Lifting-type spray quenching machine tool for large thin-walled cylinder

A technology of thin-walled cylinder and lifting type, which is applied in the direction of quenching device, furnace type, heat treatment equipment, etc., can solve the problems of long working hours, poor workpiece adaptability, high investment cost, etc., to reduce deformation, realize height adjustment, improve The effect of heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Refer to the attached Figure 1-7 The specific implementation of the large-scale thin-wall cylinder lifting spray quenching machine tool described in the present invention will be described in detail.

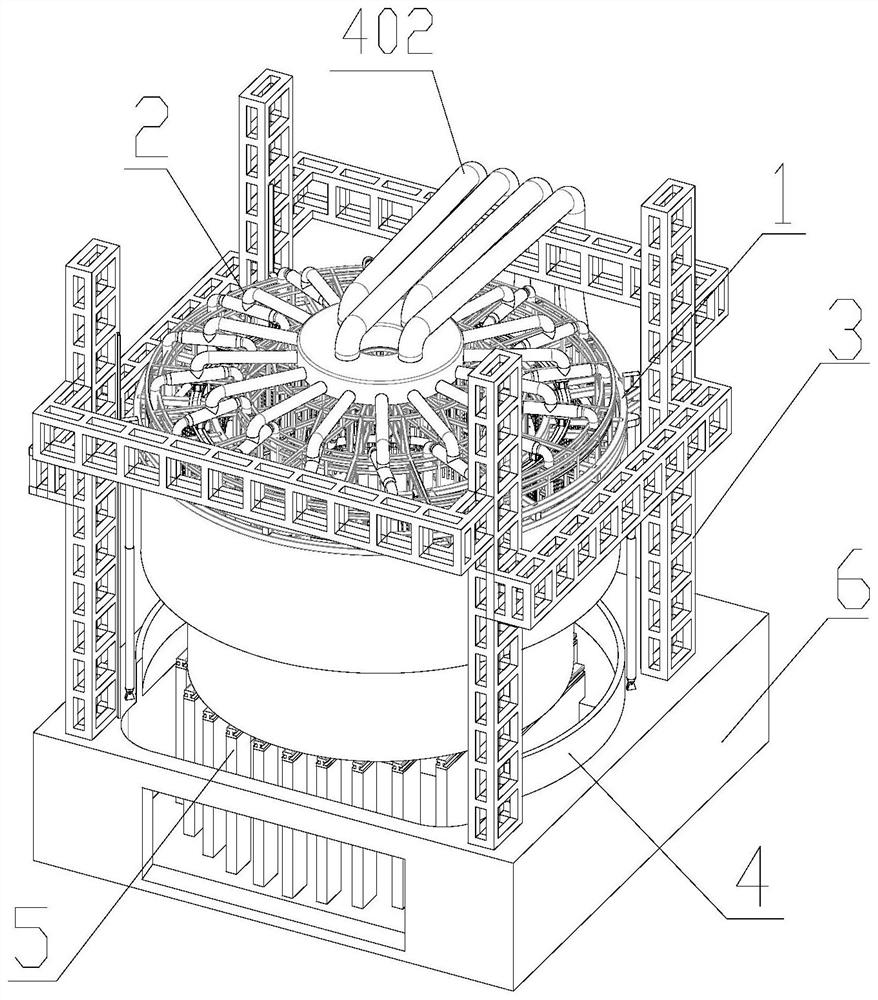

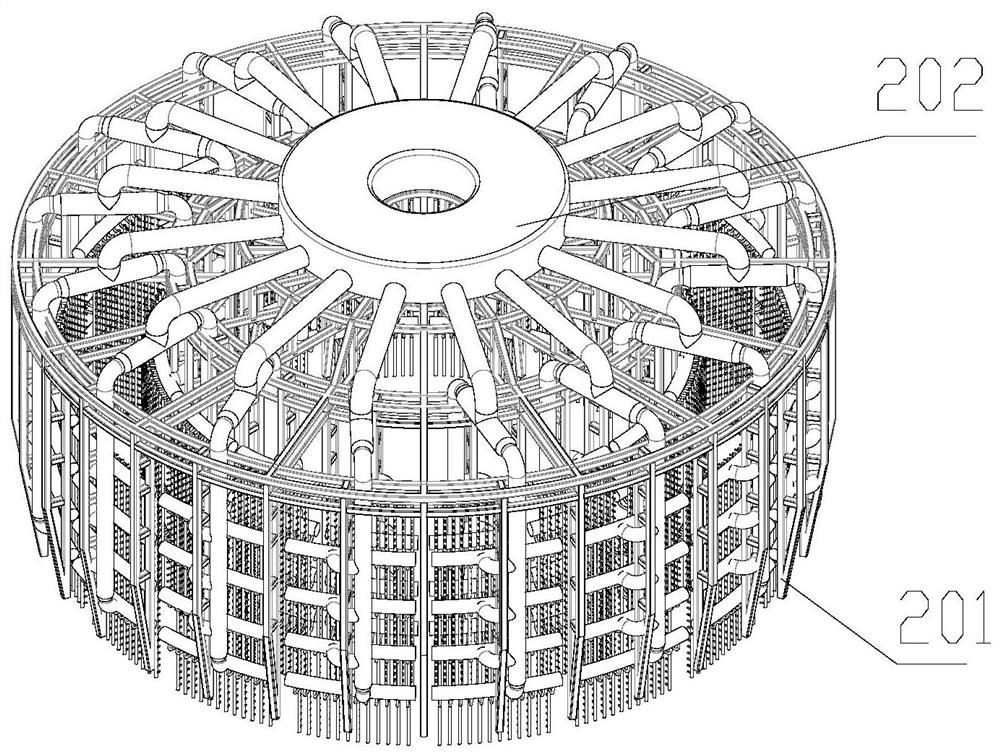

