Spring spray quenching system, working method thereof and prepared spring

A technology of quenching system and quenching oil, which is applied in the field of metal processing, can solve the problems affecting the performance of springs and the deviation of quenching effect, and achieve the effect of uniform spray quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

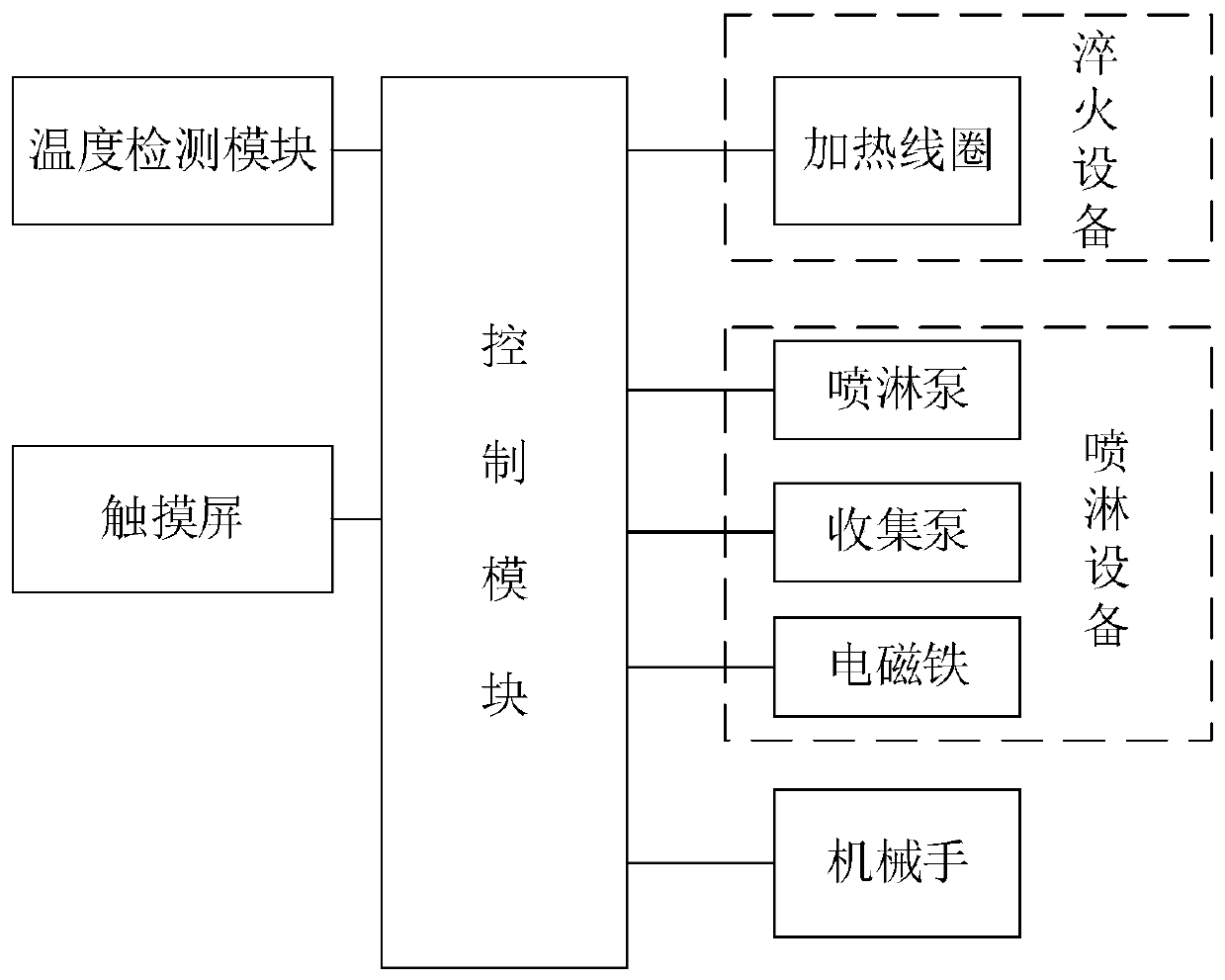

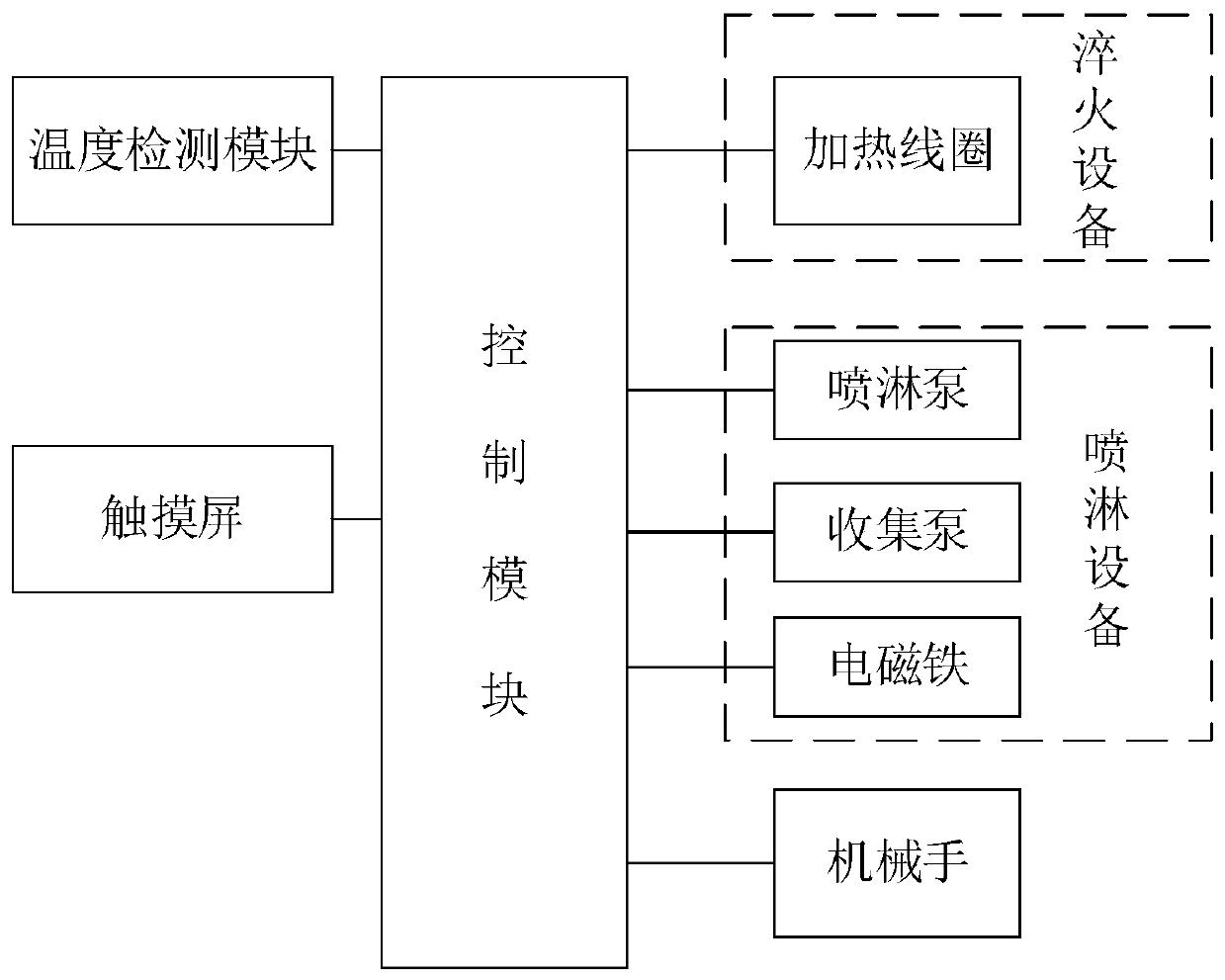

[0026] figure 1 It is the principle block diagram of the spring spray quenching system of the present invention.

