A hanger for easy adjustment of parts during assembly

A technology for parts and hangers, applied in the field of mechanical processing, can solve the problems of inability to disassemble and meet the requirements of use, and achieve the effect of preventing the workpiece from falling off, facilitating automatic disassembly and assembly, and realizing convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

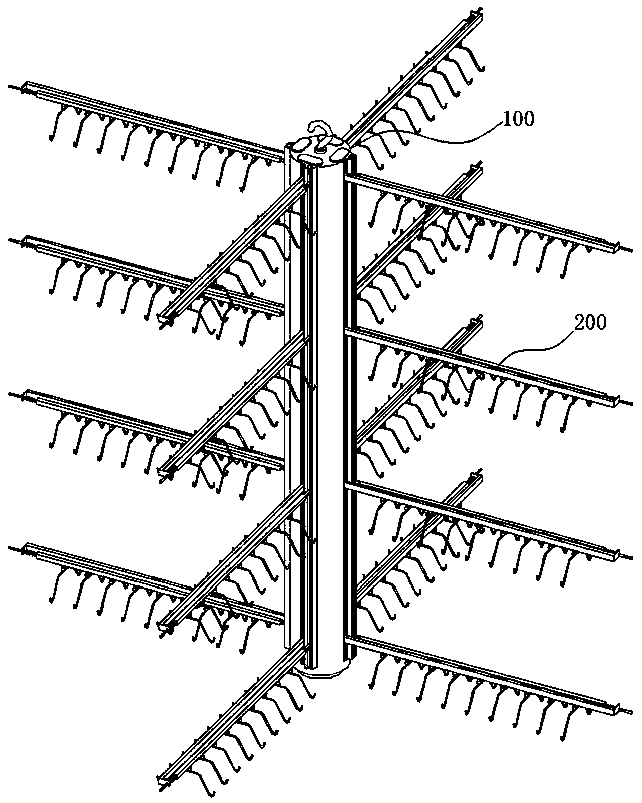

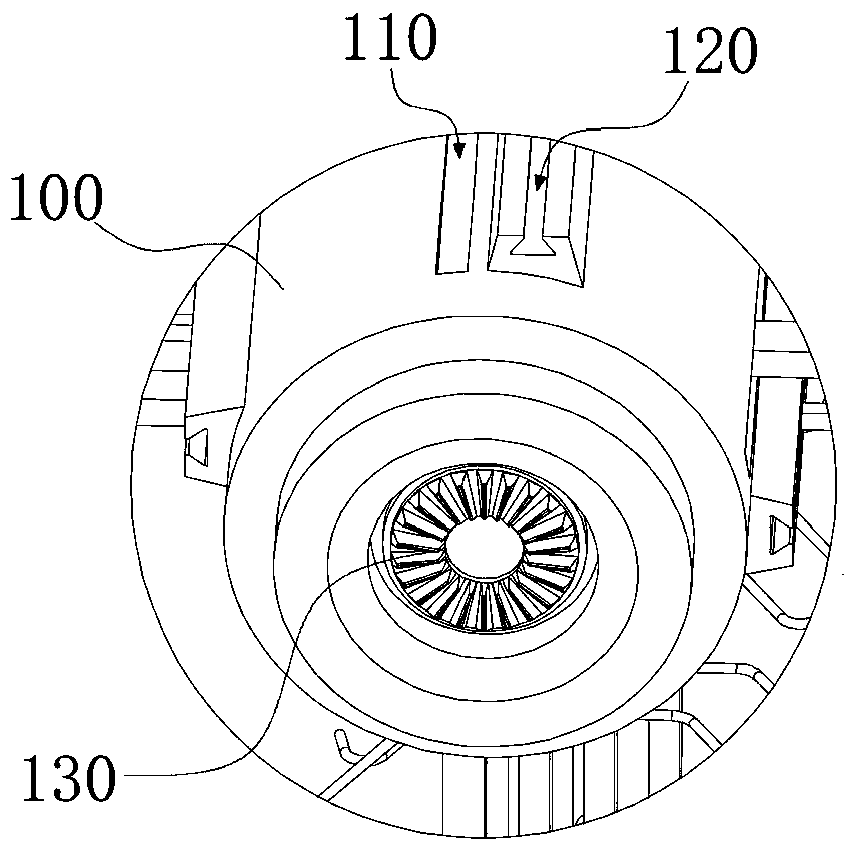

[0040] refer to Figure 1-5 , in the embodiment of the present invention, a hanger that is convenient for adjusting parts during assembly is proposed, including a hook 300, a hanger 200 and a hanger main body 100, the hook 300 is installed on the hanger 200, and the hook 300 is used for hanging The workpiece, the hanger 200 is detachably installed on the hanger main body 100 , and the hanger main body 100 is used to support the hanger 200 .

[0041] The present invention divides the step of hooking the workpiece into two steps through the setting of the split hanger 200 and the hanger main body 100. In the first step, each hanger 200 is first hung on the workpiece, and then each hanger 200 is assembled. On the main body 100 of the hanger, the action is clear, which is convenient for