Hydraulic cooling system and construction machinery with same

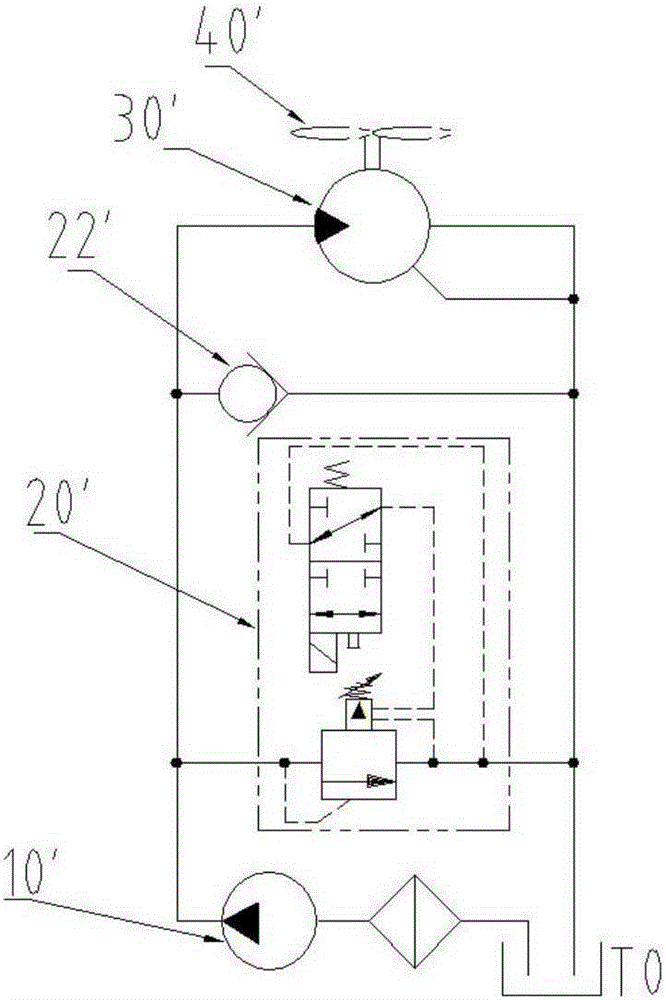

A cooling system and hydraulic technology, applied in the direction of fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve the problems of high heat generation in the system, inability to cool on demand, and inability to control the flow rate of the quantitative motor 30', etc. , to achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

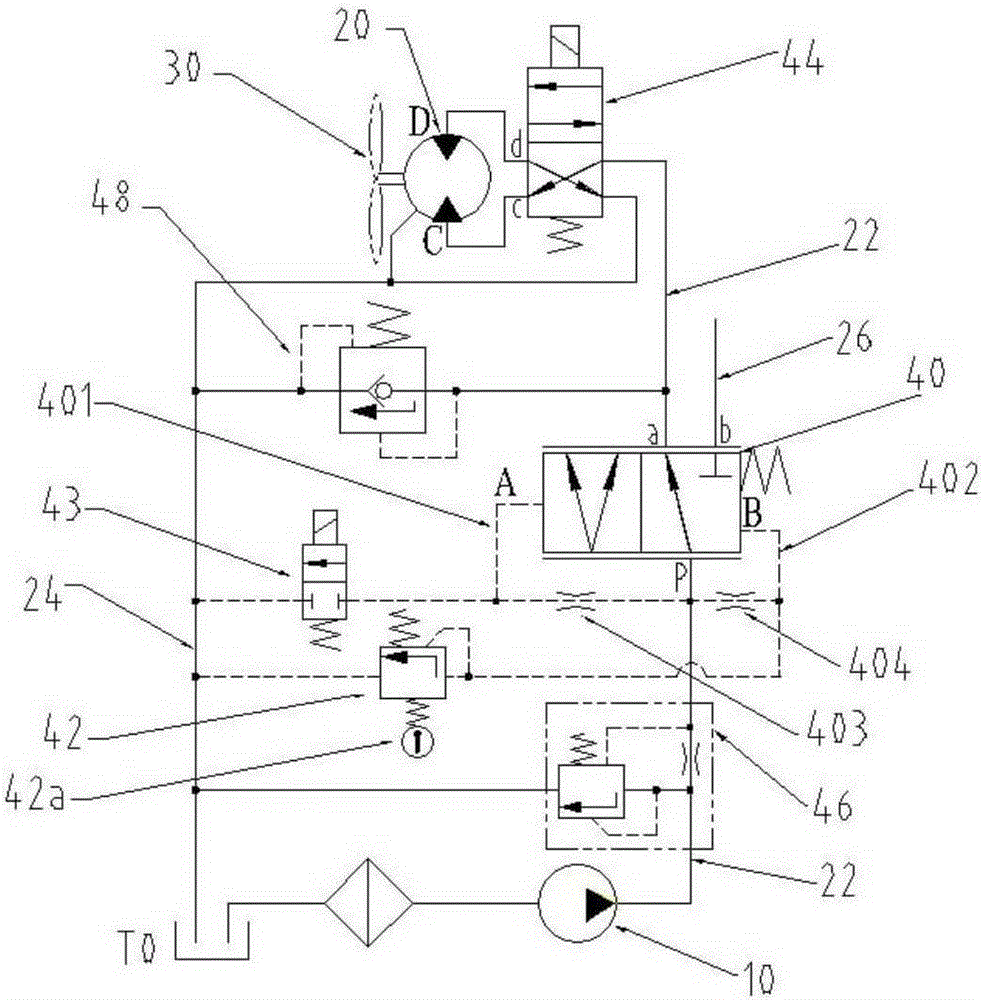

[0025] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

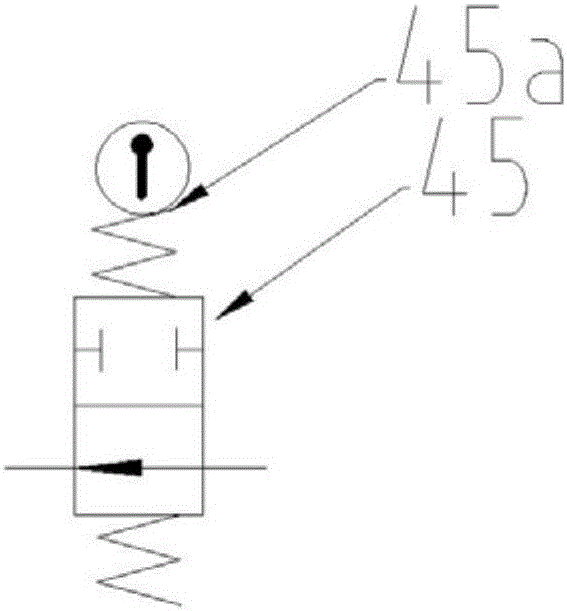

[0026] The embodiment of the present invention provides a hydraulic cooling system, which includes a pump 10, a cooling motor 20, a cooling fan 30 driven and operated by the cooling motor 20, and an oil inlet oil passage 22 connected between the cooling motor 20 and an oil outlet of the pump 10 And an oil return oil path 24 connected between the cooling motor 20 and the oil tank T0. The oil inlet oil path 22 is provided with a hydraulic control reversing valve 40 with an adjustable spool opening, the hydraulic control reversing valve 40 It includes a hydraulic control end A and a hydraulic control end B at opposite ends thereof, an oil inlet P communicated with the pump 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com