Patents

Literature

32results about How to "Cool down in real time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

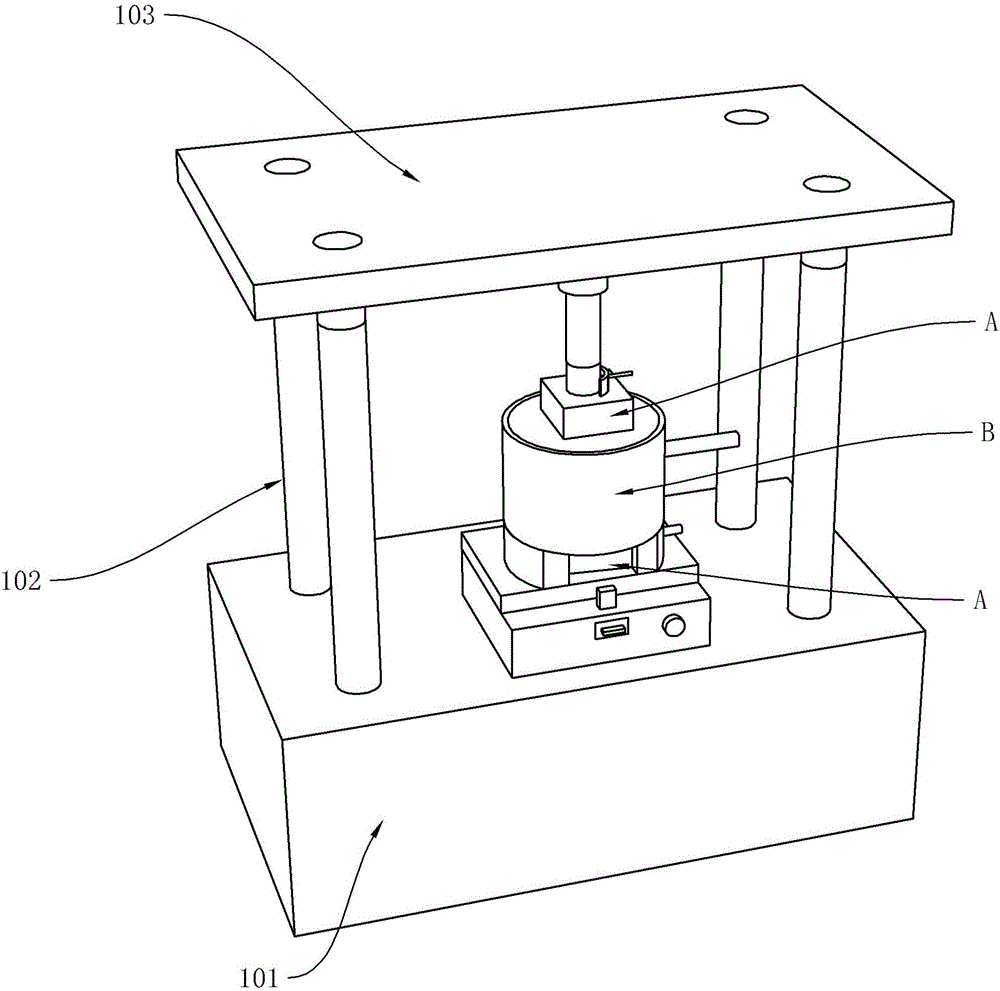

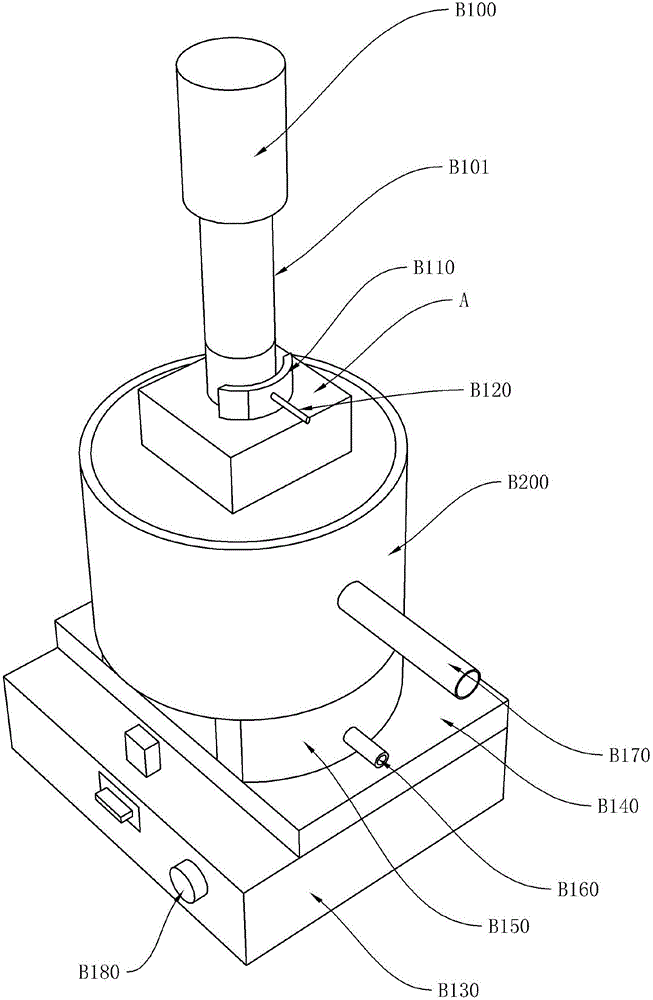

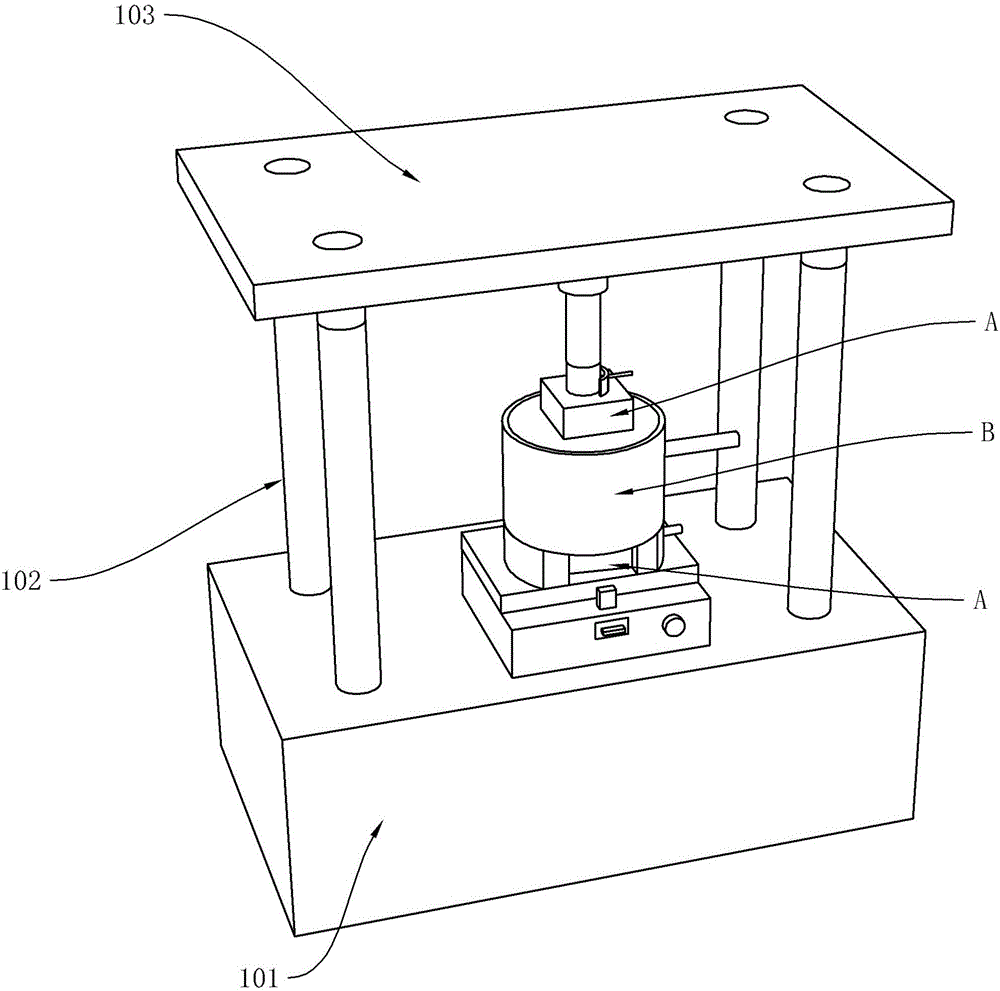

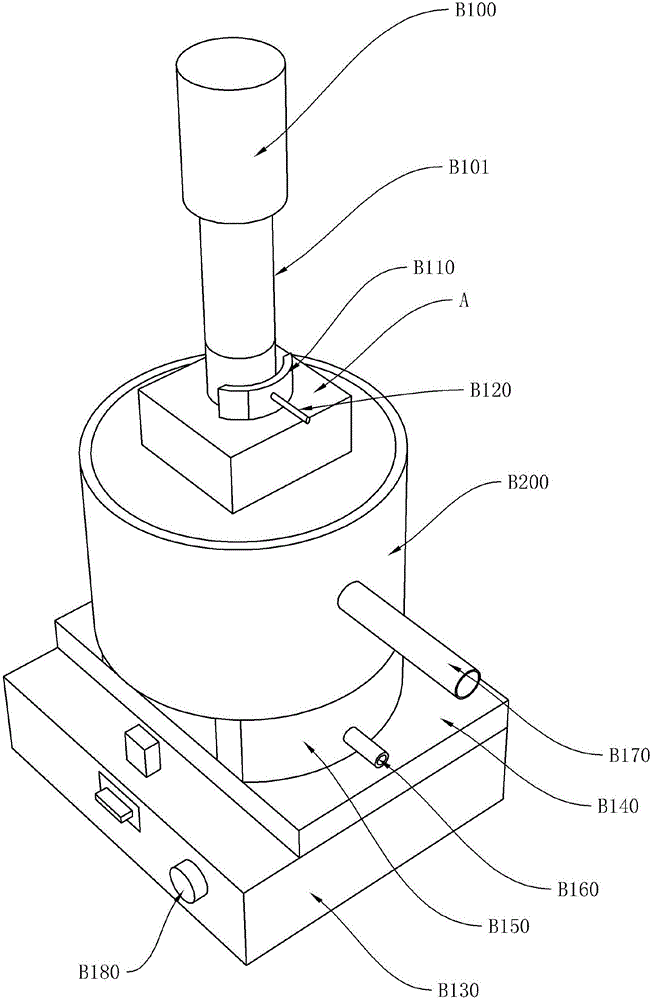

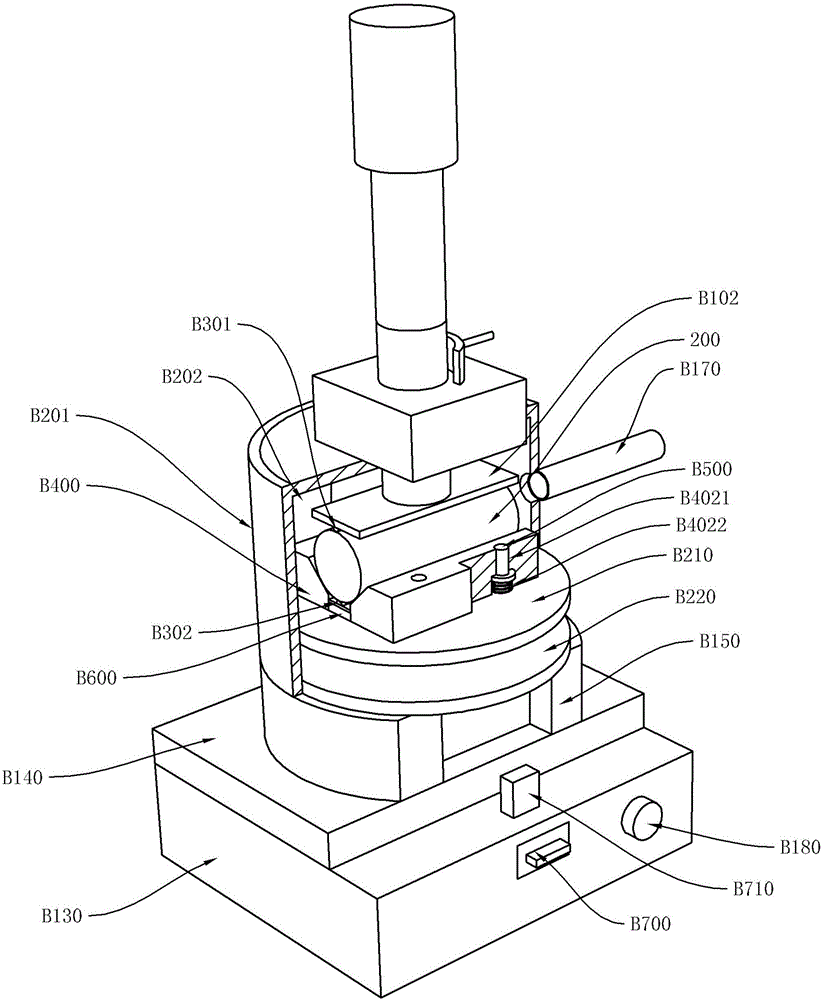

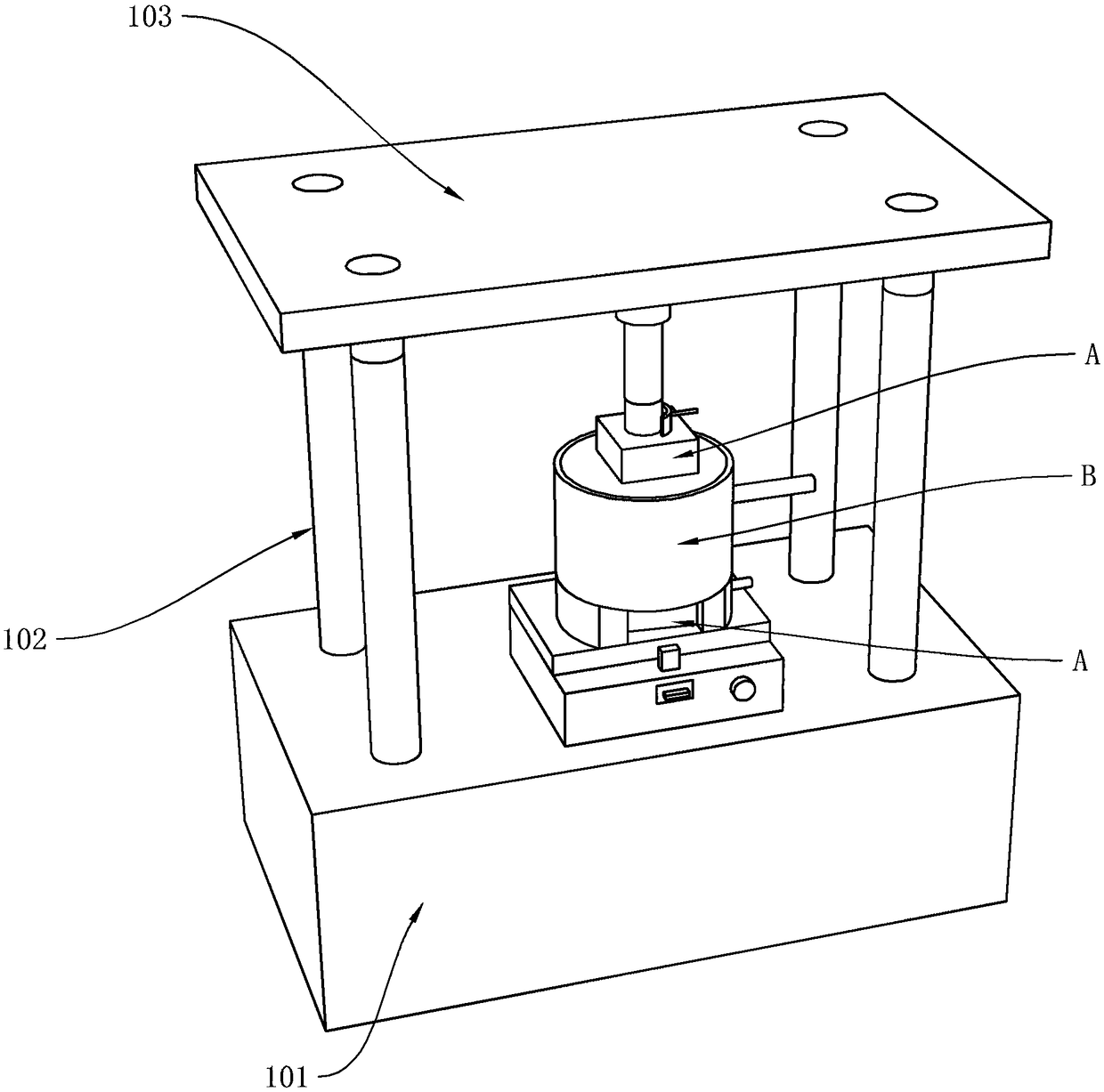

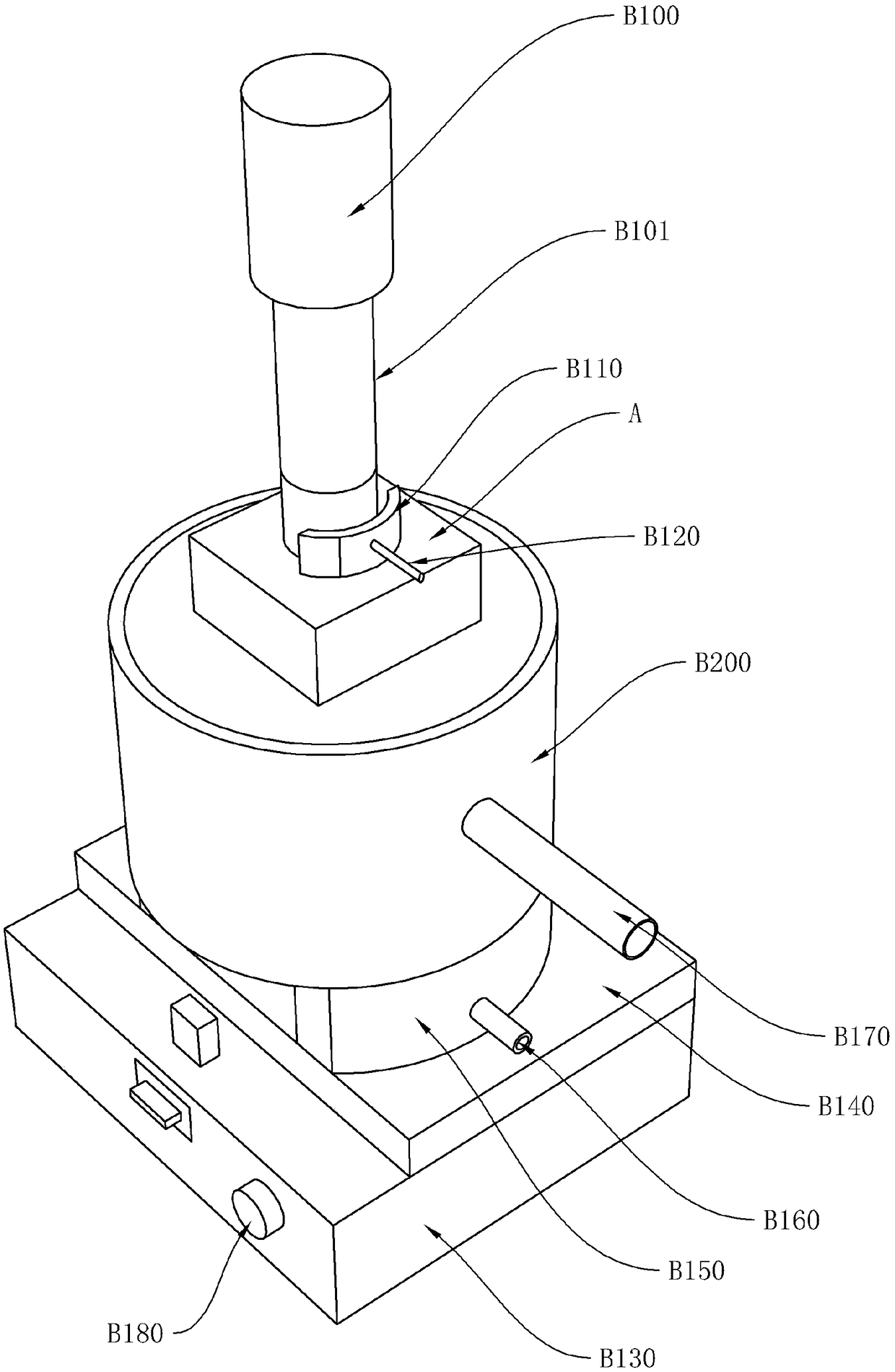

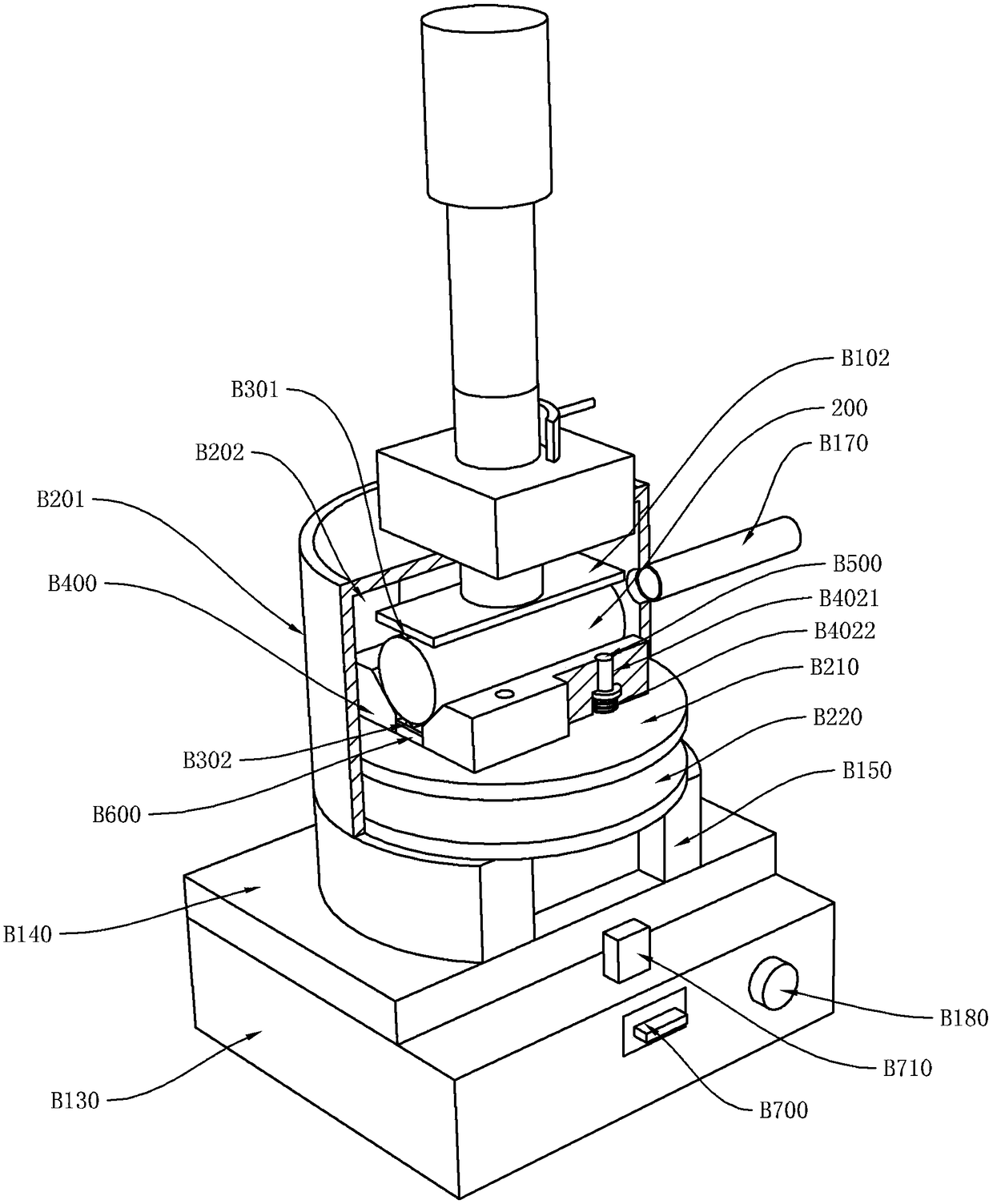

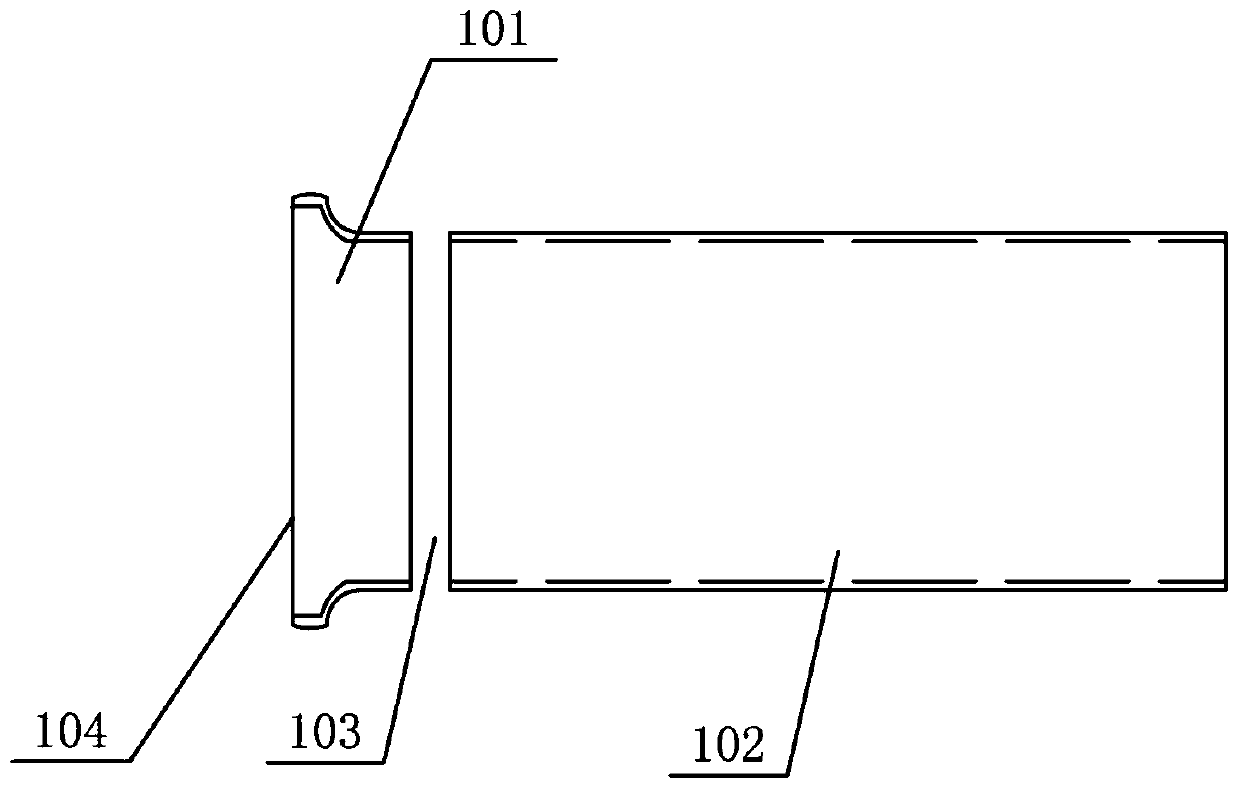

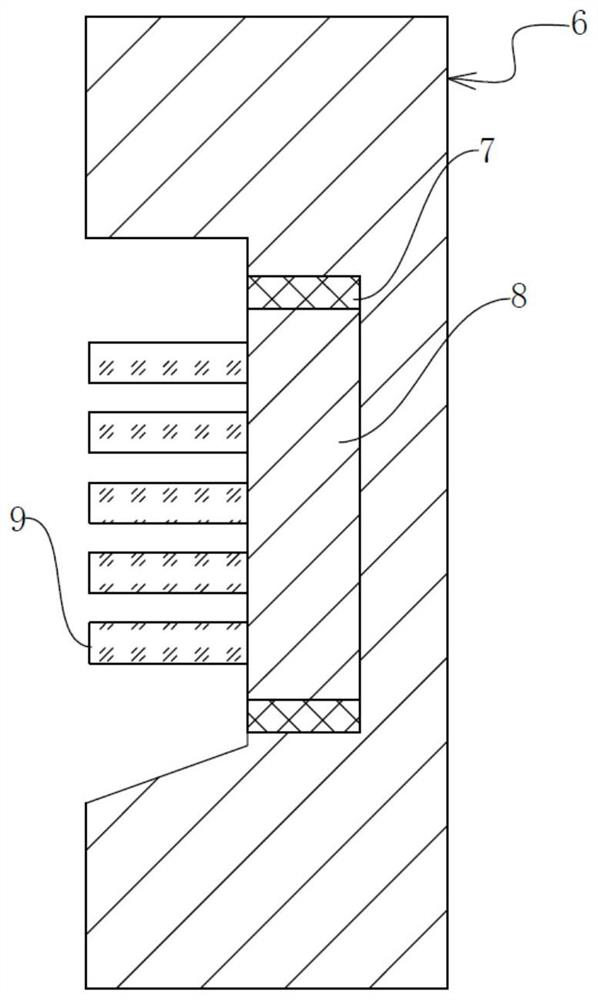

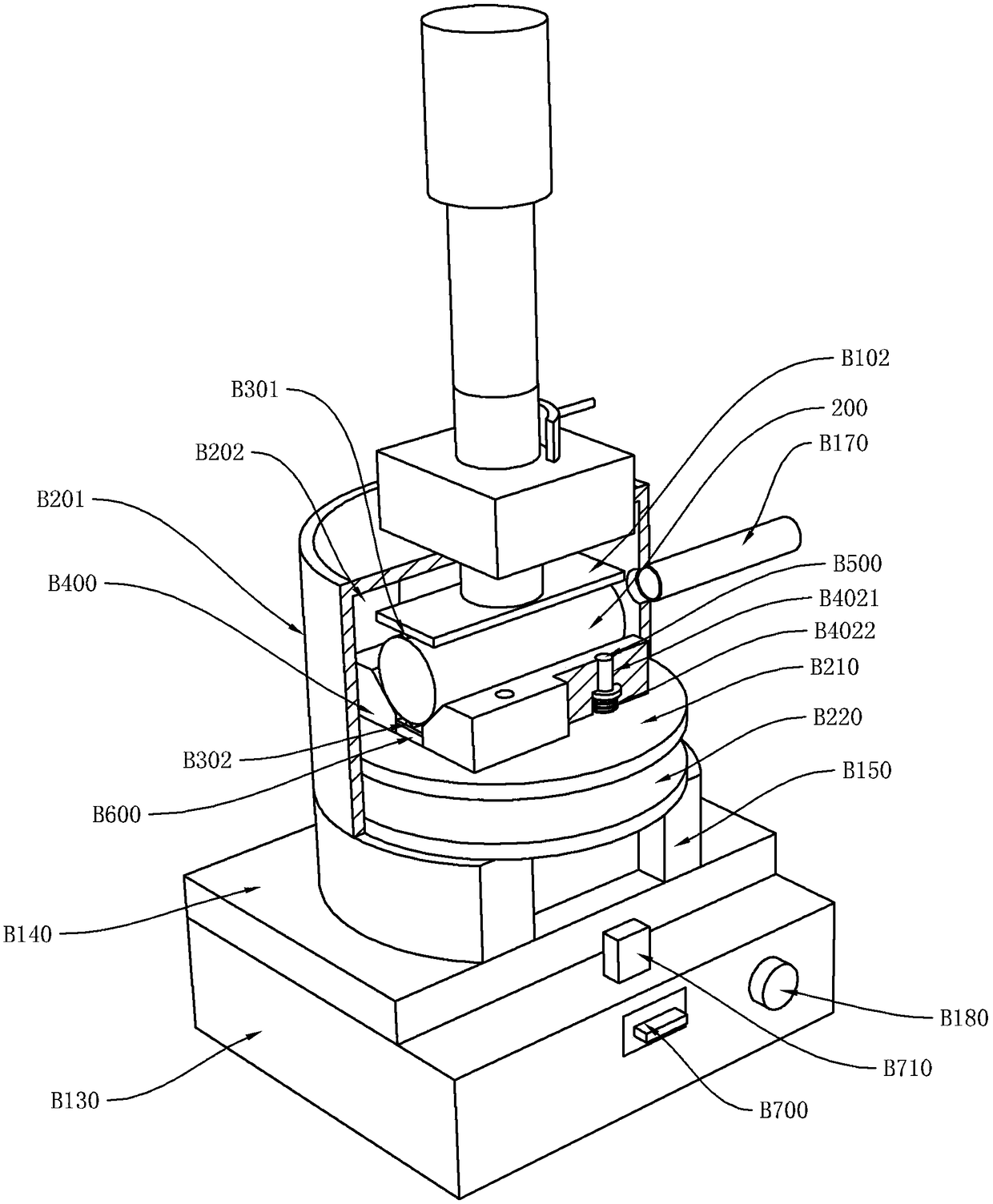

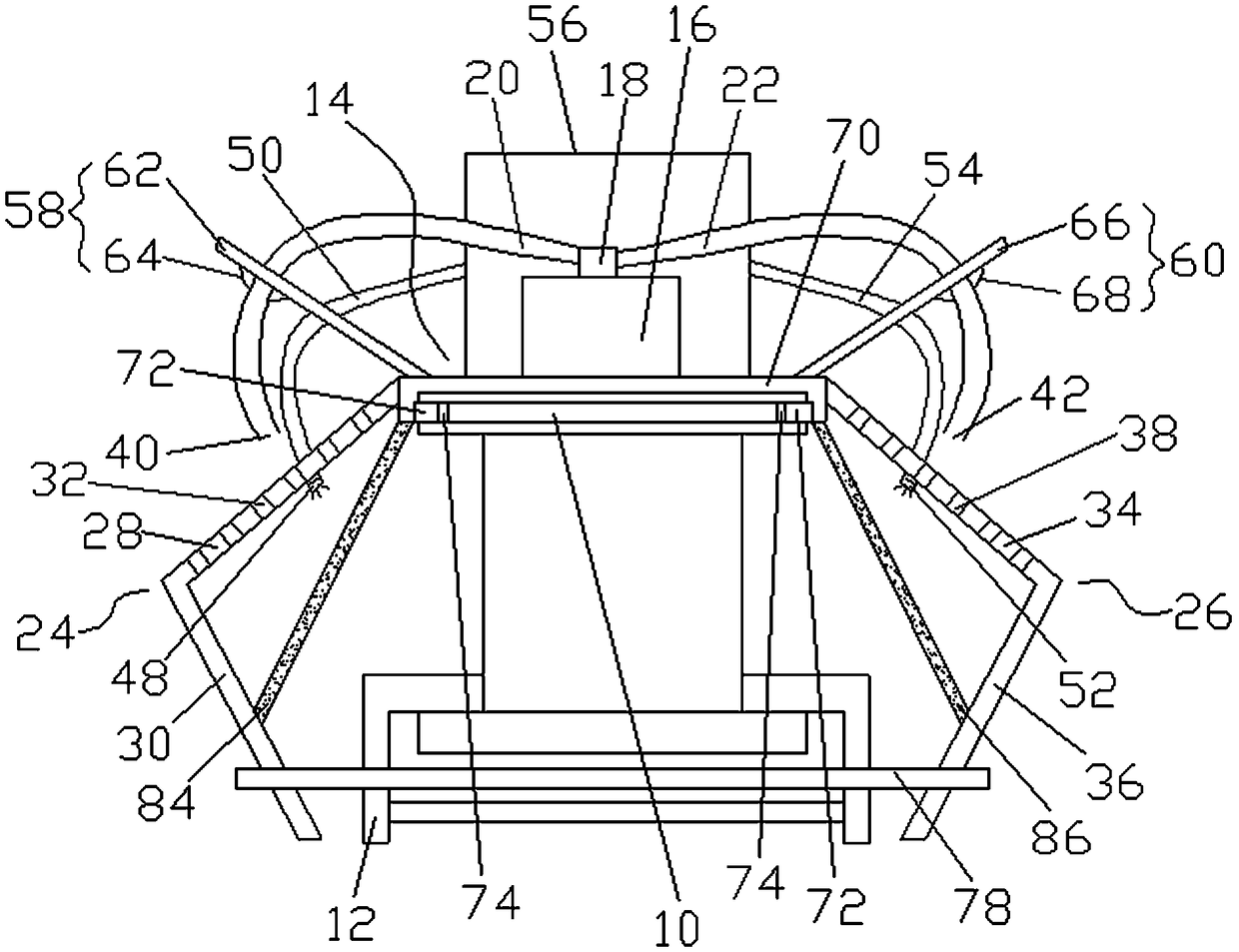

Rock tensile strength test apparatus capable of applying confining pressure

ActiveCN106644719AAccurate force situationAccurate force strengthMaterial strength using tensile/compressive forcesStress conditionsTest sample

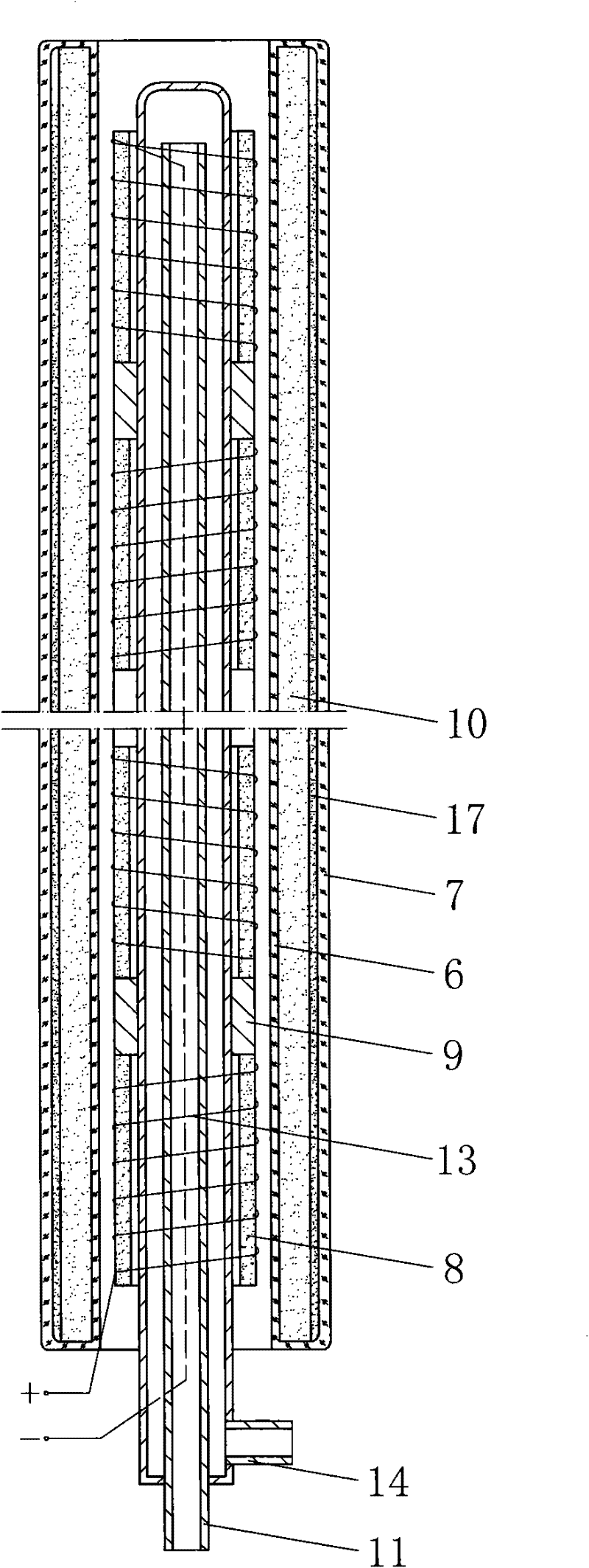

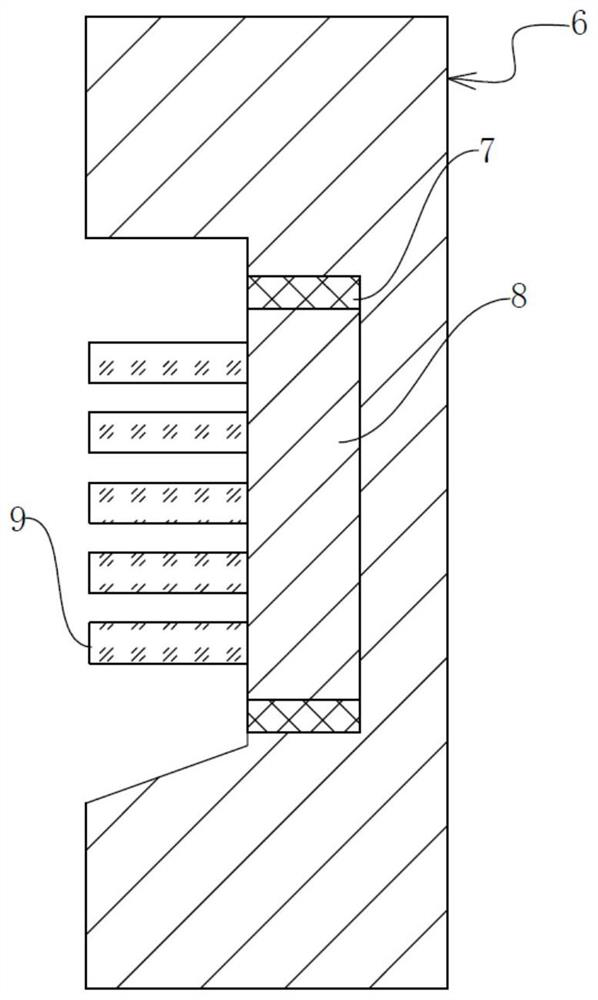

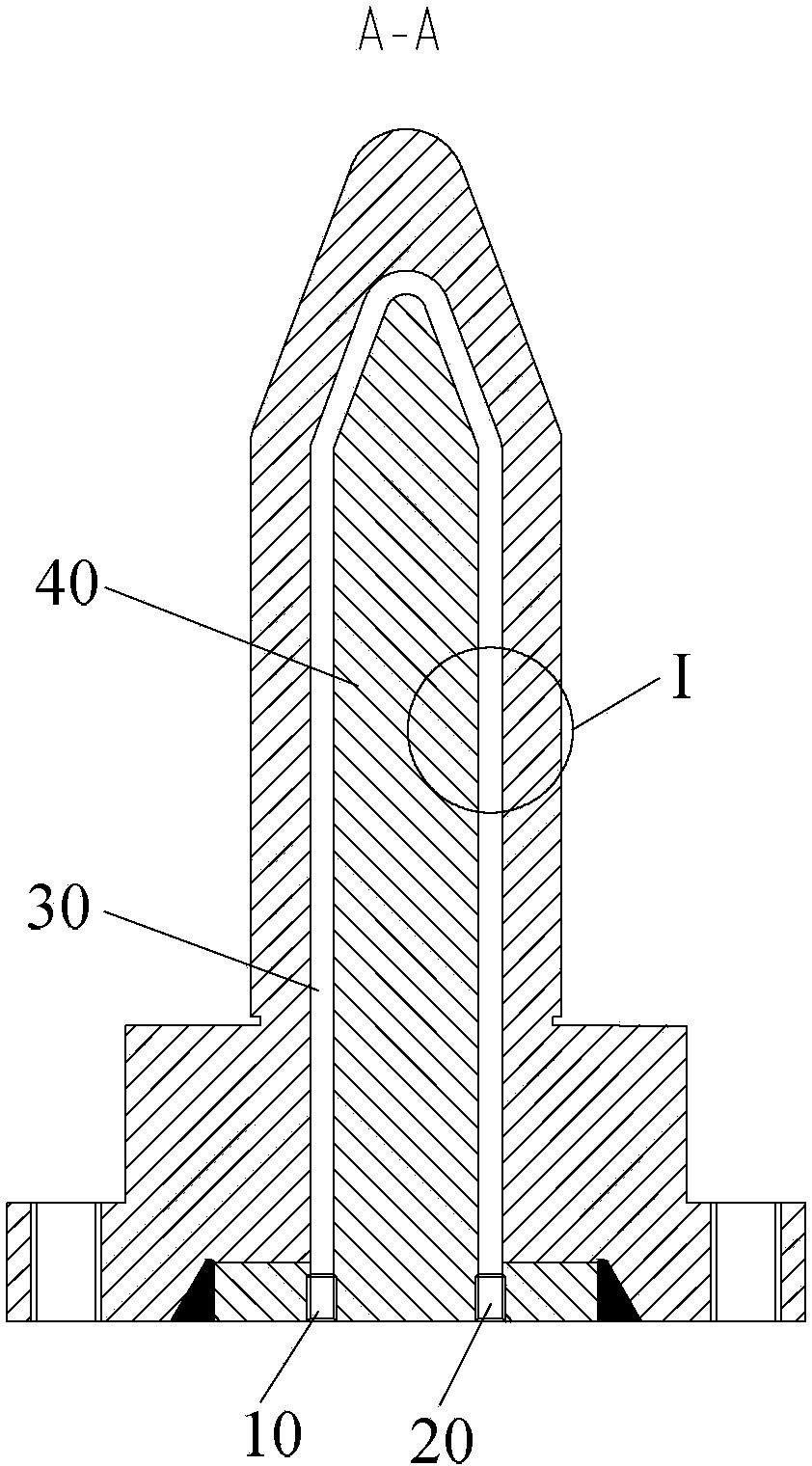

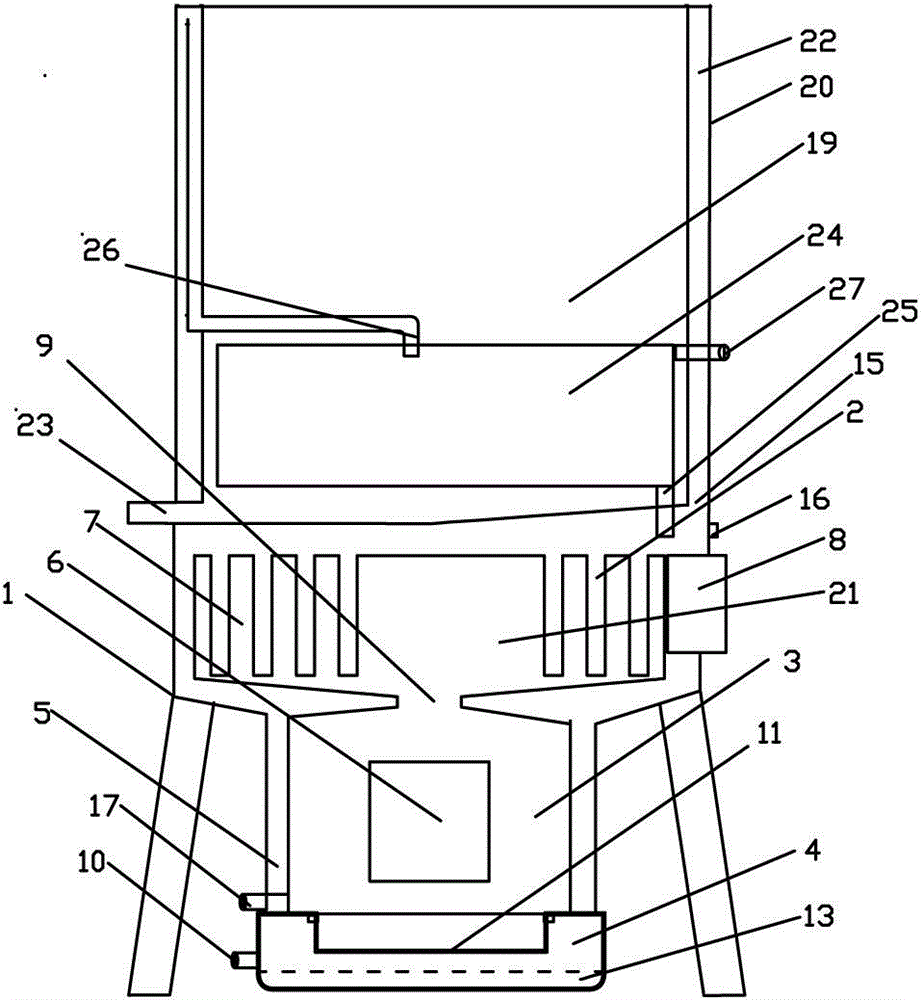

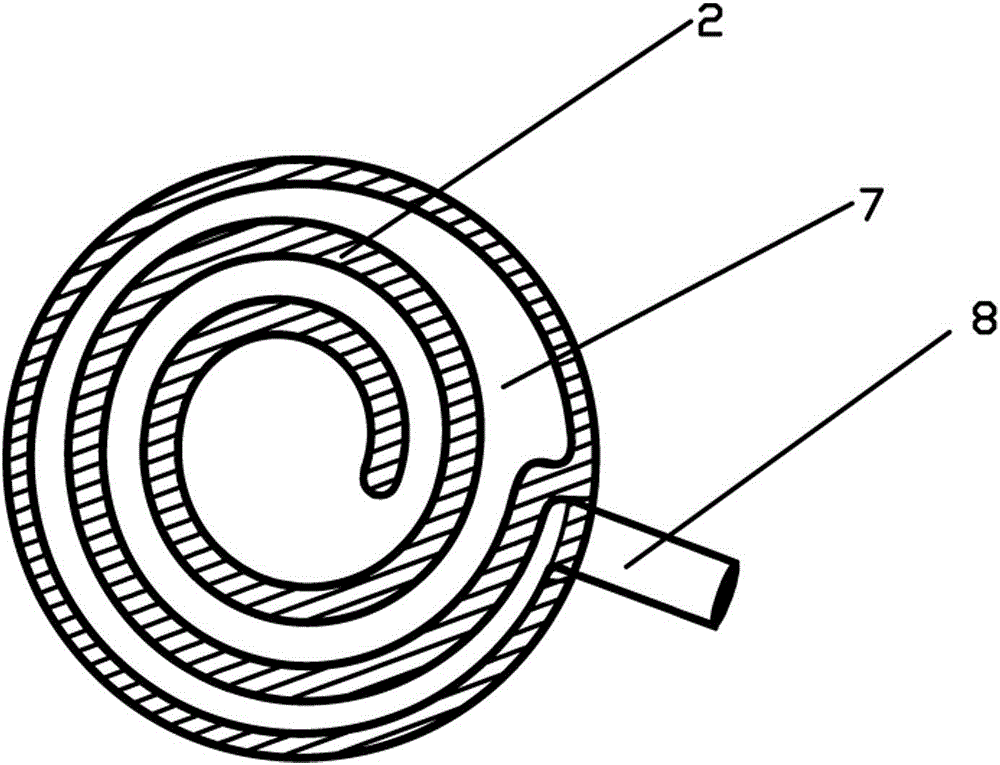

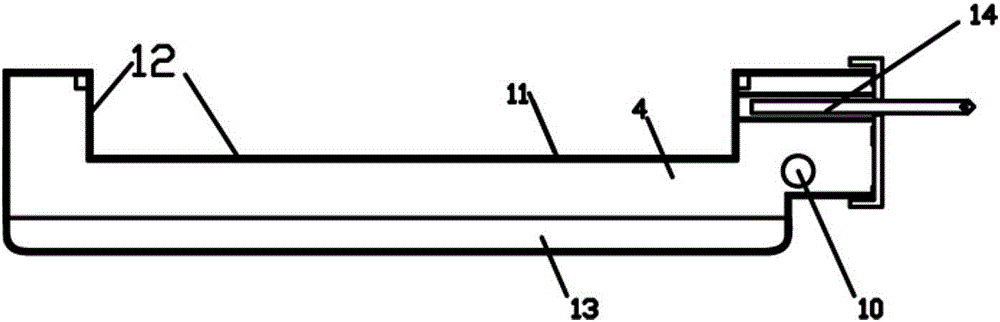

The invention discloses a rock tensile strength test apparatus capable of applying confining pressure, which can truly restore an environment in which rock is disposed. The rock tensile strength test apparatus comprises a base, wherein the base is connected with a top plate by virtue of a connecting rod; and the base is fixedly provided with a test assembly, the top plate is fixedly provided with a loading oil cylinder, and a loading rod of the loading oil cylinder stretches into the test assembly. By adopting the rock tensile strength test apparatus, the confining pressure, different temperature environments and rock burst can be applied to a test sample, an underground environmental condition of the rock can be truly simulated, so that an underground stress condition of the rock and the variation of tensile strength can be more precisely researched, and instructions and references can be provided for the subsequent design, construction, teaching, research and the like. By adopting the rock tensile strength test apparatus, the test sample can be rapidly centered, and a breaking time and pressure at the breaking time of the test sample can be discovered in time by virtue of a displacement of the loading rod. By virtue of a cooling assembly, heat of the loading rod and a lower supporting rod can be prevented from damaging the test apparatus.

