Water-gas mixing flushing device, supercharging device and design method

A design method and mixed flushing technology, applied in the field of sanitary ware, can solve the problems of unclean toilet bowl and urination, small coverage area of water flow, waste of outflowing water, etc., so as to reduce maintenance and repair costs, eliminate moving friction, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

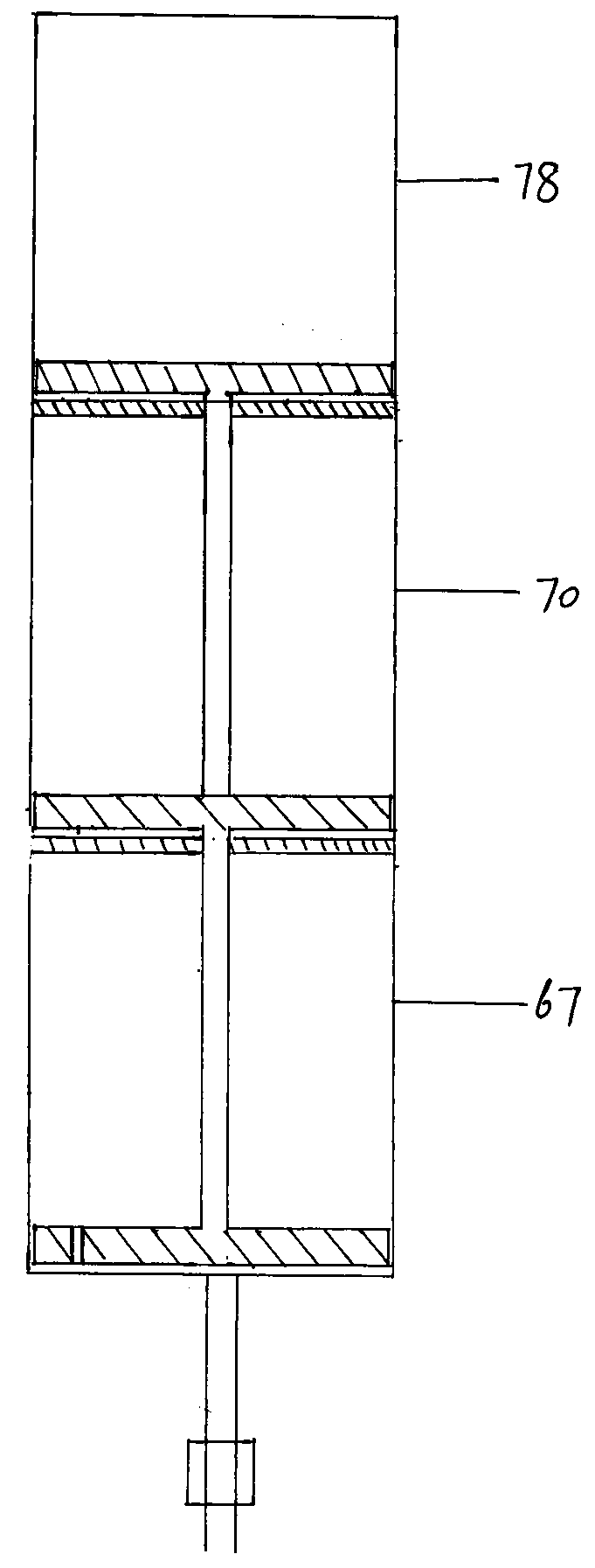

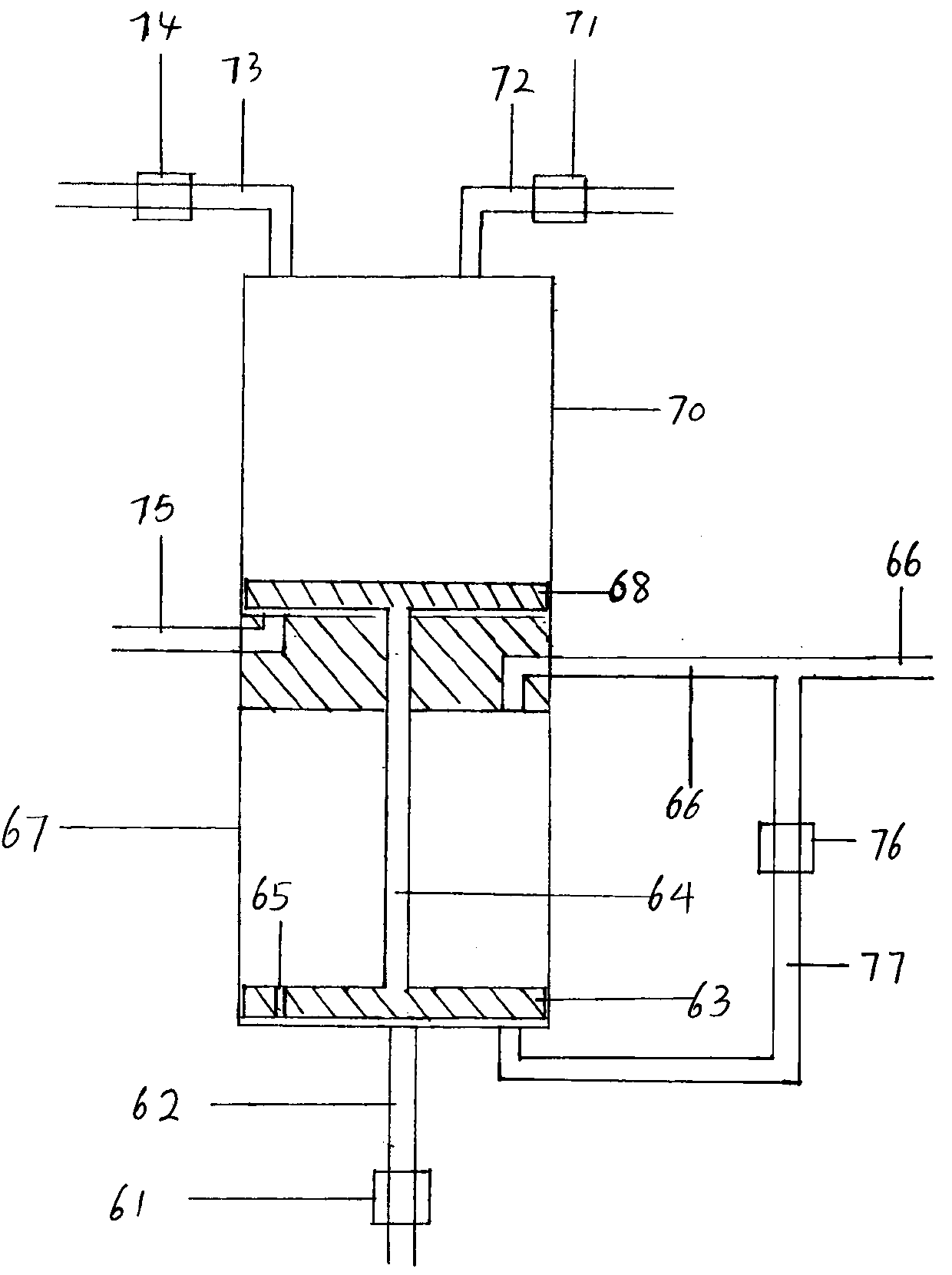

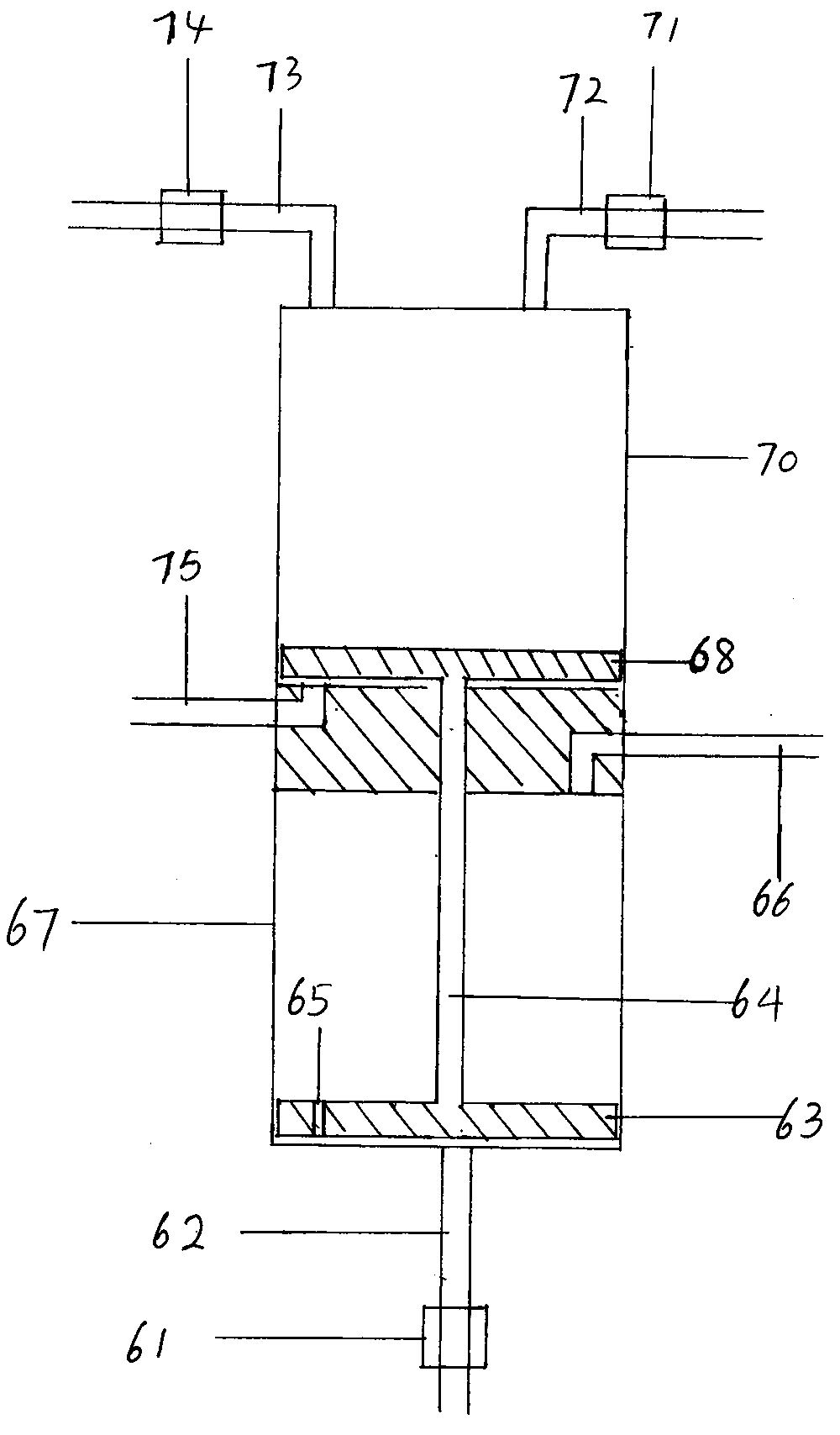

[0073] The water-air mixed flushing device of the present invention includes a first cylinder 67, a water inlet pipe 66, a flushing water pipe 62, a first valve 61, and a second cylinder 70. The first cylinder is fixedly connected to the second cylinder. A cylinder includes a first cavity, a first piston 63, and a piston rod 64. The two sides of the first piston in the first cavity are non-sealed structures, water can circulate on both sides of the first piston, and the bottom of the first cavity is connected to the flushing pipe. There is a first valve on the flushing pipe, the top of the first chamber is connected to the first water inlet pipe, the second cylinder includes the second chamber, the second piston 68, and the exhaust pipe 75, and the second piston and the first piston pass through the first A pull rod is fixedly connected, the bottom of the second cylinder communicates with the exhaust pipe, and the top of the second cylinder has an exhaust hole.

[0074] The de...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap