High-precision multi-layer chip capacitor forming process and capacitor thereof

A multi-layer chip and molding process technology, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems of internal dielectric layering, capacity dispersion, collapse high-frequency characteristics, etc., and achieve good performance consistency , easy to use frequency, low ESL effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

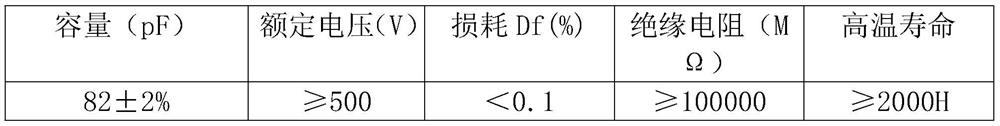

[0041] Design Class I Porcelain High Power Capacitor 1111 BC 820H501NT Products

[0042] 1. Prepare medium slurry suitable for waterfall casting:

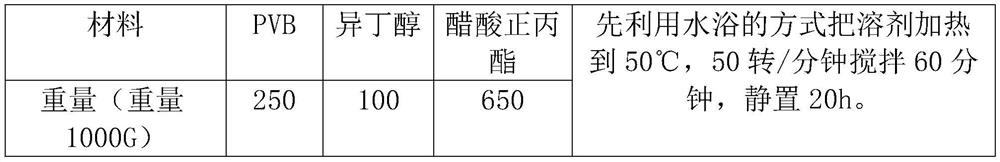

[0043] Prepare Adhesive A

[0044]

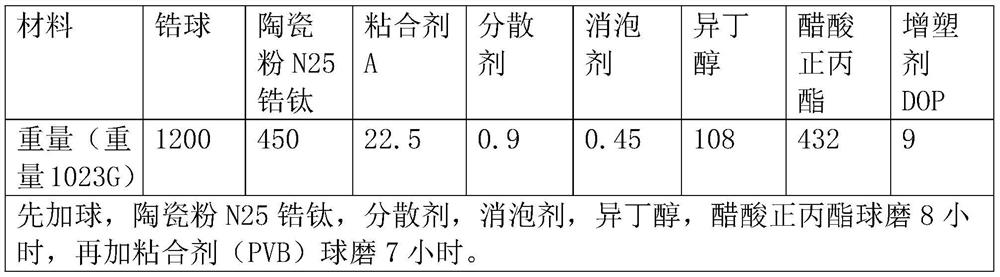

[0045] Select ceramic powder, N25 zirconium titanium and other ceramic materials, the particle size D50 of the ceramic powder is 0.5 μm (using a particle size analyzer).

[0046] Material ball mill dispersion: ball: ceramic powder: solvent = 3:1:1.2, first add ball, ceramic powder, solvent according to this ratio, then add plasticizer, dispersant, defoamer, the amount added is based on the proportion of ceramic powder The ratios are: plasticizer DOP: 2%, dispersant: 0.2%, defoamer: 0.1%. The solvent used is a mixed solvent of n-propyl acetate and isobutanol, and the ratio of n-propyl acetate to isobutanol is 8:2. The balls used were zirconium balls with a diameter of 5.5 mm.

[0047] The first ball mill: After mixing the materials, ball mill at 50 rpm for 7 hours.

[0048] The second bal...

Embodiment 2

[0059] Design Class I Porcelain Capacitor 0805CG102H201NT Products

[0060] 1. Prepare medium slurry suitable for waterfall casting:

[0061] Prepare Adhesive B

[0062]

[0063] Select ceramic powder, ceramic materials such as N25 zirconium titanium, and the particle size D50 of the powder is 0.4 μm (using a particle size analyzer).

[0064] Material ball mill dispersion: ball: ceramic powder: solvent = 3:1:1.1, first add ball, ceramic powder, solvent according to this ratio, then add plasticizer, dispersant, defoamer, the amount added is based on the proportion of ceramic powder The ratios are: plasticizer DOP: 1.5%, dispersant: 0.1%, defoamer: 0.1%. The solvent used is a mixed solvent of n-propyl acetate and isobutanol, and the ratio of n-propyl acetate to isobutanol is 7:1. The balls used were zirconium balls with a diameter of 5.5 mm.

[0065] The first ball mill: After mixing the materials, ball mill for 7 hours under the condition of 50 rpm.

[0066] The second ...

Embodiment 3

[0078] Design Class II Porcelain Capacitor 1206B104K631NT Products

[0079] 1. Prepare medium slurry suitable for waterfall casting:

[0080] Prepared Adhesive C

[0081]

[0082] Select ceramic powder, GN262 barium titanate and other ceramic materials, and the particle size D50 of the powder is 0.6 μm (using a particle size analyzer).

[0083] Material ball milling dispersion: ball: ceramic powder: solvent = 3:1:1.0, first add ball, ceramic powder, solvent according to this ratio, then add plasticizer, dispersant, defoamer, the amount added is based on the proportion of ceramic powder The ratios are: plasticizer DOP: 2.5%, dispersant: 0.3%, defoamer: 0.1%. The solvent used is a mixed solvent of n-propyl acetate and isobutanol, and the ratio of n-propyl acetate to isobutanol is 6:1. The balls used were zirconium balls with a diameter of 6.5 mm.

[0084] The first ball mill: After mixing the materials, ball mill at 50 rpm for 5 hours.

[0085] The second ball mill: Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com