A temperature control system and its temperature control method and tensile strength testing device

A technology of temperature control system and testing device, which is applied in the direction of measuring device, strength characteristics, and the use of stable tension/pressure test material strength, etc., which can solve problems such as incompleteness and low heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

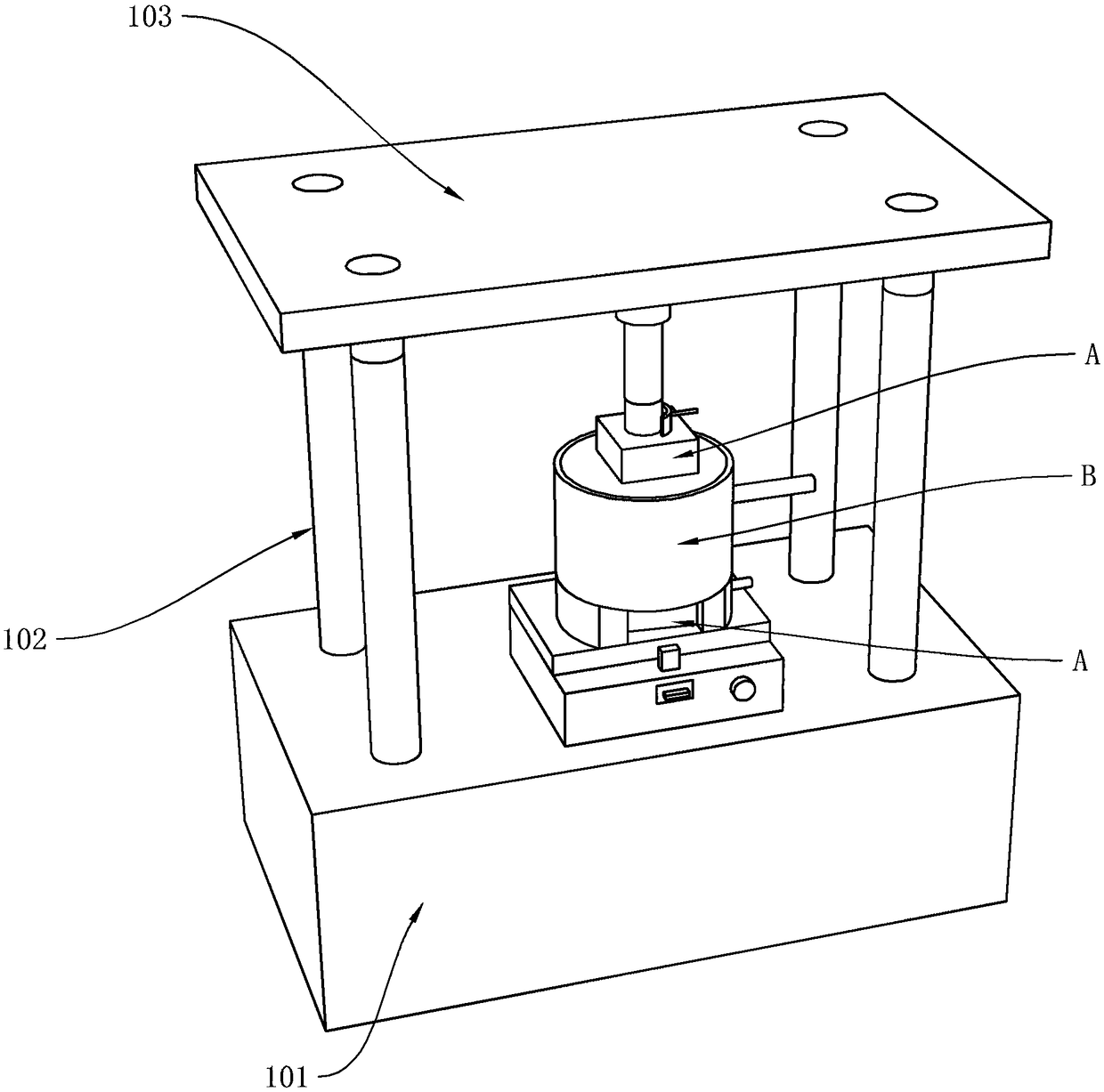

[0116] see figure 1 , a rock tensile strength testing device capable of adding confining pressure, comprising a base 101, the base 101 is connected to a top plate 103 through a connecting rod 102;

[0117] The test component B is fixed on the base 101 , the loading cylinder B100 is fixed on the top plate 103 , and the loading rod B101 of the loading cylinder B100 extends into the test component B.

