Spray quenching unit

A technology of quenching device and spray chamber, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of explosion, pressure increase, loss of human resources and property, etc., achieve uniform spray quenching, reasonable overall structure, and reduce investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

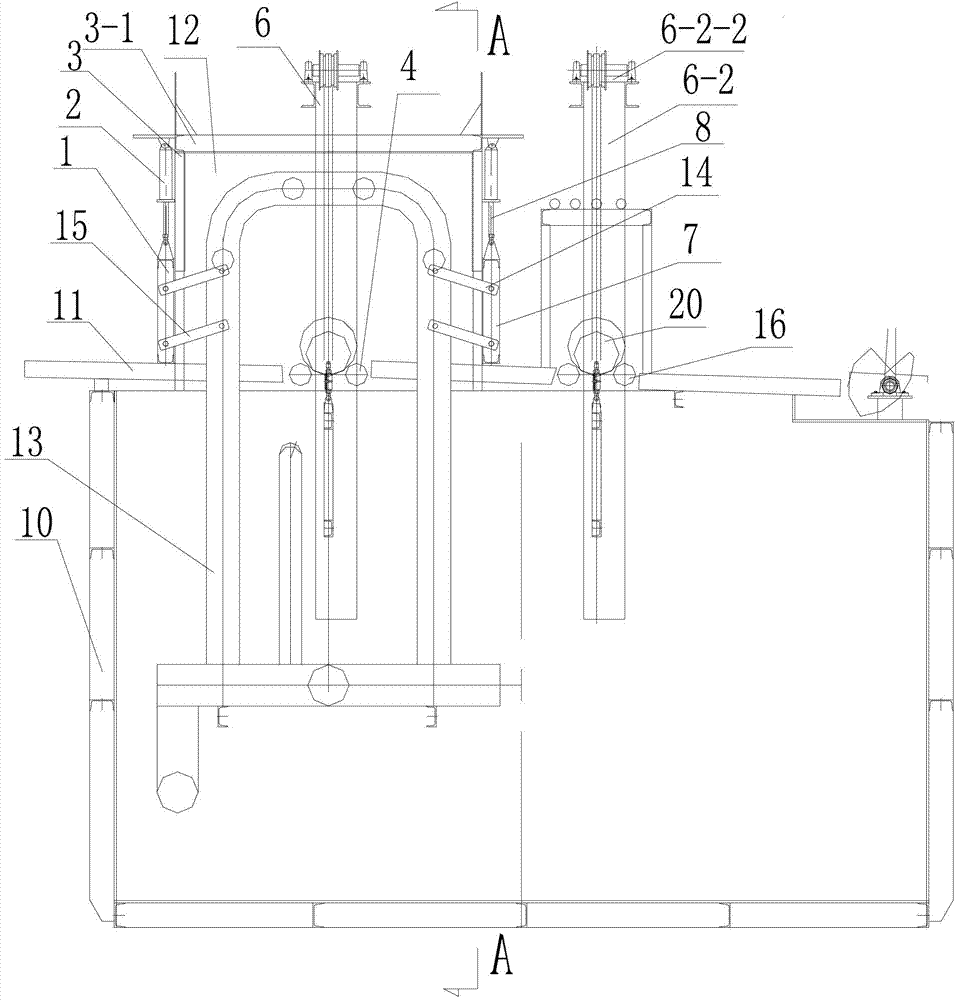

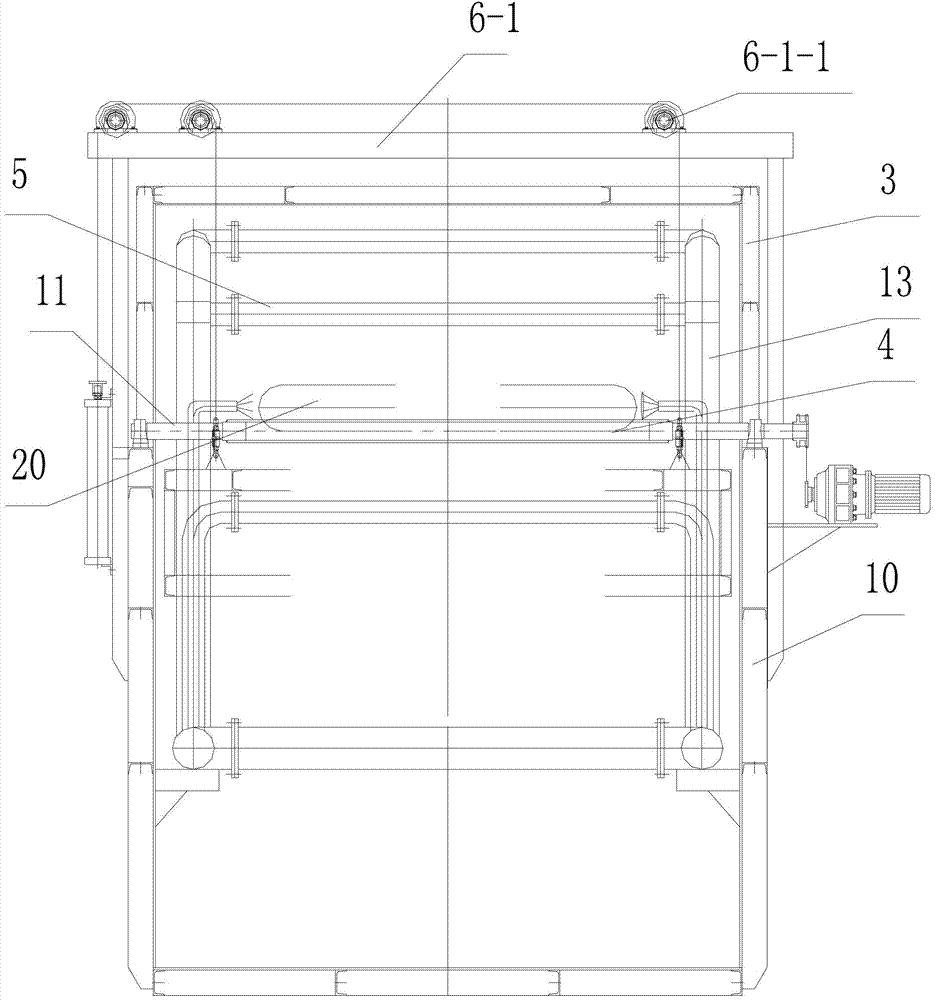

[0014] combined with figure 1 , figure 2 The present invention is further described:

[0015] A kind of spray quenching device of the present invention, its structure is: comprise quenching water tank 10, be arranged on three sliding slant plates 11 above quenching water tank 10, slide slant plate 11 is used for supporting quenching workpiece, the slant of sliding slant plate The degree of design requirement is as long as the workpiece can roll on the swash plate 11. Two rotating rollers 4 that are rotatably connected to the quenching water tank 10 are also arranged between every two adjacent sliding swash plates 11 . A cavity that can support the workpiece is formed between the two rotating rollers 4 ; A spray chamber 3 is also arranged above the swash plate 11 , the quenching water tank 10 communicates with the spray chamber 3 and a spray quenching cavity 12 is formed between the quenching water tank 10 and the spray chamber 3 . In the spray quenching cavity 12 , two sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com