Electric valve and cooling system using electric valve

A technology of electric valves and spools, applied in the direction of valve operation/release devices, refrigerators, multi-way valves, etc., can solve the problems of unable to adjust the throttling amount of refrigerant, difficult to achieve stable temperature and energy saving, and difficult to quickly cool down the room, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

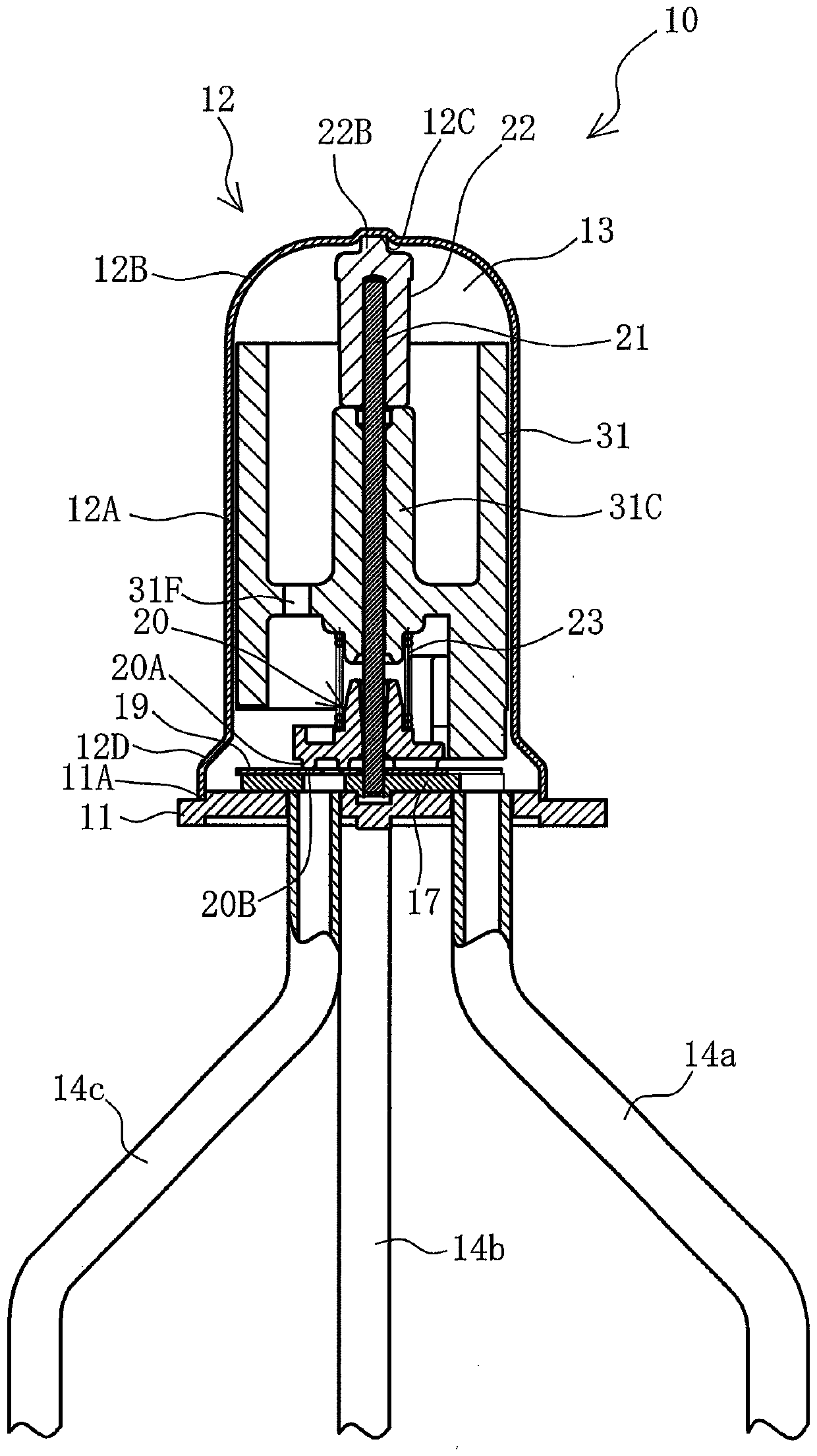