Owner:ANHUI UNIV OF SCI & TECH

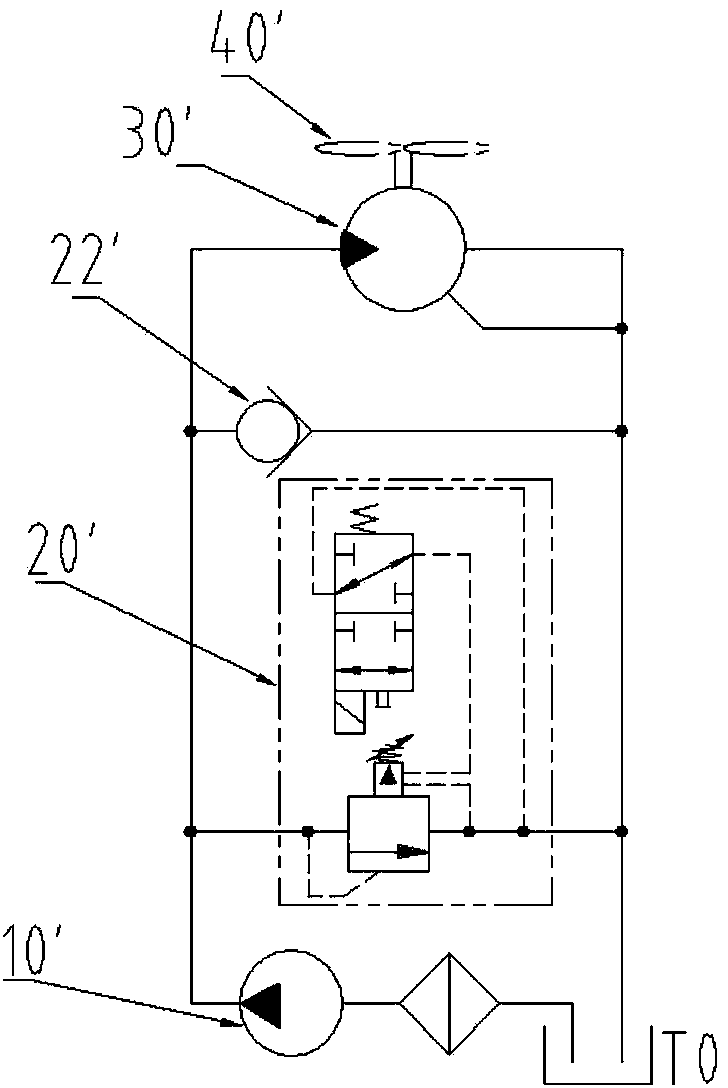

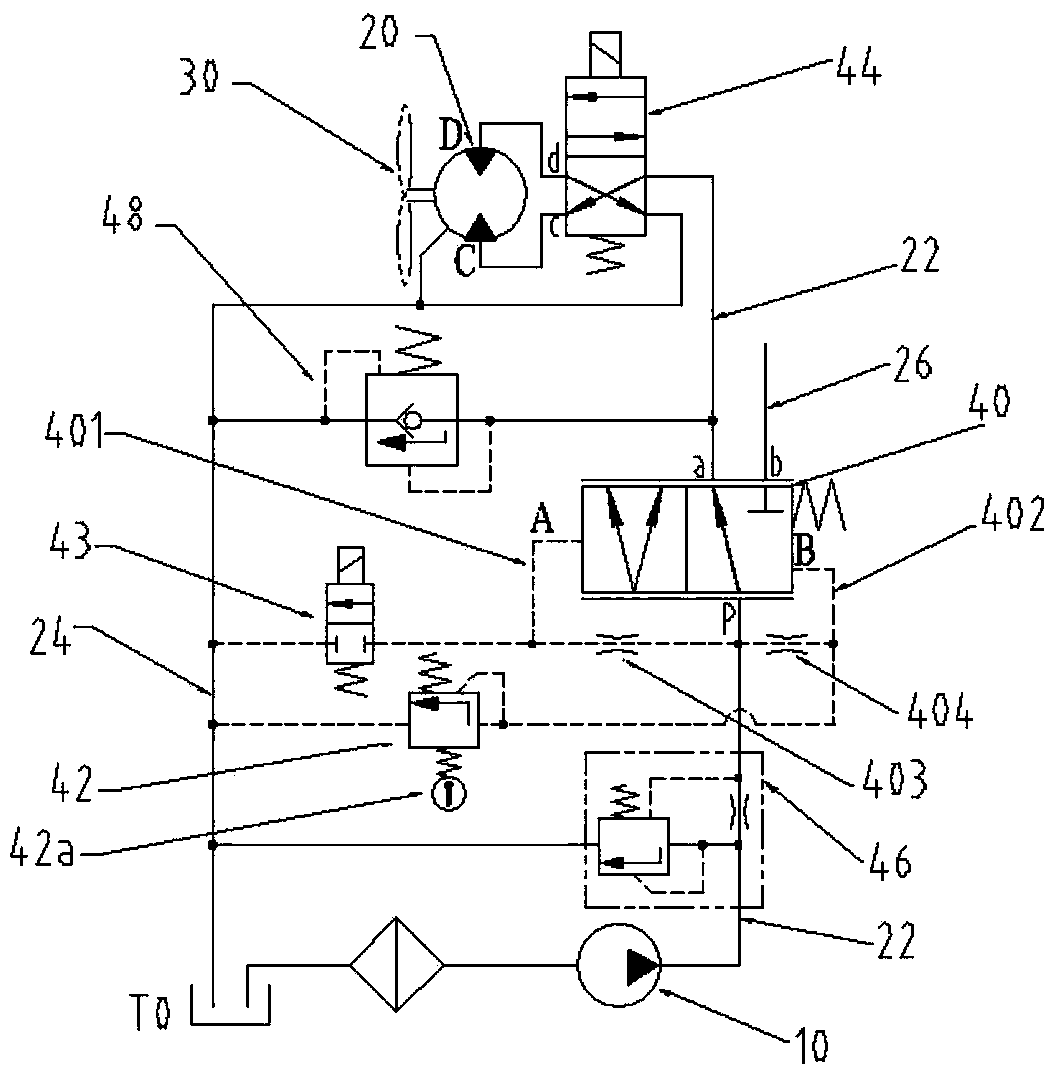

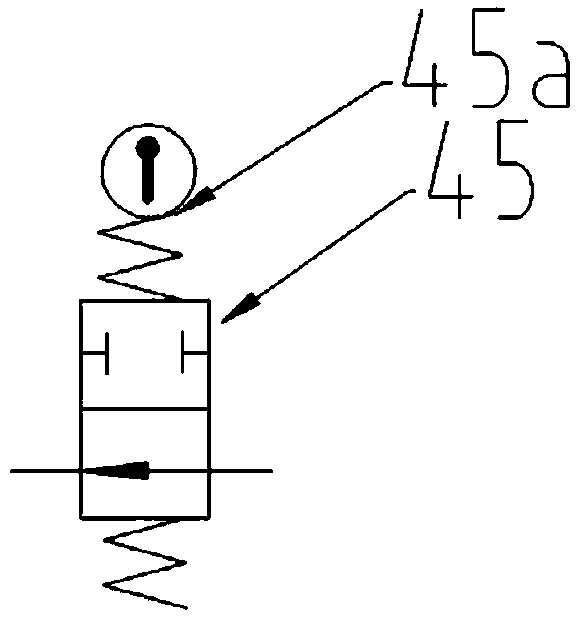

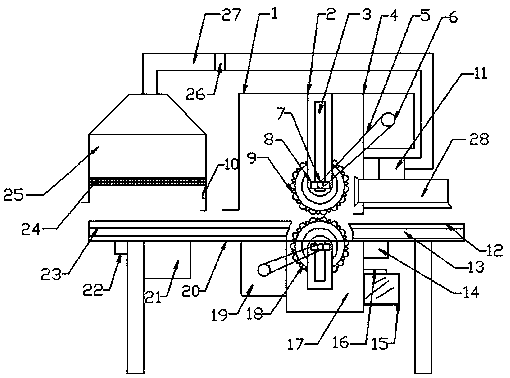

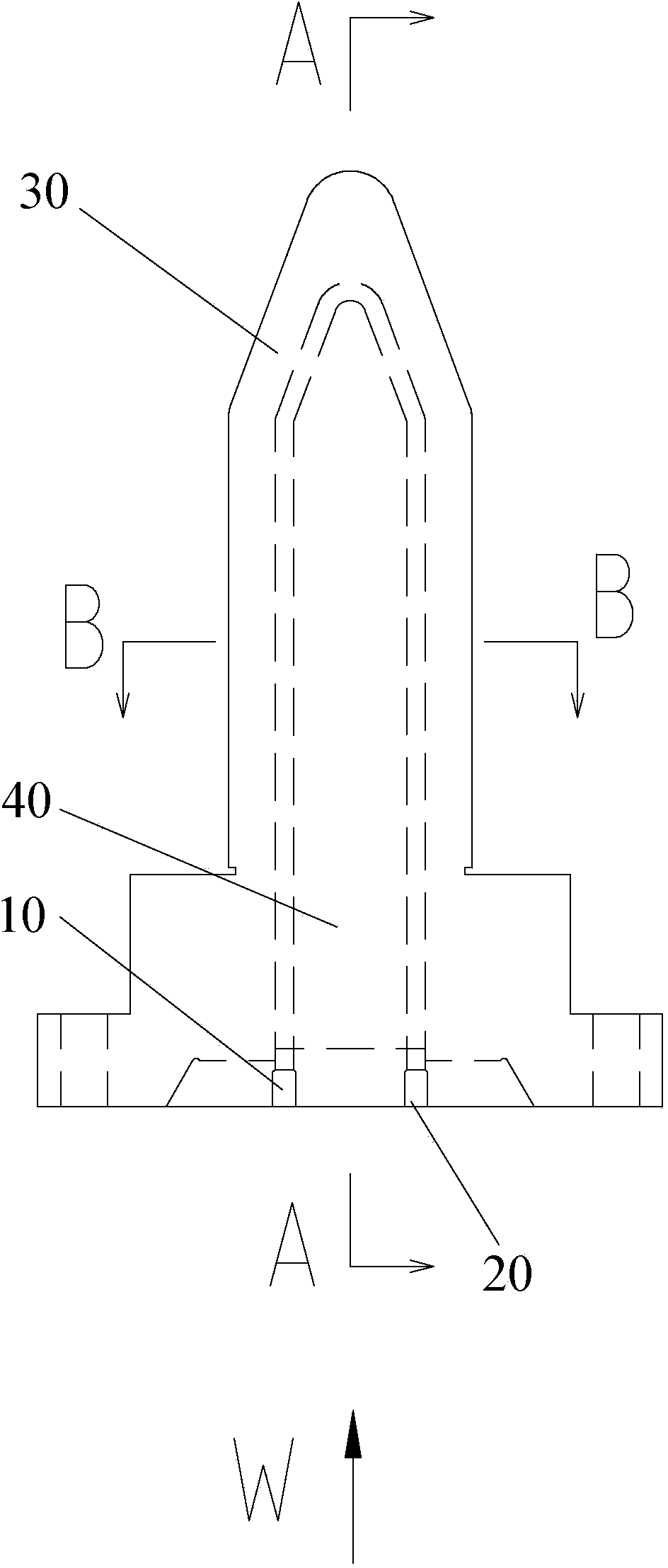

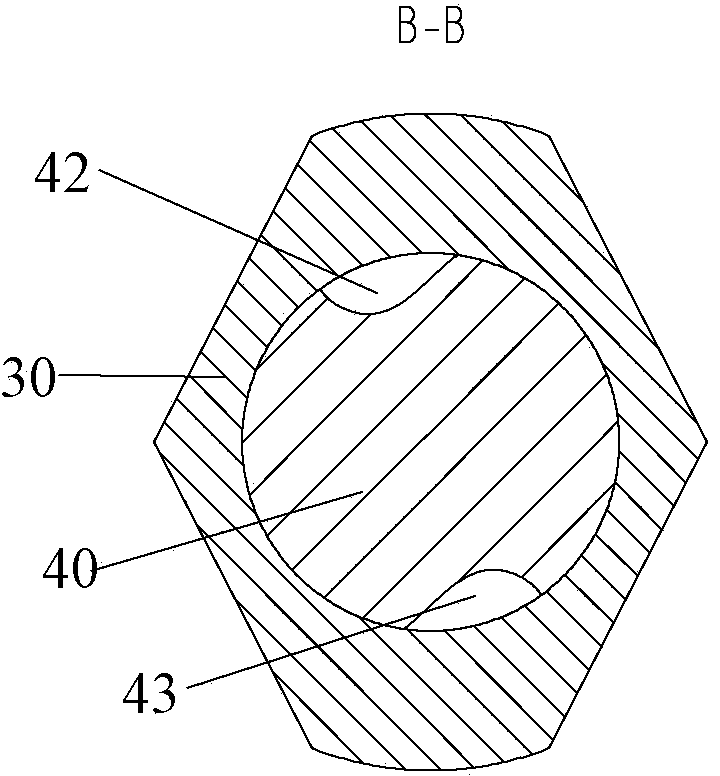

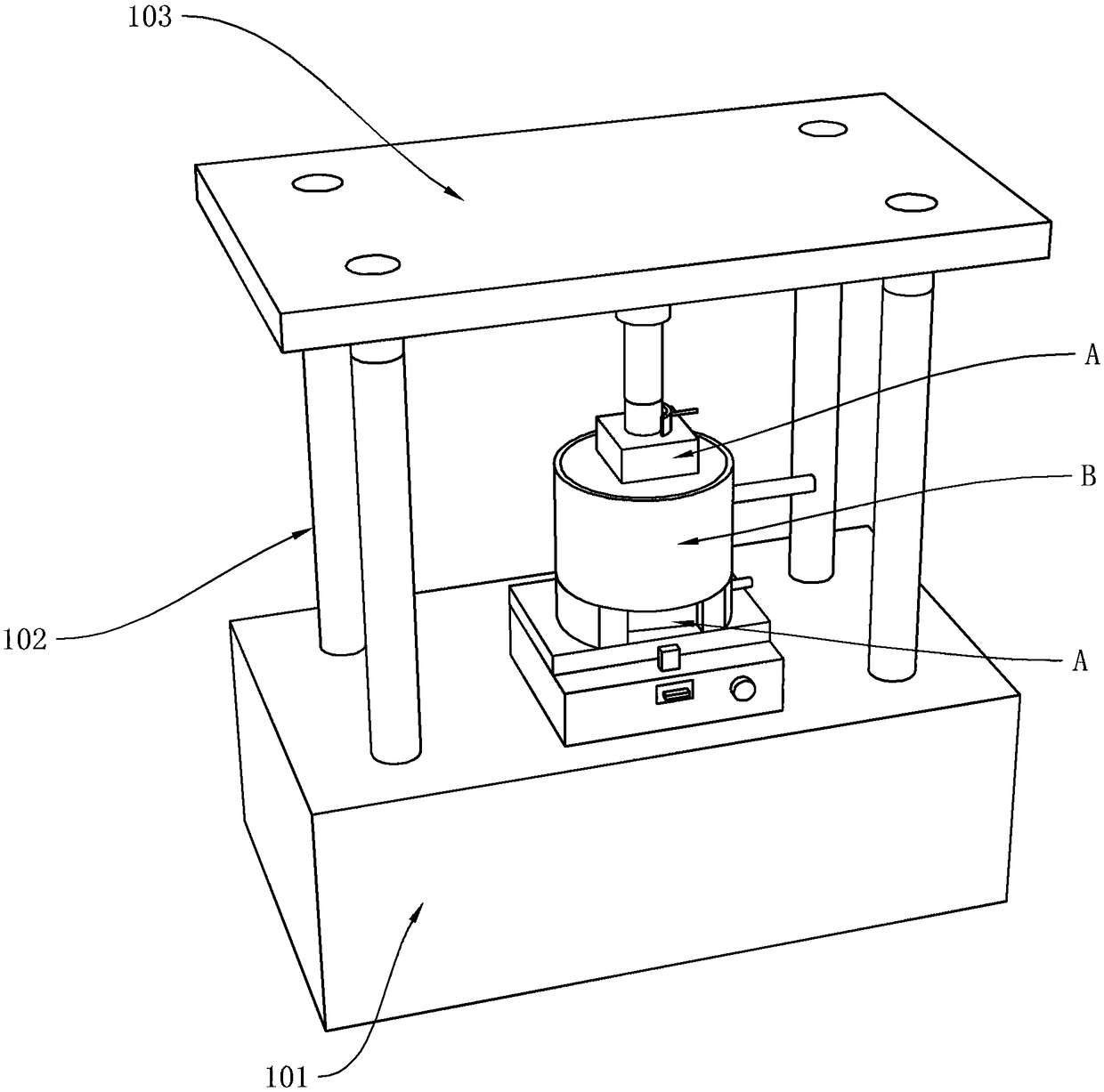

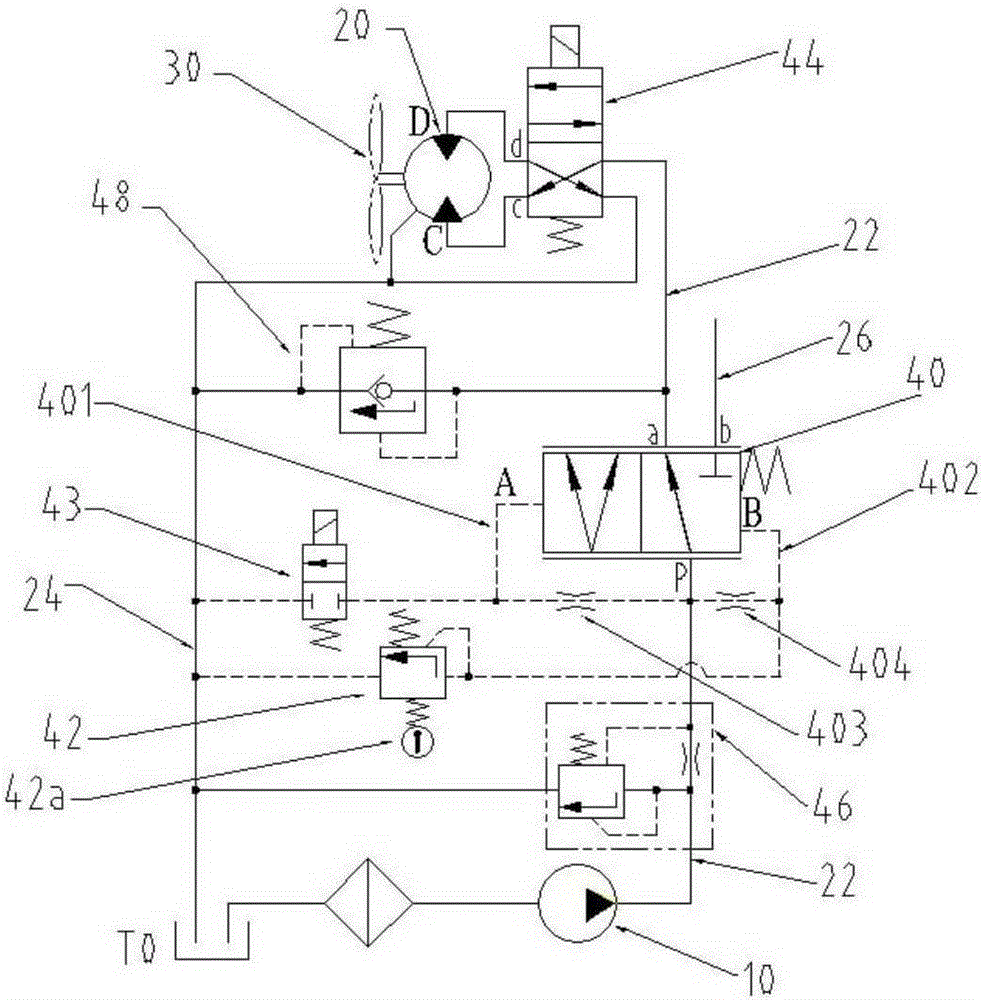

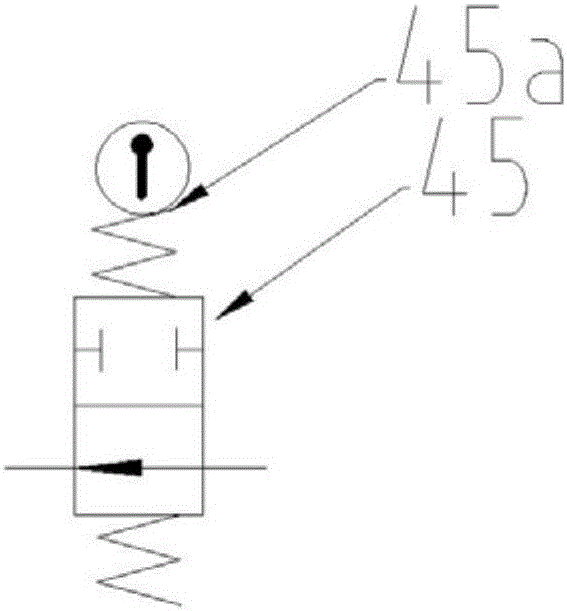

Hydraulic cooling system and engineering machine including same

ActiveCN103511403AAchieve pre-coolingReal-time coolingFluid-pressure actuator componentsTemperature controlFuel tank

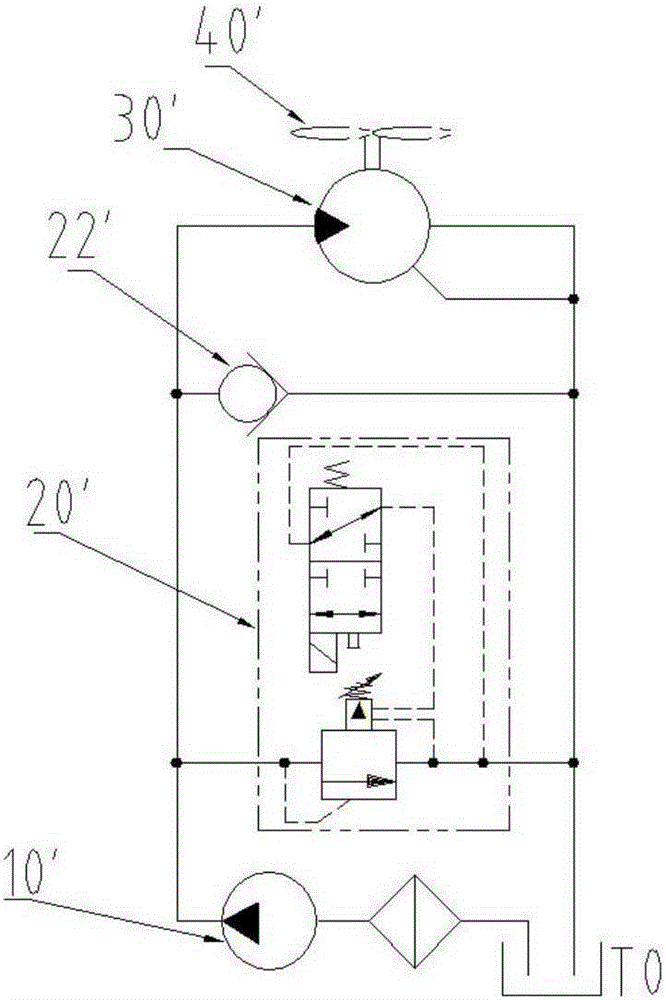

The invention discloses a hydraulic cooling system. The hydraulic cooling system comprises a pump (10), a cooling motor (20), a cooling fan (30), an oil inlet oil way (22) and an oil return oil way (24). The cooling fan (30) is driven by the cooling motor (20) to run, the oil inlet oil way (22) is connected between the cooling motor (20) and the oil outlet of the pump (10), and the oil return oil way (24) is connected between the cooling motor (20) and an oil tank (T0). The hydraulic cooling system is characterized in that a hydraulic control reversing valve (40) with the adjustable aperture of a valve core is arranged on the oil inlet oil way (22); the hydraulic control reversing valve (40) comprises a hydraulic control end A and a hydraulic control end B, an oil inlet P, a working oil port a and a working oil port b. The hydraulic control end A and the hydraulic control end B are located at the two opposite ends of the hydraulic control reversing valve, the oil inlet P is communicated with the oil inlet of the pump (10), the working oil port a is communicated with the cooling motor (20), and the working oil port b is connected with other working oil ways (26). The hydraulic cooling system further comprises a temperature control pressure device, wherein the temperature control pressure device is connected with the hydraulic control end B and enables the pressure of the hydraulic control end B to change along with the temperature of hydraulic oil. The hydraulic cooling system has both the precooling function and the cooling as required function and is good in energy saving and economic returns. Through the hydraulic cooling system, the power of the hydraulic system can be effectively utilized to cool the hydraulic oil.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

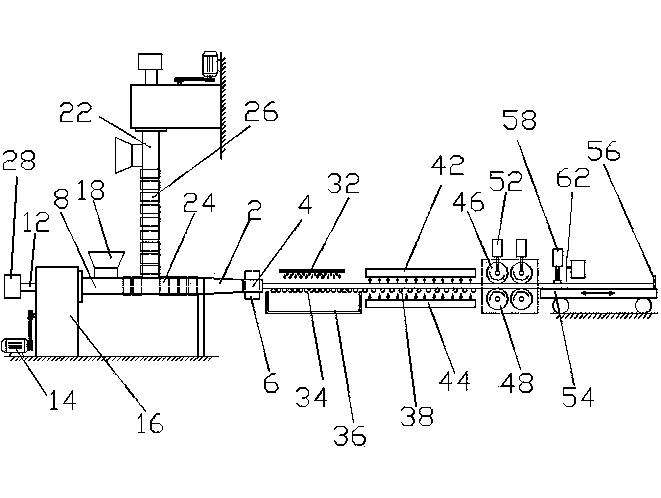

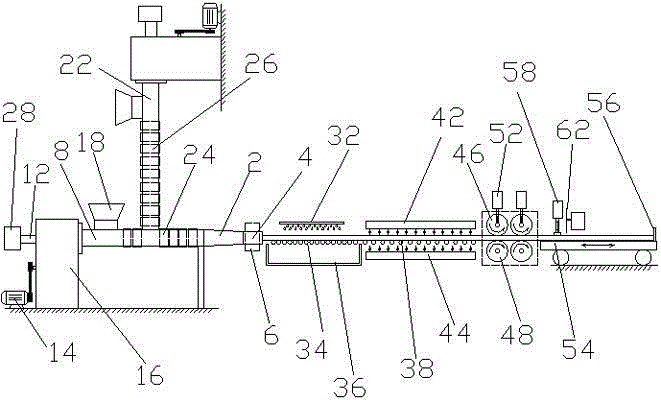

Technology for preparing micropore pipe through semi-molten continuous extrusion of high molecular powder

The invention relates to a technology for preparing a micropore pipe through semi-molten continuous extrusion of high molecular powder. The technology is characterized by comprising the following steps: (1) feeding solid powdered material in a screw extruding device through a hopper; (2) heating a barrel entering the screw extruding device, and performing initial compaction by a threaded rod at the same time so as to enable materials to be in a semi-molten state; (3) feeding the material in a handpiece for further compaction; (4) feeding the materials in a mould cavity of a neck mould of the screw extruding device to be tubular, determining inner and outer diameters under the effect of a vacuum cooling forming sleeve, and initially cooling; (5) cutting through a cutting device to obtain the micropore pipe. According to the technology, the high molecular powder is continuously extruded and formed when being in semi-molten state and the produced product does not need to be subjected to aftertreatment simultaneously when production of micropore pipes is realized, so that the production efficiency is greatly improved. According to the technology, a solvent is not used, and thus the micropore pipe is beneficial to environmental protection and health of operators.

