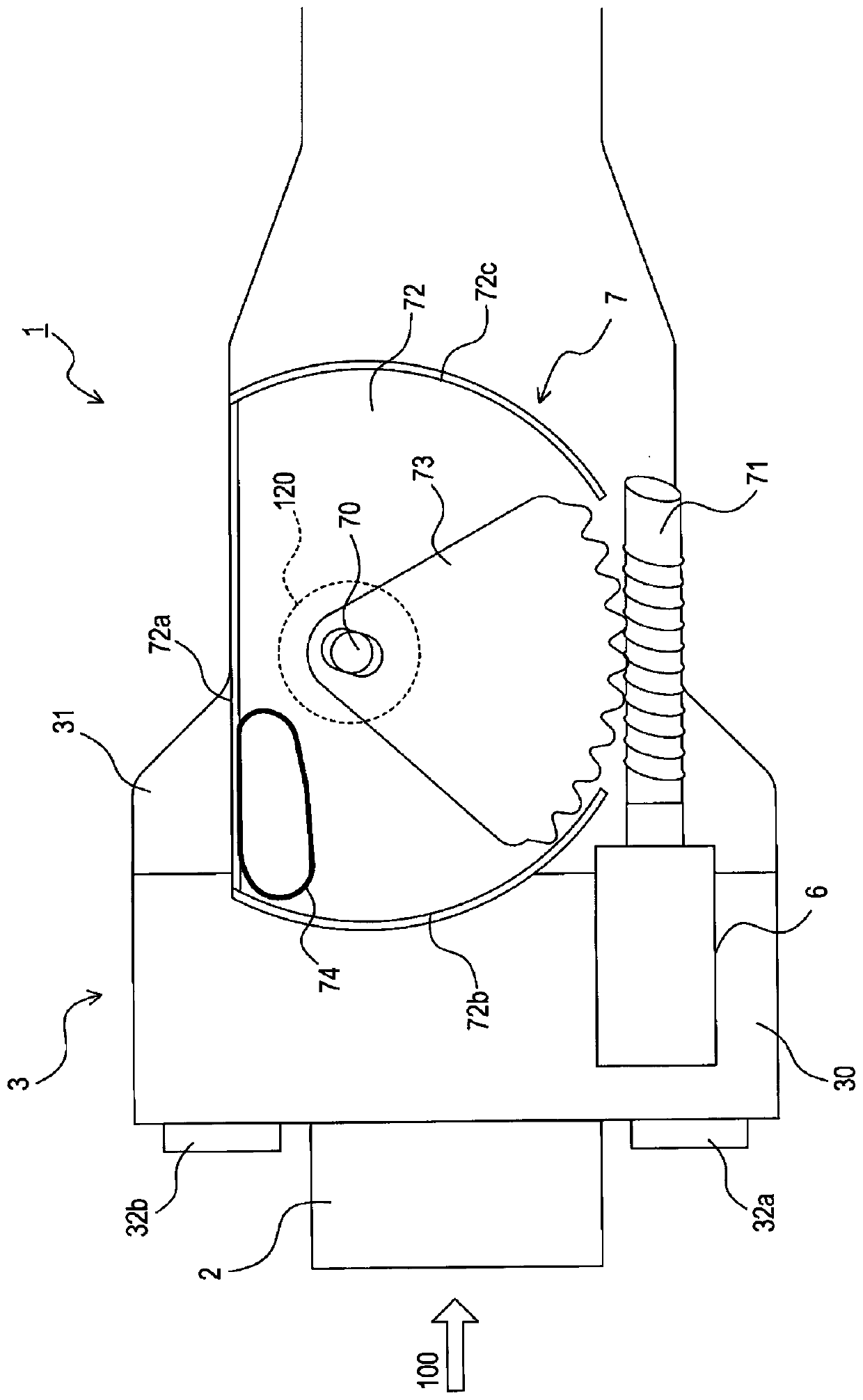

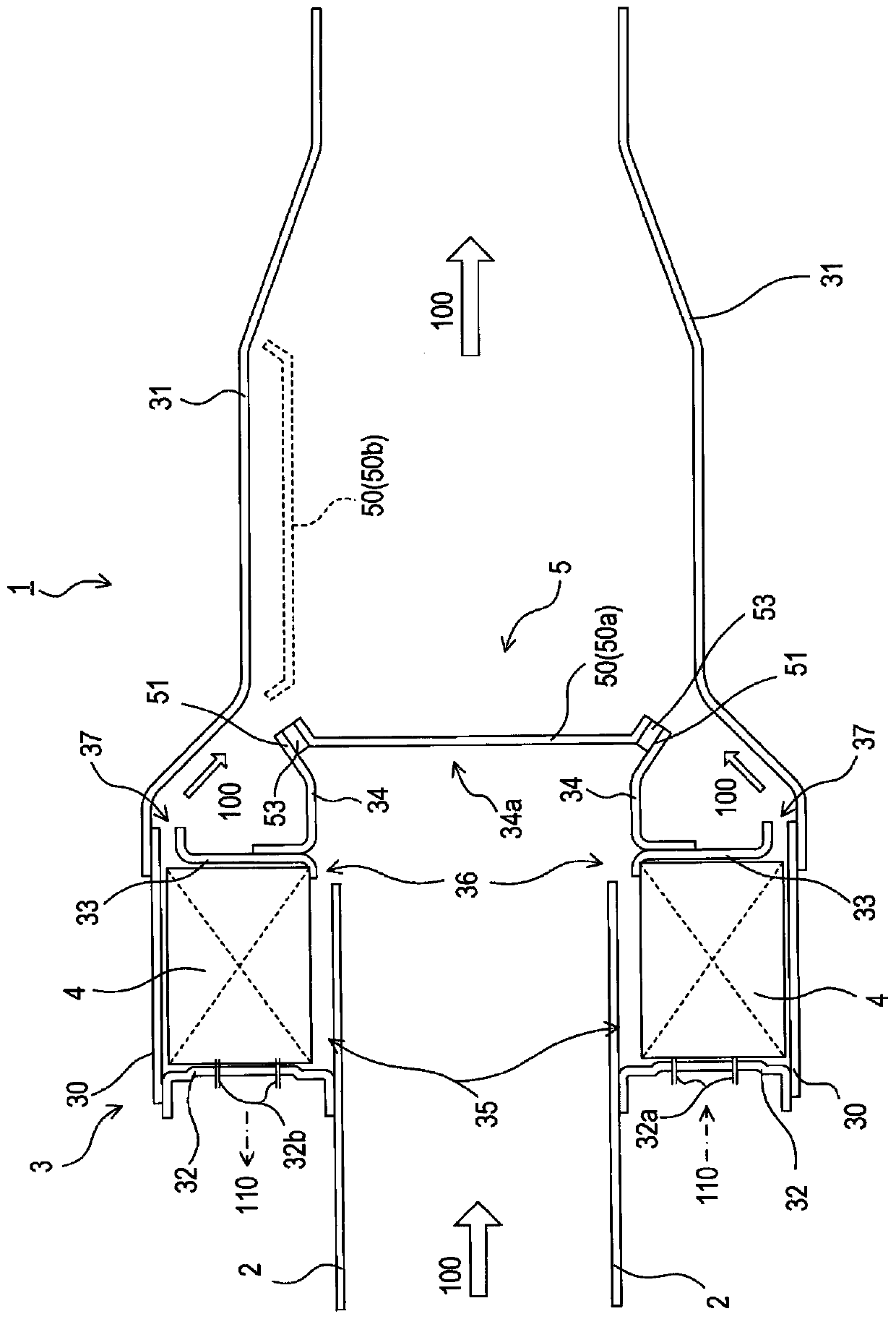

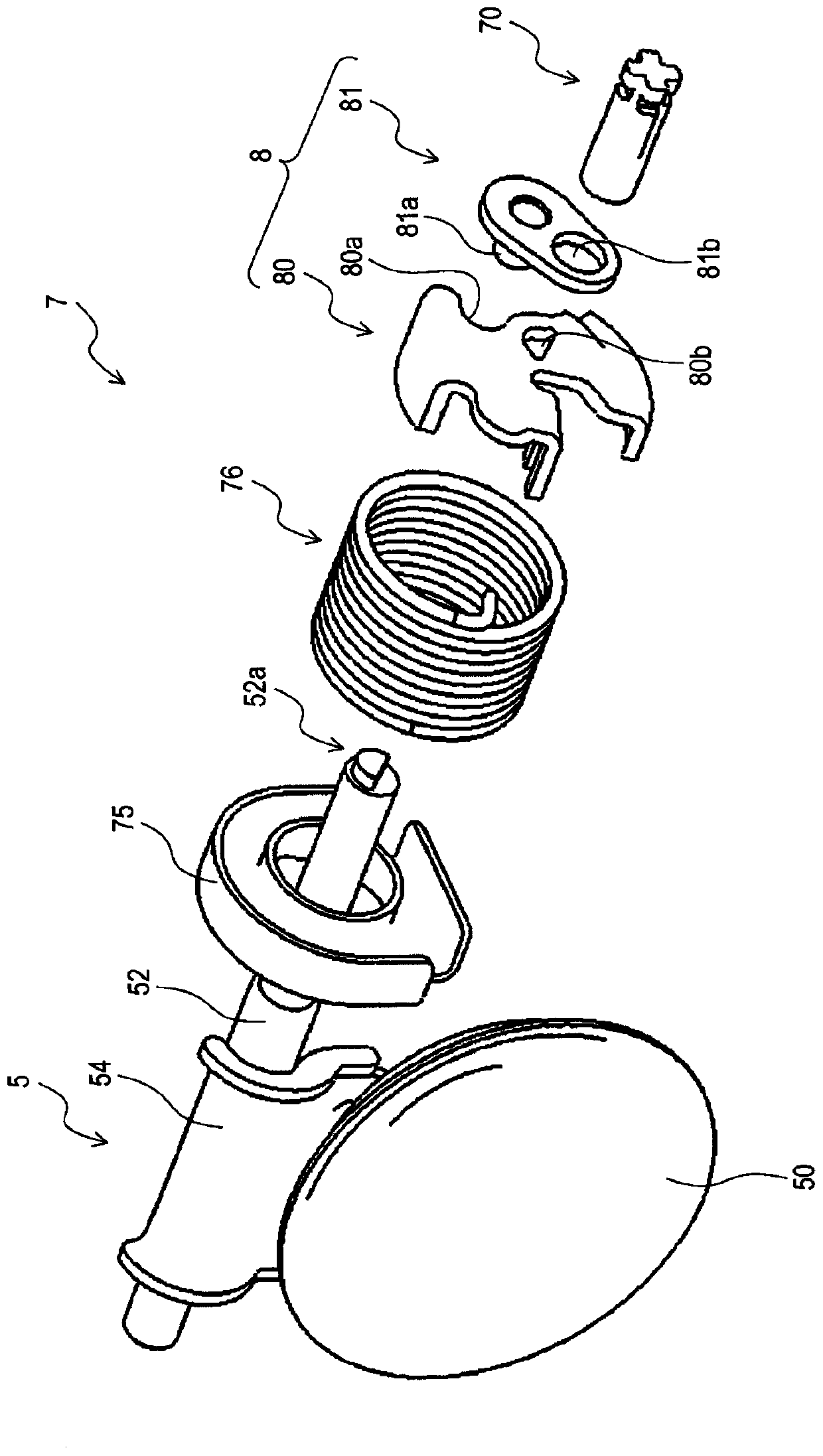

[0089] (1) In the valve opening and closing mechanism 7 of the exhaust heat recovery device 1 of this embodiment, the rotational force of the motor 6 is transmitted to the valve body 50 via the sector gear 73, the worm 71, the drive member 81, etc., as a result, The valve 5 is opened and closed. Furthermore, the sector gear 73 and the worm 71 are disengaged when the drive member 81 reaches the first stop position 81c and the sector gear 73 reaches the first stop position 73a. Then, the sector gear 73 and the worm 71 are disengaged when the driving member 81 reaches the second stop position 81d and the sector gear 73 reaches the second stop position 73b. However, the sector gear 73 and the worm 71 may also be disengaged in one of the above cases, and kept engaged in the other case.

[0090] (2) In the valve opening and closing mechanism 7, the sector gear 73 and the worm 71 are used to transmit the rotational force of the motor 6 to the valve body 5. However, it is also possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com