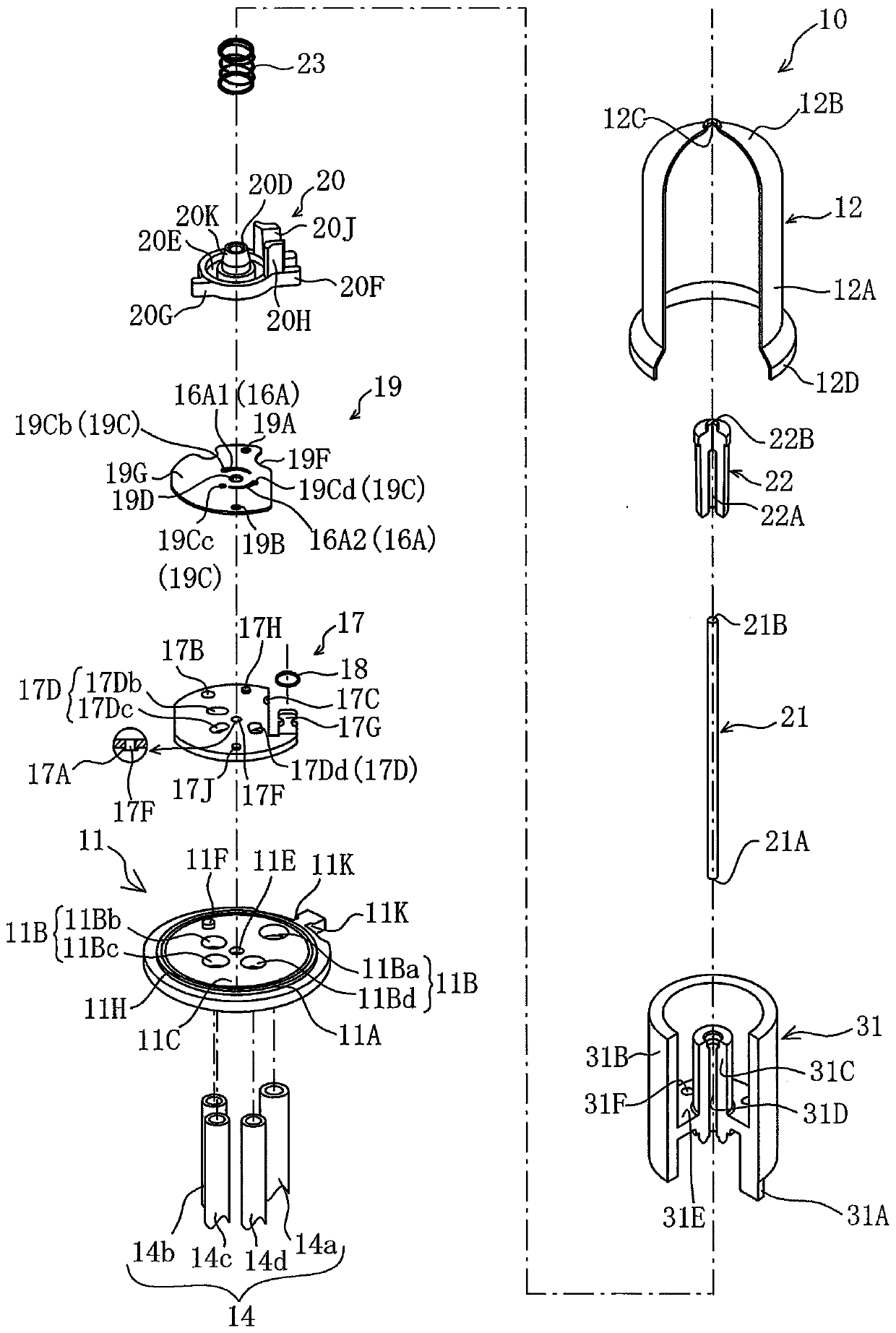

[0055] Hereinafter, an electric valve according to a first embodiment will be described with reference to the drawings. figure 1 is a cross-sectional view of the electric valve of the first embodiment, figure 2 yes figure 1 An exploded perspective view of the electric valve shown. In addition, in this specification, "upper" or "lower" means figure 1 The motor valve 10 shown is specified as a reference.

