Turbine last-stage blade protection device for high back pressure heat supply

A protection device, the technology of the last stage blade, which is used in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large distance between the last stage blades and the inability to effectively protect the last stage blades, so as to reduce turbulent flow and harmful volume, The effect of smooth and safe low-pressure flow passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the technology of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

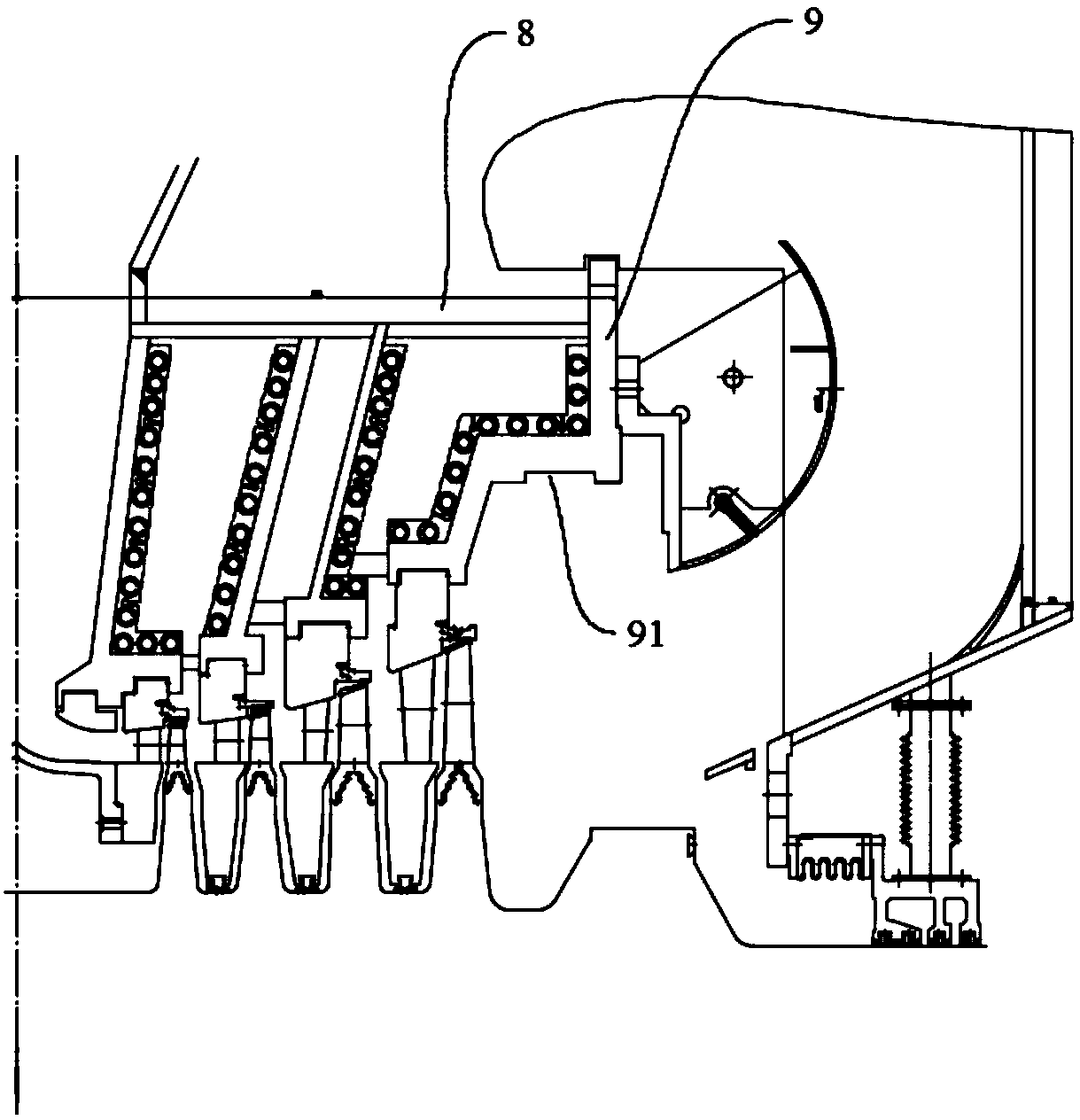

[0024] figure 1 It is a partial view of a steam turbine without protective devices. It can be seen that after the inner cover 9 of the cylinder block 8 is removed from the last stage of the low-pressure section, the steam ejected from the remaining final stage will enter an open irregular space. In turn, severe turbulence will be generated, which will damage the equipment.