Owner:SUZHOU KAHO POLYMER TECH CO LTD +1

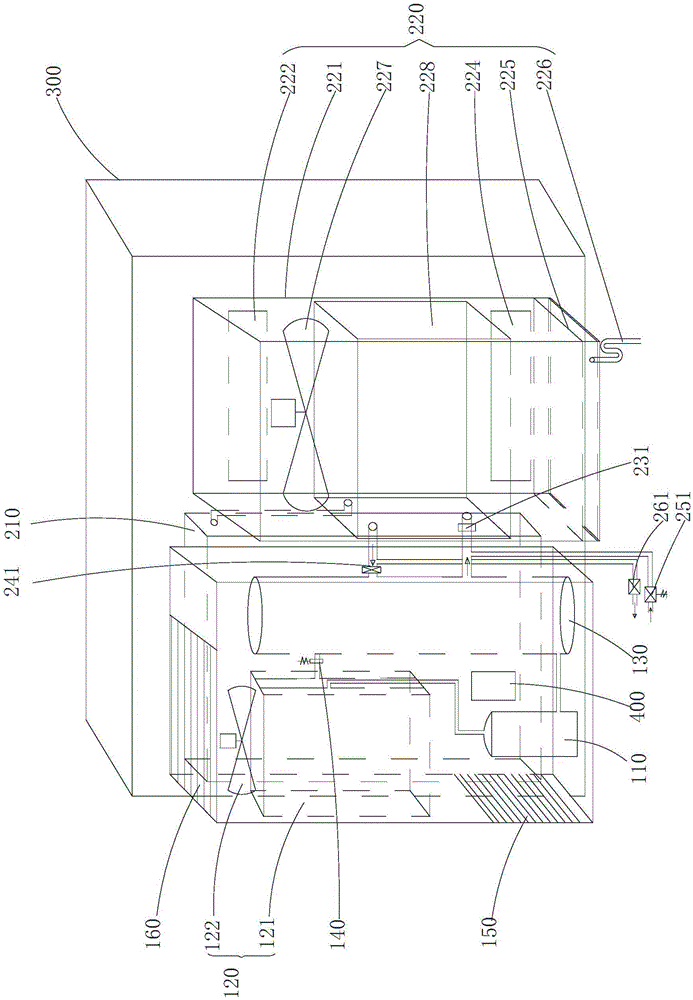

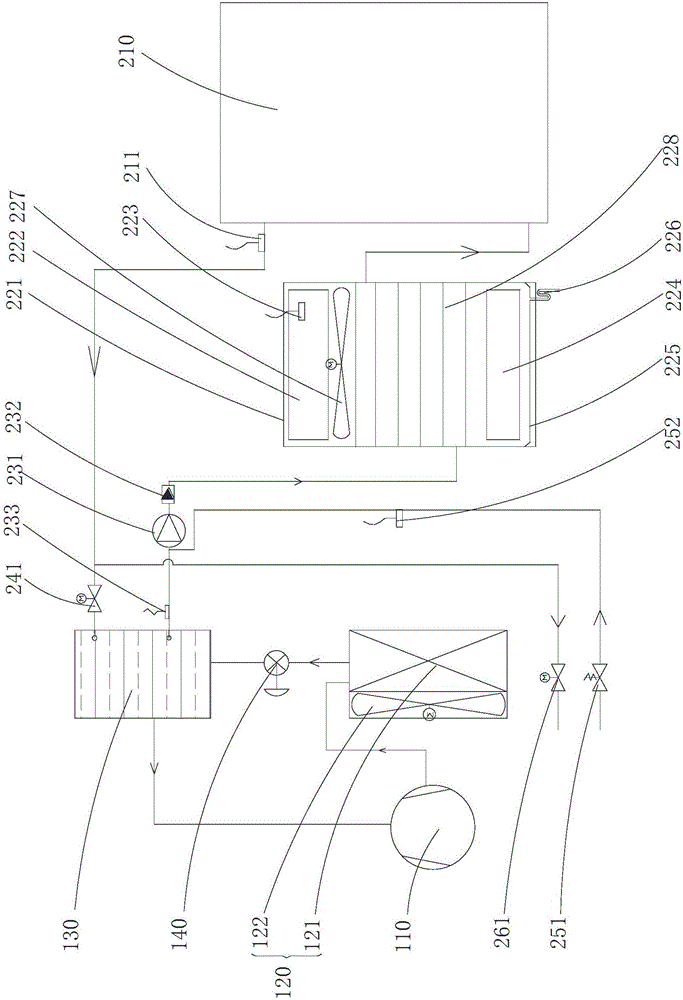

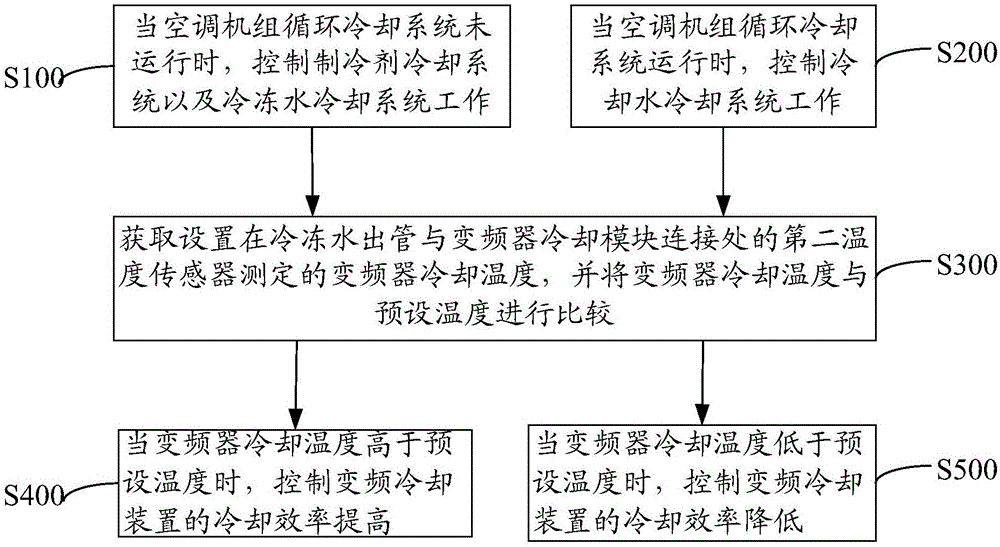

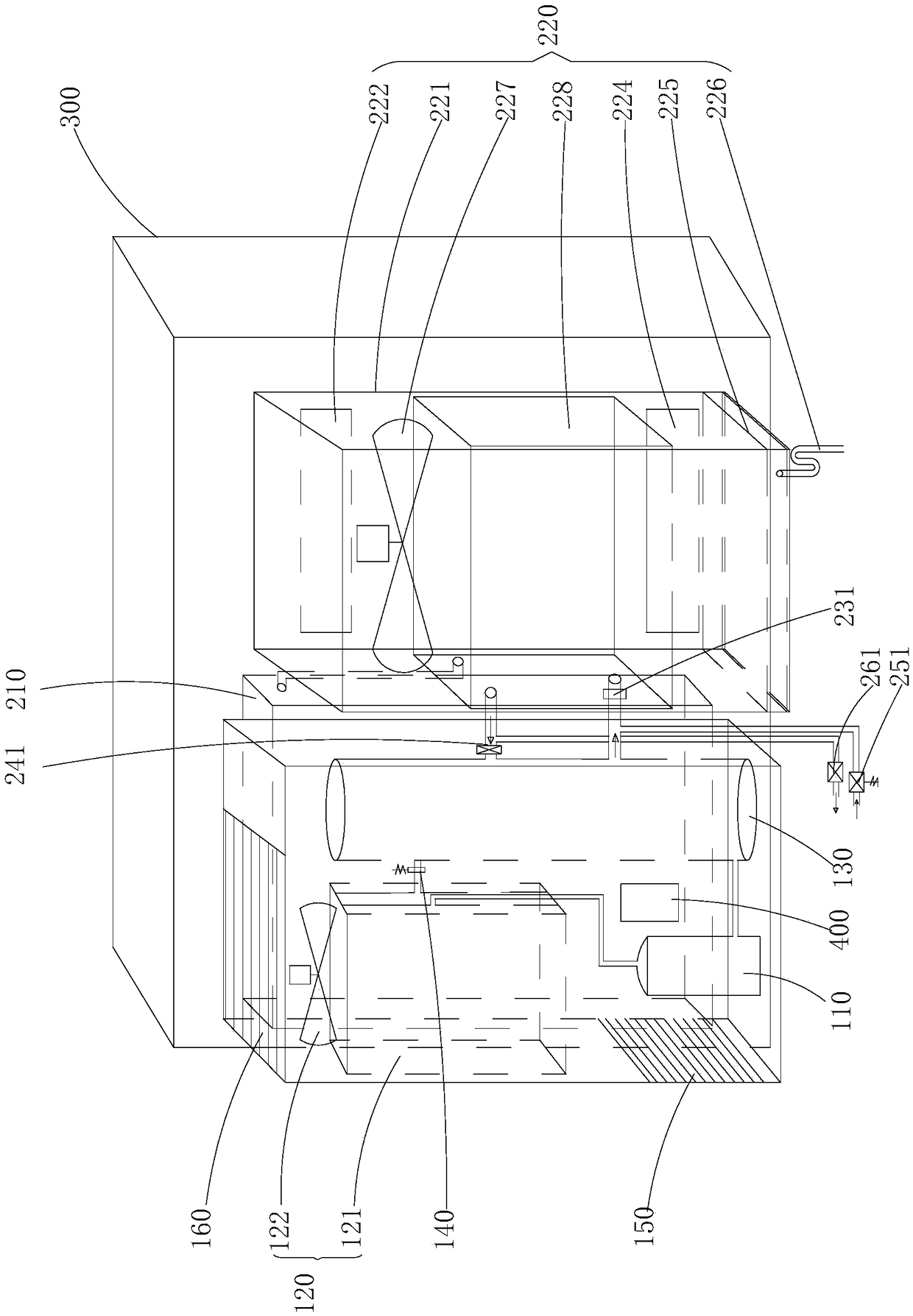

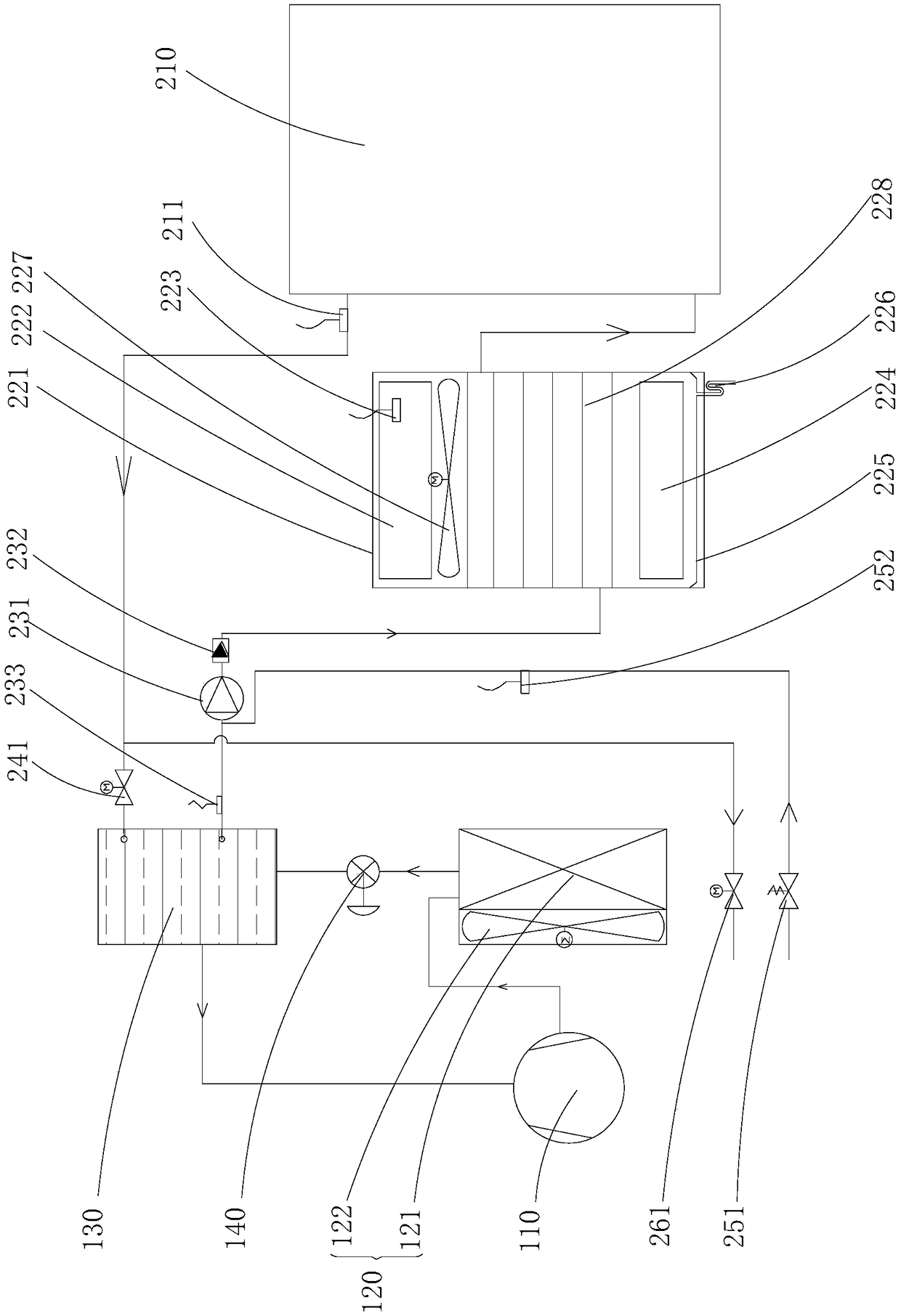

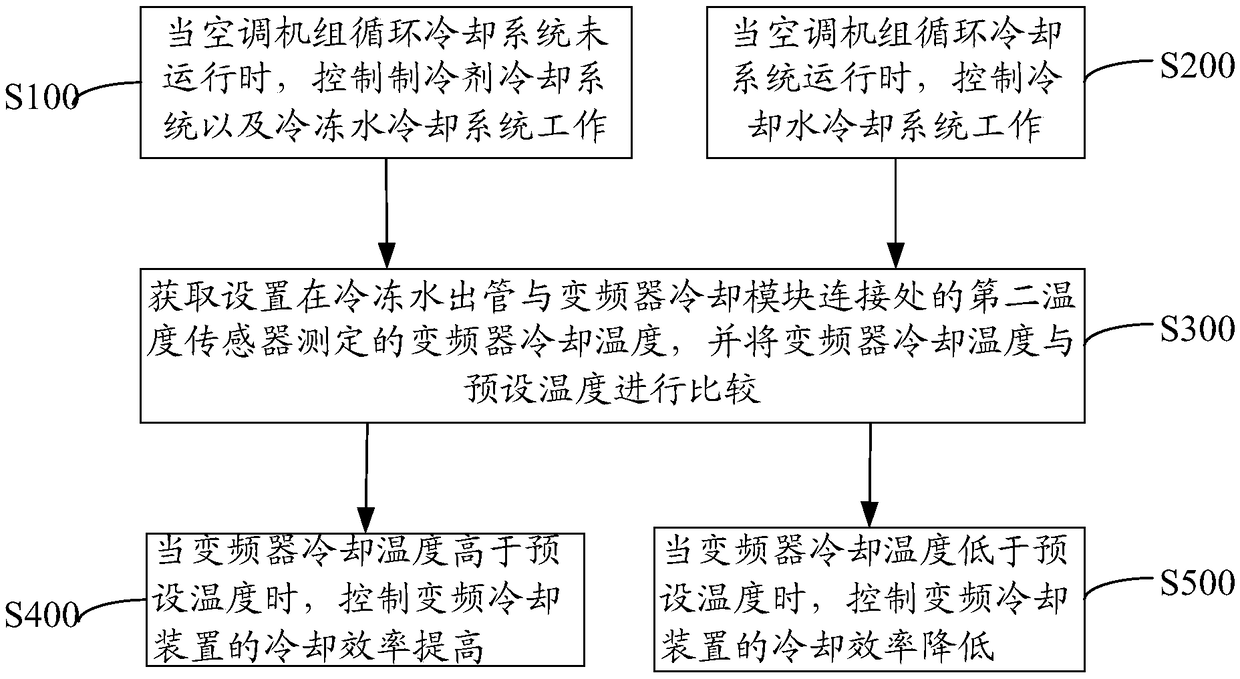

Frequency converter cooling device, air conditioning unit and control method

ActiveCN106546045AReal-time coolingImprove securitySpace heating and ventilation detailsRefrigeration safety arrangementFrequency changerEngineering

The invention provides a frequency converter cooling device. The frequency converter cooling device comprises a refrigerant cooling system and a freeze water cooling system. A compressor, a cooling assembly and a heat exchanger assembly of the refrigerant cooling system are successively connected through a pipeline to form a refrigerant loop; a freeze water inlet pipe, a frequency converter cooling module, a freeze water outlet pipe and the heat exchanger assembly of the freeze water cooling system are successively connected to form a freeze water loop. According to the frequency converter cooling device, heat exchange for cooling is performed between water in the freeze water cooling system and a refrigerant in the refrigerant cooling system in the heat exchanger assembly, and the frequency converter is further cooled by virtue of water in the freeze water cooling system, and the frequency converter can be cooled in real time even if a circular cooling system of the air conditioning unit where the frequency converter is does not operate, so that the operating safety of the frequency converter is improved.

Owner:GREE ELECTRIC APPLIANCES INC

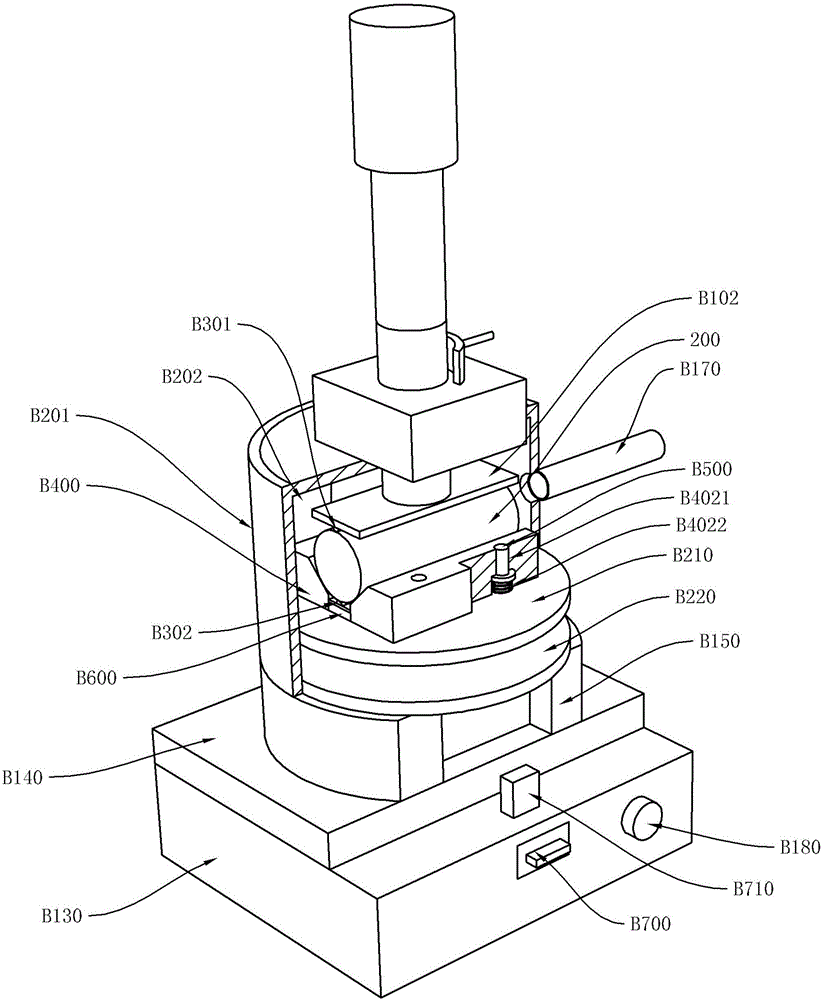

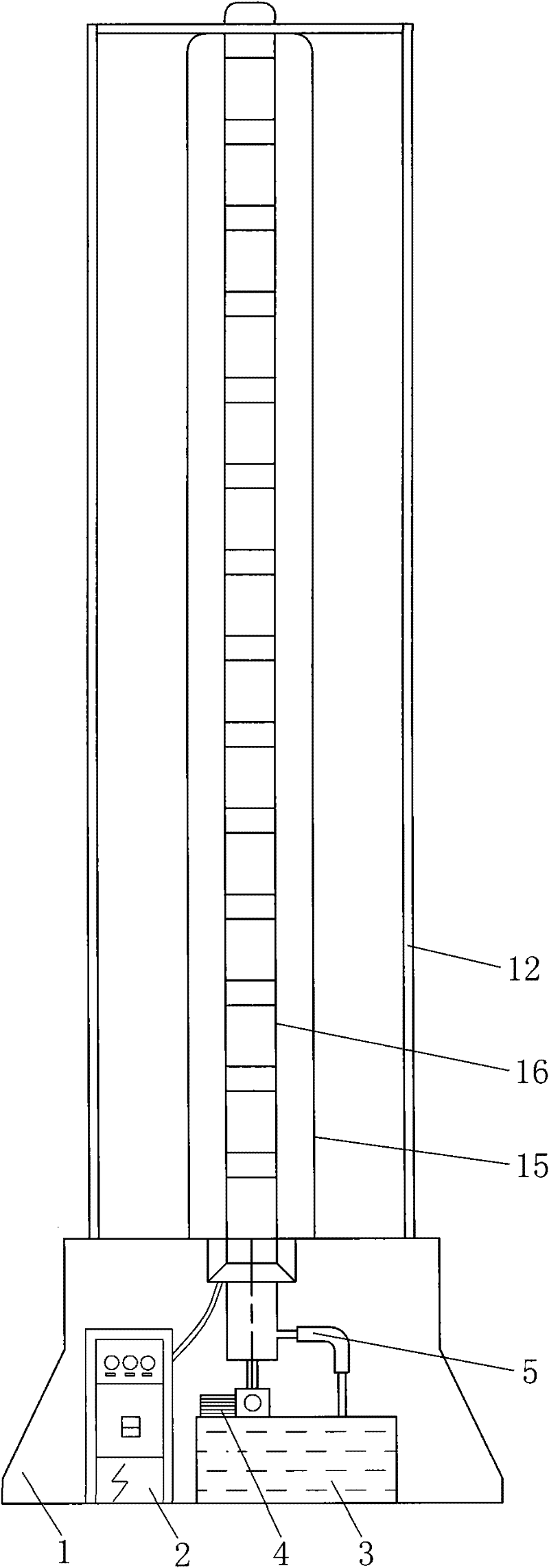

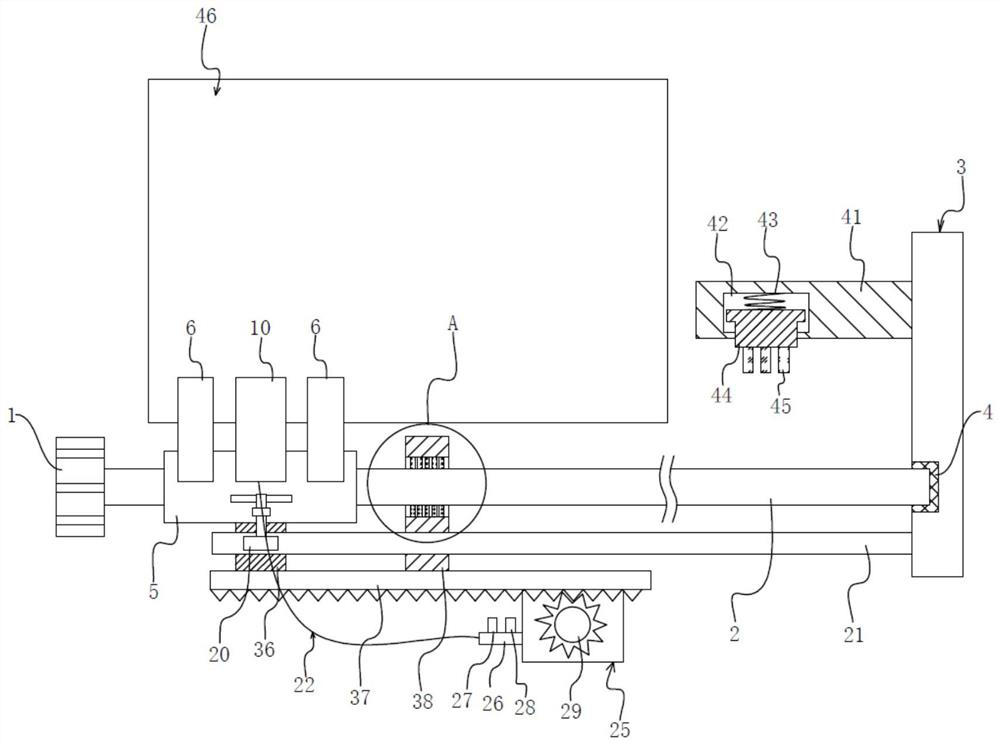

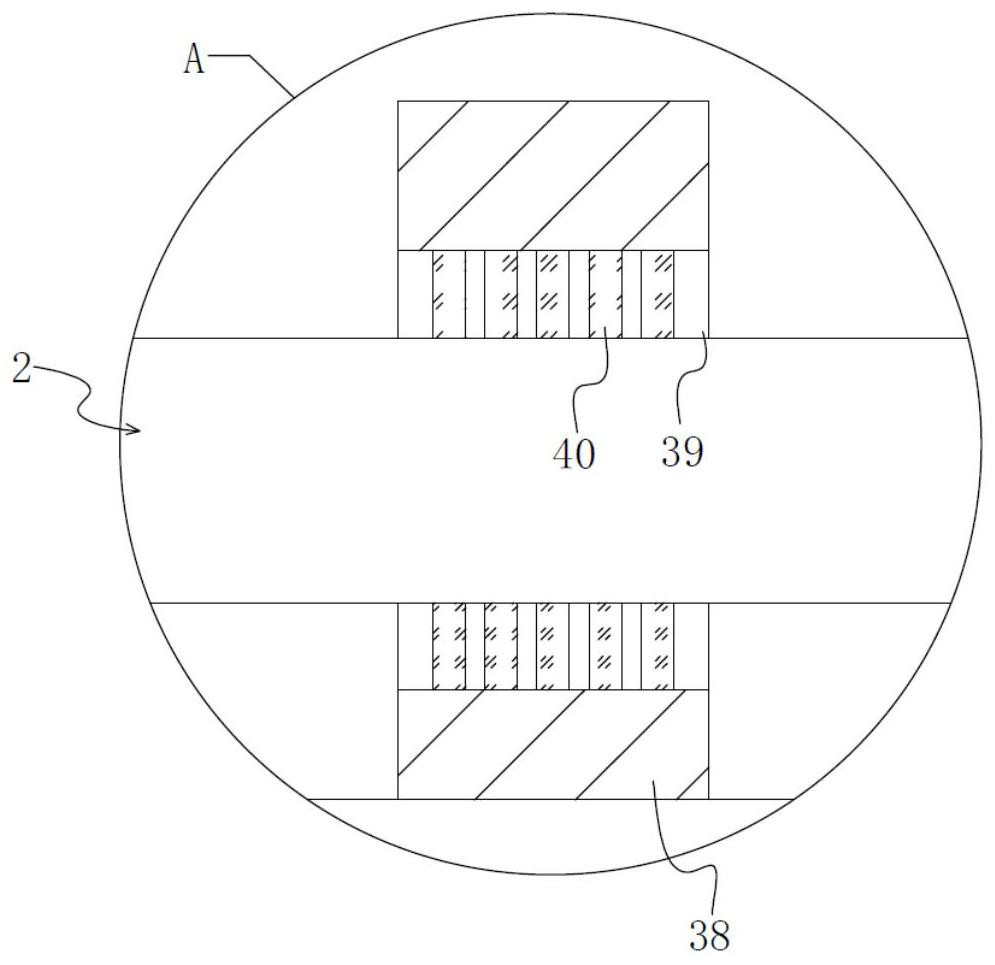

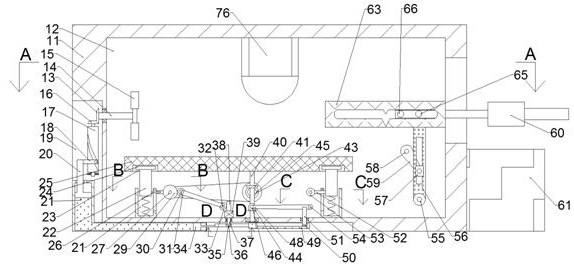

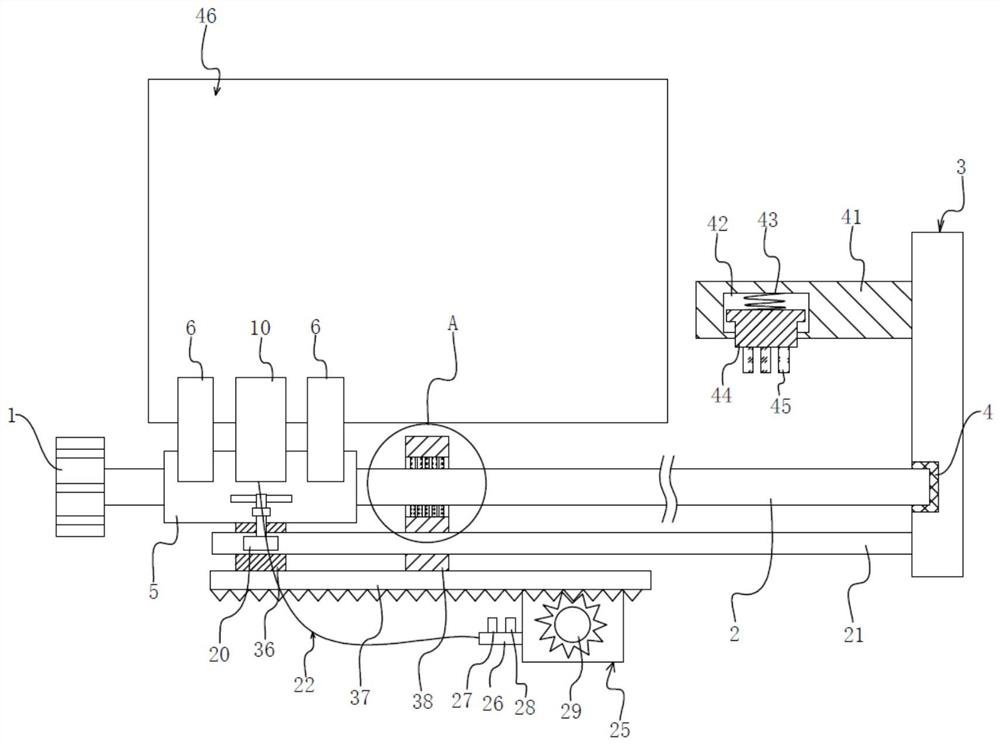

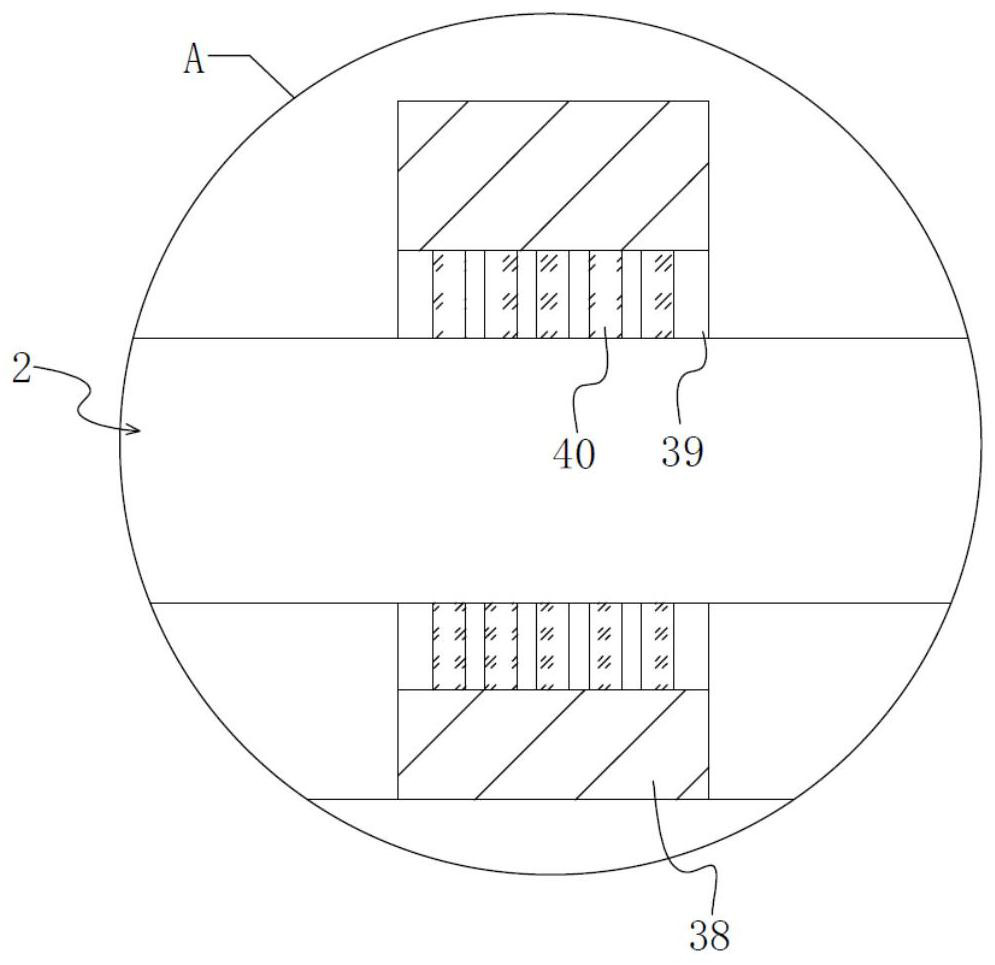

Temperature control system, temperature control method thereof and tensile strength testing device

ActiveCN106769528AAccurate force situationAccurate researchMaterial strength using tensile/compressive forcesTemperature controlFuel tank

The invention discloses a temperature control system. The temperature control system comprises an oil tank and is characterized in that the oil tank is communicated with the first oil inlet of a heating reversing valve through a pipeline, the oil outlet of the heating reversing valve is communicated with the oil inlet of a first oil inlet pump, and the oil outlet of the first oil inlet pump is communicated with the oil inlet of a first temperature control module; the oil outlet of the first temperature control module is connected with the oil inlet of a first temperature control valve module, the first oil outlet of the first temperature control valve module is connected with the water inlet of a second water inlet pump, and the water outlet of a second temperature control module is communicated with the water inlet of a second temperature control valve module; the first oil outlet of the second temperature control valve module is communicated with the second oil inlet pump, and the second oil outlet of the second temperature control valve module is communicated with the second oil inlet of the heating reversing valve; the oil outlet of the second oil inlet pump is communicated with an oil inlet pipe; an oil outlet pipe is communicated with the first oil inlet of a refrigerating reversing valve, and the oil outlet of the refrigerating reversing valve is communicated with a cooling component. The invention further provides a temperature control method based on the temperature control system and a tensile strength testing device.

Owner:ANHUI UNIV OF SCI & TECH

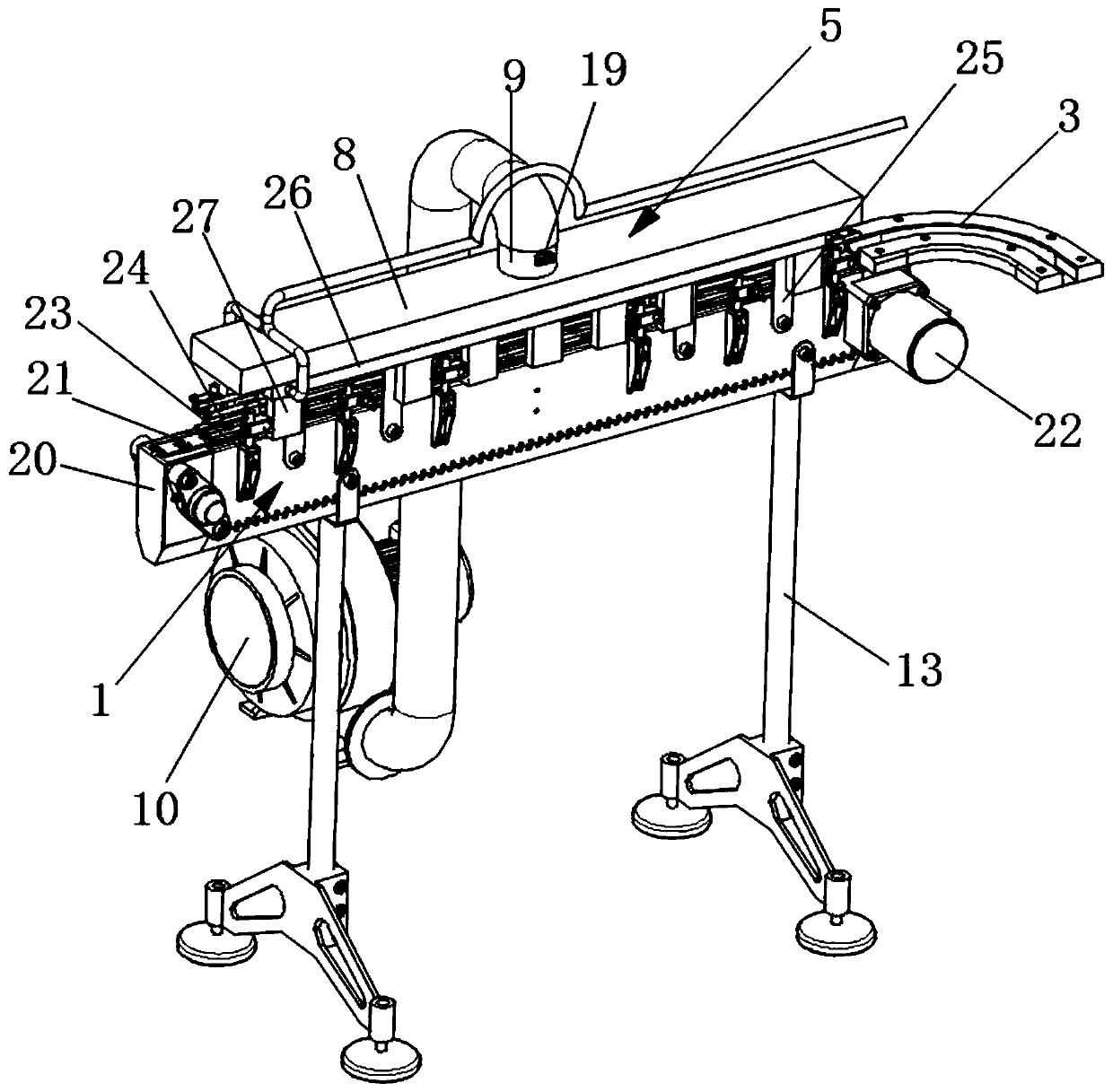

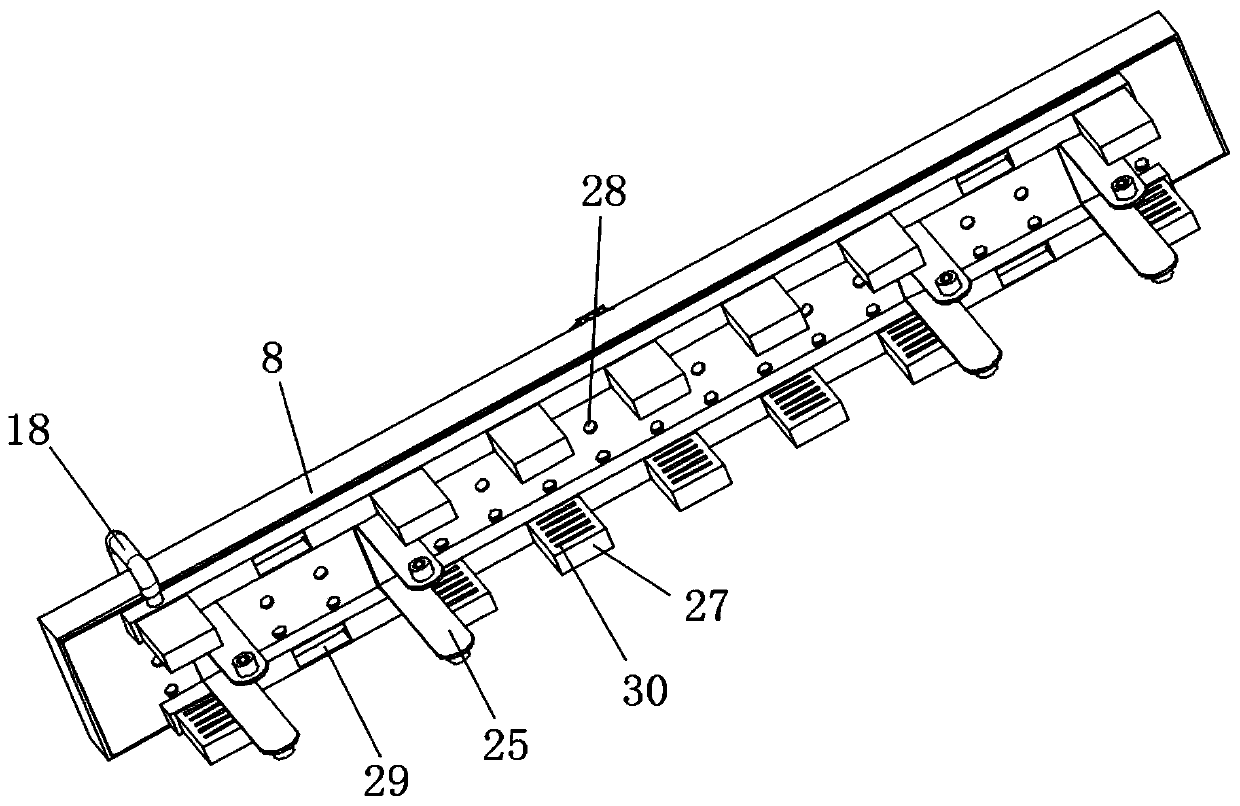

Carton O-shaped corrugated paper production device

InactiveCN107639888ACool down in real timeEasy to pasteMechanical working/deformationSimultaneous control of multiple variablesCartonPaper production

The invention discloses a carton O-shaped corrugated paper production device, which comprises a first cabinet, wherein a first corrugated roller is arranged inside the first cabinet, two sides of thefirst corrugated roller are movably connected with slots of a connecting piece through a fixing piece, one end of the connecting piece is connected with the top of the first cabinet, a second corrugated roller is arranged inside a control console at the bottom of the first corrugated roller, one end of the second corrugated roller is placed inside a third cabinet, one side of the third cabinet isfixedly connected with a second driving motor, while the other side of the third cabinet is provided with a control panel, and a controller is arranged on the upper end of the control panel. The carton O-shaped corrugated paper production device has the advantages that the cost of materials is reduced under the conditions of using the same paper and at the same pressure, thereby helping promote the benefits of carton manufacturing enterprises, and meanwhile corrugated papers can be properly heated in the corrugating process of paper used for manufacturing cartons, thereby facilitating the sticking of the corrugated papers.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

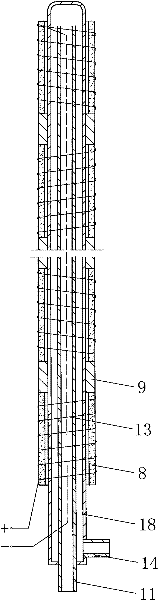

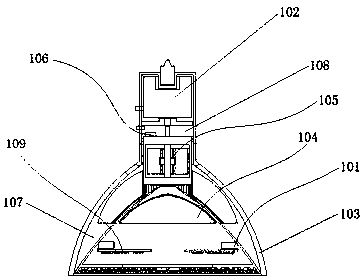

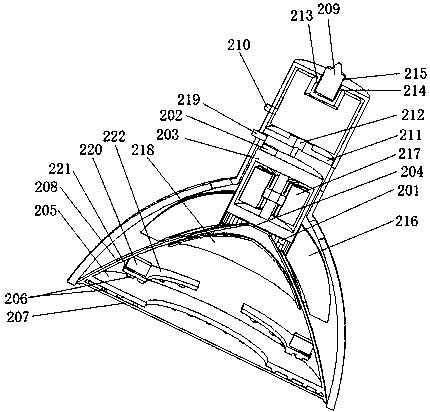

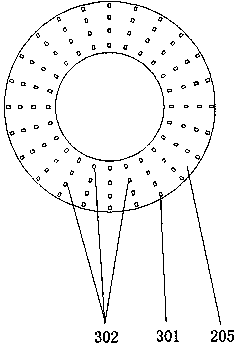

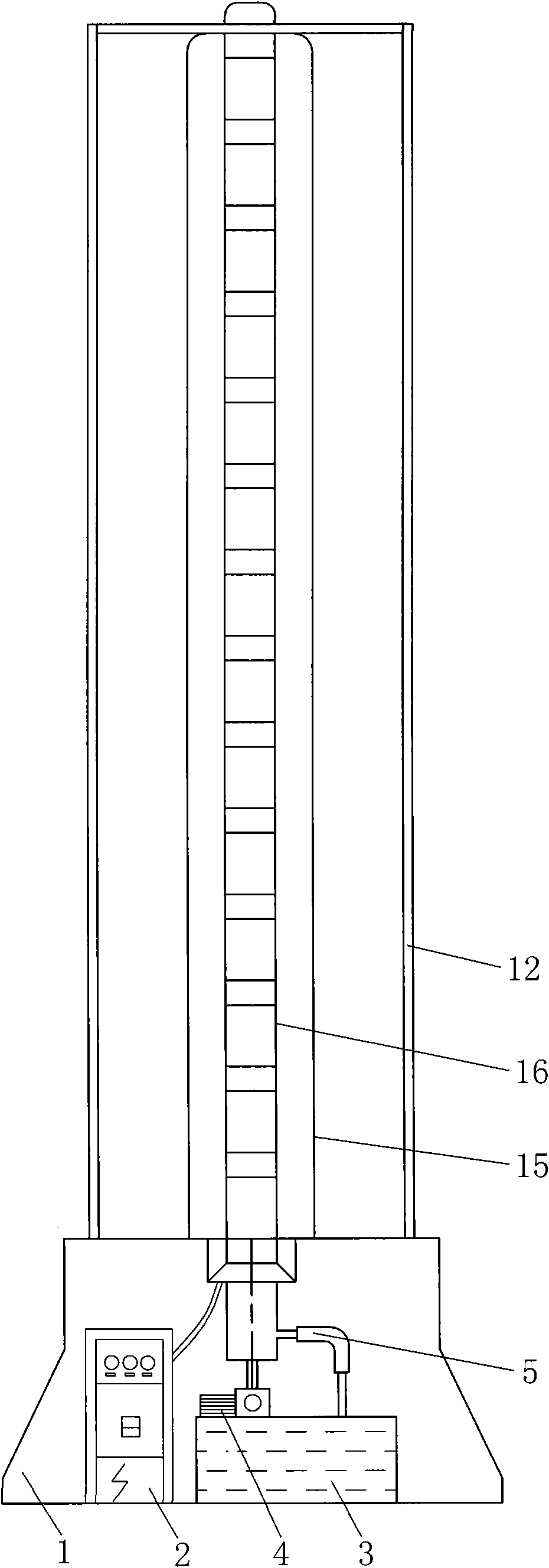

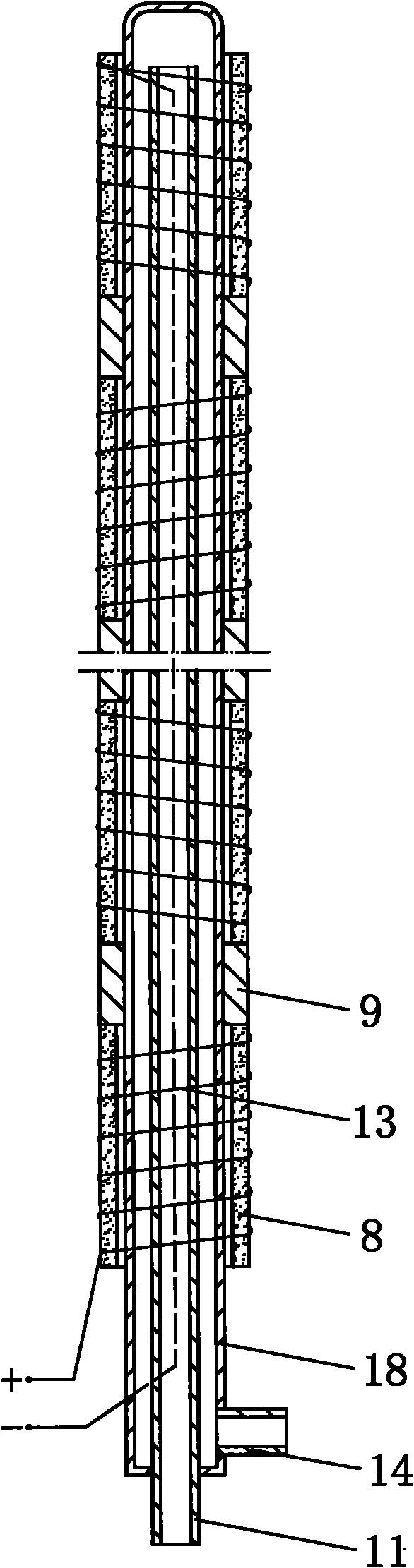

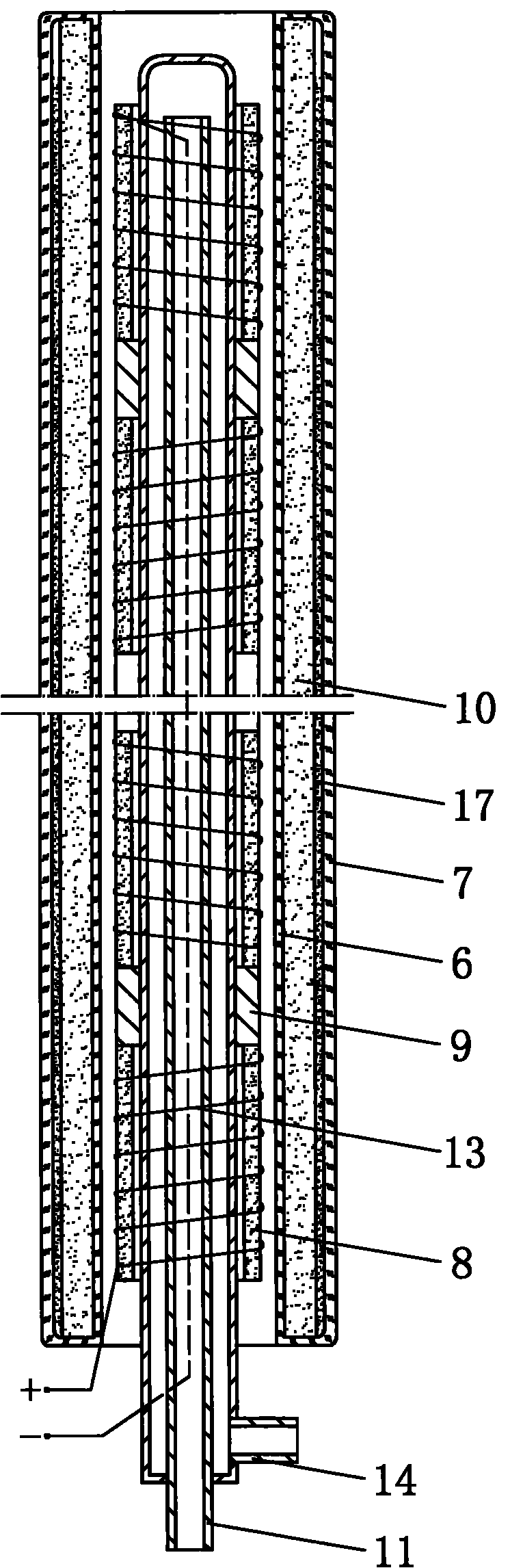

Electrodeless illuminating lamp

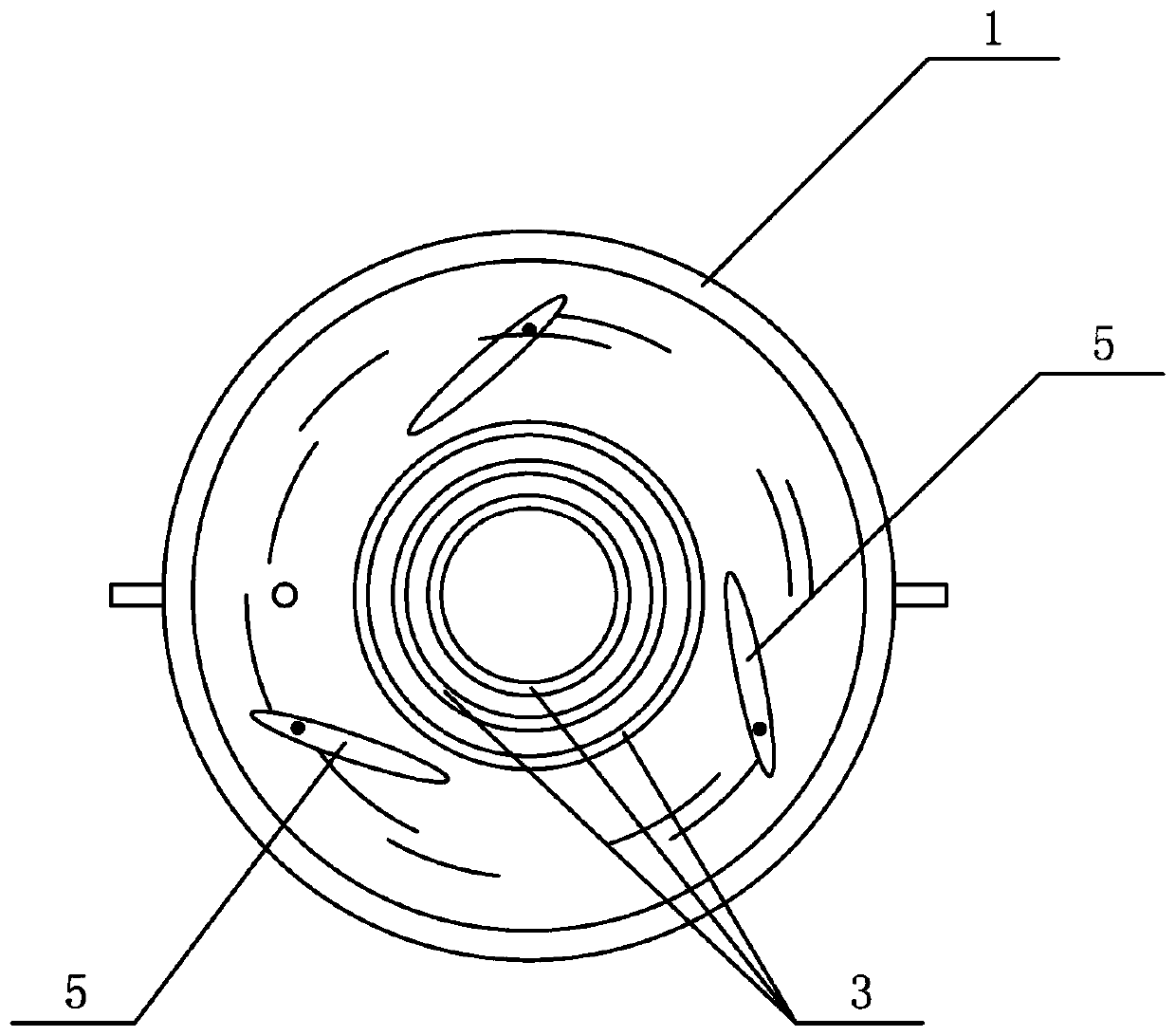

ActiveCN102243982ASimple structureImprove lighting effectsGas discharge lamp detailsMagnetic polesMagnetic shield

An electrodeless illuminating lamp, which belongs to the illuminating lamp technology field, is disclosed. The electrodeless illuminating lamp comprises: an electric control cabinet, a pedestal, a support, a luminous tube, a coupler and a cooling system. The support is placed on the pedestal. The tube is installed on the pedestal in the support. The coupler is arranged in the luminous tube. The cooling system is used to cool the coupler. The coupler is respectively connected with the electric control cabinet and the cooling system. The coupler comprises: an inner water pipe, an external water pipe, a coil, multi-group magnets and a magnetic shield. The magnets are sleeved on the external water pipe, wherein the magnetic shield is arranged between the magnets. The coil is wound around the magnets. Coil winding directions of two adjacent magnets are opposite and magnetic poles of opposite ends of the adjacent magnets are same. Two ends of the coil form an anode and a cathode which are respectively connected with the electric control cabinet. The inner water pipe is arranged in the external water pipe, extends out of the external water pipe and forms seal connection with the end of the external water pipe. The inner water pipe is connected with a water pump of the cooling system and a water outlet nozzle is arranged on the external water pipe. In the invention, arbitrary multi-group magnets are adopted to form different models of the electrodeless illuminating lamps. A large or an ultra-large illuminating lamp can be made.

Owner:杨卡

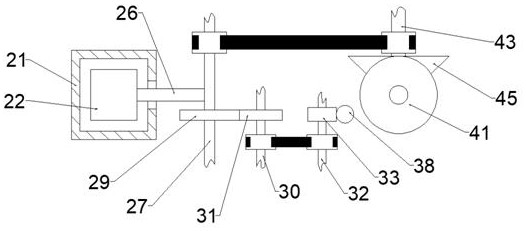

Glass cover plate circumferential polishing mechanism and circumferential polishing equipment

ActiveCN112621537AImprove polishing effectEasy to usePolishing machinesRotary stirring mixersPolishingStructural engineering

The invention provides a glass cover plate circumferential polishing mechanism and circumferential polishing equipment. The glass cover plate circumferential polishing mechanism comprises a rotating motor, wherein a screw rod is fixedly arranged at the output end of the rotating motor, and a nut block is movably arranged on the screw rod; a dust removing block, wherein a glass cover plate cleaning brush is fixedly arranged on a circular bottom plate; a polishing block, wherein a polishing wheel is fixedly arranged on a rotating shaft, and a plurality of spraying covers are arranged on a water tank in a communicating mode; a polishing liquid box, wherein a stirring shaft is fixedly arranged in the center of a second transmission wheel, and a second rack plate can drive the second transmission wheel to rotate; and a cleaning rod, wherein a lead screw cleaning brush can be in contact with a lead screw and is used for cleaning the lead screw. According to the glass cover plate circumferential polishing mechanism and the circumferential polishing equipment, polishing liquid can be sprayed, generated glass chippings and disintegrating slag can be removed in time, the polishing liquid can be stirred to avoid precipitation, the lead screw is cleaned to avoid blocking movement of a nut block, a polishing motor is cooled in real time, functions are concentrated, and the glass cover plate circumferential polishing mechanism and the circumferential polishing equipment are quite worthy of popularization.