[0056] Such as figure 1 As shown, the electric valve 10 accommodates driving mechanisms such as a rotor 31 described later, has a disc-shaped bottom cover member 11, and a housing 12 airtightly welded on the bottom cover member 11, and the housing 12 A valve chamber 13 with an airtight chamber structure is formed on the inner side of the valve body. In addition, a stator assembly (not shown) to be described later is mounted on the outer periphery of the case 12 .

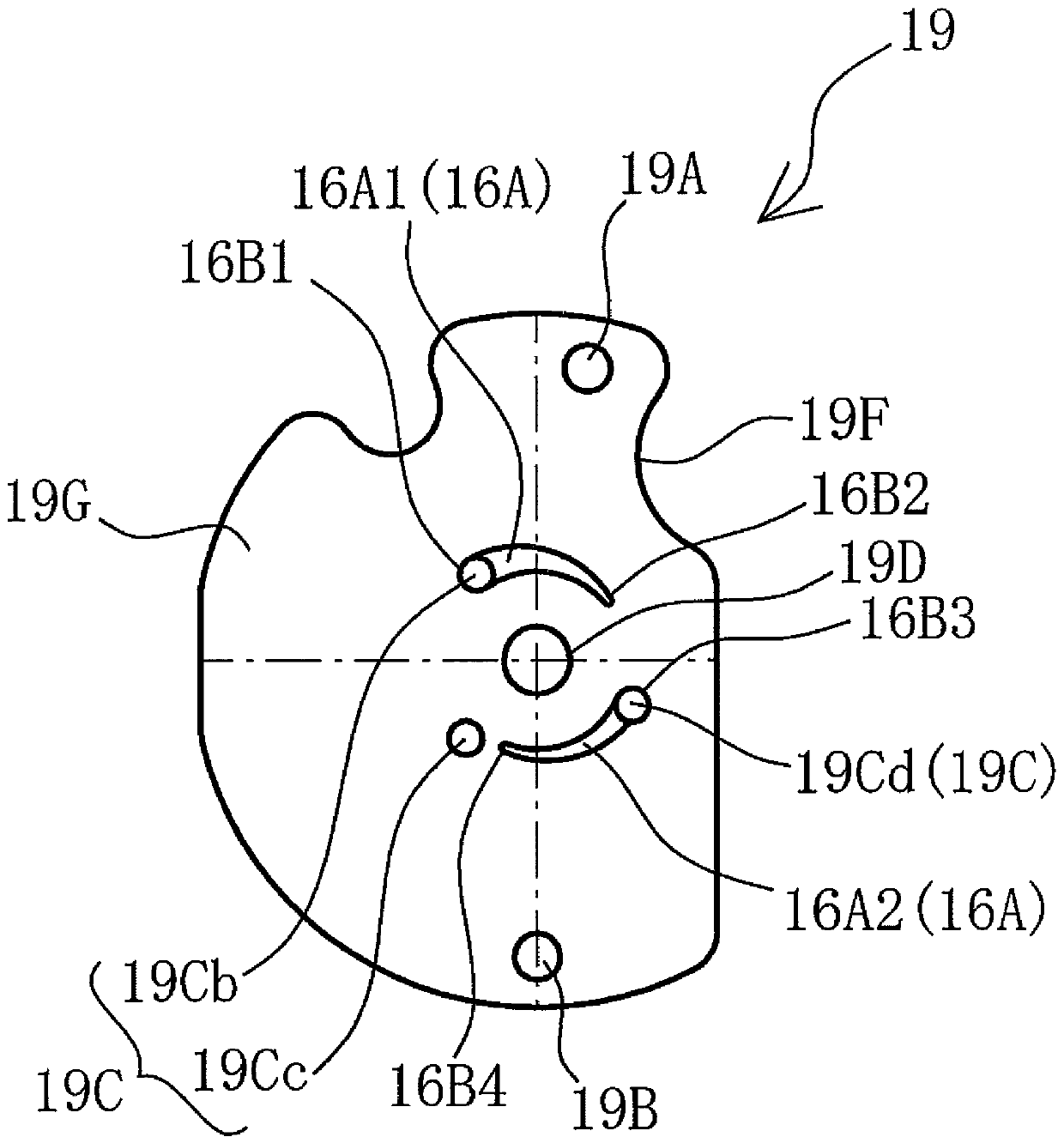

[0057] Such as figure 2As shown, in order to securely obtain the concentricity between the rotor hou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap