Cutting die

A mold and cutting technology, which is applied in metal processing and other directions, can solve the problems of slow efficiency and achieve the effect of low maintenance cost, ingenious design structure, and no takt time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

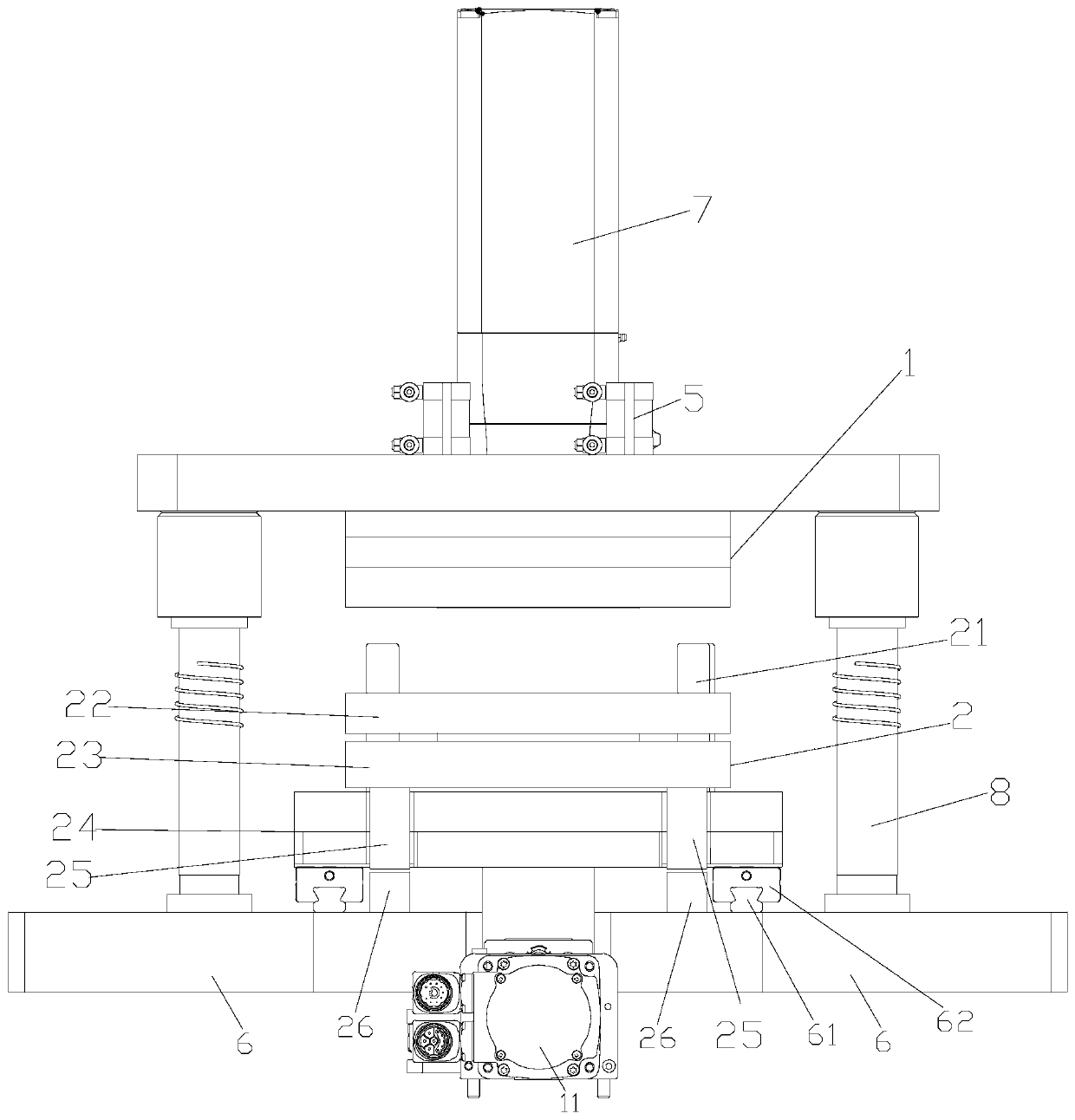

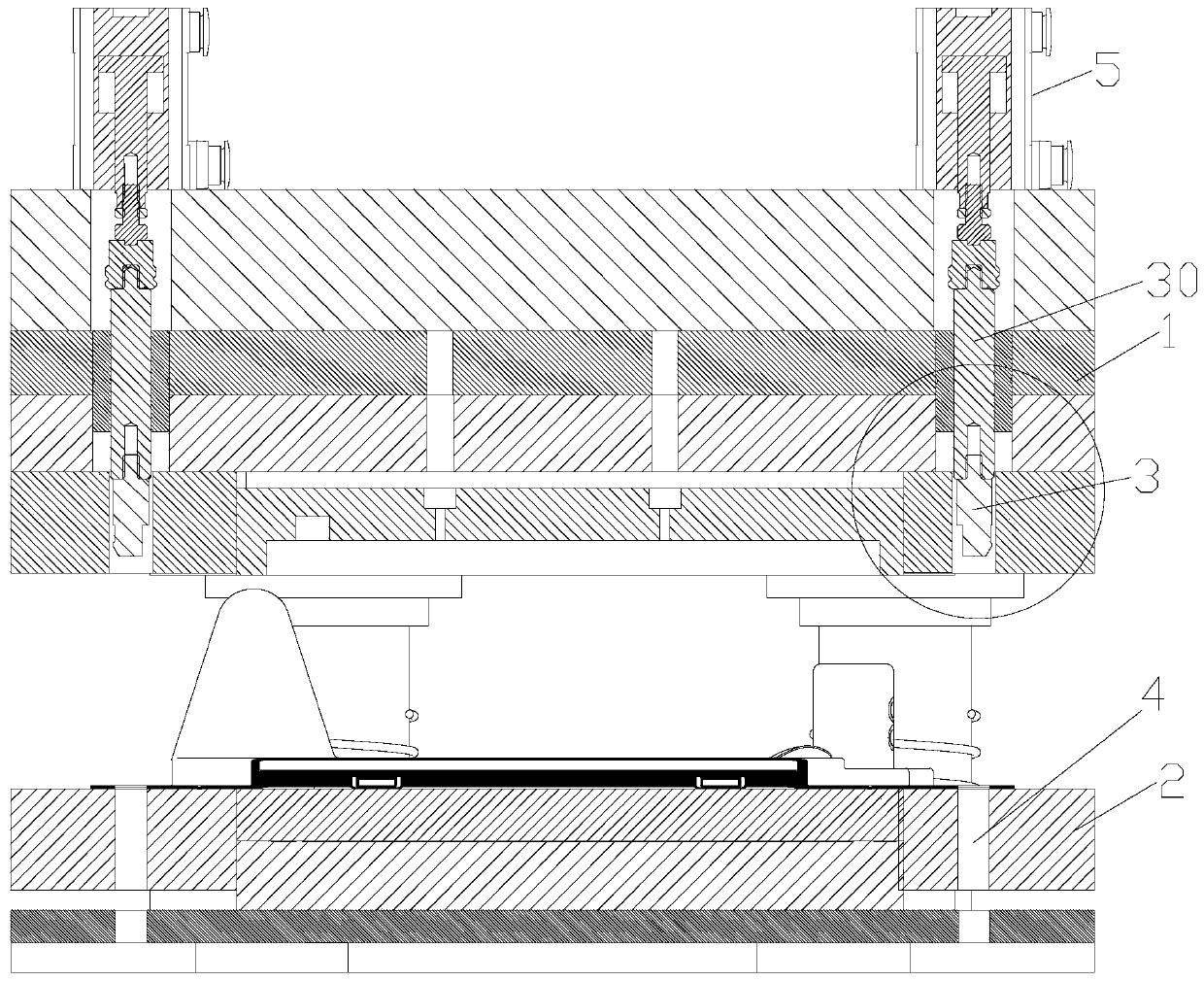

[0022] See figure 1 and 2 As shown, the present embodiment discloses a cutting mold, comprising an upper mold 1 and a lower mold 2, the bottom of the upper mold 1 is provided with an upper cutter, the bottom of the lower mold 2 is provided with a lower cutter, and the upper cutter and the lower cutter are both The same imitation shape, in this embodiment, the upper cutter and the lower cutter are ring-shaped, the lower mold 2 is provided with a guide post 21, and the bottom of the upper mold 1 is provided with a guide hole. When the upper mold 1 is pressed down, the guide post 21 Insert into the guide hole for guidance, and the guide column 21 and the guide hole are correspondingly provided with four;

