Unwinding system and process for low-tensile PVC film

A film material and roll seat technology, which is applied in the direction of film/sheet adhesive, lamination, application, etc., can solve the problems of film material wrinkling, ruffles, etc., to reduce wrinkling, lower tension, The effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

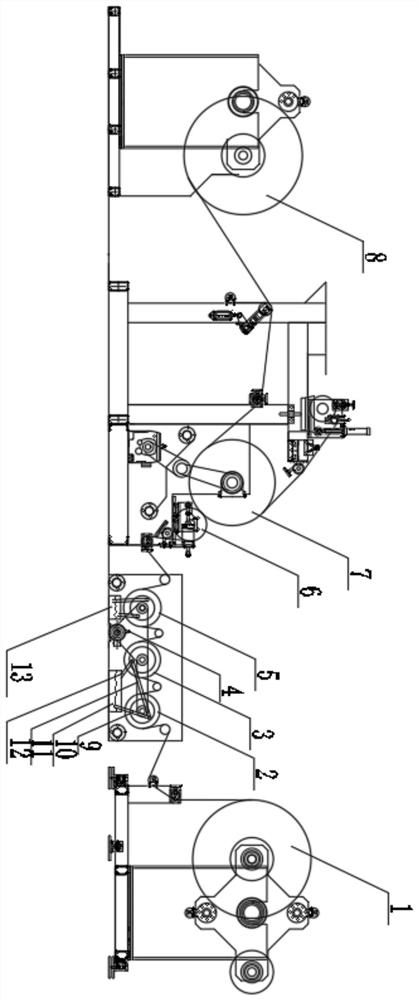

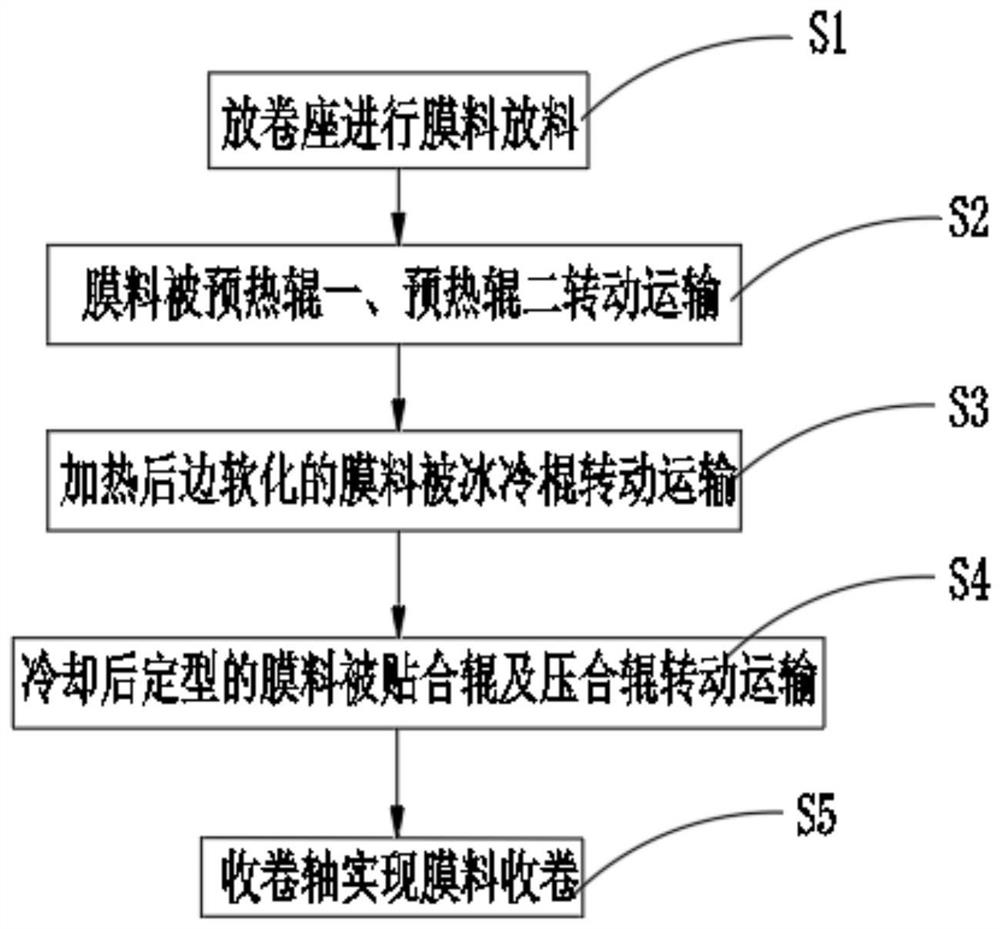

[0059] As an embodiment of the present invention, the first preheating roller 2, the second preheating roller 3 and the ice-cooling roller 5 provide the required power through the motor 4, so that the first preheating roller 2, the second preheating roller 3 and the ice-cold stick 5 rotate synchronously and keep the same speed.

[0060] The first preheating roller 2, the second preheating roller 3 and the roller shafts such as ice-cold roller 5 have the same specifications, which is beneficial to control the rotating speed of the preheating rollers, so that the uniform speed of the film material is the same, and the tension of the film material is reduced.

[0061] As an embodiment of the present invention, the first preheating roller 2, the second preheating roller 3 and the ice-cooling roller 5 are hollow mirror steel rollers with a width of 160 centimeters and a diameter of 300 millimeters. The specifications are consistent, which is conducive to centralized procurement, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com