A weldment anti-deformation device

An anti-deformation and weldment technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low cooling efficiency and weldment stress deformation, and achieve the goal of reducing welding cost, improving welding efficiency and welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

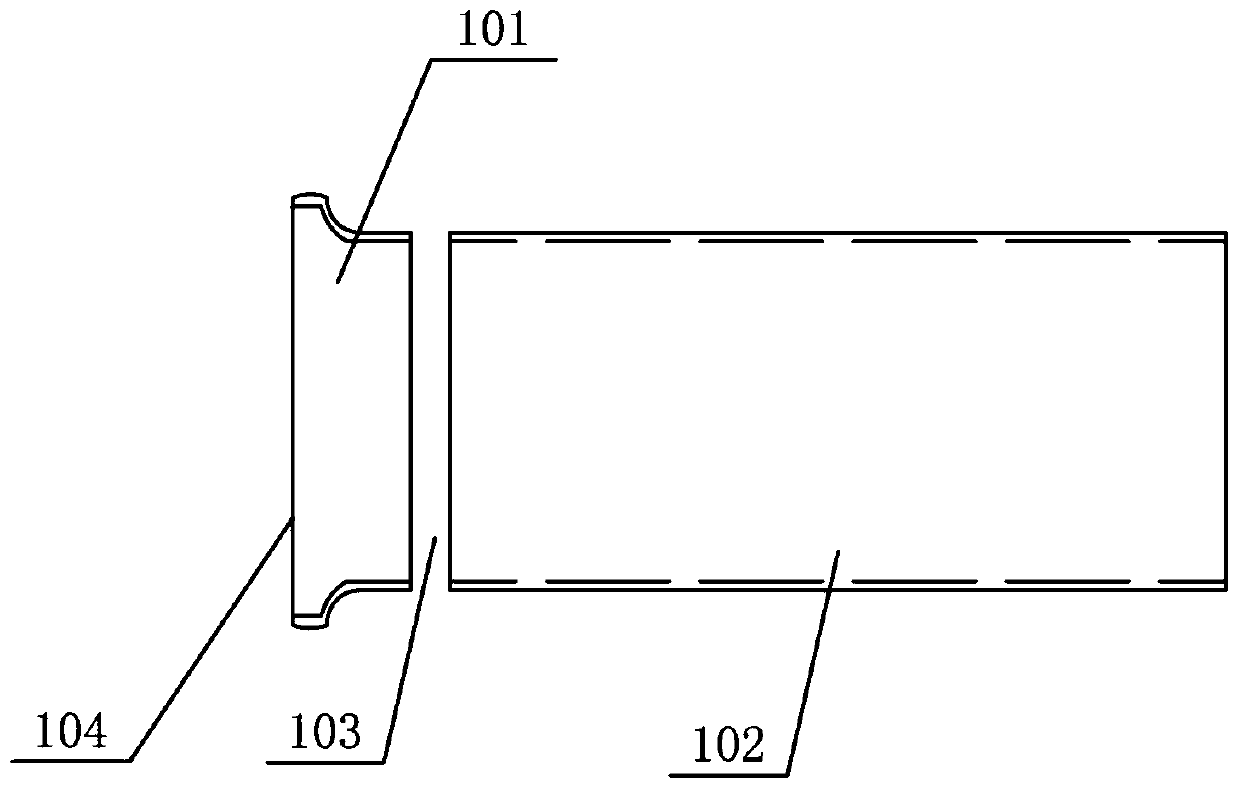

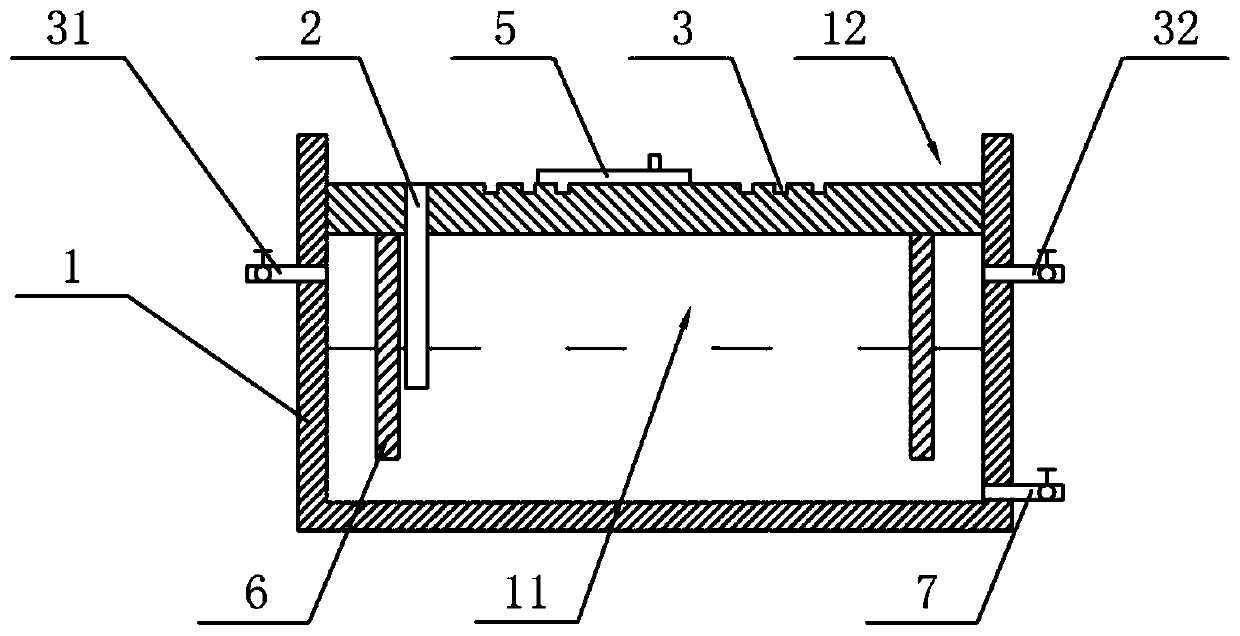

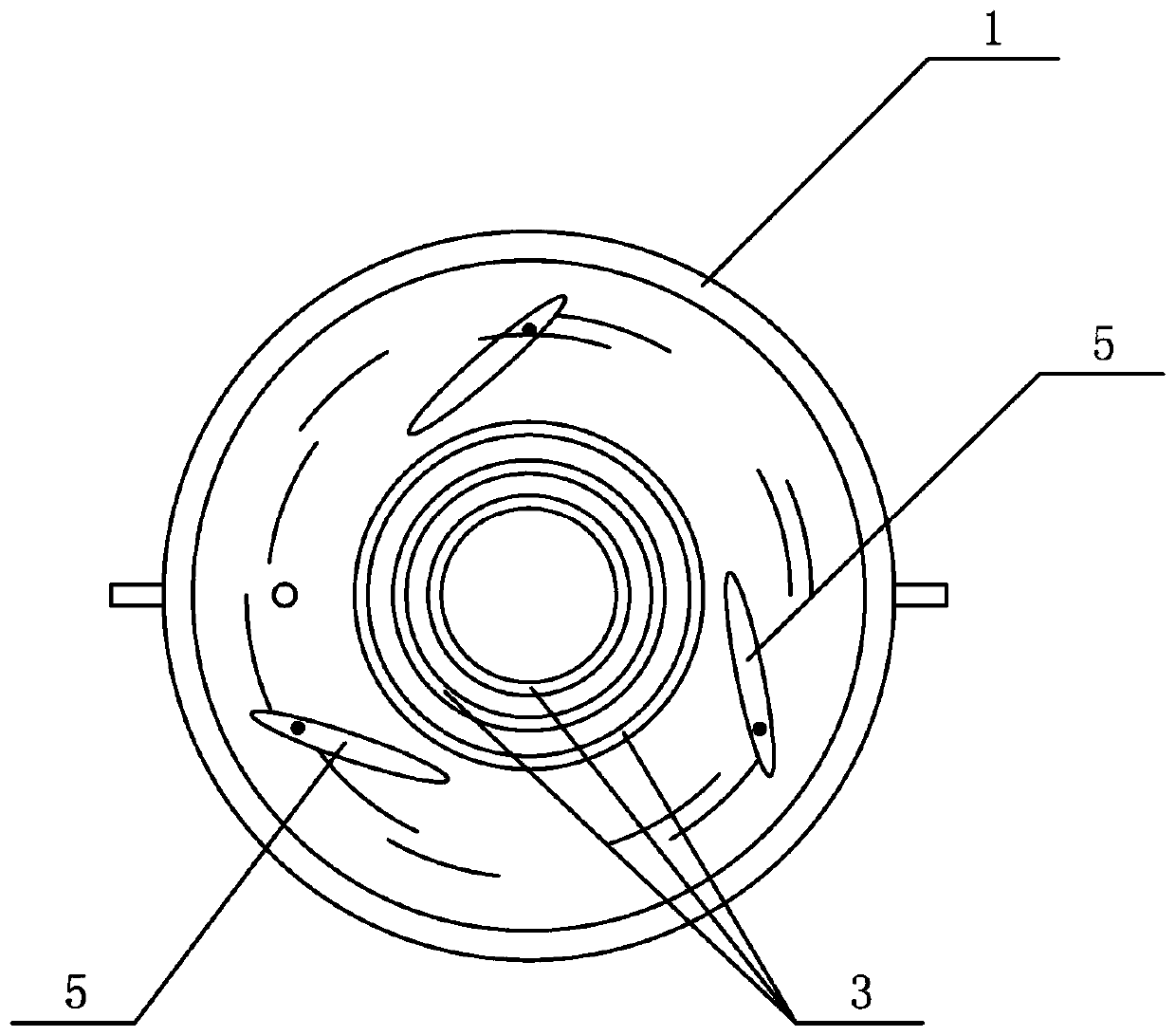

[0032] This embodiment provides a weldment anti-deformation device, such as figure 2 as well as image 3 As shown, the weldment anti-deformation device includes a box body 1, a diversion channel 2, a gas valve, a weldment positioning component and a liquid control valve 7, wherein:

[0033] The box body 1 is provided with a cavity 11 inside, and a groove 12 is arranged at the top, and the weldment is placed in the groove 12, and is welded with other weldments in the groove 12 . Cooling liquid is placed inside the cavity 11 , and the volume of the cooling liquid is no more than two-thirds of the volume of the cavity 11 . In this embodiment, the above-mentioned box body 1 has a cylindrical structure, and the box body 1 is made of metal materials. Of course, the structure of the box body 1 in this embodiment is not limited to a cylindrical shape, and other structures such as a rectangular shape may also be used.

[0034] In this embodiment, one end of the flow guide channel 2...

Embodiment 2

[0048] The difference between the present embodiment and the first embodiment is only that the structure of the diversion channel 2 is different. The present embodiment does not set the cooling liquid conduit and the ring plate 6. For details, please refer to Figure 5 as well as Figure 6 , the guide channel 2 of this embodiment includes a connection plate 21 fixed to the top wall and side wall of the cavity 11, a cavity 24 is formed between the connection plate 21 and the top wall and side wall of the cavity 11, and at the same time A liquid outlet 22 communicating with the chamber 24 is opened on the top wall of the cavity 11 . Specifically, a liquid inlet 23 is provided at the bottom of the connecting plate 21, and the liquid inlet 23 will communicate with the chamber 24 and the cavity 11. When high-pressure gas is input into the cavity 11, the high-pressure gas can make the air The cooling liquid in the cavity 11 flows into the groove 12 through the liquid inlet 23 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com