Owner:凯盛科技股份有限公司

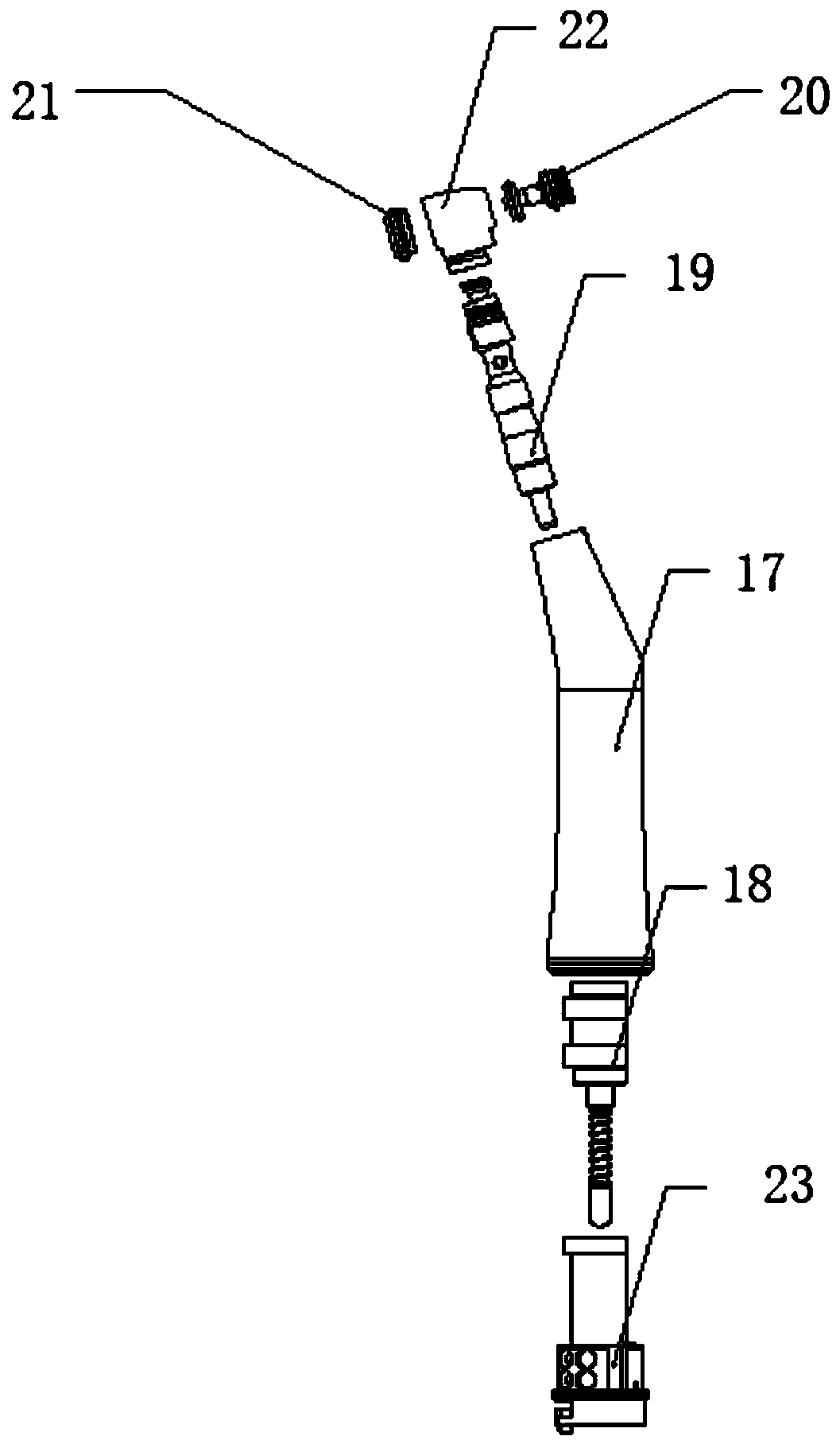

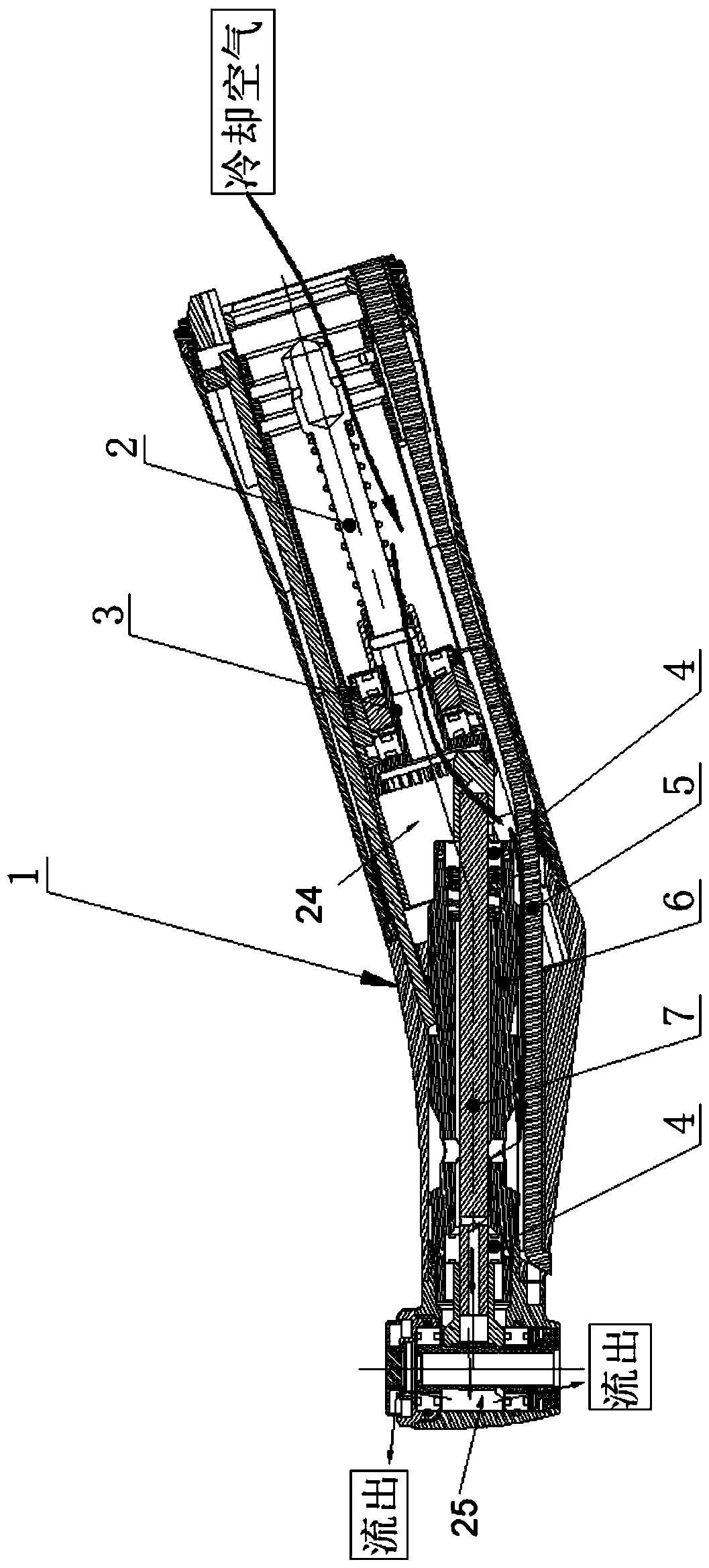

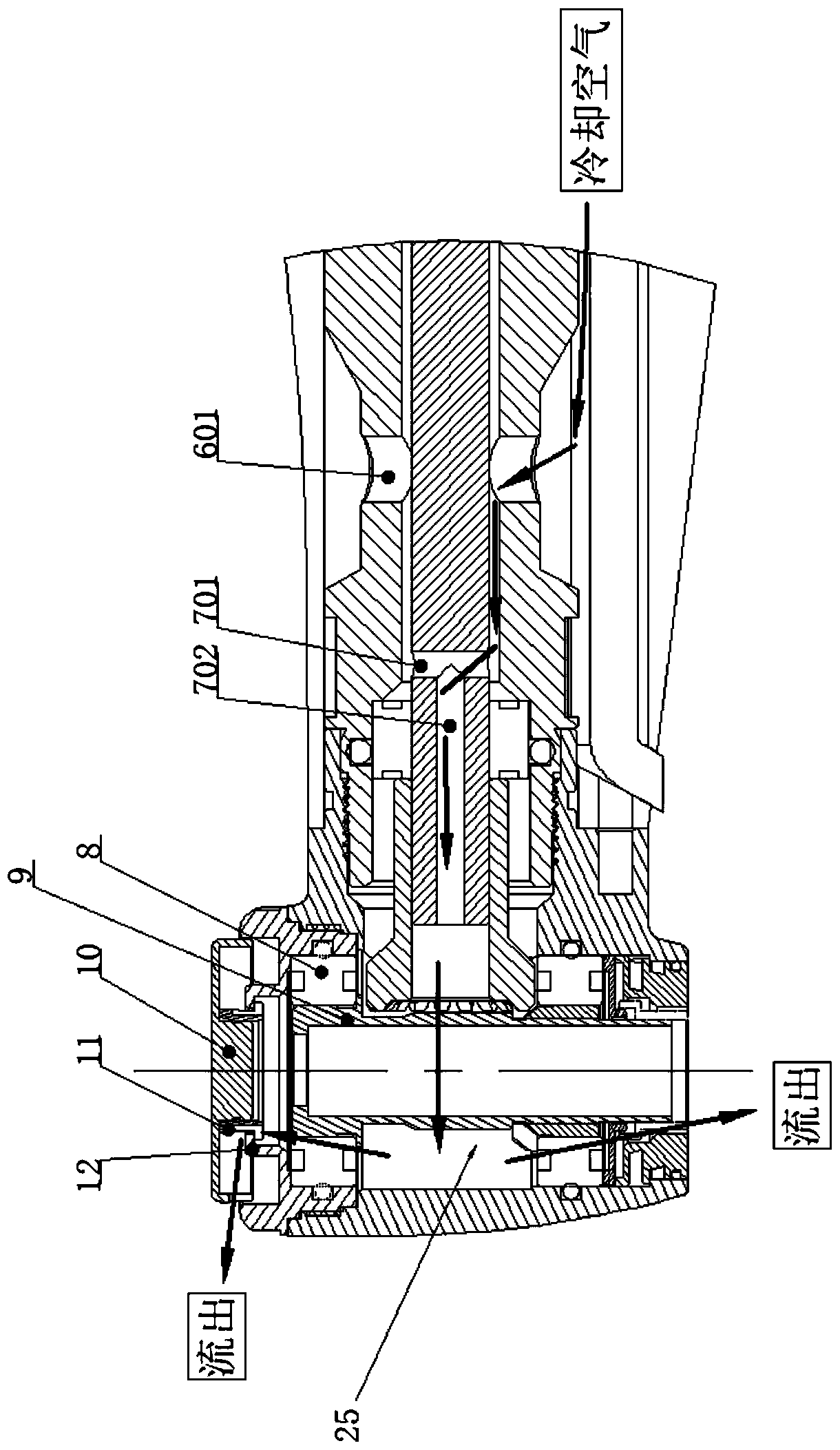

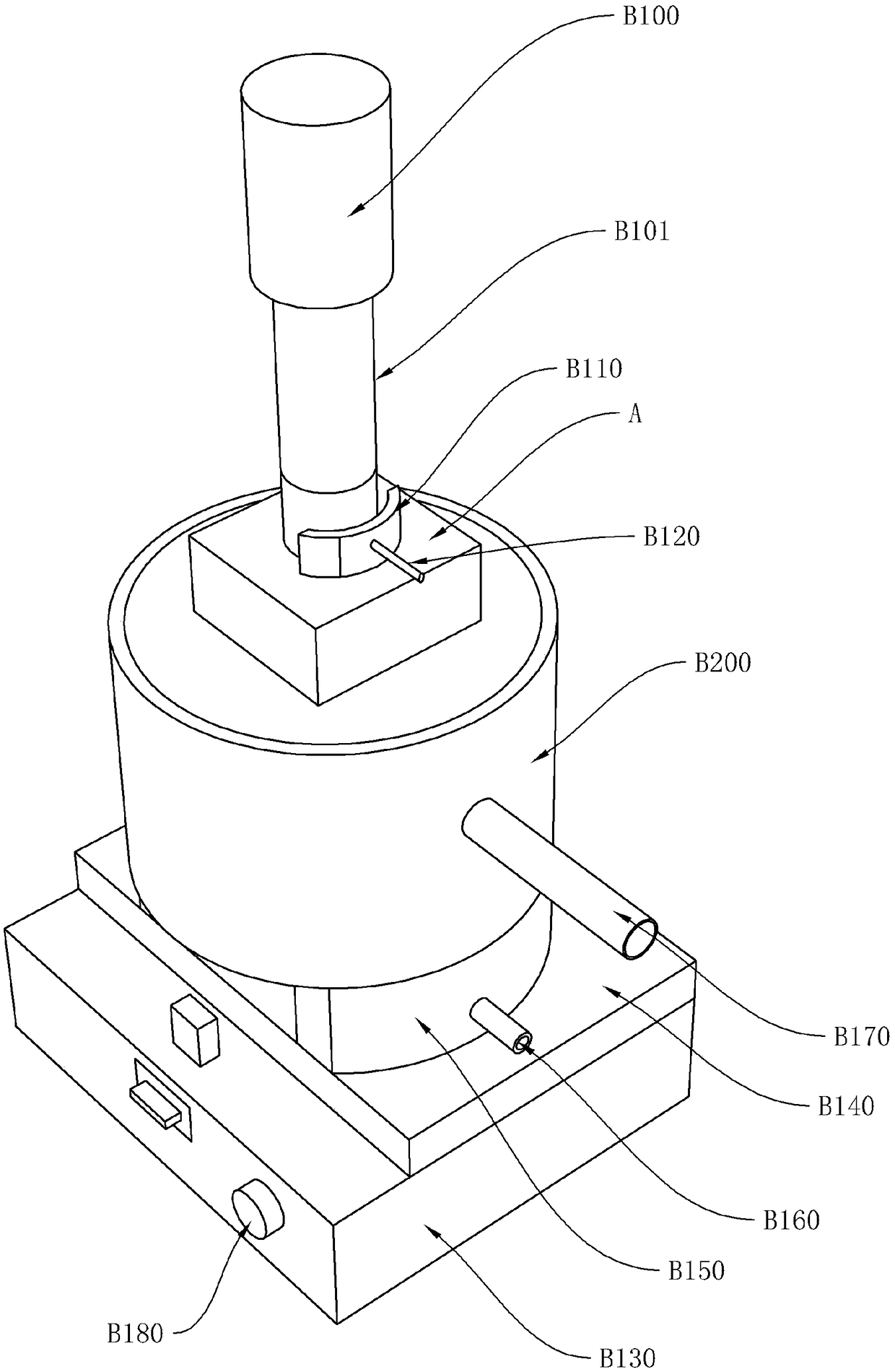

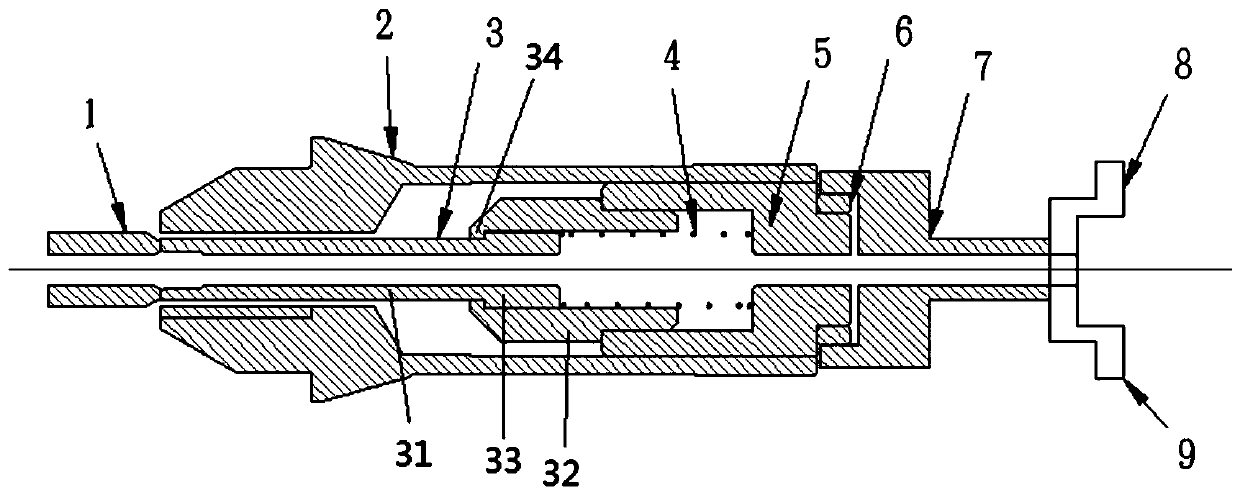

Dental handpiece with airflow cooling system

PendingCN108498189AExtended service lifeCool down in real timeBoring toolsDrive shaftWorking temperature

The invention relates to the technical field of dental handpieces, in particular to a dental handpiece with an airflow cooling system. The dental handpiece comprises a dental handpiece body, the dental handpiece comprises a back cover assembly, a handpiece, a dental handpiece core assembly, a transmission shaft assembly, a handle assembly, a connector assembly and a bending machine main body assembly; the handle assembly comprises a handle shell body, the handpiece is installed on the front end of the handle shell body, the dental handpiece core assembly is installed in the handpiece, and theback cover assembly is installed at the bottom of the handpiece; the bending machine main body assembly is installed on the back end of the handle shell body; the transmission shaft assembly is arranged at the front portion inside the handle shell body, the connector assembly is arranged at the back portion inside the handle shell body, the connector assembly and the bending machine main body assembly are both installed inside the handle assembly, and the front end of the connector assembly is connected with the transmission shaft assembly; the dental handpiece has the advantages that the useis convenient, the operation is convenient, and the dental handpiece cools the temperature in real time, protects components of gear, bearing and the like to be used at the normal working temperature,avoids easy damage of the components, ensures that oral cavities of patients cannot be scalded, and eliminates safety hazard.

Owner:广东精美医疗科技有限公司

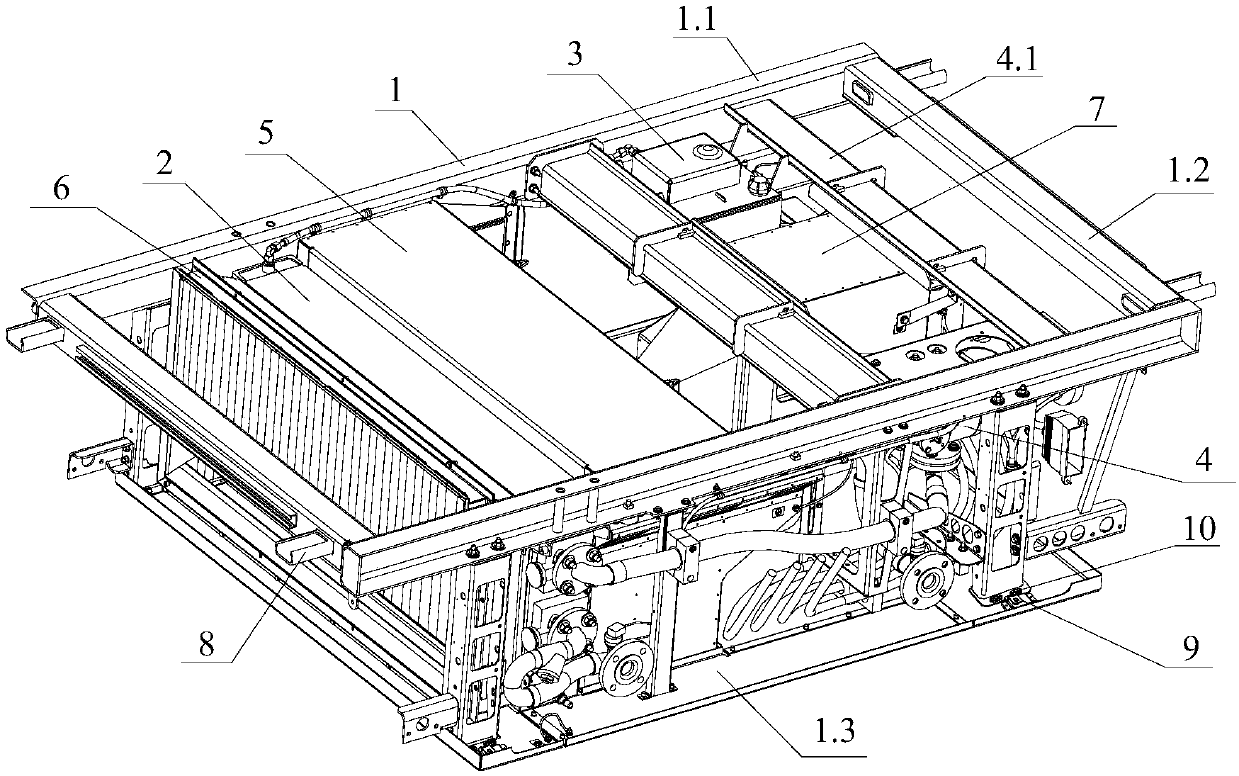

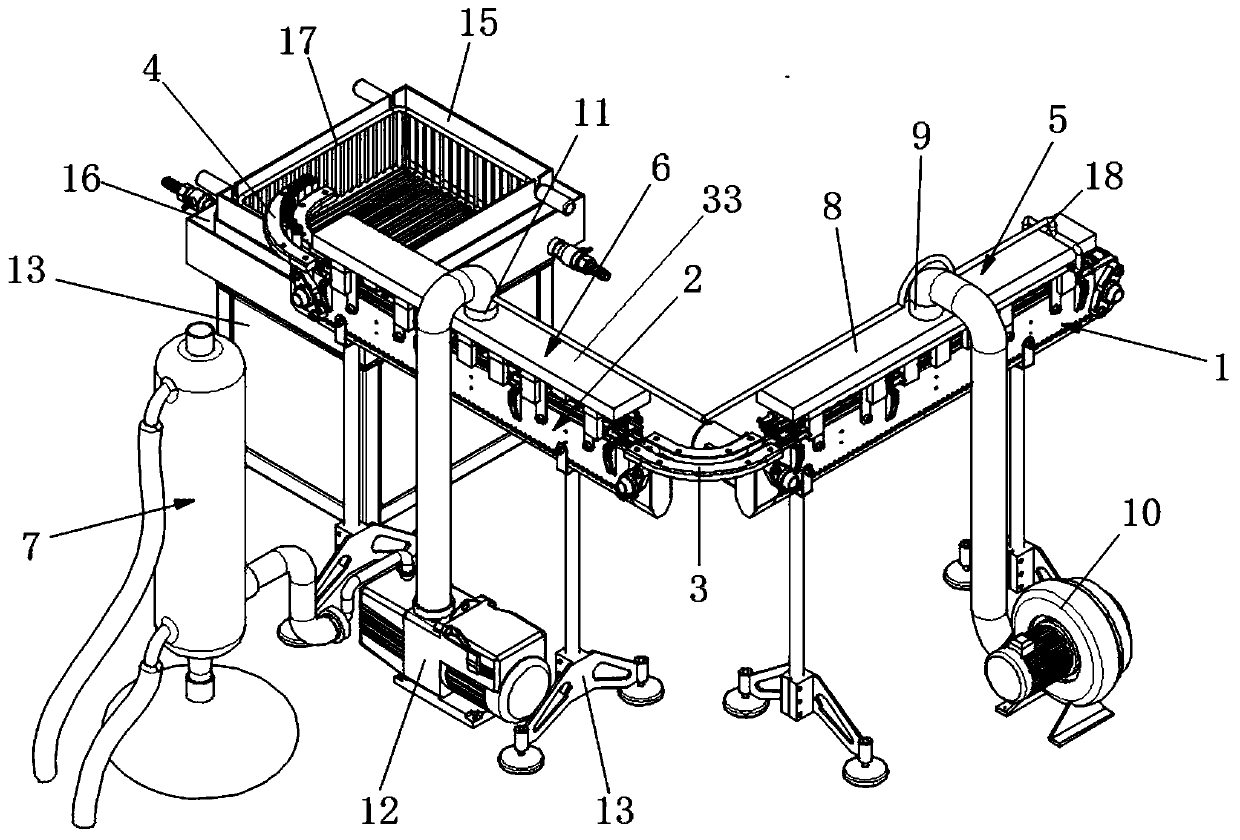

High-speed train cooling device

PendingCN107592780ACompact structureEasy to installCooling/ventilation/heating modificationsRailway transportExpansion tankAir filter

The invention discloses a high-speed train cooling device. The high-speed train cooling device comprises an installation framework, a water-cooling assembly and an air-cooling assembly, wherein the water-cooling assembly and the air-cooling assembly are arranged on the installation framework, the water-cooling assembly comprises a heat exchanger, an expansion water tank and a shielding water pumpwhich are sequentially connected via pipeline, a water outlet of the shielding water pump is used for communicating with a water inlet of a traction converter, a water inlet of the heat exchanger is used for communicating with a water outlet of the traction converter, the water-cooling assembly comprises a centrifugal cooling fan and a centrifugal air filter, an air inlet of the centrifugal cooling fan is arranged corresponding to the heat exchanger and is used for introducing outside air and taking away heat in the heat exchanger, and the centrifugal air filter is arranged at a windward sideof the centrifugal cooling fan. By the high-speed train cooling device, synchronous cooling of the traction converter and a reactor can be achieved, and the high-speed train cooling device is simple in structure, light in weight, good in sealing performance and low in manufacturing cost and is convenient to maintain.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