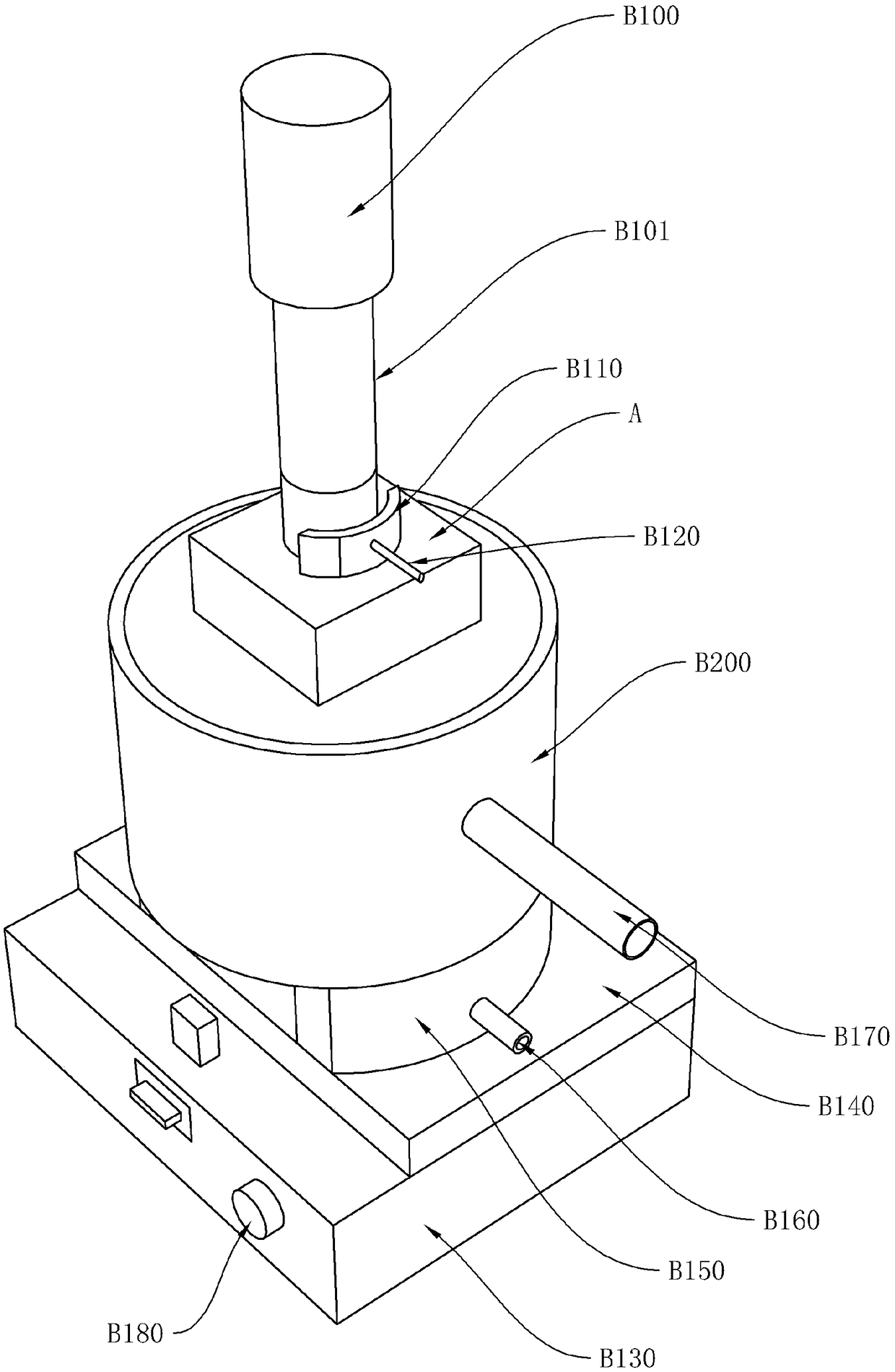

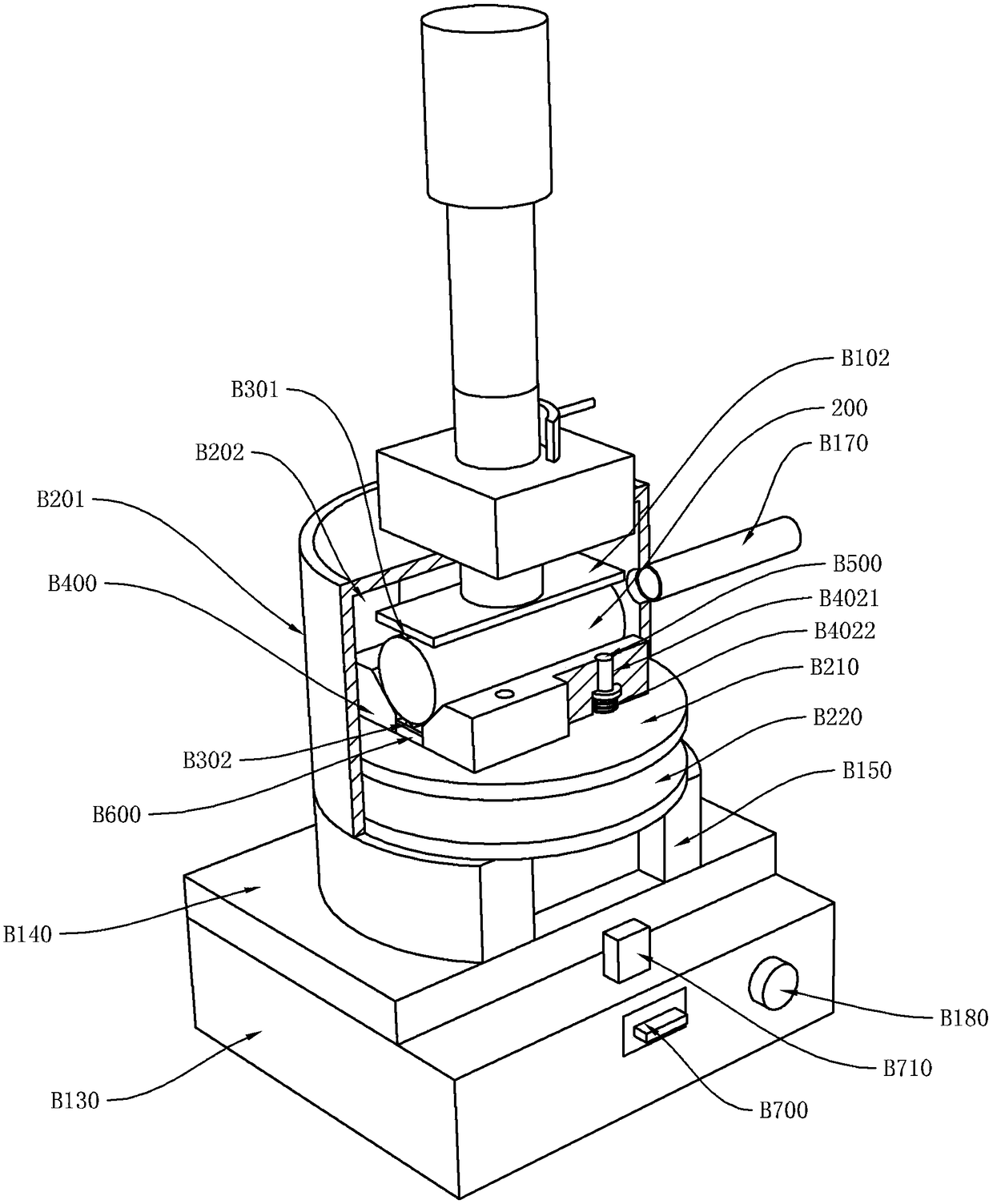

[0118] see Figure 2-Figure 12 , the test assembly B includes, a cylinder assembly B200, a first bracket B130, a second bracket B140, and a connecting column B150;

[0119] The first bracket B130 is fixed on the base 101, the second bracket B140 is fixed on the top surface of the first bracket B130, and the connecting column B150 is fixed on the top surface of the second bracket B140, The top surface of the connecting column B150 is connected and fixed to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com