automatic hooking of workpieces. At the same time, the main body 100 of the hanger can integrate multiple sets of hangers 200, which greatly improves the loading capacity and can provide stable sup...

Embodiment 2

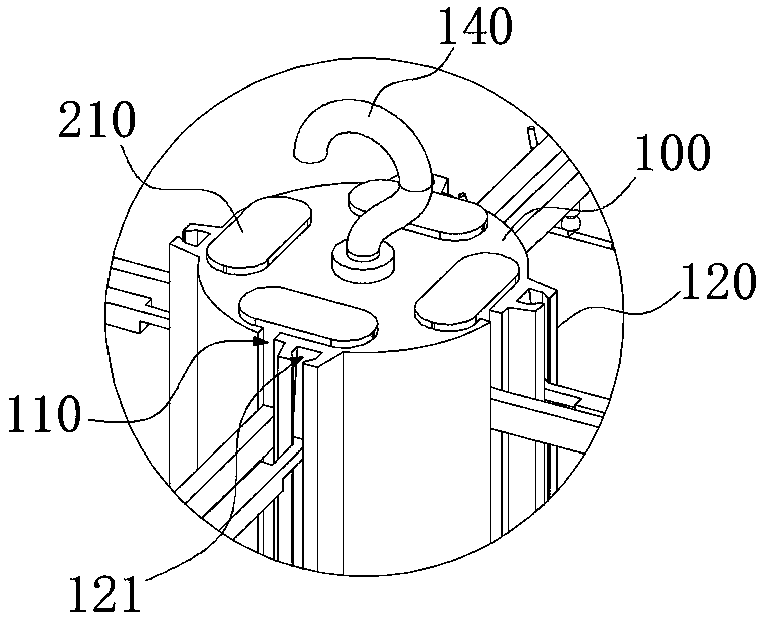

[0065] refer to Figure 4~6 , according to a hanger that is convenient for adjusting parts during assembly proposed by the present invention, a shot blasting machine hanger is proposed in the embodiment of the present invention, including a support rod 210, a fixed rod 220, a movable rod 230 and a hook 300, The fixed rod 220 is installed on the support rod 210, the support rod 210 and the fixed rod 220 are arranged crosswise, the fixed rod 220 and the movable rod 230 are correspondingly arranged in parallel, the hook 300 is movably connected to the fixed rod 220 and the movable rod 230, and the hook 300 is used to mount the workpiece , the movable rod 230 is used to drive the hook 300 to rotate, so that the projection length of the hook 300 on a vertical plane is adjustable, and the vertical plane is perpendicular to the fixed rod 220 .

[0066] The present invention realizes the supporting function to the fixed rod 220 and the hook 300 through the setting of the support rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com