Inverter cooling device, air conditioning unit and control method

A technology of a cooling device and a control method, applied in refrigerators, refrigeration components, air conditioning systems, etc., can solve the problem of inability to cool the inverter, and achieve the effect of improving safety and avoiding rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

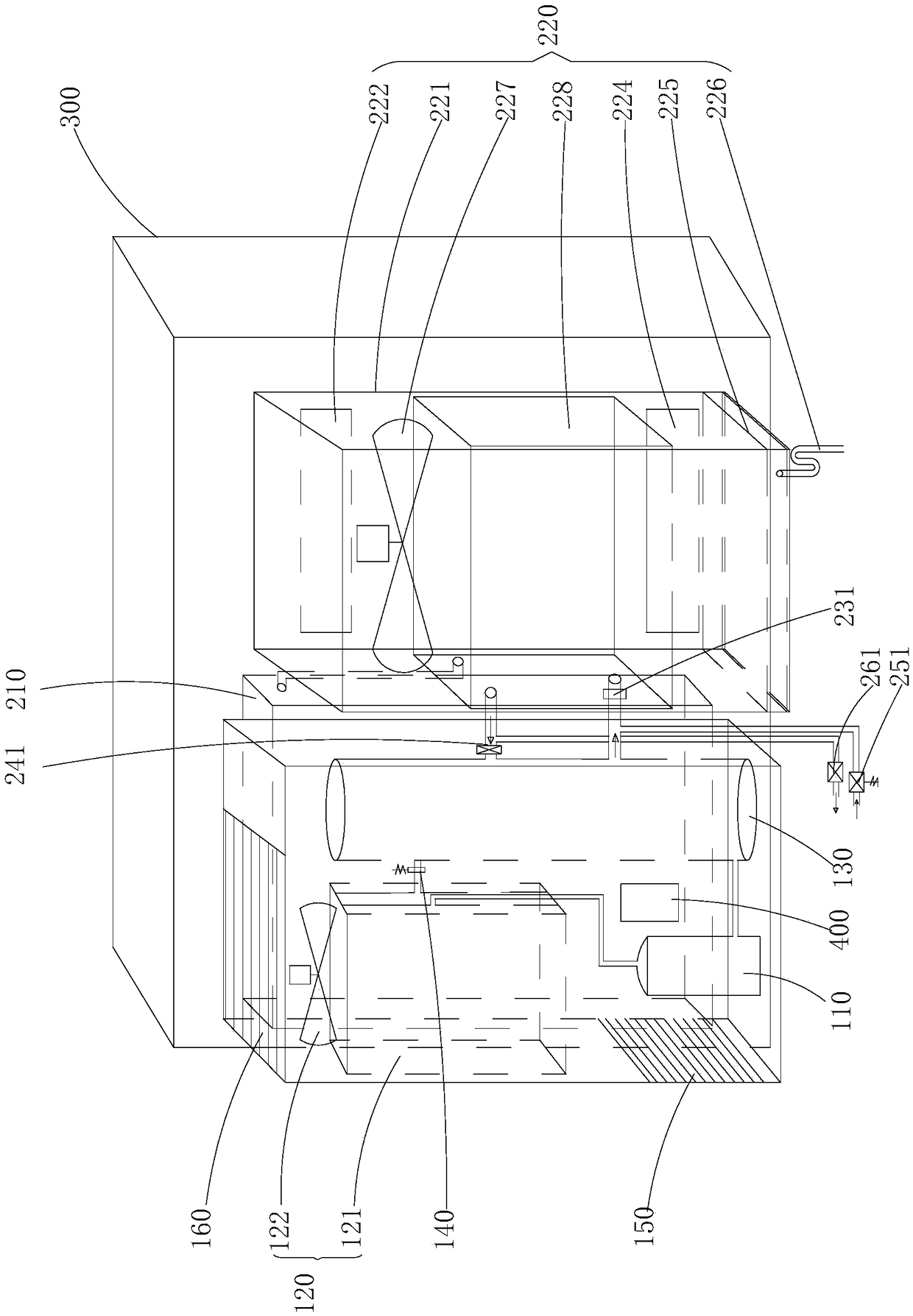

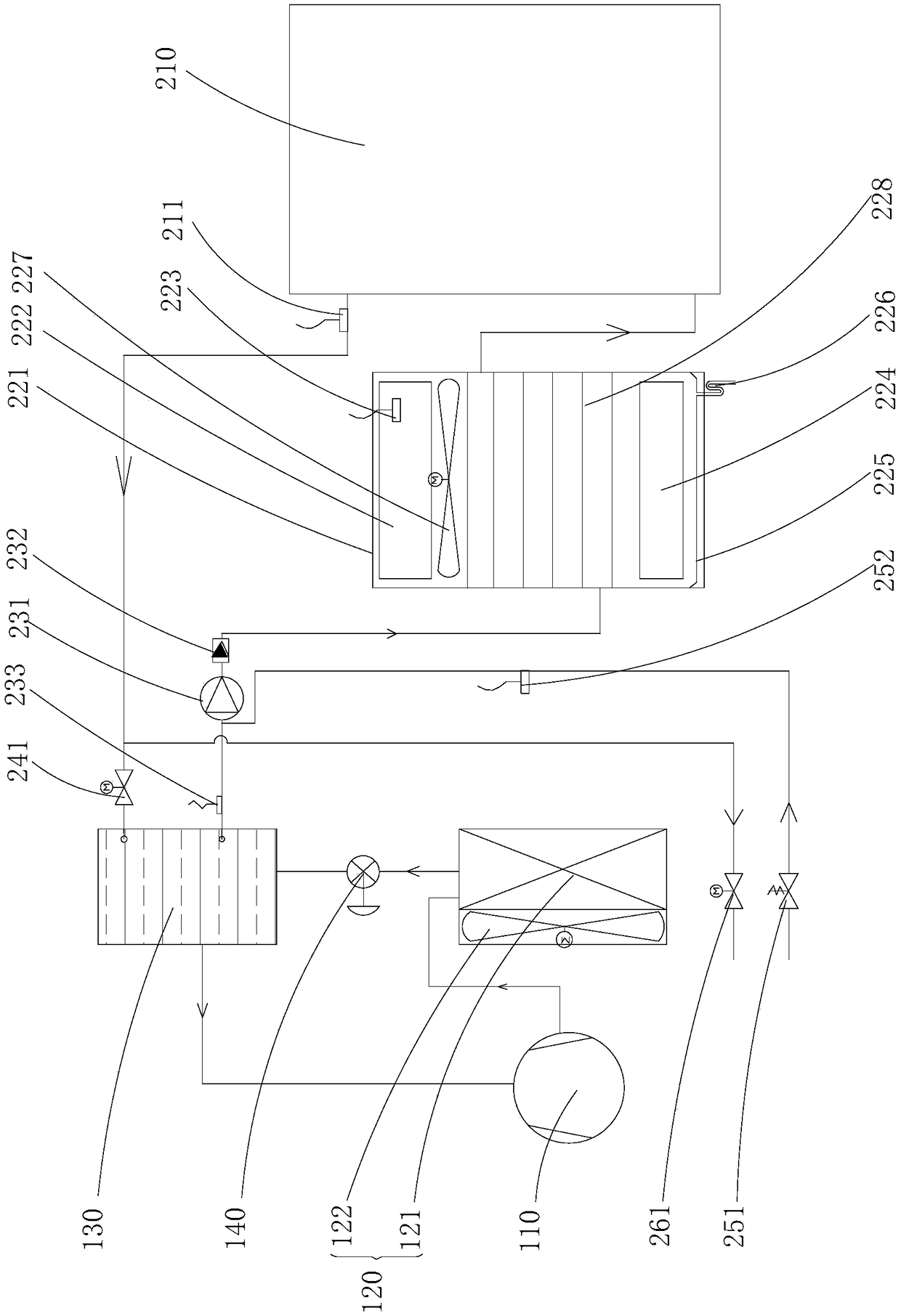

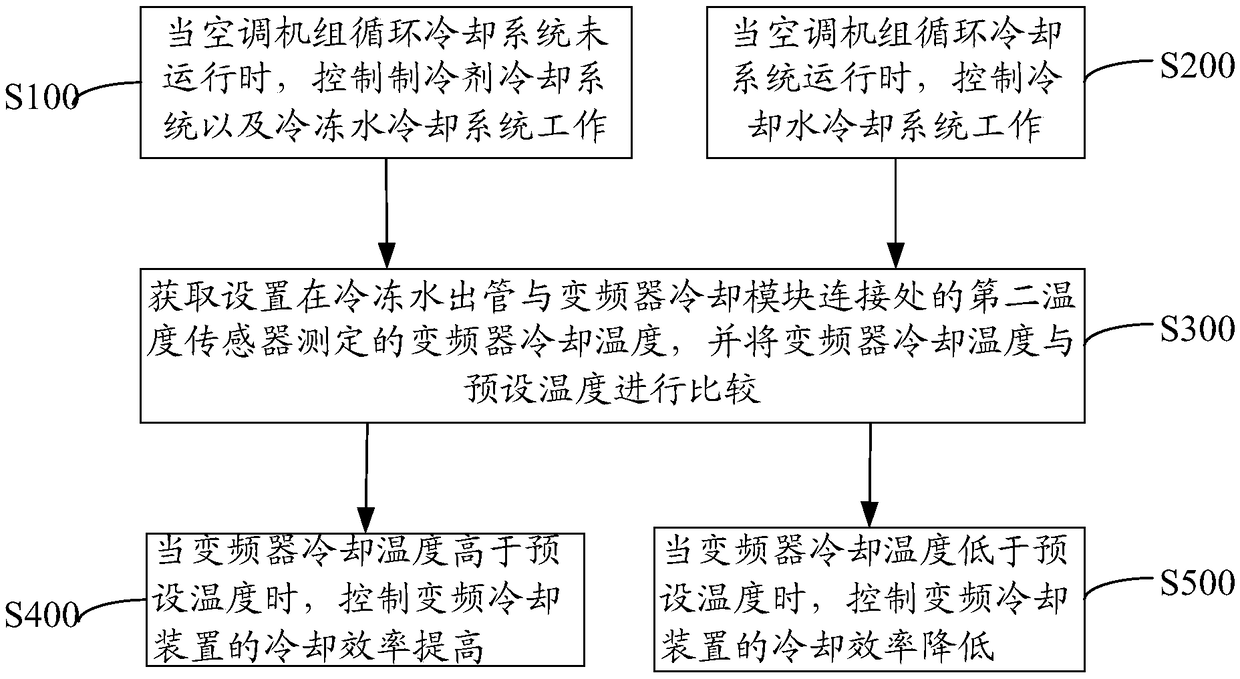

[0054] see figure 1 and figure 2As shown, the inverter cooling device of the present invention includes a refrigerant cooling system, a chilled water cooling system and a cold cabinet.

[0055] The cooling cabinet is attached to one side plate of the frequency conversion cabinet 300 and is airtightly connected with the frequency conversion cabinet. The refrigerant cooling system is set in the cooling cabinet, and the chilled water cooling system is set in the airtight frequency conversion The system is connected with the chilled water cooling system through the joint surface of the cooling cabinet and the frequency conversion cabinet.

[0056] Wherein, the refrigerant cooling system has a compressor 110, a cooling assembly 120, and a heat exchanger assembly 130, and the exhaust port of the compressor 110, the cooling assembly 120, the heat exchanger assembly 130, and the suction port of the compressor 110 are connected through pipelines in sequence Form the refrigerant circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com