Chuck device for automatically cleaning auxiliary shaft iron chips

An automatic cleaning and chucking technology, applied in positioning devices, auxiliary devices, clamping and other directions, can solve the problems of product pinching, defective products, and iron filings entering, so as to reduce the probability of product pinching and save labor. The effect of cost and process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

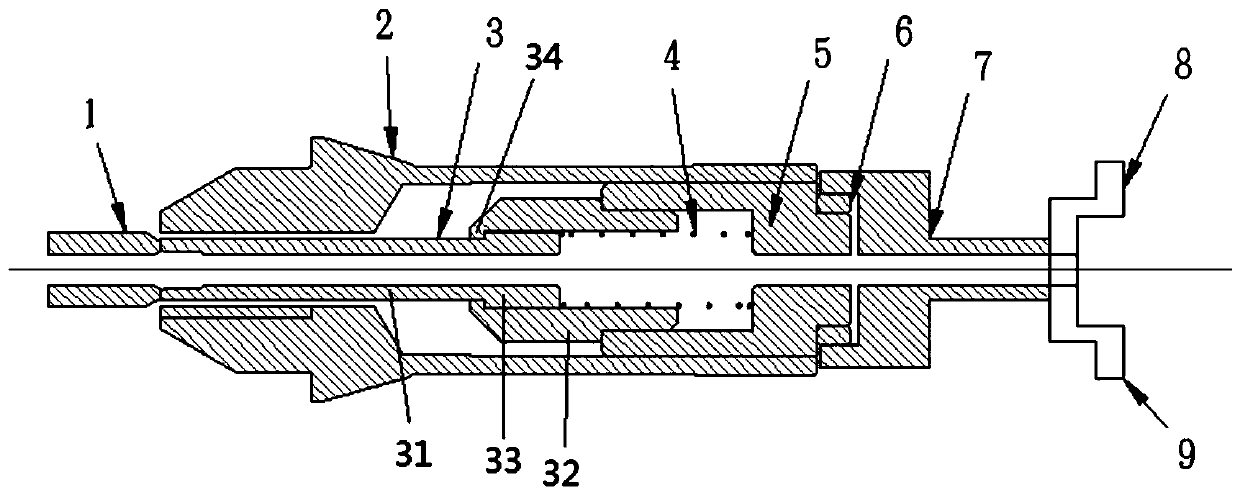

[0036] In this embodiment, the chuck device for automatically cleaning the iron filings of the auxiliary shaft is installed on the auxiliary shaft of the centering machine, and includes the chuck housing 2, the push rod assembly 3, the follow-up converter 5, the spring 4, the external converter 7, Coolant assembly 8 and air intake assembly 9 . The chuck shell 2 is clamped by the clamping motor and can rotate accordingly, and the product 1 to be processed is clamped at the head of the chuck shell 2 . The clamping motor is clamped on the outside of the chuck shell 2, and plays the role of clamping the chuck shell 2 and driving the chuck shell 2 to rotate at the same time. The external converter 7 is axially connected with the follow-up converter 5 through the ball bearing 6, and has a hollow tubular structure.

[0037] The chuck shell 2 further clamps the product 1 to be processed and drives the product 1 to rotate. The push rod assembly 3 is arranged inside the chuck shell 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com