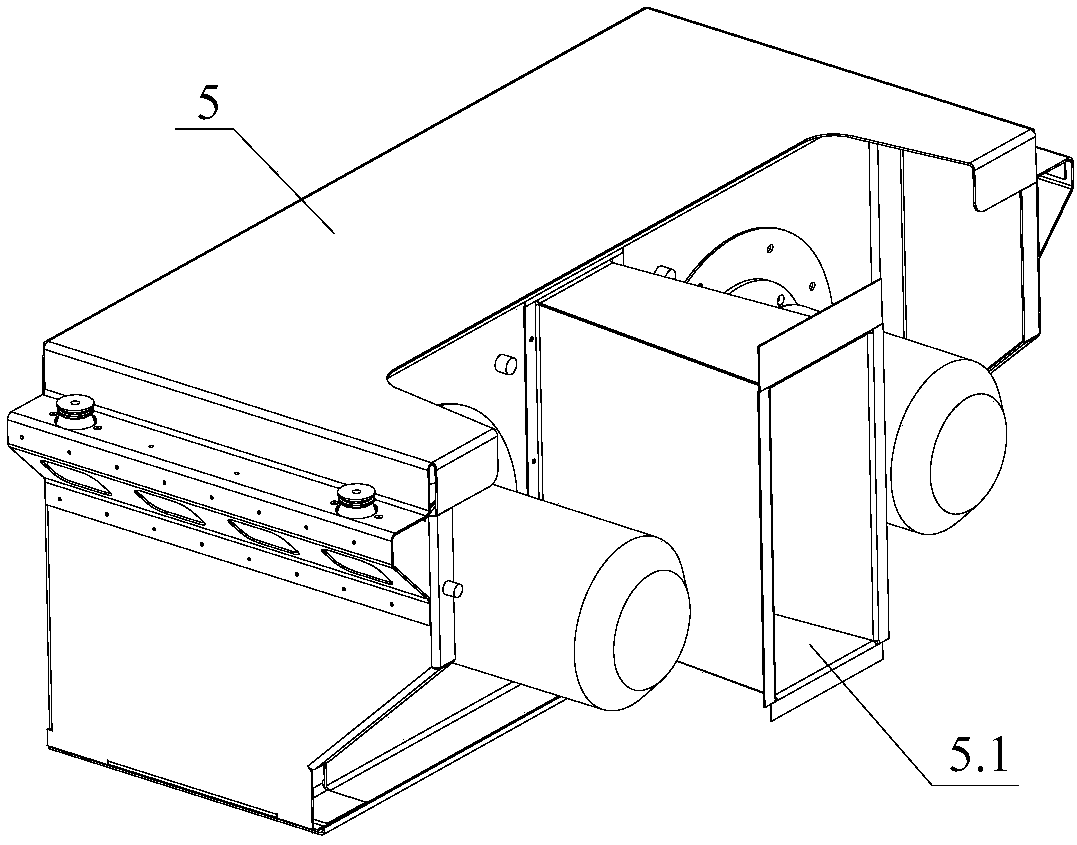

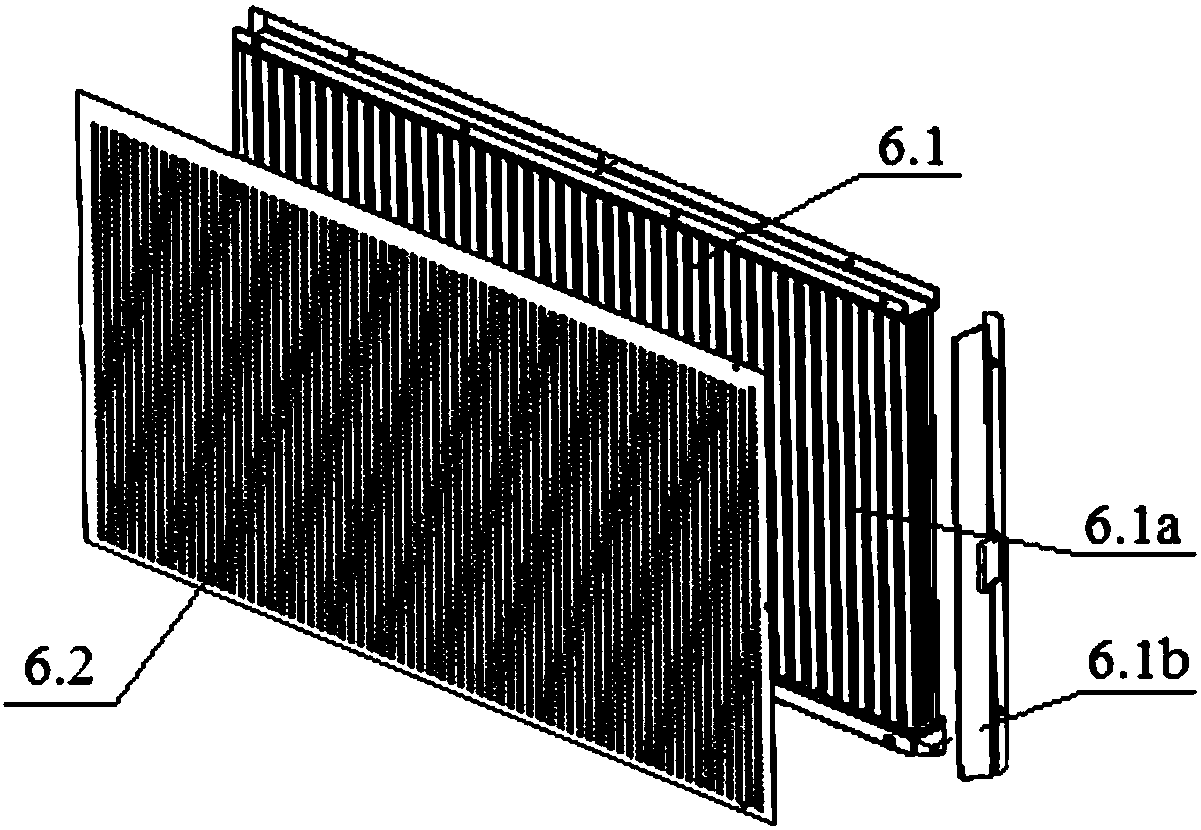

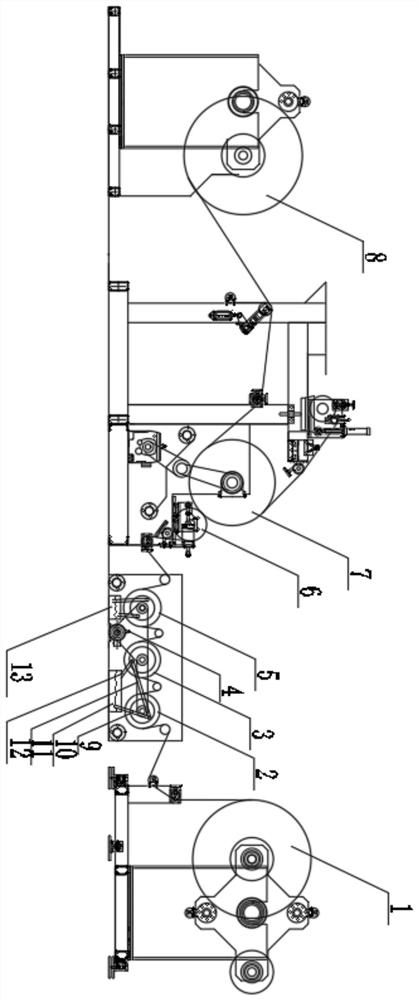

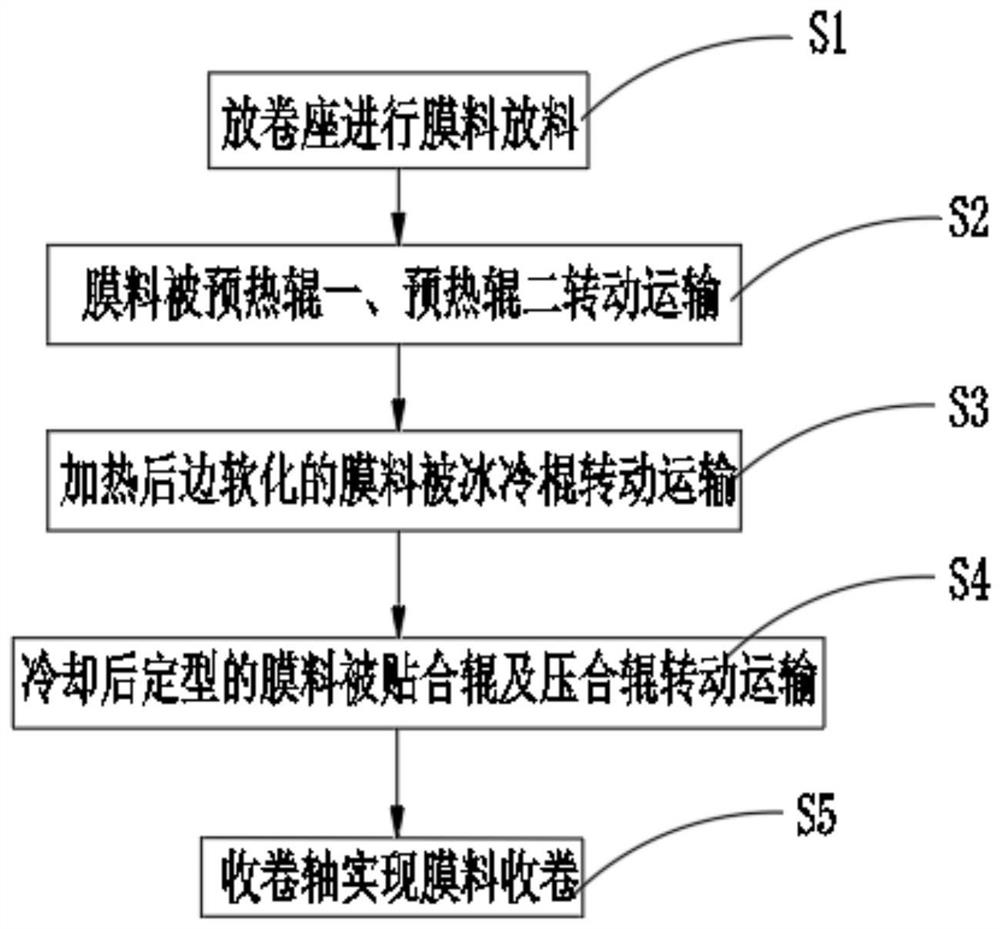

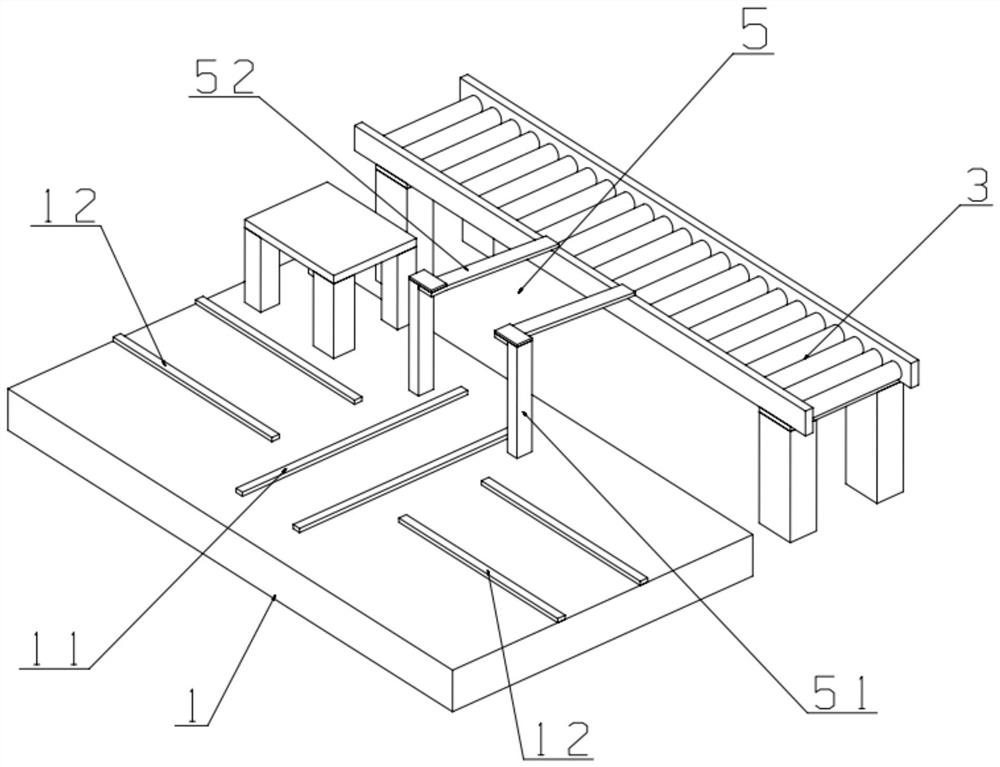

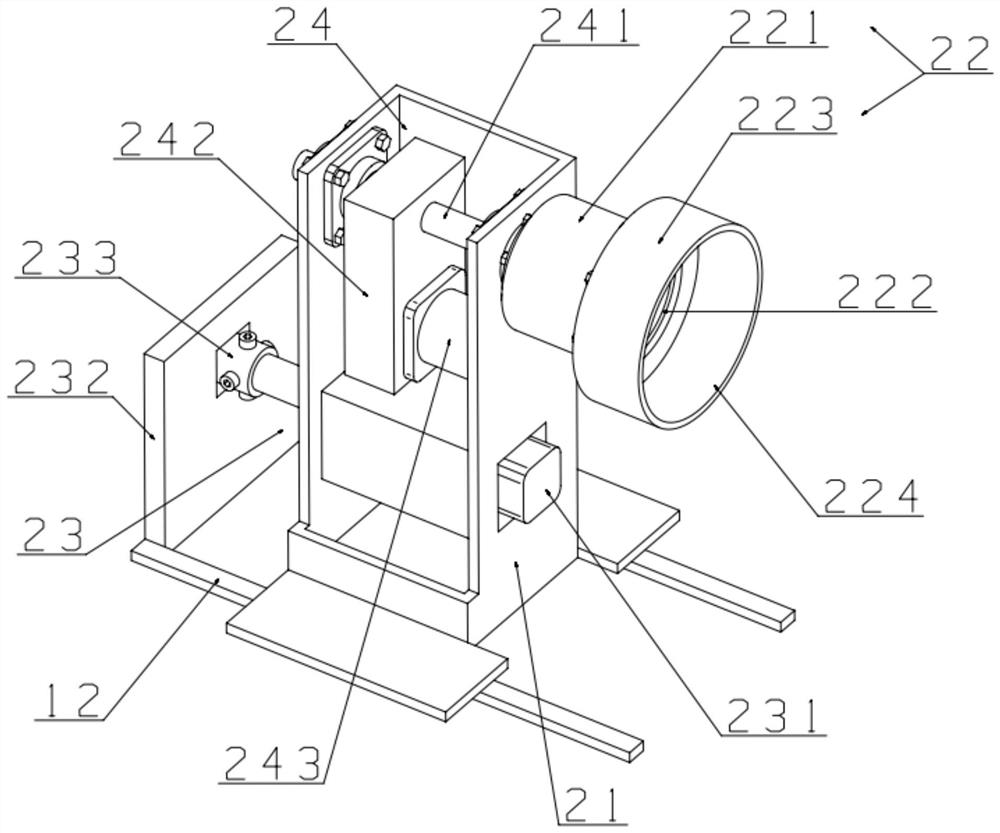

Unwinding system and process for low-tensile PVC film

PendingCN112143390AHeating up fastFast coolingLamination ancillary operationsFilm/foil adhesivesFilm materialCooling Units

The invention relates to an unwinding system for a low-tensile PVC film. The unwinding system comprises an unwinding unit, a preheating unit, a cooling unit, a laminating unit and a winding unit whichare horizontally arranged in sequence, due to the fact that the film materials of an unwinding base can be gradually reduced, the unwinding base can change the speed of the unwinding rotating shaft in real time according to the speed of a roller shaft in the subsequent process, and the phenomena of film material deformation and edge folding are reduced as much as possible. By means of the material characteristics of heat softening and cold hardening of a PVC film material, uneven breadth and wrinkling occurring when the film material is unfolded by the unwinding unit are avoided; after the temperature of the film material is increased by the preheating unit, the film material is softened, and the situations of uneven breadth and wrinkling disappear; the film material enters the cooling unit to be hardened again, and the problems that the whole film material is prone to wrinkling, lotus leaf edges and the like in the unwinding process are solved; then, the film material is laminated with the adhesive sticker through the laminating unit to form a product; and finally, winding of the film material is completed through the winding unit.

Owner:浙江辉柯纸塑制品有限公司

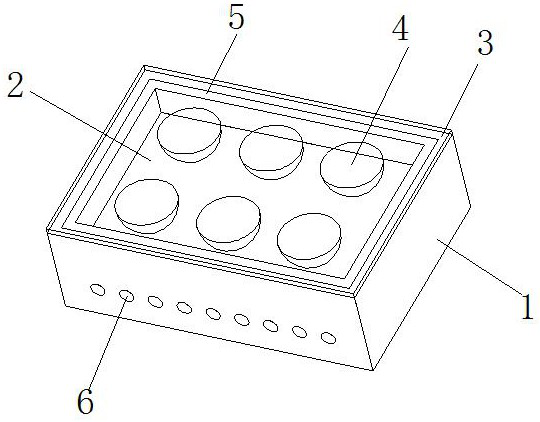

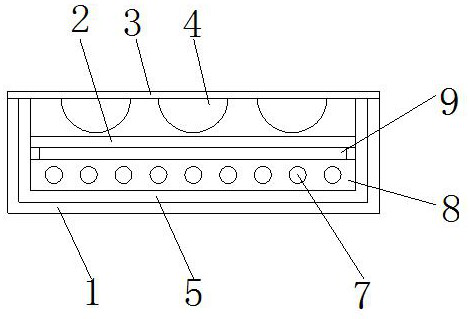

Mechanical cooling device capable of changing cooling speed in real time

InactiveCN111998609AAvoid high temperature burnsClear division of laborDomestic cooling apparatusLighting and heating apparatusRobot handCooling capacity

The invention discloses a mechanical cooling device capable of changing the cooling speed in real time. The mechanical cooling device comprises a box body, wherein a processing cavity is formed in thebox body, a real-time rotating device is arranged in the processing cavity, and the real-time rotating device comprises an adjusting rod which is rotationally connected with the inner wall of the lower side of the processing cavity. According to the mechanical cooling device, high-temperature objects can be cooled according to mechanical transmission, the cooling capacity of the device is controlled according to the number of the placed high-temperature objects, and the rotating speed of a high-temperature rotating disc is controlled to improve heat dissipation; and moreover, the high-temperature objects are carried by controlling a mechanical arm, so that high-temperature scalding of operators is prevented, the components are clear in division of labor, the cooling efficiency of the device is exerted to the maximum extent, real-time cooling is achieved, and unnecessary resource waste is reduced.

Owner:建德席次机械设备有限公司

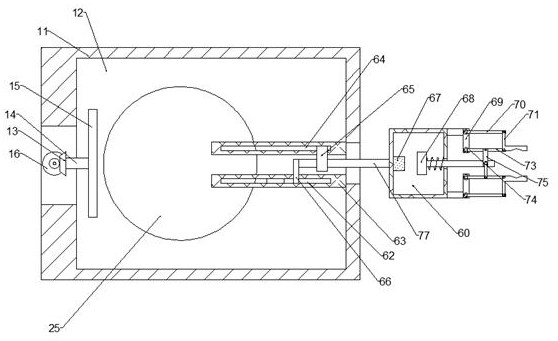

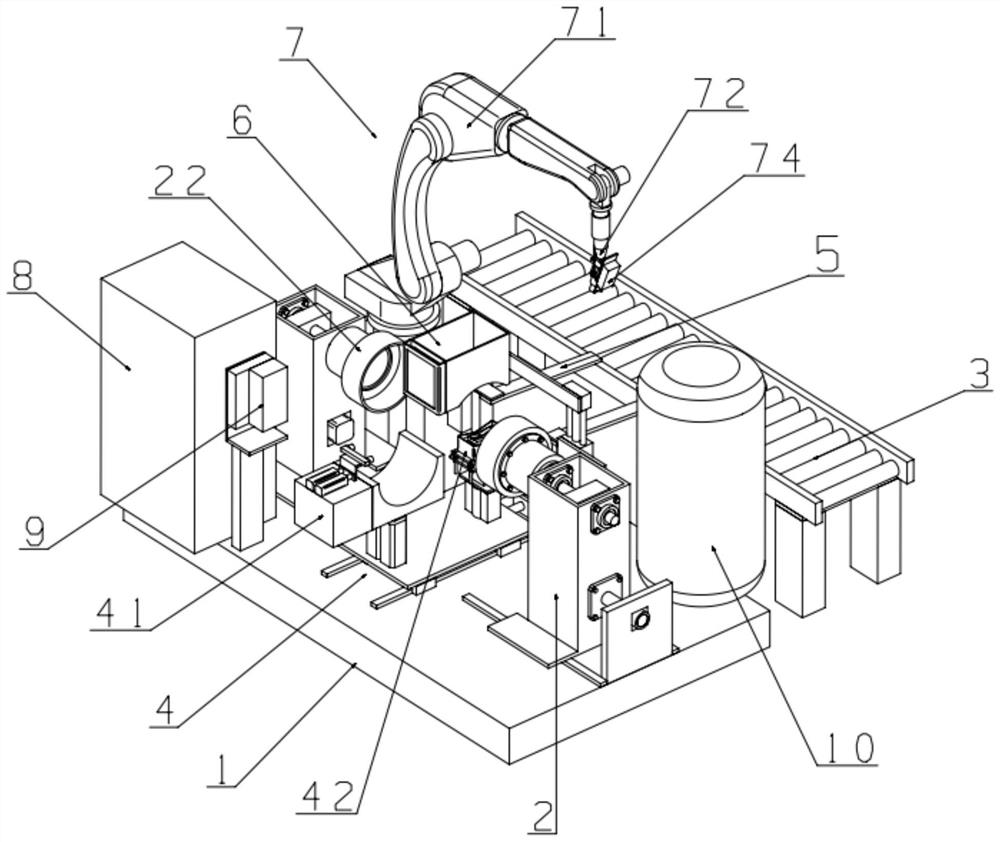

Automatic linear welding device for tank body

PendingCN114310064AExtended service lifeCool down in real timeWelding/cutting auxillary devicesAuxillary welding devicesLaser rangingStructural engineering

The invention relates to the technical field of tank welding, and particularly discloses an automatic linear tank welding device which comprises a workbench, a rotating assembly, a rotating cylinder assembly, a discharging roller way, a feeding and discharging device, a material guiding assembly, a protection device, a multi-axis welding robot, a water cooling jacket, a laser range finder, a controller, a gun washing machine and a protection gas tank. The laser range finder is arranged on the welding gun head of the multi-axis welding robot, multi-point sampling can be carried out on the periphery of the tank body before linear welding is carried out on the tank body, so that the actual position coordinates and the shape tolerance of a welding seam of the tank body are determined, then self-adaptive linear welding is carried out through the welding gun of the multi-axis robot, and the welding quality of the tank body is improved. The influence of repeated positioning errors on the welding seam precision is eliminated; by arranging the feeding and discharging device and the material guiding assembly, rapid feeding and discharging can be conducted, and therefore the production takt is improved; the water-cooled jacket is mounted on the protective jacket, so that the protective jacket of the welding gun can be cooled in real time, and the service life of the protective jacket is prolonged.

Owner:广西乾岳气瓶制造有限公司

Integrated photovoltaic module production process

InactiveCN112420863AAccurate irradiationCost-effectiveFinal product manufacturePhotovoltaicsInsulation layerEngineering

The invention discloses an integrated photovoltaic module production process comprising an outer protection frame, a photovoltaic panel and transparent tempered glass; a heat insulation layer is fixedly installed on the inner side of the outer protection frame, a heat absorption box is fixedly installed at the bottom of an inner cavity of the outer protection frame, and a heat conduction block isfixedly installed in the top wall of the heat absorption box; a plurality of condensing convex lenses are fixedly installed at the bottom of the transparent tempered glass, the photovoltaic panel comprises a back plate, a heat conduction plate is fixedly installed in the back plate, a limiting frame is fixedly installed at the top of the back plate, and a lower EVA film is bonded to the interior of the limiting frame. A plurality of condensing convex lenses are mounted at the bottom of transparent tempered glass and can be arranged to form a condensing layer, so that no matter which directionsolar rays irradiate the condensing convex lenses, the condensing convex lenses can well refract and condense the rays, the rays can accurately irradiate the top of a photovoltaic panel. And the orientation of the photovoltaic panel does not need to be changed frequently for tracking the sun, so that the cost performance of the whole assembly is improved, and popularization and application of thephotovoltaic assembly are facilitated.

Owner:安徽日旭新能源科技有限公司

Directional casting machine for nonferrous metals

The invention relates to the field of casting machines, in particular to a directional casting machine for nonferrous metals. According to the technical scheme, the directional casting machine for thenonferrous metals comprises a rack, a crystallizer is mounted on the rack, an opening is formed in one side of the crystallizer, and a steel belt is spliced on the open side of the crystallizer; a trapezoidal die cavity is formed between the steel belt and the crystallizer, the trapezoidal die cavity is in the shape of a trapezoidal column, a pouring gate is formed in one end of the trapezoidal die cavity, and a pull mechanism for driving the steel belt to continuously move is mounted on the rack. A driving mechanism for driving the pull mechanism to act is mounted on the rack, and an outputshaft of the driving mechanism is connected with the pull mechanism. According to the directional casting machine for the nonferrous metals, a casting is free of torsion yield stress, and the problemthat the casting produced by an existing casting machine is large in torsion yield stress is solved.

Owner:CHENGDU SHUHONG EQUIP MFG

A temperature control system and its temperature control method and tensile strength testing device

ActiveCN106769528BAccurate force situationAccurate researchMaterial strength using tensile/compressive forcesTemperature controlComputer module

The invention discloses a temperature control system. The temperature control system comprises an oil tank and is characterized in that the oil tank is communicated with the first oil inlet of a heating reversing valve through a pipeline, the oil outlet of the heating reversing valve is communicated with the oil inlet of a first oil inlet pump, and the oil outlet of the first oil inlet pump is communicated with the oil inlet of a first temperature control module; the oil outlet of the first temperature control module is connected with the oil inlet of a first temperature control valve module, the first oil outlet of the first temperature control valve module is connected with the water inlet of a second water inlet pump, and the water outlet of a second temperature control module is communicated with the water inlet of a second temperature control valve module; the first oil outlet of the second temperature control valve module is communicated with the second oil inlet pump, and the second oil outlet of the second temperature control valve module is communicated with the second oil inlet of the heating reversing valve; the oil outlet of the second oil inlet pump is communicated with an oil inlet pipe; an oil outlet pipe is communicated with the first oil inlet of a refrigerating reversing valve, and the oil outlet of the refrigerating reversing valve is communicated with a cooling component. The invention further provides a temperature control method based on the temperature control system and a tensile strength testing device.