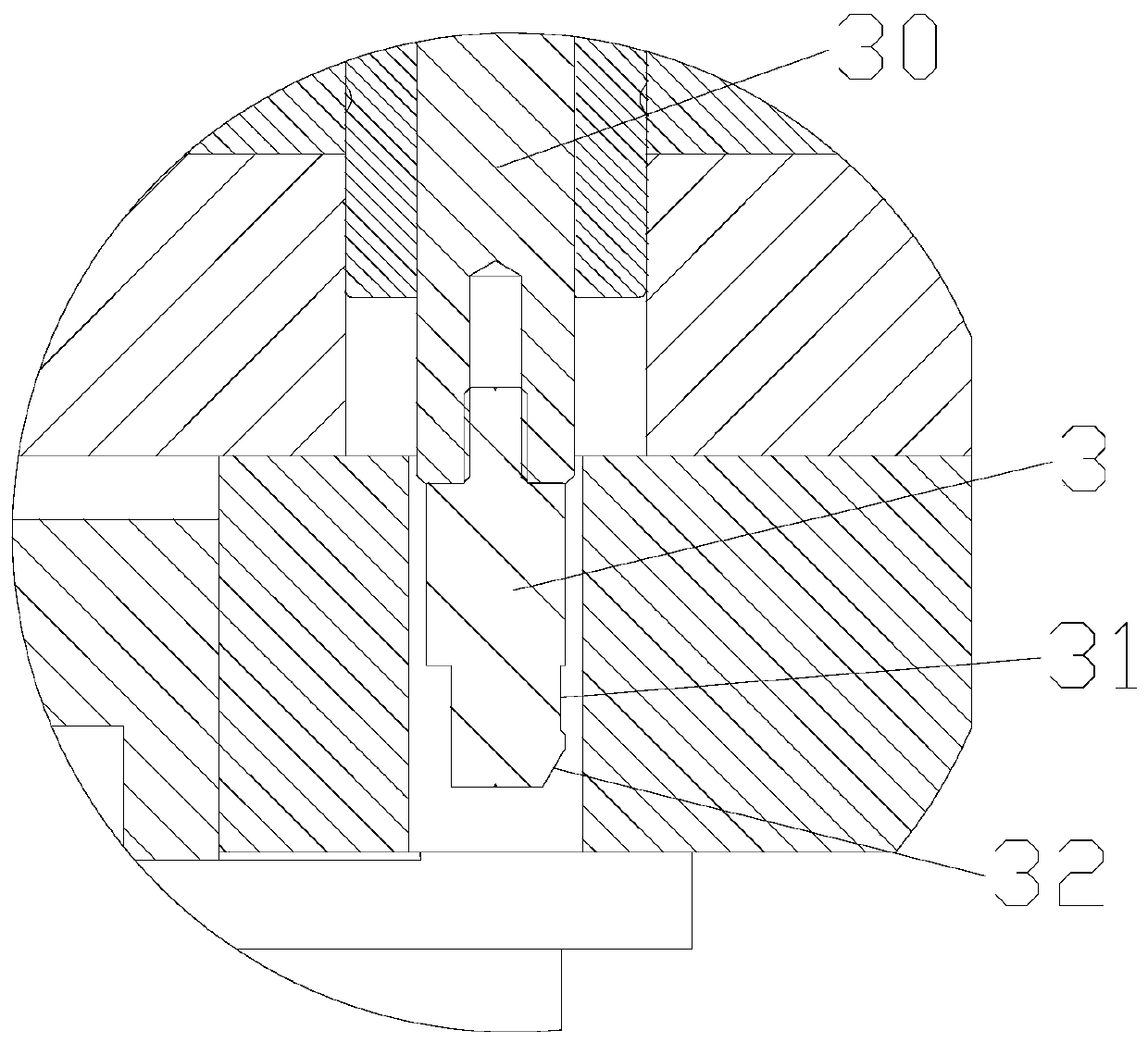

[0023] The upper mold 1 is provided with a retractable material taking column 3, and the lower mold 2 is provided with a positioning hole 4 for the material taking column 3 to extend into, and a through hole corresponding to the positioning hole 4 is also provided on the part ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap