Automatic plug device and rolling stock power supply automatic connector

A plug-in and automatic technology, which is applied in the direction of railway couplings, transportation and packaging, railway car body parts, etc., can solve the problems of low accuracy rate and inability to effectively provide power supply, so as to eliminate up and down movement and solve the problem of unconfigured power source and power supply problems, improve the effect of accurate docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

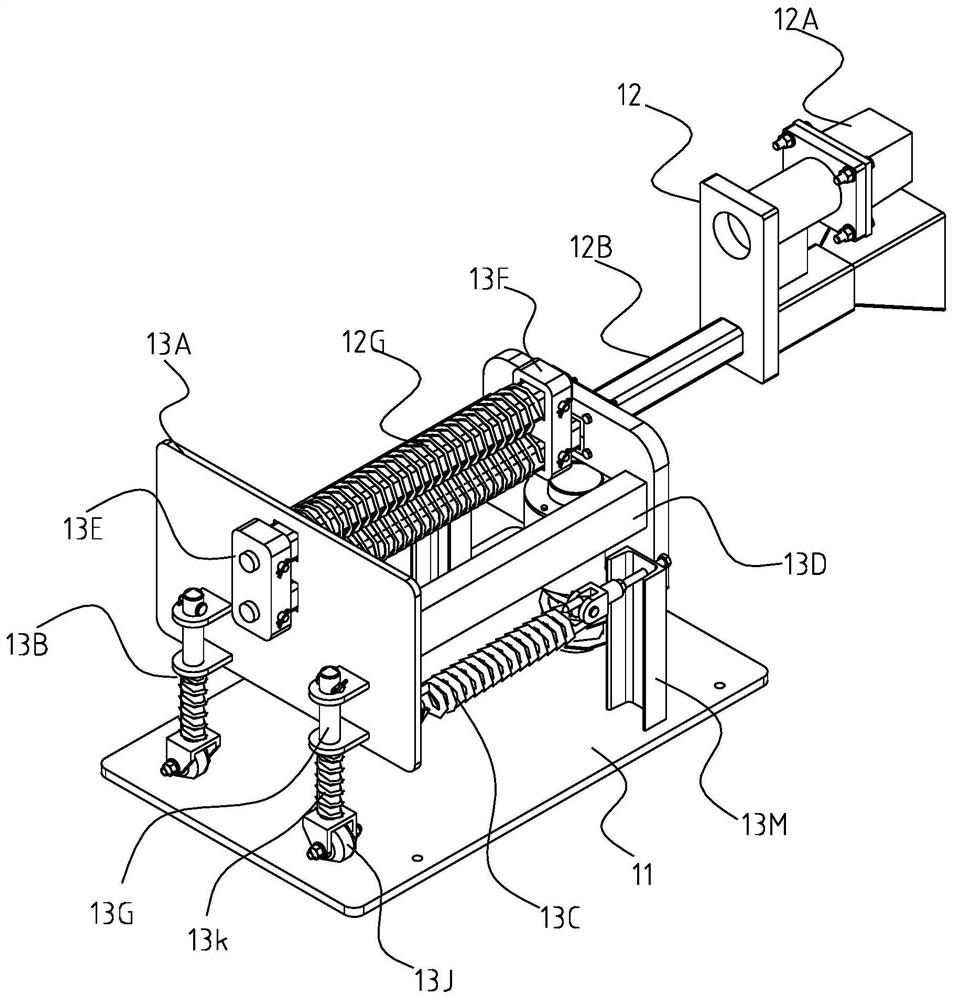

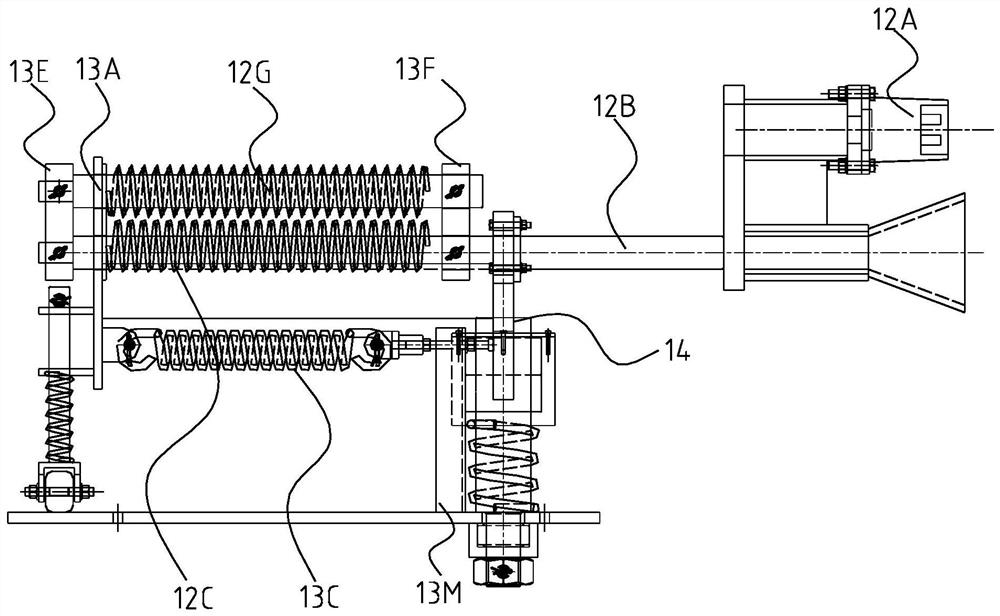

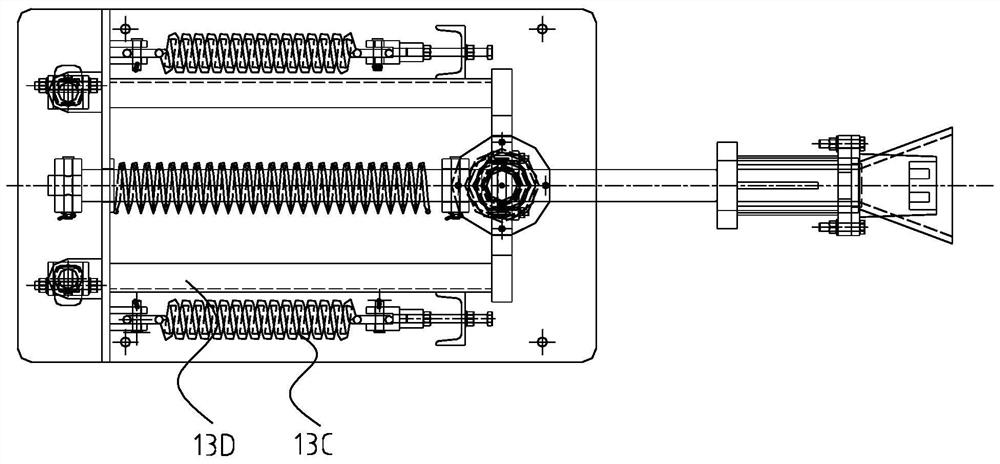

[0028] Such as figure 1 and figure 2 as well as image 3 As shown, this embodiment provides an automatic plug device, including a base 11, on which a plug assembly 12, a rotary reset assembly, and an automatic plug rotary member 14 are provided, wherein the plug assembly 12 includes a plug 12A and is connected with the A slide bar assembly connected to the plug 12A, the slide bar assembly includes a slide bar 12B and a first elastic element 12C located on the slide bar 12B, the plug 12A is connected between the slide bar 12B and the first elastic element Driven by 12C, it can move along the length direction of the base 11. The rotary reset assembly includes a slide plate 13A movably connected with the slide bar 12B, a rotating assembly 13B and a reset element 13C, and the rotating assembly 13B and the reset element 13C are all connected to the sliding plate 13A, and the sliding plate 13A and the rotating assembly 13B roll around the automatic plug rotating member 14 on the ...

Embodiment 2

[0037] Such as Figure 7 and Figure 8 As shown, this embodiment provides an automatic power supply connector for rolling stock, including the automatic plug device and socket assembly 15 described in Embodiment 1, and the plug 12A in the automatic plug device and the socket in the socket assembly 15 15A are interconnected.

[0038] The automatic power supply connector for rolling stock in this embodiment includes the automatic plug device and the socket assembly 15 described in Embodiment 1, and the plug 12A in the automatic plug device is kept horizontal to the socket assembly 15, which is beneficial to all The plug 12A is connected to the socket 15A in the socket assembly 15, since the socket assembly 15 is installed on the locomotive, it can provide power for the whole operation.

[0039] The socket assembly 15 also includes a second connecting plate 15B and a guide rod 15C fixed on the second connecting plate 15B, and the socket 15A is fixed on the second connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com