High-speed train cooling device

A technology for high-speed EMUs and cooling devices, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of numerous auxiliary structures, high maintenance costs, inconvenient installation and disassembly, etc., to reduce maintenance costs, maintenance efficiency, and maintenance costs , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

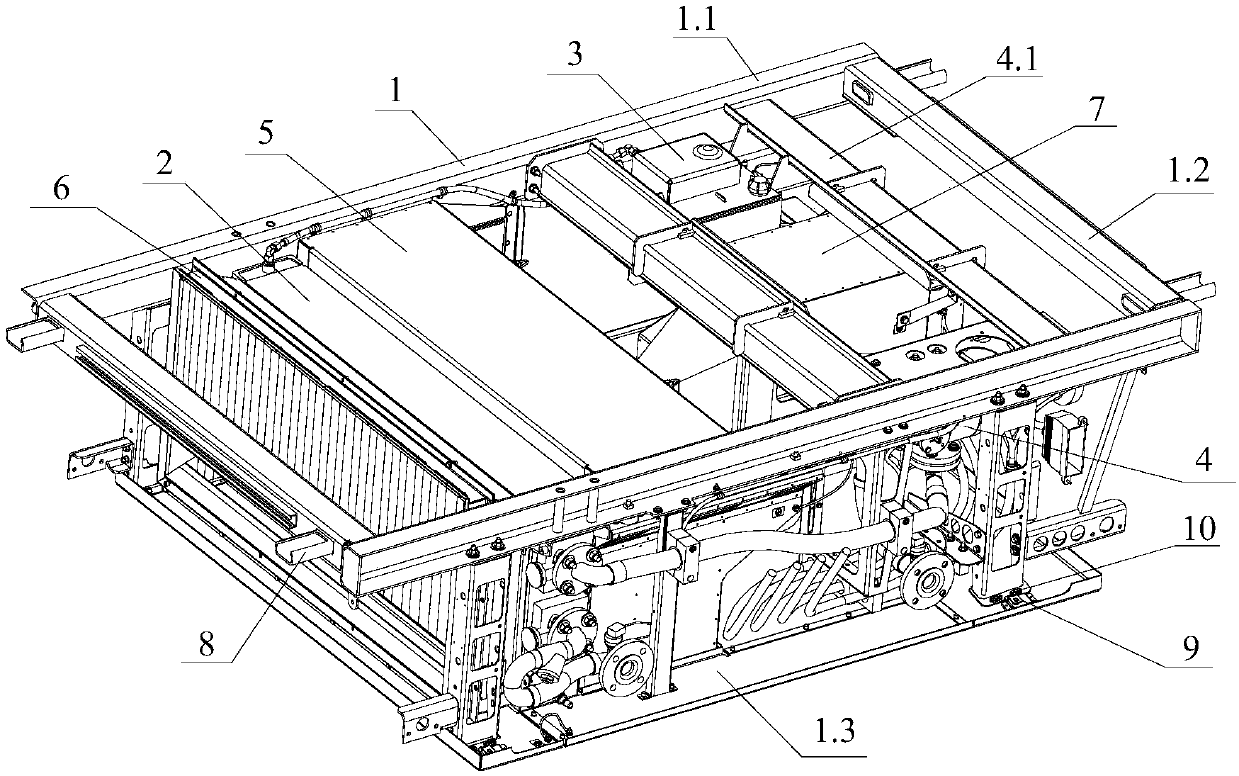

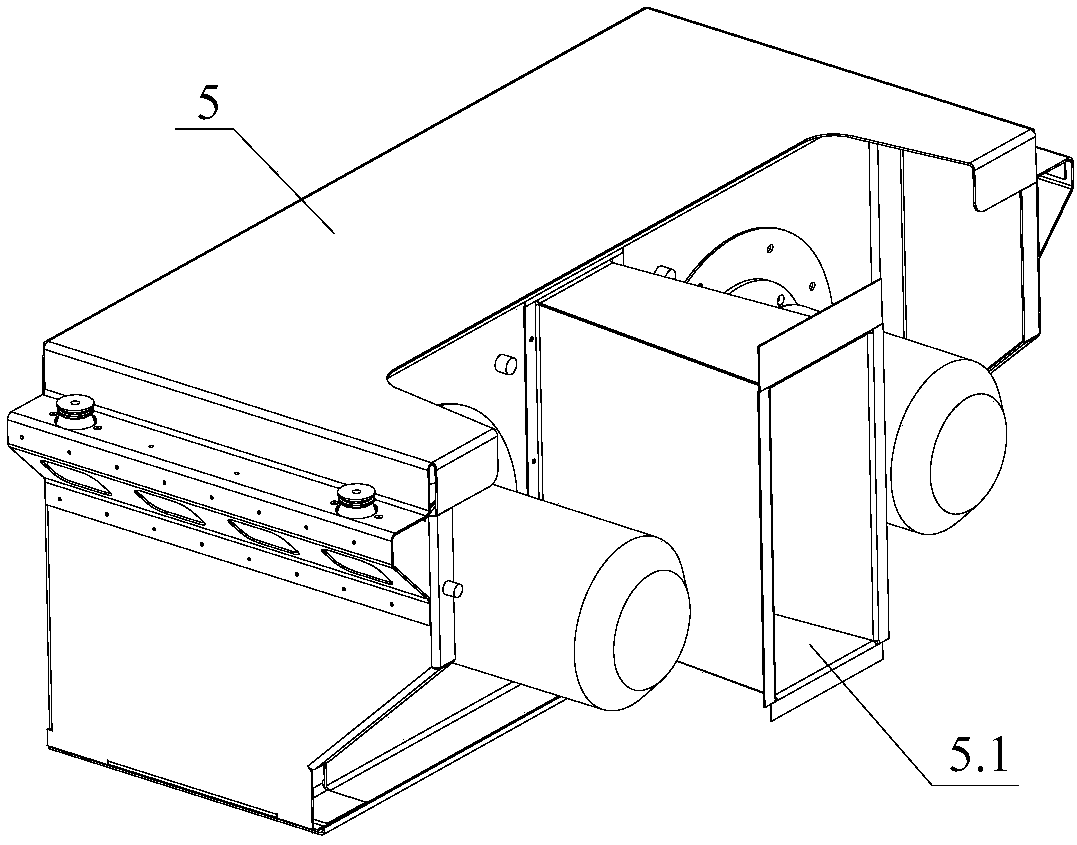

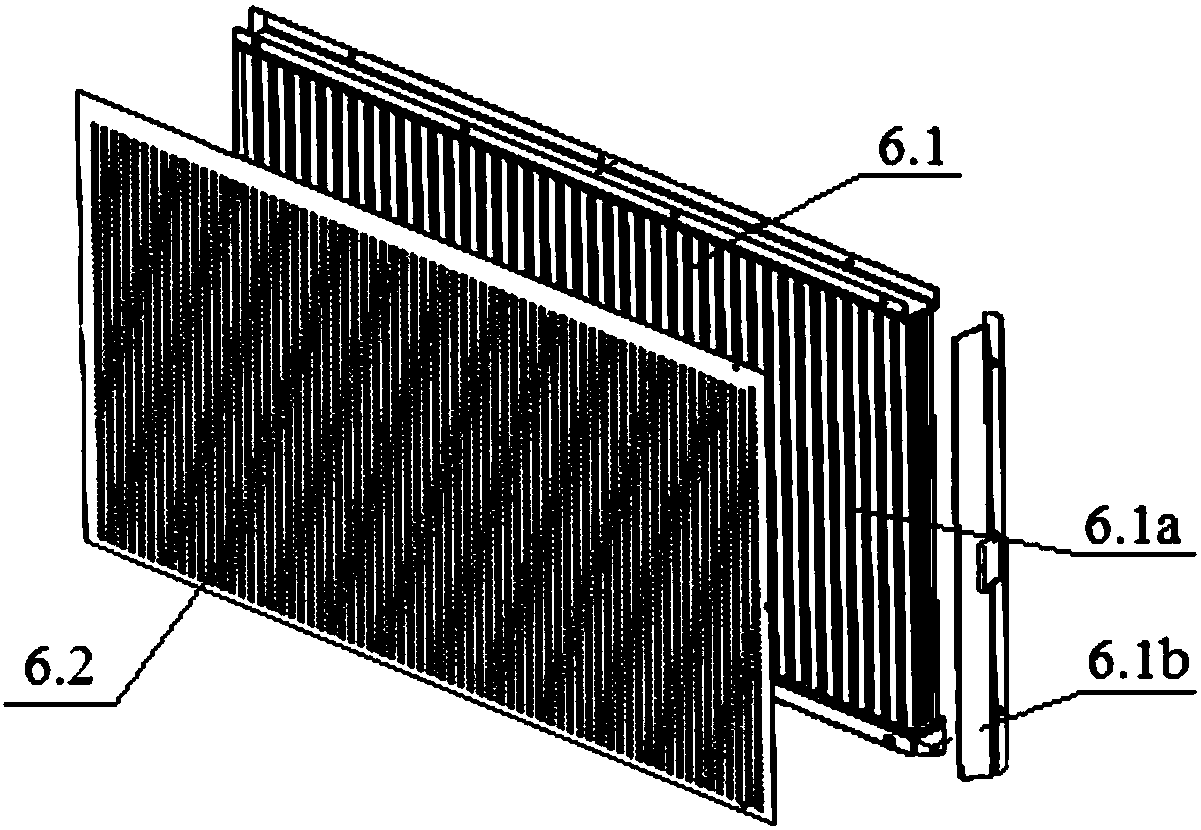

[0024] see Figure 1 to Figure 5 , a high-speed EMU cooling device of the present invention includes a mounting frame 1, a water-cooling assembly 2 and an air-cooling assembly 3, and the water-cooling assembly 2 is arranged on the mounting frame.

[0025] The installation frame 1 includes two top longitudinal beams 1.1, multiple top beams 1.2, bottom plate 1.3 and multiple columns, the top longitudinal beams, top beams and columns are all welded and connected, and the columns and the bottom plate are detachable through anti-off locks arranged at the four corners of the bottom plate connect. The cooling device is suspended on the bottom of the EMU car body through the bottom mount 8.

[0026] The water-cooling assembly includes a heat exchanger 2, an expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com