Integrated wall heat exchange device

A heat exchange device and an integrated technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of high discharge temperature of safety chimneys, affecting material hygiene and quality, discounting service life, etc., achieve compact structure, improve circling Speed, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

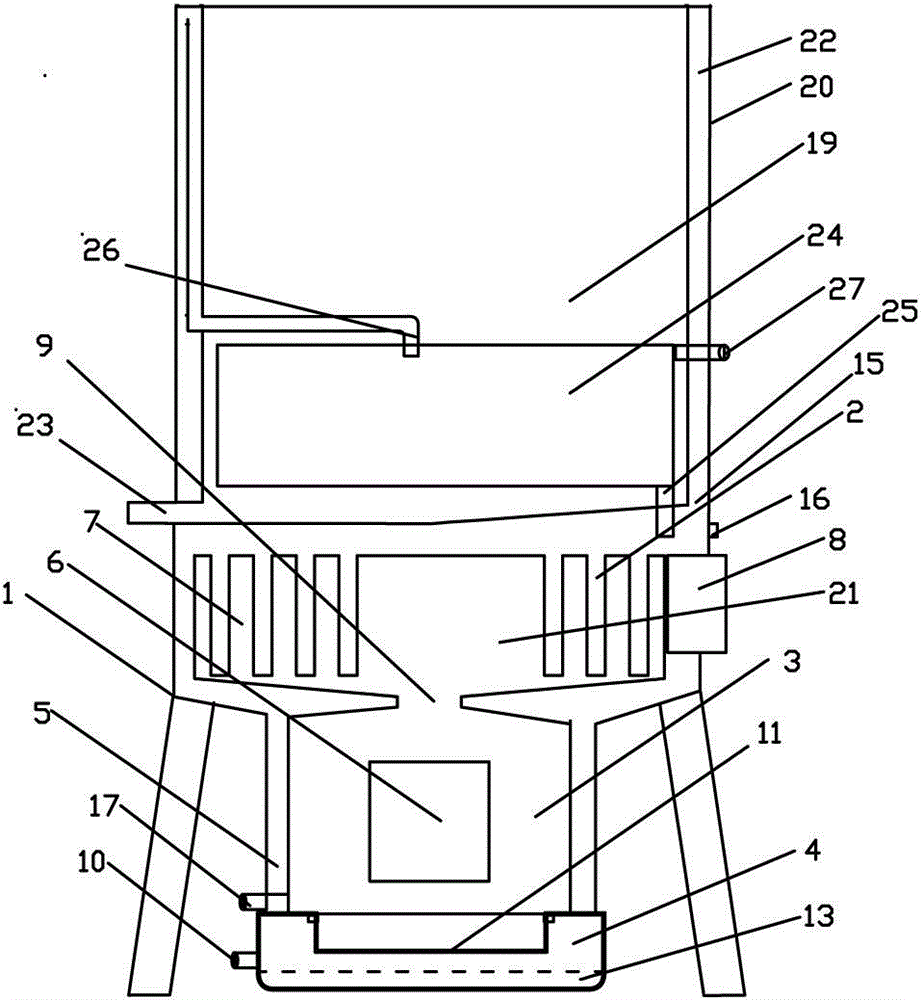

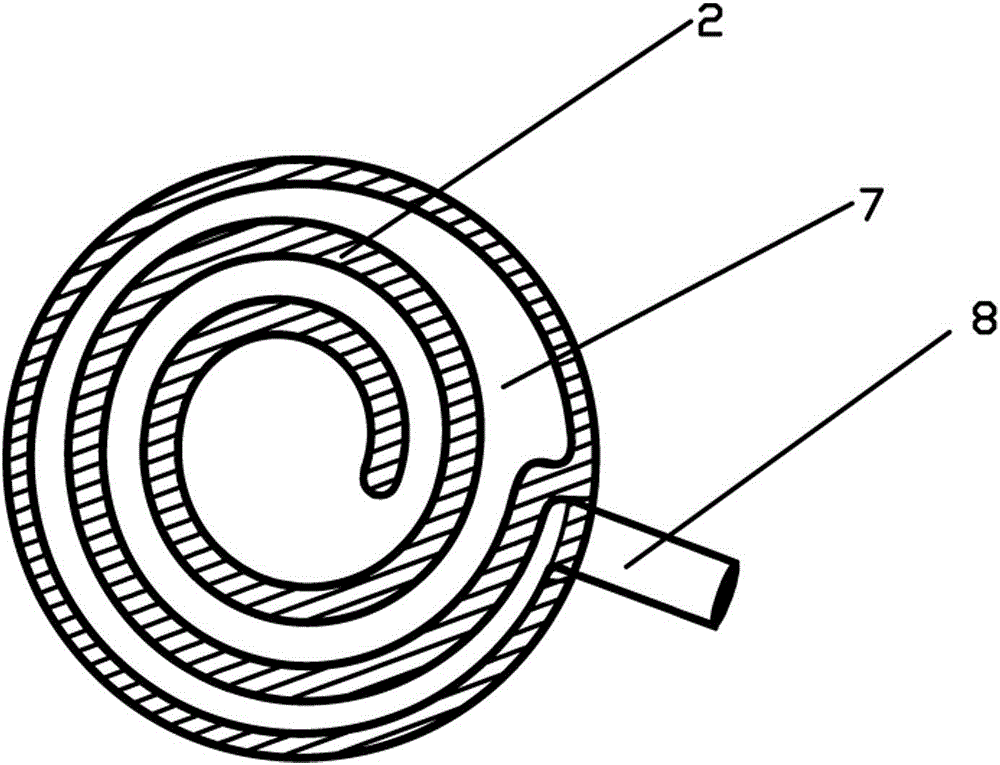

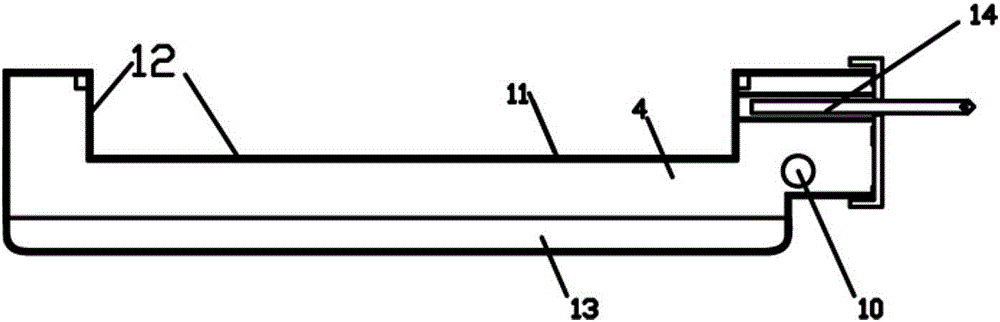

[0015] Such as figure 1 , figure 2 As shown, this embodiment is an integrated partition heat exchange device, which includes an inner pot body 19 with a material discharge port 23 at the bottom, an outer pot body 20 located outside the inner pot body, and a steam generator placed under the inner pot body twenty one. The outer pot body 2 is provided with a steam annular channel 22, the bottom of the inner pot body 19 is provided with a heat exchange member 24, the heat exchange member 24 is provided with a steam inlet 26 communicating with the outer pot body, and the lower part of the heat exchange member 24 is provided with a waste liquid discharge port 25. An air inlet and outlet 27 is provided on the upper part of the heat exchange component. The steam generating furnace includes a furnace body 1 , an inner container 2 with a single-channel spiral plate structure, a combustion chamber 3 located below the inner container 2 and an air inlet device 4 located below the combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com