Cooling device for mechanical parts

A technology for cooling devices and mechanical parts, applied in the field of cooling of mechanical parts, can solve problems such as cracking, easy deformation, oxidation, etc., and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

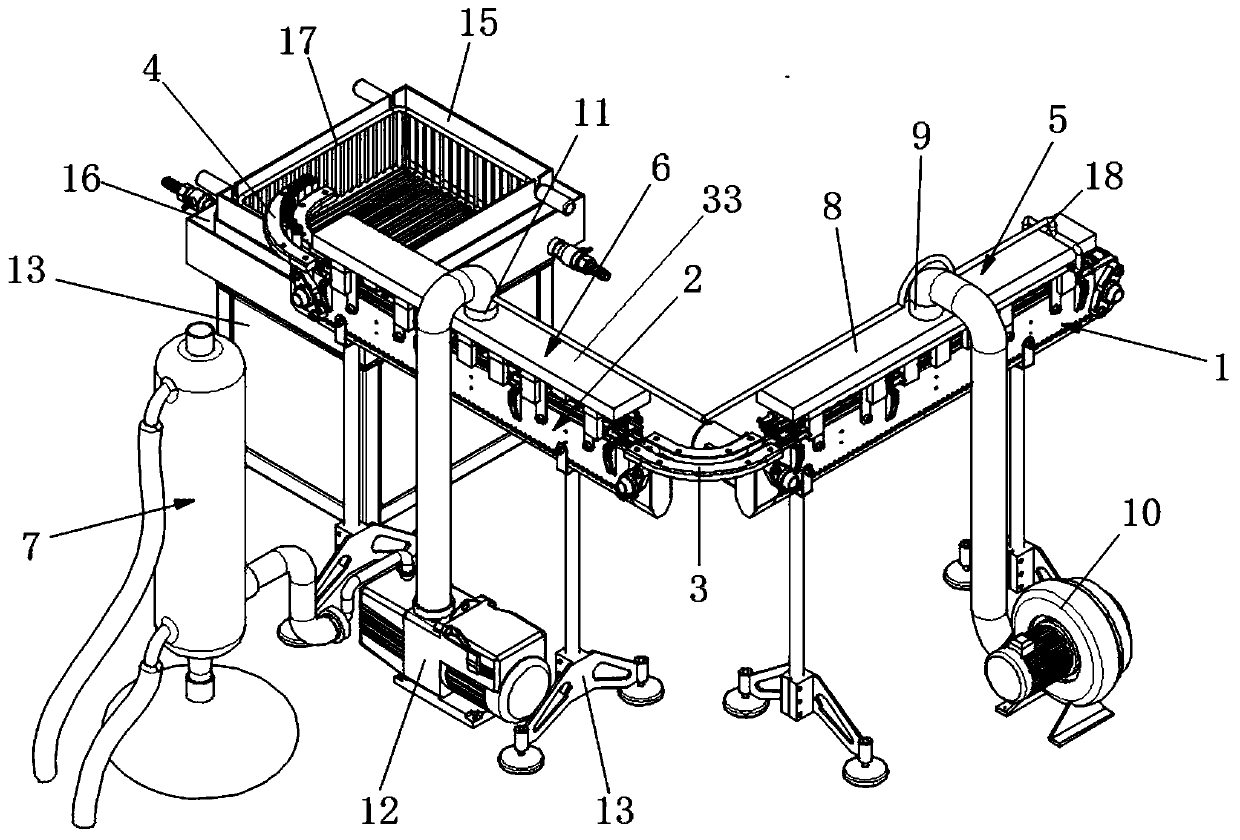

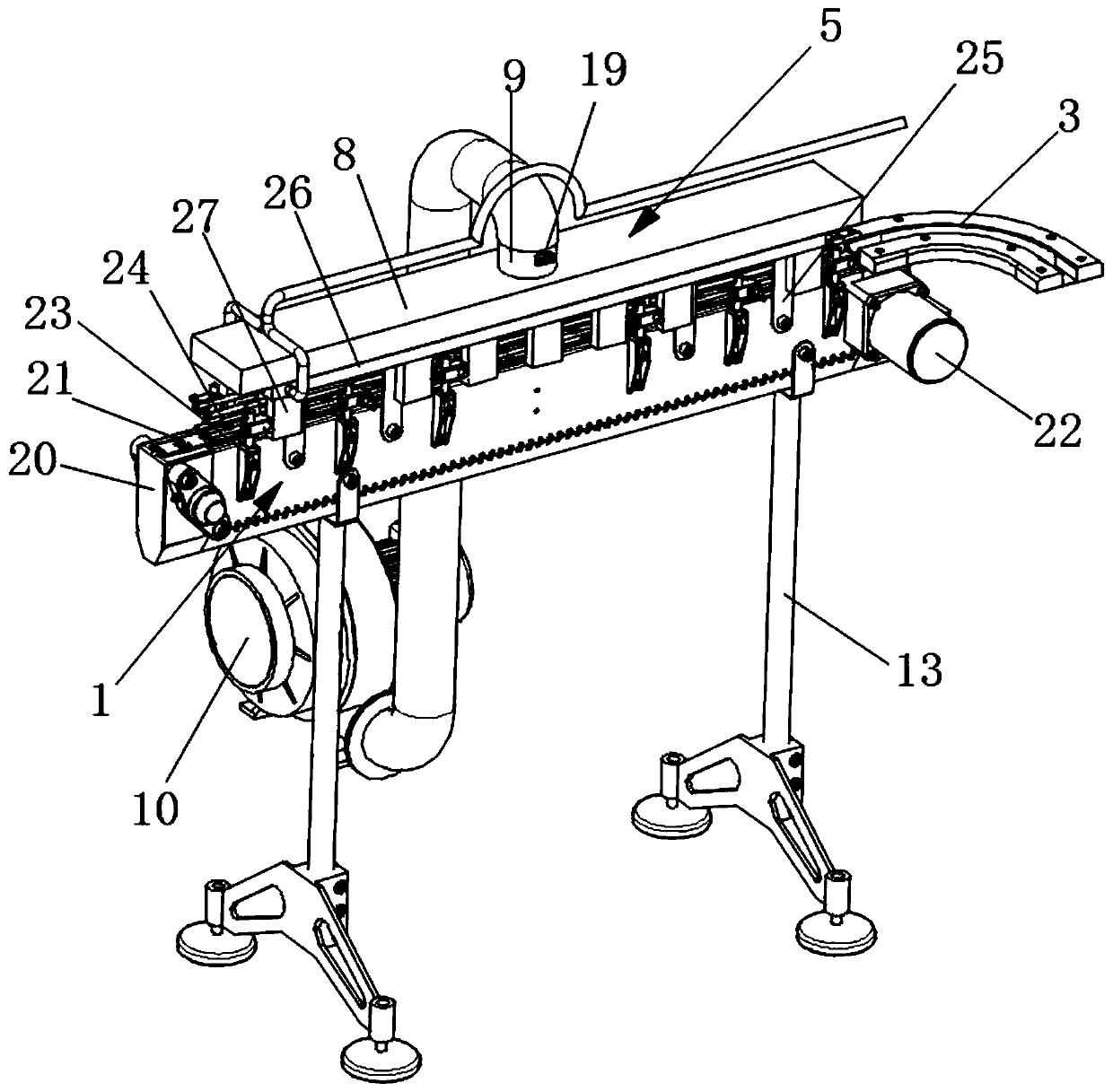

[0039] The present invention provides as attached Figure 1-8 The cooling device for mechanical parts shown includes a first transmission mechanism 1 and a second transmission mechanism 2, the first transmission mechanism 1 is connected to the second transmission mechanism 2 through the first guide groove 3, and the end of the second transmission mechanism 2 A second guide groove 4 is provided.

