L-shaped hanger for prefabricated T-beam formwork

A beam formwork, L-shaped technology, applied in the field of prefabricated T-beam formwork L-shaped spreader, can solve problems such as difficult operation, formwork shaking, and collision with surrounding objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

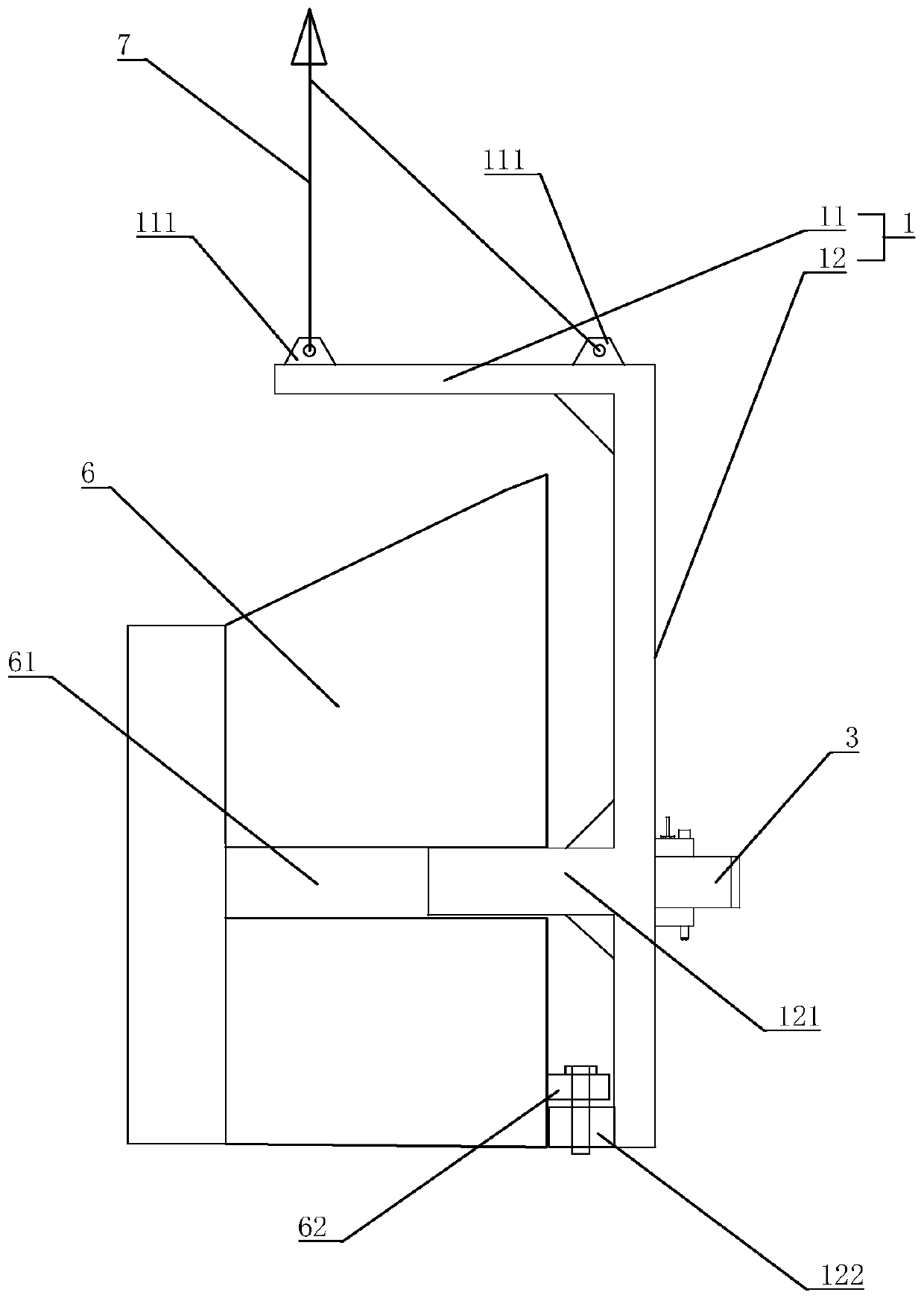

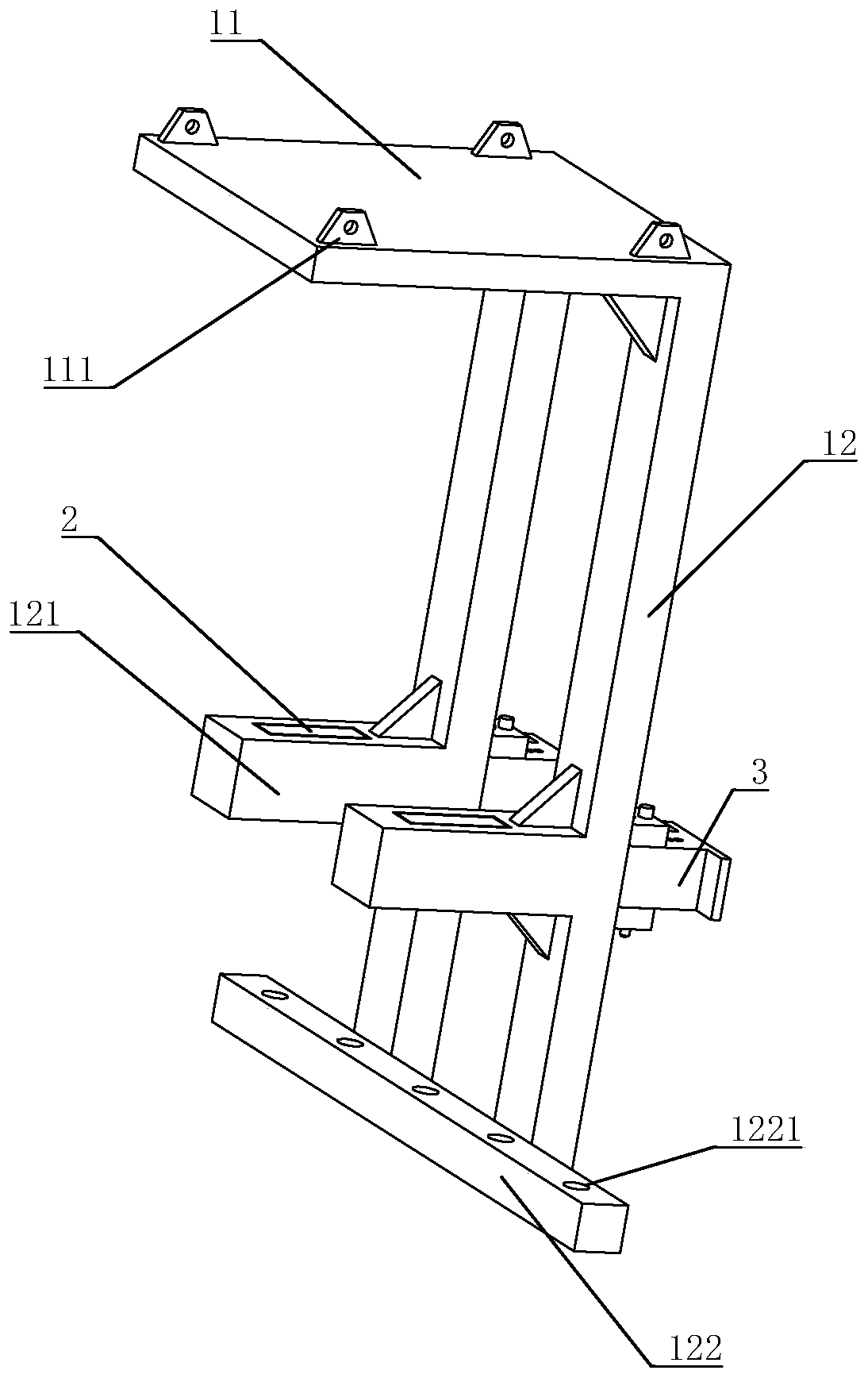

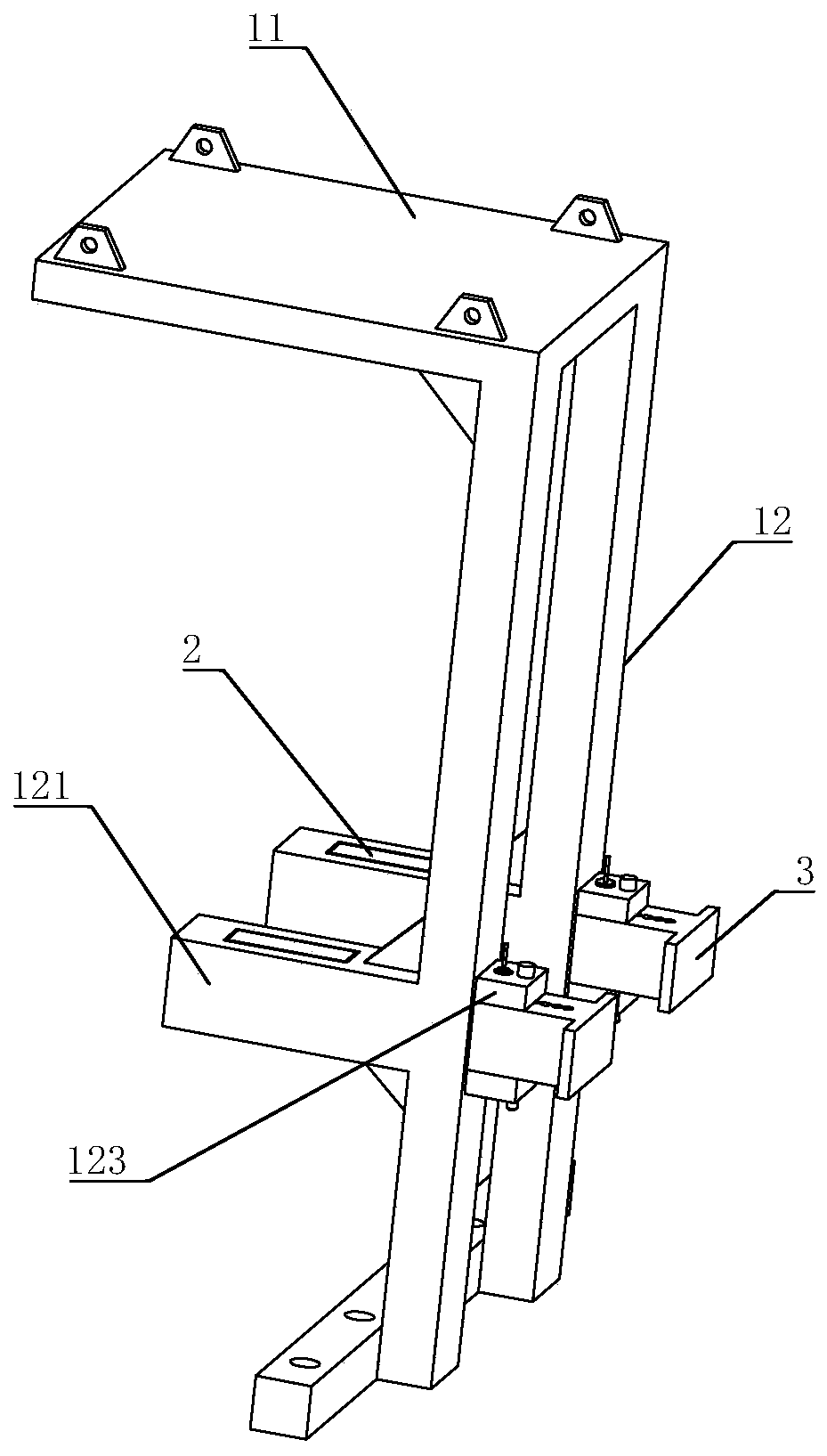

[0025] refer to Figure 1 to Figure 9 , a prefabricated T-beam formwork L-shaped spreader of the present invention is used for hoisting prefabricated T-beam formwork 6, such as Figure 9 As shown, gaps 61 are provided on both sides of the middle part of the prefabricated T-beam formwork 6, and the middle of the prefabricated T-beam formwork is a T-beam cavity 63, and the gaps 61 are arranged on both sides of the waist of the T-beam cavity 63. The prefabricated T-beam formwork L-shaped hanger includes an L-shaped hanging plate 11, a pair of pre-tightening blocks 2 and a pre-tightening mechanism.

[0026] The L-shaped hanging plate 11 includes a horizontally arranged top plate 11 and a vertical plate 12 vertically connected to one side of the top plate 11. The upper end of the top plate 11 is provided with a plurality of hanging plates 111 for connecti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap