Integrated photovoltaic module production process

A photovoltaic module and production process technology, applied in photovoltaic power generation, photovoltaic modules, semiconductor devices, etc., can solve the problems of solar cell output power decline, inaccurate light irradiation, and poor heat dissipation effect, so as to facilitate popularization and use, Solve the effect of heat generation and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

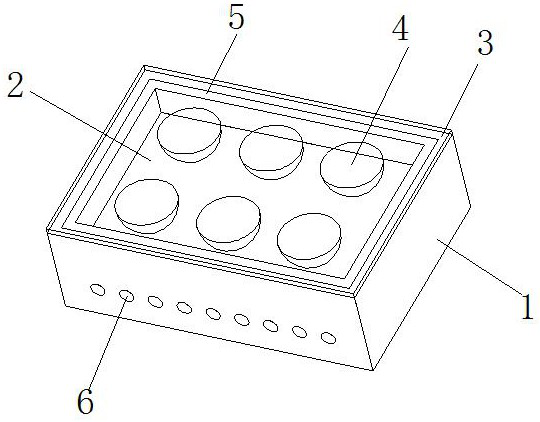

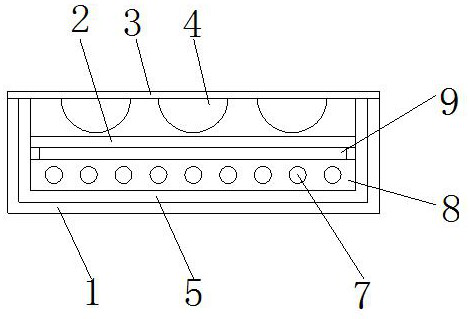

[0030] see Figure 1-5 , the present invention provides a technical solution: an integrated photovoltaic module, including an outer protective frame 1, a photovoltaic panel 2 and a transparent tempered glass 3, the inner side of the outer protective frame 1 is fixedly installed with a heat insulation layer 5, and the inner cavity of the outer protective frame 1 A heat-absorbing box 8 is fixedly installed at the bottom, a heat-conducting block 9 is fixedly installed inside the top wall of the heat-absorbing box 8 , and a plurality of converging convex lenses 4 are fixedly installed at the bottom of the transparent tempered glass 3 .

[0031] Photovoltaic panel 2 includes a back plate 201, inside the back plate 201 is fixedly installed with a heat conduction plate 202, on the top of the back plate 201 is fixedly installed with a limit frame 203, inside the limit frame 203 is bonded with a lower EVA film 204, the lower EVA film 204 The side away from the back plate 201 is bonded ...

Embodiment 2

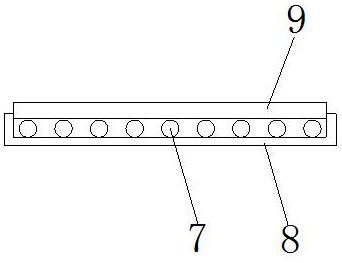

[0034] see Figure 1-5On the basis of Embodiment 1, the present invention provides a technical solution: the front and back of the outer protective frame 1 and the heat insulation layer 5 are provided with first cooling holes 6, and the front and back of the heat absorption box 8 are provided with The second cooling hole 7, the first cooling hole 6 and the second cooling hole 7 are multiple, and the positions of the first cooling hole 6 and the second cooling hole 7 are corresponding, and the back plate 201 is glued on the top of the heat conduction block 9 , the size of the heat conduction plate 202 is smaller than the size of the heat conduction block 9 , and the heat conduction plate 202 is in contact with the heat conduction block 9 .

[0035] In this embodiment, the heat generated by the photovoltaic panel 2 can be absorbed by setting the heat absorption box 8, the heat conduction block 9 and the heat conduction plate 202, and the first cooling hole 6 on the front side of...

Embodiment 3

[0037] see Figure 1-5 , on the basis of Embodiment 1, Embodiment 2, and Embodiment 3, the present invention provides a technical solution: transparent tempered glass 3 is bonded to the top of the outer protective frame 1, and a plurality of converging convex lenses 4 are located at the top of the outer protective frame 1 internal.

[0038] In this embodiment, by installing a plurality of converging convex lenses 4 at the bottom of the transparent tempered glass 3, a light concentrating layer composed of a plurality of concentrating convex lenses 4 can be formed between the transparent tempered glass 3 and the photovoltaic panel 2, regardless of the sunlight From which direction the condensing convex lens 4 is irradiated, the condensing convex lens 4 can refract and condense the light well, so that the light can be accurately irradiated on the top of the photovoltaic panel 2, and there is no need to change the photovoltaic panel 2 frequently in order to track the sun The orie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com