Compound reamer for valve port

A kind of reamer and valve hole technology, applied in the direction of reamer, reaming device, metal processing equipment, etc., can solve the problems of shortening the life of the cutter body, hindering the heat dissipation of the cutter body, complicated valve structure, etc., so as to improve the service life and structure. Practical and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

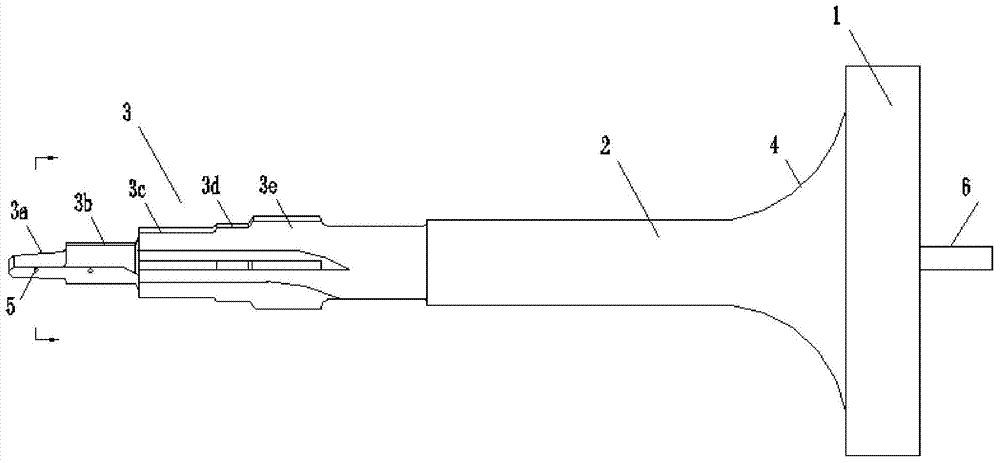

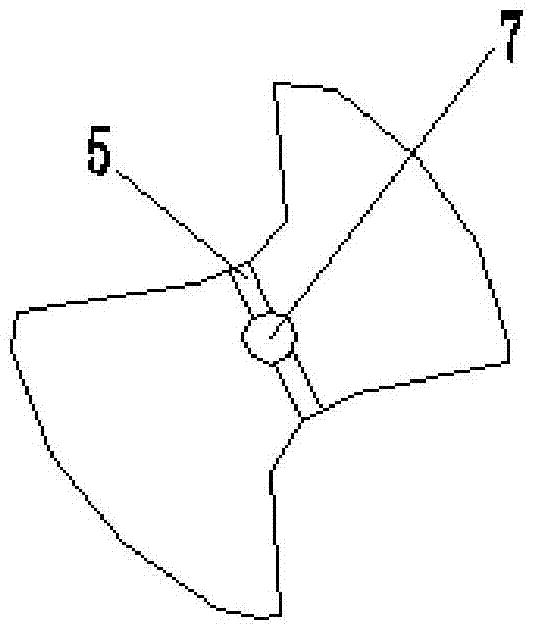

[0010] like figure 1 As shown, a compound reamer for a valve hole includes a reamer disc 1, a reamer rod 2 and a reamer head 3, and the reamer head includes a first-stage cutter head 3a, a second-stage cutter head 3b, and a third-stage cutter head 3c , the fourth-order cutter head 3d and the fifth-order cutter head 3e, the cutter head 1 and the reamer bar 2 are connected by an arc surface 4, the first-order cutter head 3a is provided with a coolant outlet 5, and the reamer head 1 is provided with a cooling The liquid inlet pipe 6 , the reamer rod 2 and the reamer head 1 are provided with a coolant channel 7 , and the coolant channel 7 communicates with the coolant inlet pipe 6 and the coolant outlet 5 .

[0011] The coolant outlet is located at the bottom of the chip removal groove of the reamer head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com