High-precision simple lifting synchronization measuring system and measuring method thereof

A measurement system, high-precision technology, applied in the direction of hydrostatic pressure, etc., can solve the problems of large impact on the measurement control environment, slow measurement speed, inaccurate measurement, etc., and achieve simple construction monitoring principles, convenient operation and understanding, and accurate measurement data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

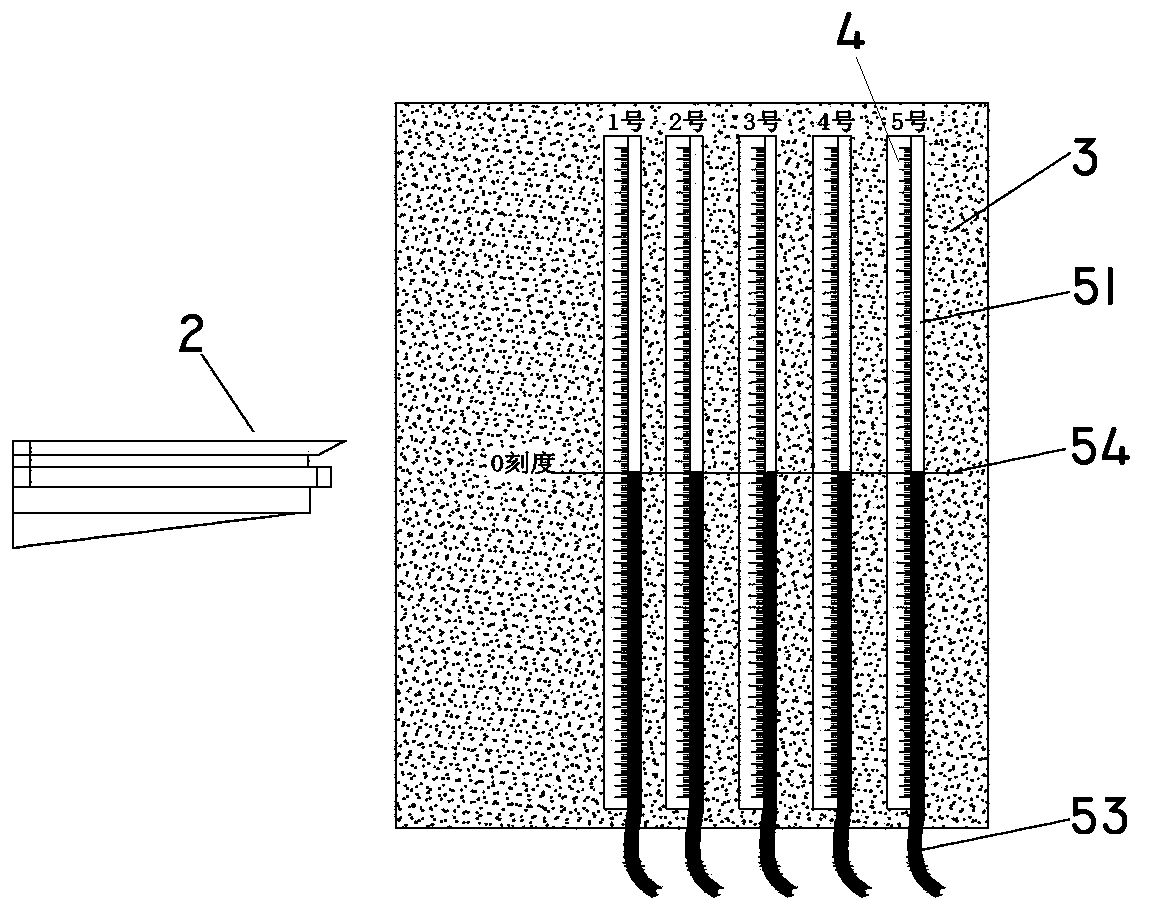

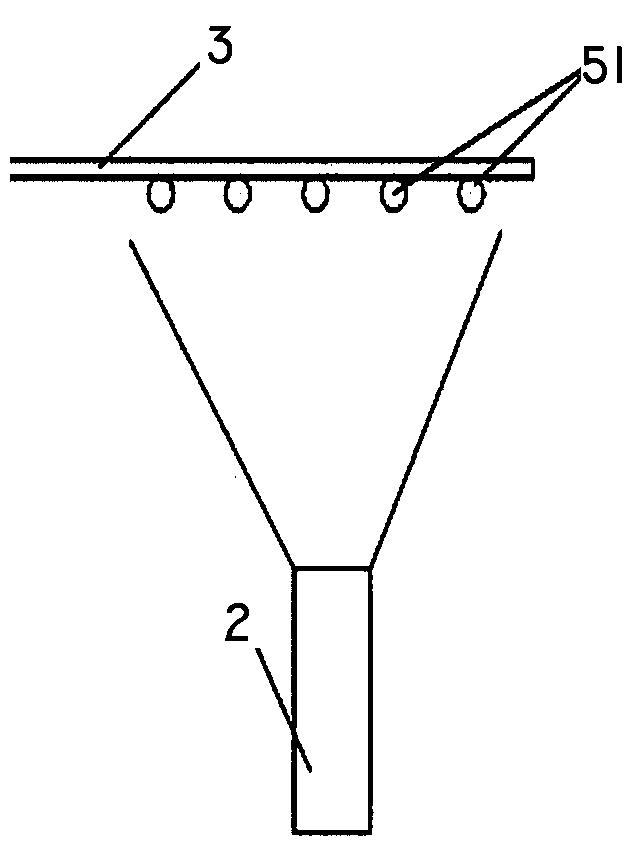

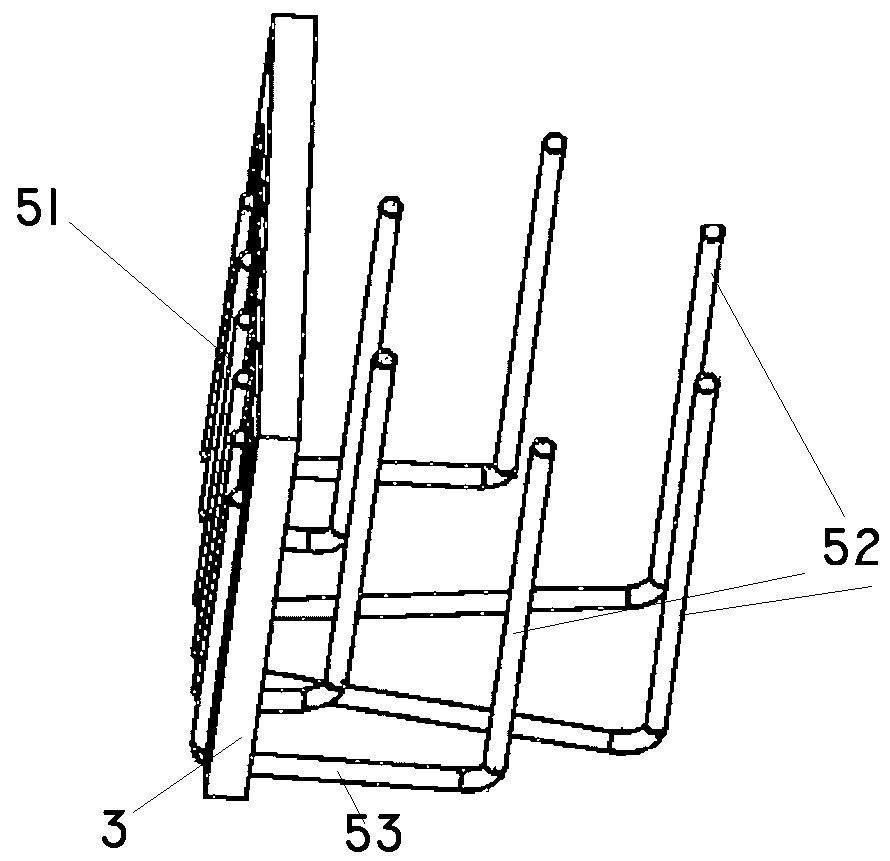

[0041] Such as figure 1 , 2 , the present invention provides a high-precision lifting synchronous simple measurement system, including a structure to be lifted 1, an observation camera 2, a rectangular fixed plate 3, a scale 4, a U-shaped tube 5 and an indicating liquid 6 filled in the U-shaped tube 5, The structure 1 to be lifted is provided with a plurality of lifting points, and the fixed plate 3 is arranged on one lifting point of the structure 1 to be lifted; the scale 4 has at least four and is arranged on the rectangular fixed plate 3 at intervals, and is fixed to the fixed plate 3 respectively. A set of long sides of the plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com