Owner:ANHUI UNIV OF SCI & TECH

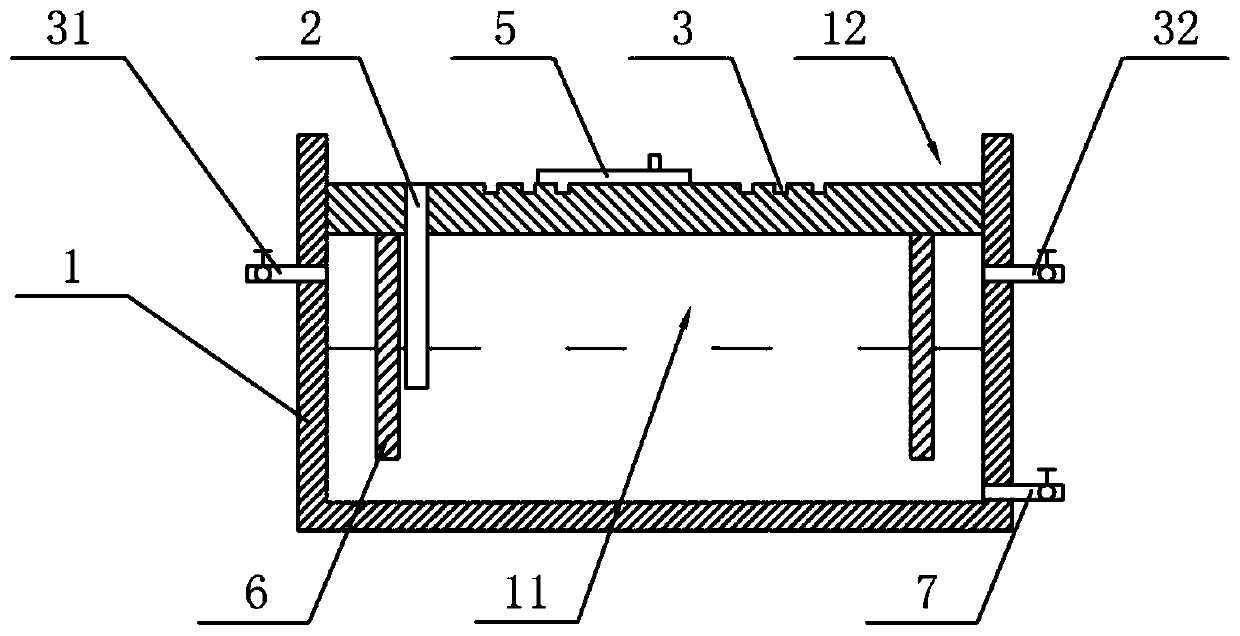

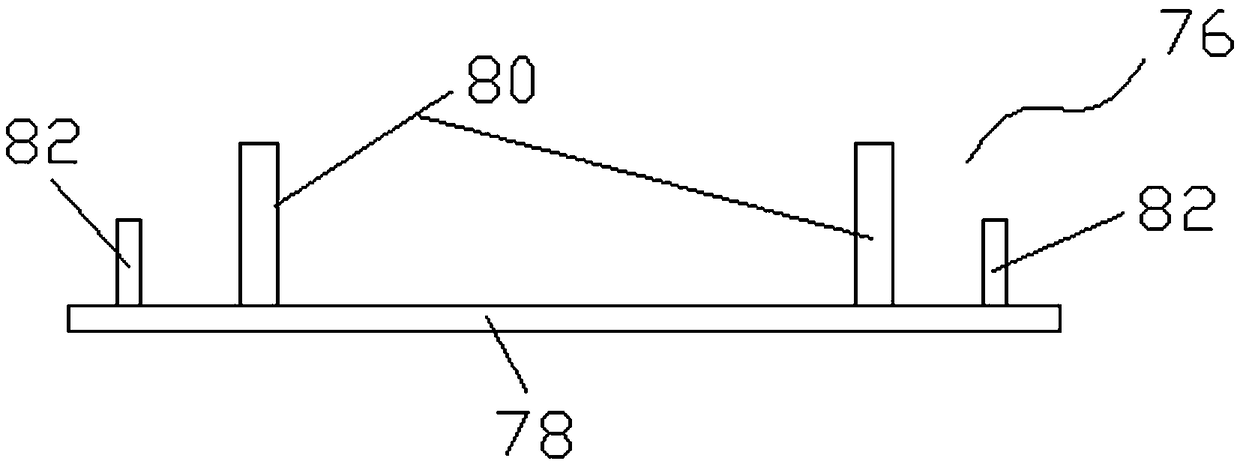

A weldment anti-deformation device

ActiveCN108422130BThere will be no problems such as deformationCool down in real timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld line

The invention belongs to the technical field of welding jigs and discloses a weldment deformation-preventing device. The weldment deformation-preventing device comprises a box body, a flow guide channel, a gas valve and a weldment positioning assembly, wherein the box body is internally provided with a cavity for containing cooling liquid, and the top of the box body is provided with a groove; oneend of the flow guide channel communicates with the groove, and the other end of the flow guide channel is arranged in the cooling liquid in the cavity; the gas valve communicates with the cavity; and the weldment positioning assembly is arranged in the groove and used for fixing a weldment to be welded. By means of the weldement deformation-preventing device, when a weldment is welded, firstly,the weldment is fixed through the weldment positioning assembly, then, high-pressure gas is fed into the cavity, the high-pressure gas extrudes the cooling liquid in the cavity into the groove to immerse the fixed end of the weldment, in the welding process, real-time, rapid and effective cooling is carried out on the welding line position of the weldment through the cooling liquid, and thereforeit is ensured that the weldement deformation and other problems caused by welding point heat concentration and unsmooth heat dissipation cannot occur to the weldment. The welding efficiency and the weldment quality are effectively improved, and the welding cost is reduced.

Owner:WEICHAI POWER CO LTD

A glass cover plate weekly throwing mechanism and weekly throwing equipment

ActiveCN112621537BImprove polishing effectEasy to usePolishing machinesShaking/oscillating/vibrating mixersGlass coverElectric machine

The invention provides a glass cover plate weekly throwing mechanism and weekly throwing equipment, comprising: a rotating motor, the output end of the rotating motor is fixedly provided with a screw rod, and a nut block is movably arranged on the screw rod; a dust removal block, the A glass cover plate cleaning brush is fixedly arranged on the circular bottom plate; a polishing block, a polishing wheel is fixedly arranged on the rotating shaft, and a plurality of spray covers are connected to the water tank; a polishing liquid tank, the center of the transmission wheel two A stirring shaft is fixedly arranged at the position, the rack plate 2 can drive the transmission wheel 2 to rotate; and a cleaning rod, the screw cleaning brush can be in contact with the screw and used to clean the screw. The invention provides a glass cover plate weekly polishing mechanism and weekly polishing equipment, which can spray the polishing liquid, can remove the generated glass debris in time, can stir the polishing liquid to avoid its precipitation, clean the screw rod to avoid blocking the movement of the nut block and Real-time cooling of the polishing motor, with concentrated functions, is worth promoting.

Owner:凯盛科技股份有限公司

Brightness-adjustable LED mining lamp

InactiveCN109724059AIncrease brightnessReduce brightnessElectrical apparatusLighting heating/cooling arrangementsElectricityStopped work

The invention discloses a brightness-adjustable LED mining lamp. The brightness-adjustable LED mining lamp comprises a mining lamp body and a driving power supply, wherein the driving power supply isarranged inside the mining lamp body. The mining lamp body comprises a mining lamp shell, a light-emitting device, a heat dissipation device, an adjusting device and a protection device, wherein the interior of the mining lamp shell is provided with a heat dissipation cavity for containing the heat dissipation device and a driving cavity for containing the driving power supply, the side, back on to the driving power supply, of the heat dissipation device is connected with the light-emitting device, and the adjusting device is connected with the light-emitting device and the driving cavity; andthe driving power supply is electrically connected with the light-emitting device, the heat dissipation device and the adjusting device. The brightness of the LED mining lamp during working can be improved, the intensity of the illumination can be automatically adjusted when the temperature is too high so as to decrease the temperature of the LED mining lamp, cooling can be carried out in real time, and elements in the LED mining lamp are prevented from damage; and when the voltage is unstable or short circuit occurs, a controller controls the LED mining lamp to stop working, so that the personal injury is prevented, the service life of the LED mining lamp is prolonged, and the LED mining lamp is convenient to use.

Owner:上海永朗照明科技有限公司

Cooling positioning pin

Owner:ZOOMLION HEAVY IND CO LTD

A rock tensile strength testing device capable of adding confining pressure

ActiveCN106644719BAccurate force situationAccurate researchMaterial strength using tensile/compressive forcesStress conditionsTest sample

The invention discloses a rock tensile strength test apparatus capable of applying confining pressure, which can truly restore an environment in which rock is disposed. The rock tensile strength test apparatus comprises a base, wherein the base is connected with a top plate by virtue of a connecting rod; and the base is fixedly provided with a test assembly, the top plate is fixedly provided with a loading oil cylinder, and a loading rod of the loading oil cylinder stretches into the test assembly. By adopting the rock tensile strength test apparatus, the confining pressure, different temperature environments and rock burst can be applied to a test sample, an underground environmental condition of the rock can be truly simulated, so that an underground stress condition of the rock and the variation of tensile strength can be more precisely researched, and instructions and references can be provided for the subsequent design, construction, teaching, research and the like. By adopting the rock tensile strength test apparatus, the test sample can be rapidly centered, and a breaking time and pressure at the breaking time of the test sample can be discovered in time by virtue of a displacement of the loading rod. By virtue of a cooling assembly, heat of the loading rod and a lower supporting rod can be prevented from damaging the test apparatus.

Owner:ANHUI UNIV OF SCI & TECH

Chuck device for automatically cleaning auxiliary shaft iron chips

InactiveCN110695381ACool down in real timeEasy to cleanAuxillary equipmentPositioning apparatusConvertersElectric machine

The invention relates to a chuck device for automatically cleaning auxiliary shaft iron chips. The chuck device comprises a chuck shell, a pushing rod assembly, a rotating following converter, a spring, an outer connected converter, a coolant assembly and an air intake assembly, the chuck shell is clamped by a clamping motor and rotates along with the clamping motor, the pushing rod assembly is arranged in the chuck shell, one end of the pushing rod assembly is connected to a to-be-machined product in a propped mode, the rotating following converter is arranged at the tail of the chuck shell,and the two axial ends of the spring are correspondingly connected to the pushing rod assembly and the rotating following converter. Compared with the prior art, the chuck device is used for being mounted on a precise digital-controlled machine tool, a cooling device is connected into the special chuck device, during inner machining of an auxiliary shaft hole, cooling can be conducted on a machining position of a cutter in real time, chip winding due to the high temperature is avoided, after auxiliary shaft machining finishing, an inner pushing rod in a special chuck of the chuck device can push the iron chips left in the auxiliary shaft out, the air intake assembly can lead air pressure in, the iron chips in the device are effectively cleaned, and the chance of the secondary shaft iron chips clamping the product is greatly reduced.

Owner:上海奥林汽车安全系统有限公司

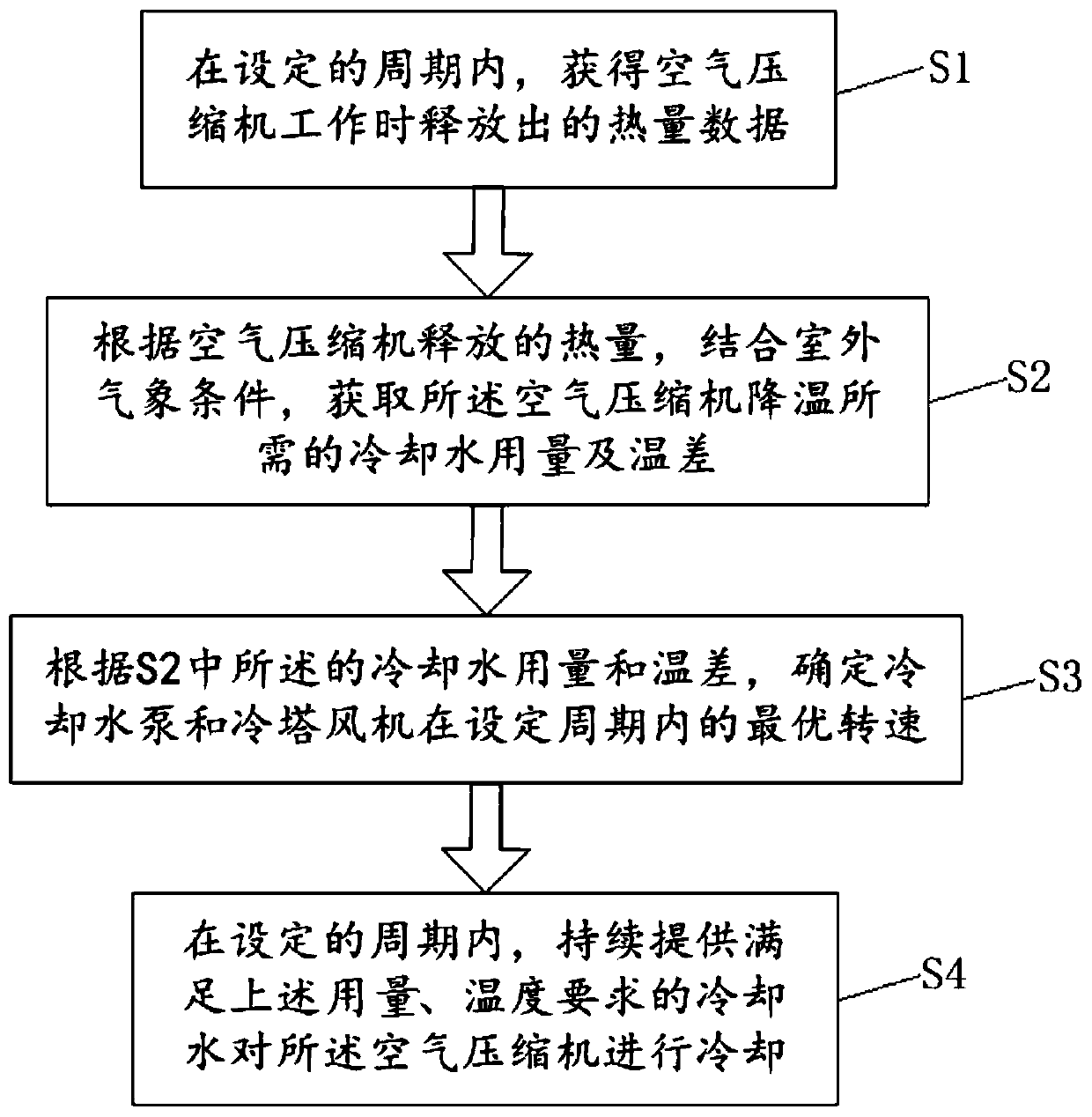

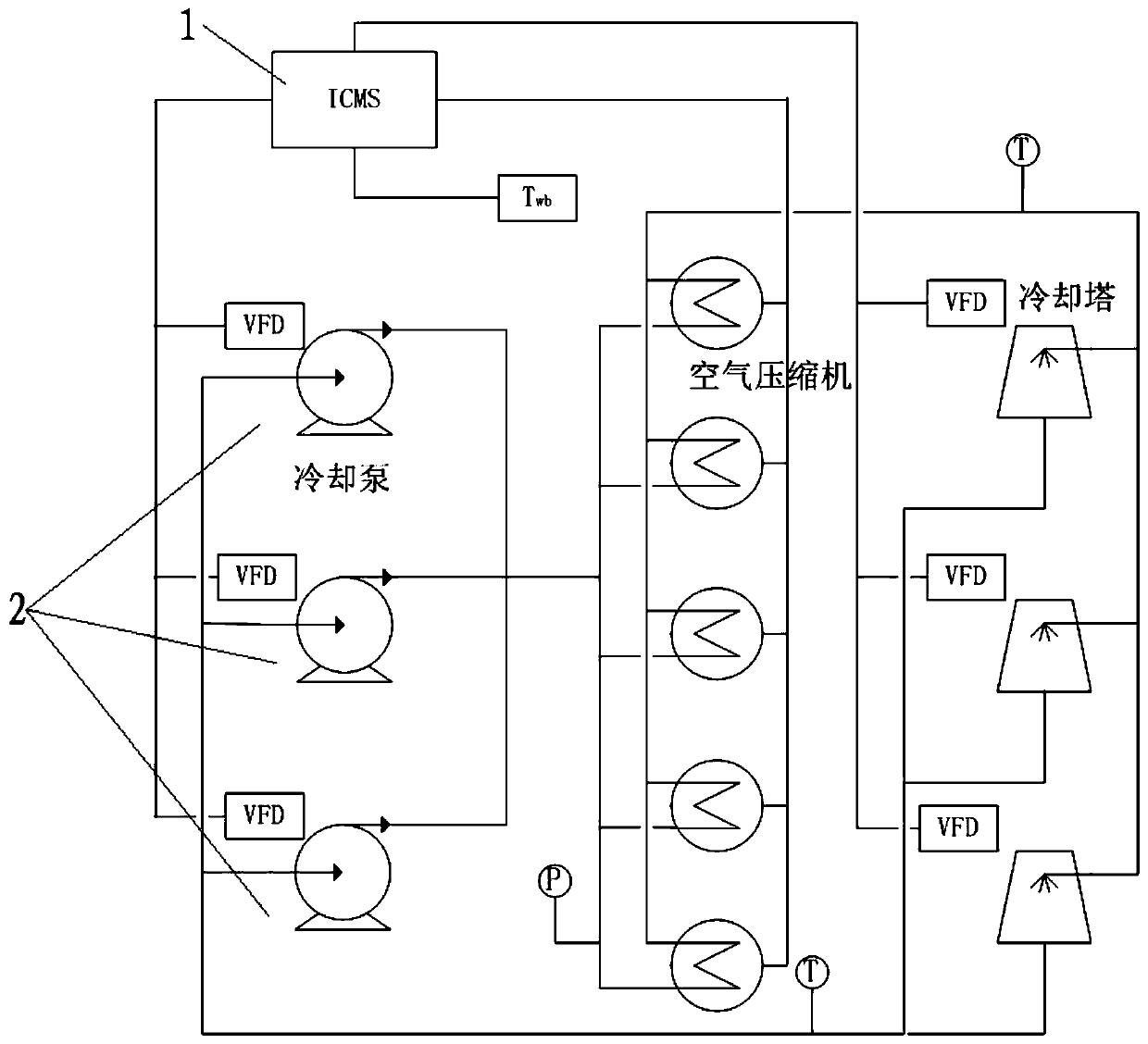

Air compressor cooling method and system

ActiveCN107191359BCool down in real timeGuaranteed uptimePositive displacement pump componentsPositive-displacement liquid enginesAxial compressorCooling tower

The invention provides an air compressor cooling method and system. The air compressor cooling method comprises the following steps that S1, data of heat released by an air compressor in the working process are acquired during the set period; S2, the consumption amount of cooling water needed by cooling of the air compressor and the temperature difference are acquired according to the combination of the heat released by the air compressor and the outdoor weather conditions; S3, the optimal rotating speed of a cooling water pump and the optimal rotating speed of a cooling tower fan are determined during the set period according to the consumption amount of the cooling water and the temperature difference; and S4, the cooling water which meets the requirements for the consumption amount and the temperature difference is continuously provided and conducts cooling on the air compressor during the set period. The air compressor cooling method and system overcome the defects of an existing air compressor cooling method, can conduct cooling on the air compressor in real time, enable the working temperature of the air compressor to be kept within the appropriate range all the time, conveniently guarantee normal operation of the air compressor, and also avoid the waste of energy sources and water resources.

Owner:BAISHITELING SUZHOU INTELLIGENT TECH CO LTD

Integrated wall heat exchange device

ActiveCN103776173BIncrease hovering speedExtended service lifeFluid heatersCombustorPlate heat exchanger

An integrated dividing wall heat exchanger comprises an inner pot body, an outer pot body and a steam generator, wherein the outer pot body is provided with a steam annular passage, the inner pot body is provided with a heat exchange component, the heat exchange component is provided with a steam inlet, the steam generator comprises a furnace body, an inner container with a single-channel spiral plate structure, a combustor and an air intake device, flue gas produced by the combustor enters from the center of the inner container and surrounds the external space of the inner container to form an annular spiral flue, water placed inside the inner container is heated to form steam, the produced steam enters the steam annular passage of the outer pot body, brushes the outer wall of the inner pot body from the top to the bottom and then enters the heat exchange component from the steam inlet of the heat exchange component to heat materials inside the inner pot body, and waste liquid produced after heat exchange of the heat exchange component enters the inner container of the steam generator from the waste liquid discharge opening for recycling. The integrated dividing wall heat exchanger has a compact entire structure, is high in heat exchange efficiency, water is not required to be added during heat exchange, and more functions of carrying out mixed type heat exchange on the materials by steam or supplying steam to the outside directly are integrated.

Owner:夏品荷

Hydraulic cooling system and construction machinery with same

ActiveCN103511403BAchieve pre-coolingCool down in real timeFluid-pressure actuator componentsTemperature controlFuel tank

The invention discloses a hydraulic cooling system. The hydraulic cooling system comprises a pump (10), a cooling motor (20), a cooling fan (30), an oil inlet oil way (22) and an oil return oil way (24). The cooling fan (30) is driven by the cooling motor (20) to run, the oil inlet oil way (22) is connected between the cooling motor (20) and the oil outlet of the pump (10), and the oil return oil way (24) is connected between the cooling motor (20) and an oil tank (T0). The hydraulic cooling system is characterized in that a hydraulic control reversing valve (40) with the adjustable aperture of a valve core is arranged on the oil inlet oil way (22); the hydraulic control reversing valve (40) comprises a hydraulic control end A and a hydraulic control end B, an oil inlet P, a working oil port a and a working oil port b. The hydraulic control end A and the hydraulic control end B are located at the two opposite ends of the hydraulic control reversing valve, the oil inlet P is communicated with the oil inlet of the pump (10), the working oil port a is communicated with the cooling motor (20), and the working oil port b is connected with other working oil ways (26). The hydraulic cooling system further comprises a temperature control pressure device, wherein the temperature control pressure device is connected with the hydraulic control end B and enables the pressure of the hydraulic control end B to change along with the temperature of hydraulic oil. The hydraulic cooling system has both the precooling function and the cooling as required function and is good in energy saving and economic returns. Through the hydraulic cooling system, the power of the hydraulic system can be effectively utilized to cool the hydraulic oil.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

Electrodeless illuminating lamp

ActiveCN102243982BSimple structureImprove lighting effectsGas discharge lamp detailsMagnetic polesEngineering

An electrodeless illuminating lamp, which belongs to the illuminating lamp technology field, is disclosed. The electrodeless illuminating lamp comprises: an electric control cabinet, a pedestal, a support, a luminous tube, a coupler and a cooling system. The support is placed on the pedestal. The tube is installed on the pedestal in the support. The coupler is arranged in the luminous tube. The cooling system is used to cool the coupler. The coupler is respectively connected with the electric control cabinet and the cooling system. The coupler comprises: an inner water pipe, an external water pipe, a coil, multi-group magnets and a magnetic shield. The magnets are sleeved on the external water pipe, wherein the magnetic shield is arranged between the magnets. The coil is wound around the magnets. Coil winding directions of two adjacent magnets are opposite and magnetic poles of opposite ends of the adjacent magnets are same. Two ends of the coil form an anode and a cathode which are respectively connected with the electric control cabinet. The inner water pipe is arranged in the external water pipe, extends out of the external water pipe and forms seal connection with the end of the external water pipe. The inner water pipe is connected with a water pump of the cooling system and a water outlet nozzle is arranged on the external water pipe. In the invention, arbitrary multi-group magnets are adopted to form different models of the electrodeless illuminating lamps. A large or an ultra-large illuminating lamp can be made.

Owner:杨卡

A process for preparing microporous tubes by semi-melt continuous extrusion of polymer powder

The invention relates to a process for preparing microporous tubes by semi-melt continuous extrusion of polymer powder, which is characterized in that it includes the following steps: (1) adding solid powder materials into a screw extrusion device through a hopper; (2) entering The barrel of the screw extrusion device is heated, and at the same time, the material is initially compacted by the screw, and the material becomes a semi-molten state; (3) The material enters the machine head and is further compacted; (4) The material enters the die of the screw extrusion device The mold cavity is formed into a tube shape, and the inner and outer diameters are determined under the action of the vacuum cooling calibrating sleeve, and the preliminary cooling is performed; (5) The microporous tube is cut by a cutting device. The technology of the invention is to carry out continuous extrusion molding when the polymer powder is in a semi-molten state. While realizing the continuous production of the microporous tube, the produced product does not need post-processing, thereby greatly improving the production efficiency. Because the process of the invention does not use solvent, it is beneficial to environmental protection and the health of operators.

Owner:SUZHOU KAHO POLYMER TECH CO LTD +1

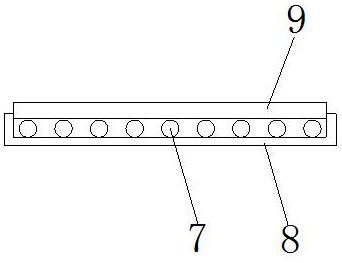

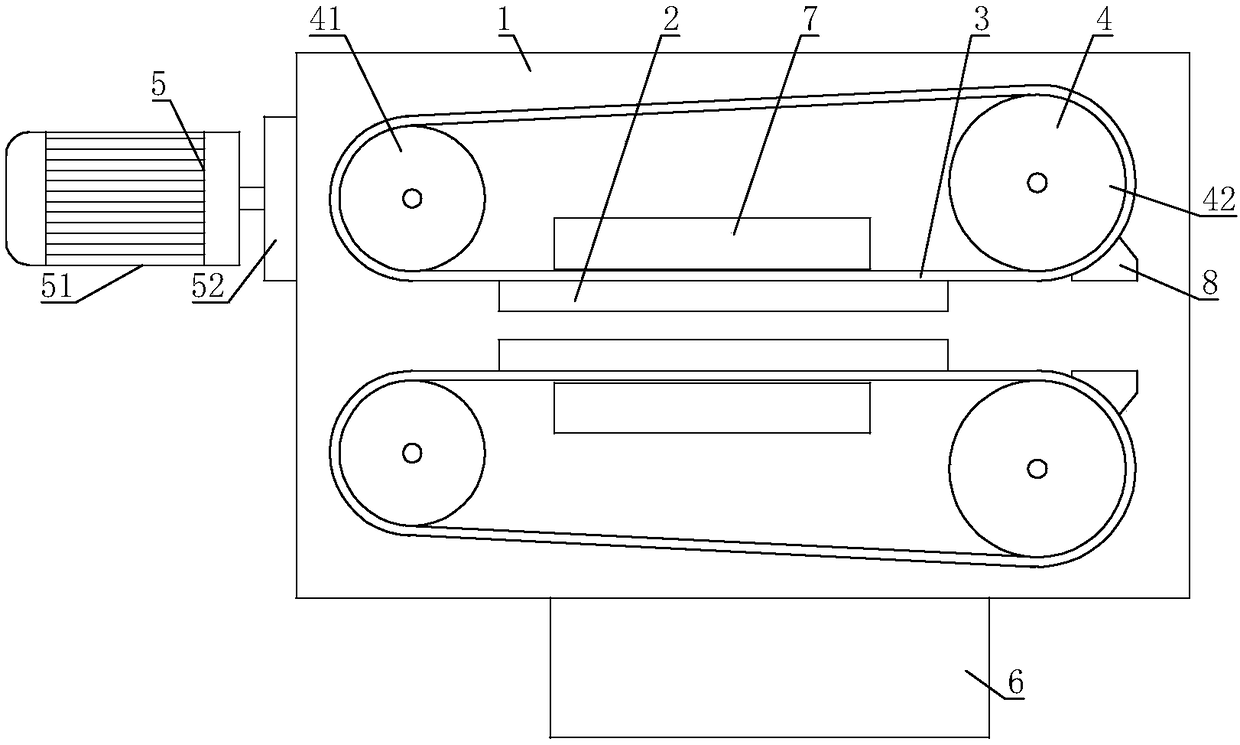

Electric hoist cooling device

The invention relates to an electric hoist cooling device. The electric hoist cooling device comprises a main beam and an electric hoist installed on the main beam; the electric hoist can move in thelength direction of the main beam; a sliding base is installed on the upper portion of the main beam; a cooling assembly and a guiding assembly are installed on the sliding base; the cooling assemblycomprises a draught fan, a header pipe connected with the draught fan, a first branch pipe and a second branch pipe, wherein the first branch pipe and the second branch pipe are connected with the header pipe; the guiding assembly comprises a first V-shaped plate and a second V-shaped plate; the first V-shaped plate comprises a first supporting plate and a first guiding plate; the first supportingplate is provided with a plurality of first through holes; the second V-shaped plate comprises a second supporting plate and a second guiding plate; and the second supporting plate is provided with aplurality of second through holes. According to the electric hoist cooling device, due to the arrangement of the first guiding plate and the second guiding plate, flowing of wind is facilitated, windis blown to the electric hoist in a concentrated manner, and the electric hoist is made fast cooled; and due to the arrangement of a first spraying assembly and a second spraying assembly, when windblown out of the draught fan passes through water mist, water evaporates and absorbs heat, and cold wind is blown out.

Owner:苏州库力铁重工有限公司

Inverter cooling device, air conditioning unit and control method

ActiveCN106546045BReal-time coolingImprove securitySpace heating and ventilation detailsRefrigeration safety arrangementWater coolingAir conditioning

The invention provides a frequency converter cooling device. The frequency converter cooling device comprises a refrigerant cooling system and a freeze water cooling system. A compressor, a cooling assembly and a heat exchanger assembly of the refrigerant cooling system are successively connected through a pipeline to form a refrigerant loop; a freeze water inlet pipe, a frequency converter cooling module, a freeze water outlet pipe and the heat exchanger assembly of the freeze water cooling system are successively connected to form a freeze water loop. According to the frequency converter cooling device, heat exchange for cooling is performed between water in the freeze water cooling system and a refrigerant in the refrigerant cooling system in the heat exchanger assembly, and the frequency converter is further cooled by virtue of water in the freeze water cooling system, and the frequency converter can be cooled in real time even if a circular cooling system of the air conditioning unit where the frequency converter is does not operate, so that the operating safety of the frequency converter is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Cooling device for mechanical parts

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com