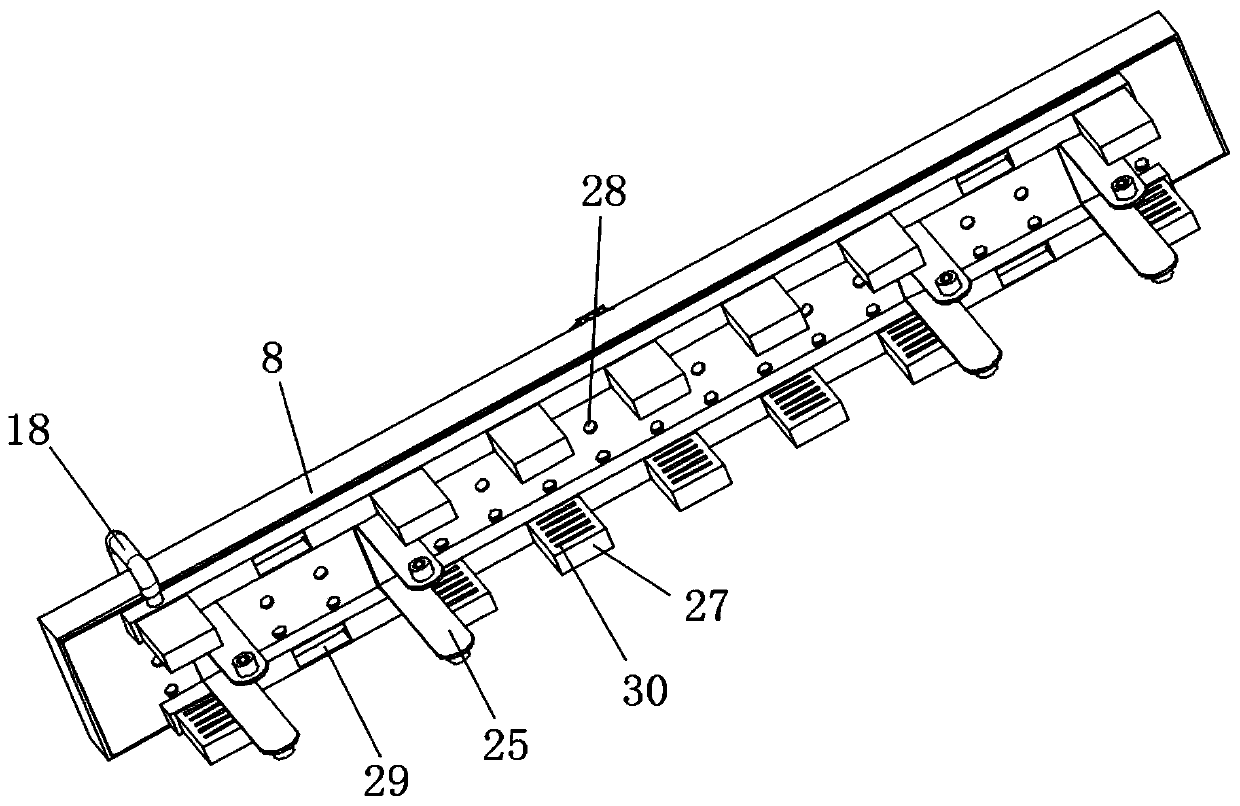

[0040] The first conveying mechanism 1 is provided with a warm air cooling mechanism 5, and the warm air cooling mechanism 5 includes a warm air box 8 fixed on the first conveying mechanism 1. The warm air box 8 can be made by splicing aluminum plates. A U-shaped connector 25 is fixed on the first transmission mechanism 1, and the two bottom ends of the first U-shaped connector 25 are connected with the first transmission mechanism 1 through bolts. The air hole 28, the top of the heater box 8 is provided with an air inlet 9, the air inlet 9 is connected with a blower 10 through a pip...

Embodiment 2

[0044] The difference with embodiment 1 is:

[0045] as attached figure 1 And attached figure 2 As shown, the first transmission mechanism 1 includes a fixed frame 20, the bottom of the fixed frame 20 is provided with a support foot 13, the support foot 13 props up the fixed frame 20 to facilitate the operation of the staff, and the two shafts on the fixed frame 20 are wrapped Covered with crawler belts 21, and one of the shafts is connected with a driving motor 22, the shaft is rotated by the driving motor 22, and the two shafts cooperate to drive the crawler belts 21 to rotate. Both sides of the fixed frame 20 are connected with guide rods 24 through a plurality of guide rod fixing parts 23, and the guide rods 24 on both sides are parallel to each other, and the mechanical parts can be neatly arranged on the crawler belt of the first transmission mechanism 1 through the guide rods 24. 21, it can also prevent mechanical parts from falling out of the first conveying mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com