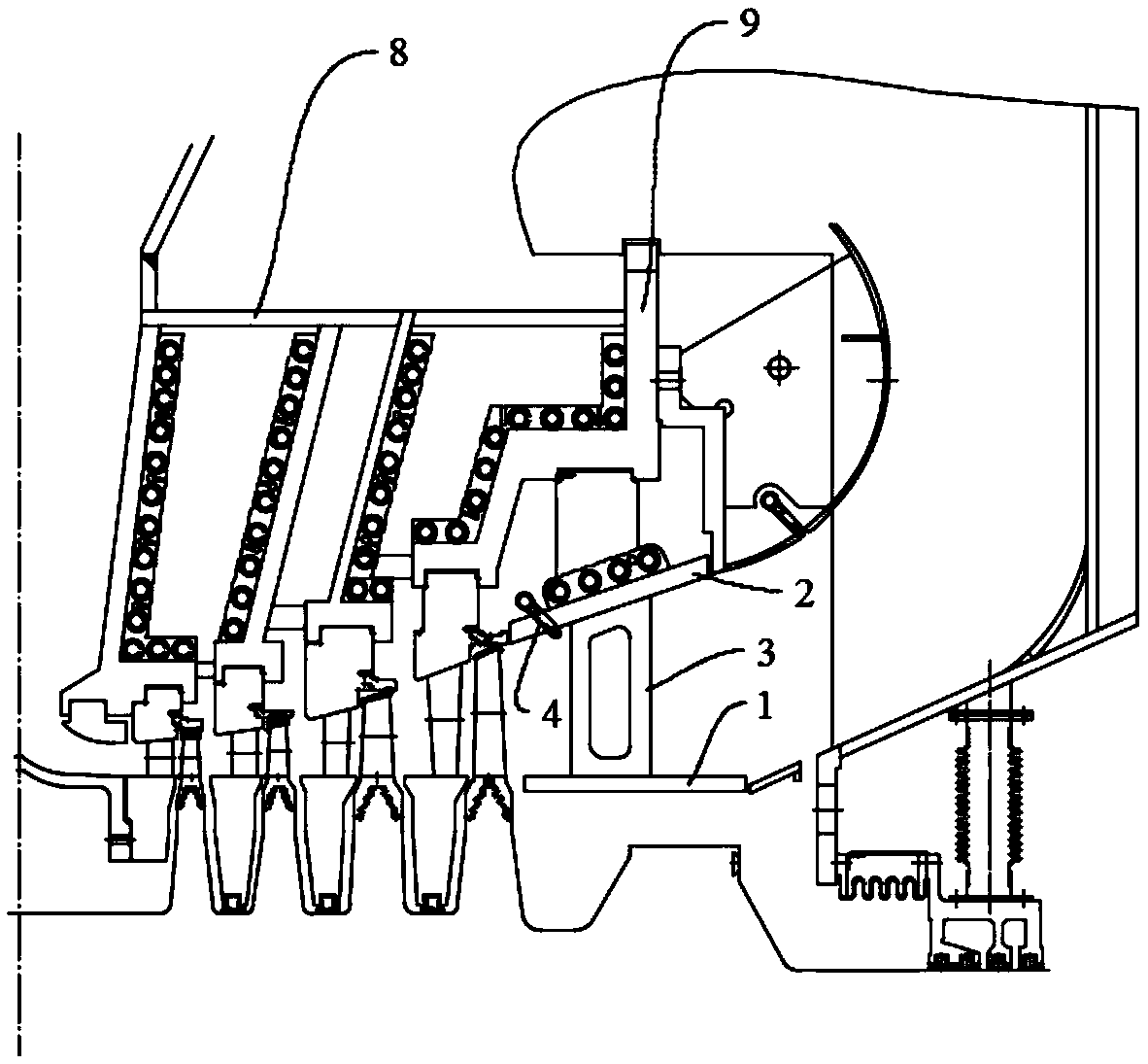

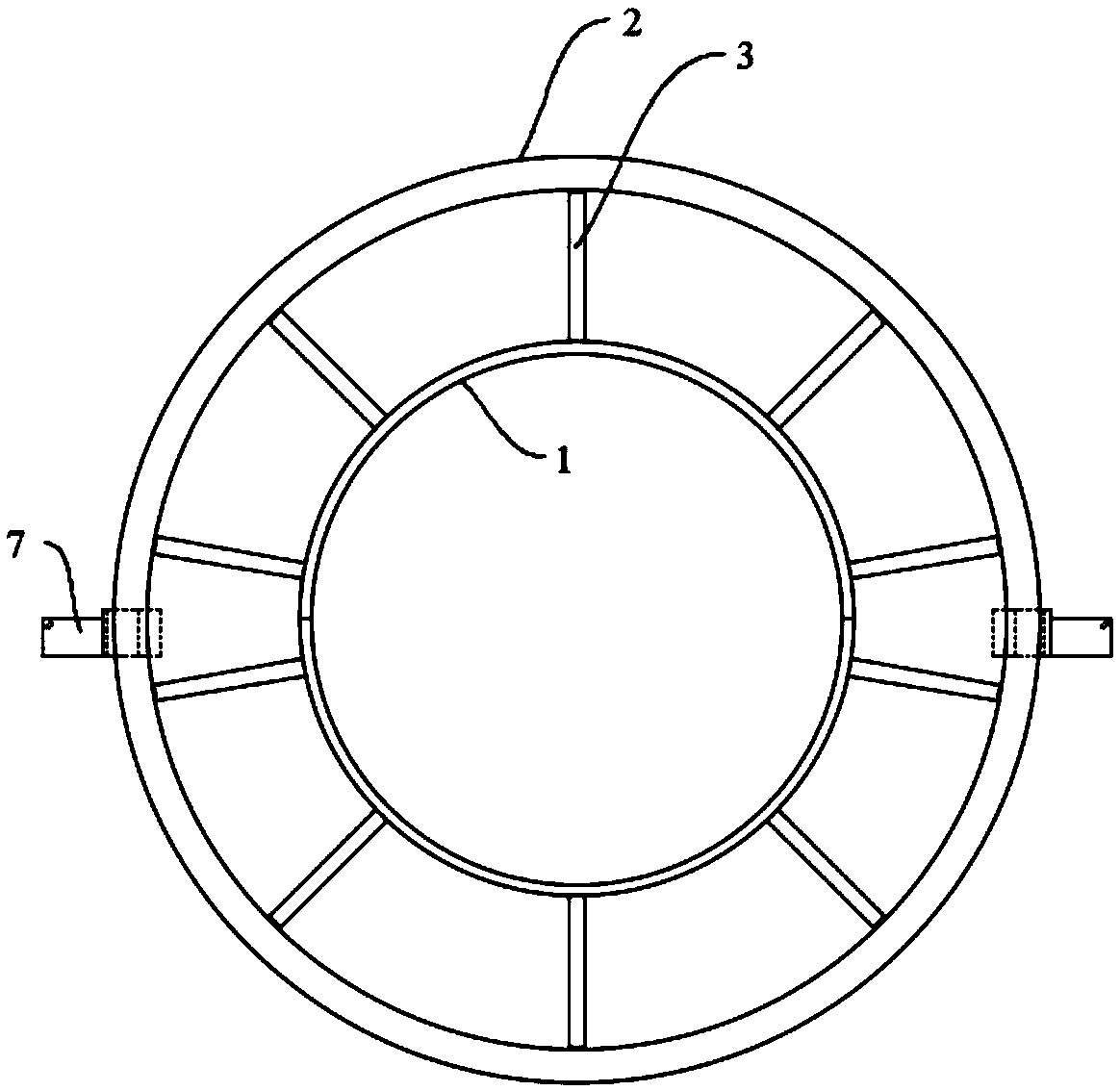

[0025] figure 2 Among them, the last-stage blade protection device of the steam turbine, which uses high back pressure for heating, can replace the removed partition and install it in the low-pressure cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com