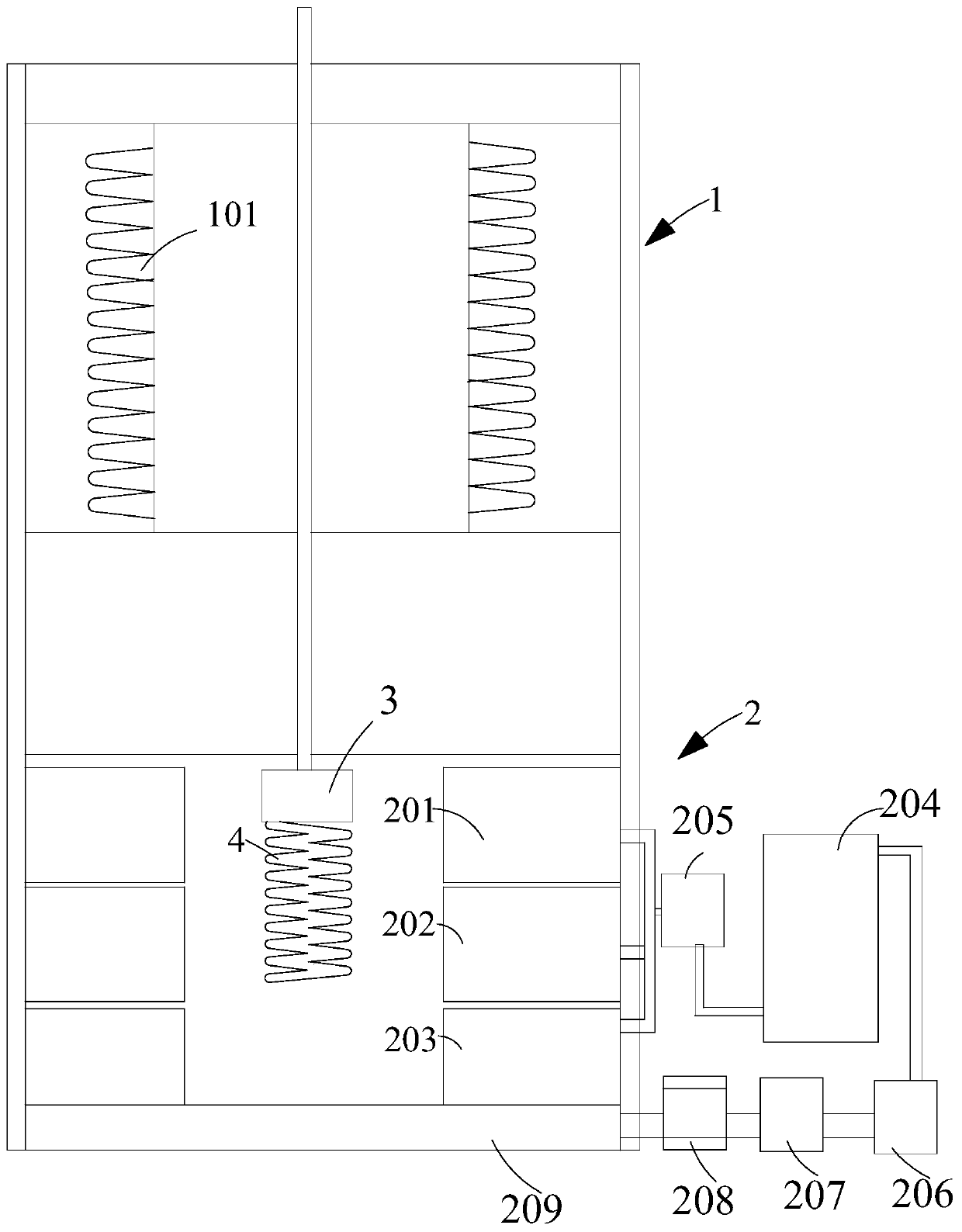

[0027] figure 2 It is a structural schematic diagram of the spring spray quenching system of the present invention.

[0028] Such as figure 1 with figure 2 As shown, this embodiment provides a spring spray quenching system, including: a heating device 1, a spray device 2, a manipulator 3 and a control module, wherein the control module is suitable for driving the manipulator 3 to send the spring 4 to be quenched to the heating device 1 for heating; after the heating device 1 finishes heating, the control module drives the manipulator 3 to send the heated spring 4 to the inside of the spray device 2, and then controls the spray device 2 to spray quenching oil to the spring 4 to quench Spring 4; the spring 4 is heated by the heating device 1, and then the quenching oil is sprayed by the uniform spray device 2, so as to realize the technical effect of uniform q...

Embodiment 2

[0038] On the basis of Example 1, this embodiment provides a spring 4, which is suitable for the preparation of the above-mentioned spray quenching system; the spring 4 prepared by spraying in the above-mentioned manner, the upper, middle and lower parts of the spring It can be uniformly quenched, and the quenching time is kept consistent, which can improve the elastic performance of the spring 4 .

Embodiment 3

[0040] On the basis of Embodiment 1, this embodiment provides a working method of the spray quenching system, including: driving the manipulator 3 through the control module to send the spring 4 to be quenched to the heating device 1 for heating; After heating, the control module drives the manipulator 3 to send the heated spring 4 to the inside of the spray device 2, and then controls the spray device 2 to spray quenching oil to the spring 4 to quench the spring 4; the spring 4 is quenched by spraying, The quenching time of each part of the spring 4 is consistent, which can improve the elastic performance of the spring 4 .

[0041] In summary, the present invention provides a spring spray quenching system and its working method. After the spring 4 to be quenched is heated to the quenching temperature by the heating coil 101 of the heating device 1, the manipulator 3 sends the spring 4 to the spray The device 2 sprays the quenching oil in the oil storage tank 204 to the heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com