[0042] Depend on figure 1 As shown, the large-scale thin-wall cylinder lifting spray quenching machine tool provided by the preferred embodiment of the present invention includes a hydraulic jacking platform 1 , a rotary spray quenching system 2 , a box-shaped frame support and guide device 3 , and a water supply and drainage system 4 .

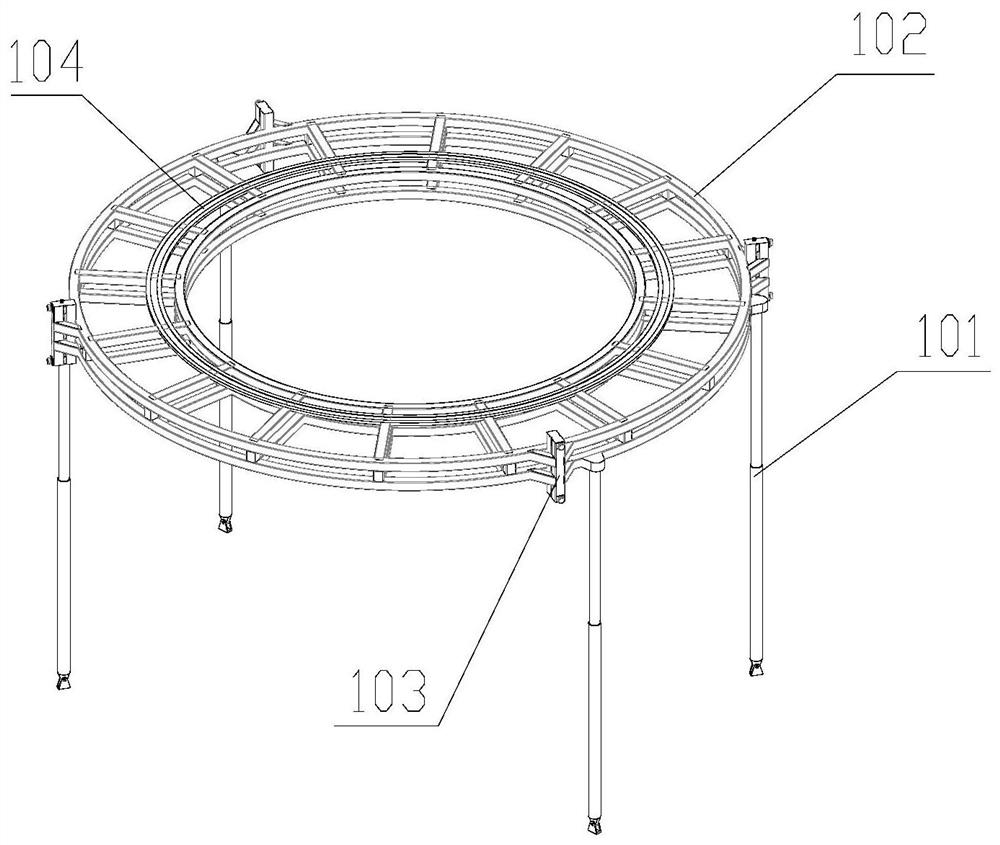

[0043] Depend on figure 2 As shown, the hydraulic jacking platform 1 of the present invention is composed of a hydraulic drive system 101 , an annular frame platform 102 and a guide wheel device 103 . The hydraulic drive system 101 is composed of four rapid-stroke hydraulic cylinders, support bases, hydraulic stations and hydraulic pipelines. The hydraulic cylinder support is fixed on the concrete embedded part 6, and the hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com