Automatic vane shear apparatus

A technology of cross plate and shearing instrument, which is applied to instruments, using stable shear force to test the strength of materials, scientific instruments, etc., can solve the problem that the undrained shear strength cannot be obtained continuously, and achieve the increase of test depth, The effect of eliminating friction and mechanical resistance torque and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

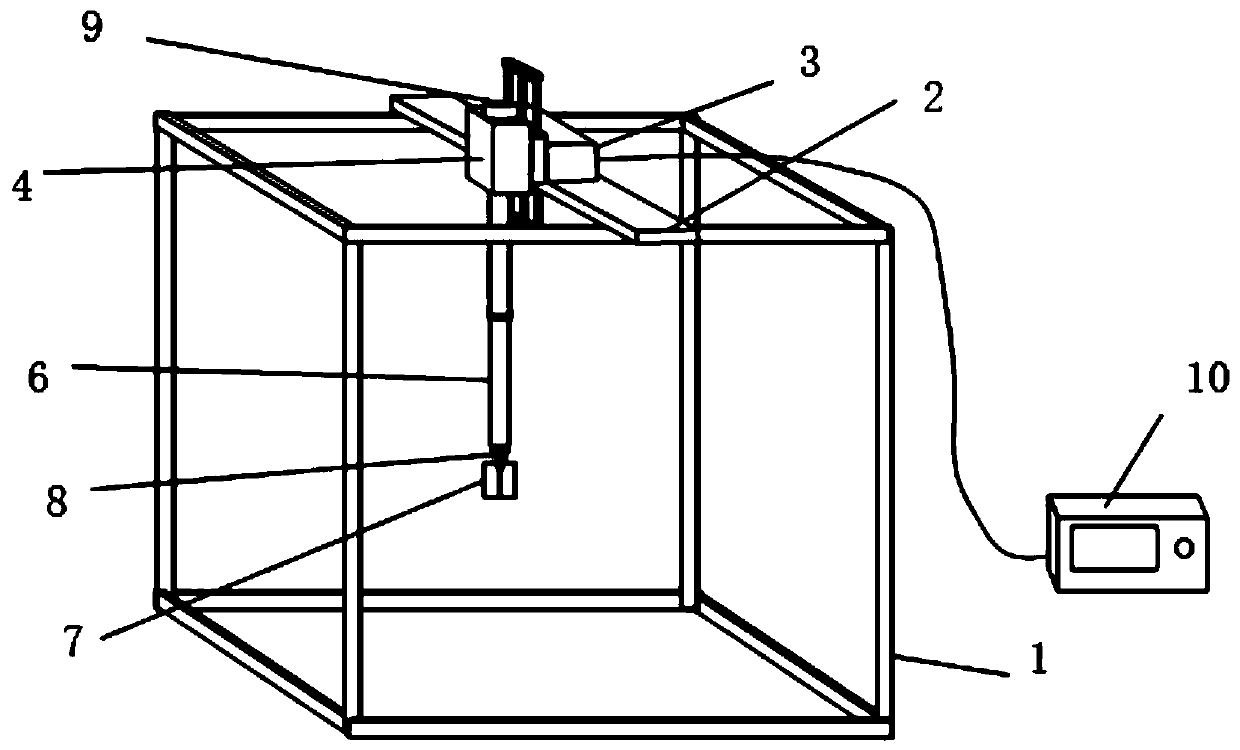

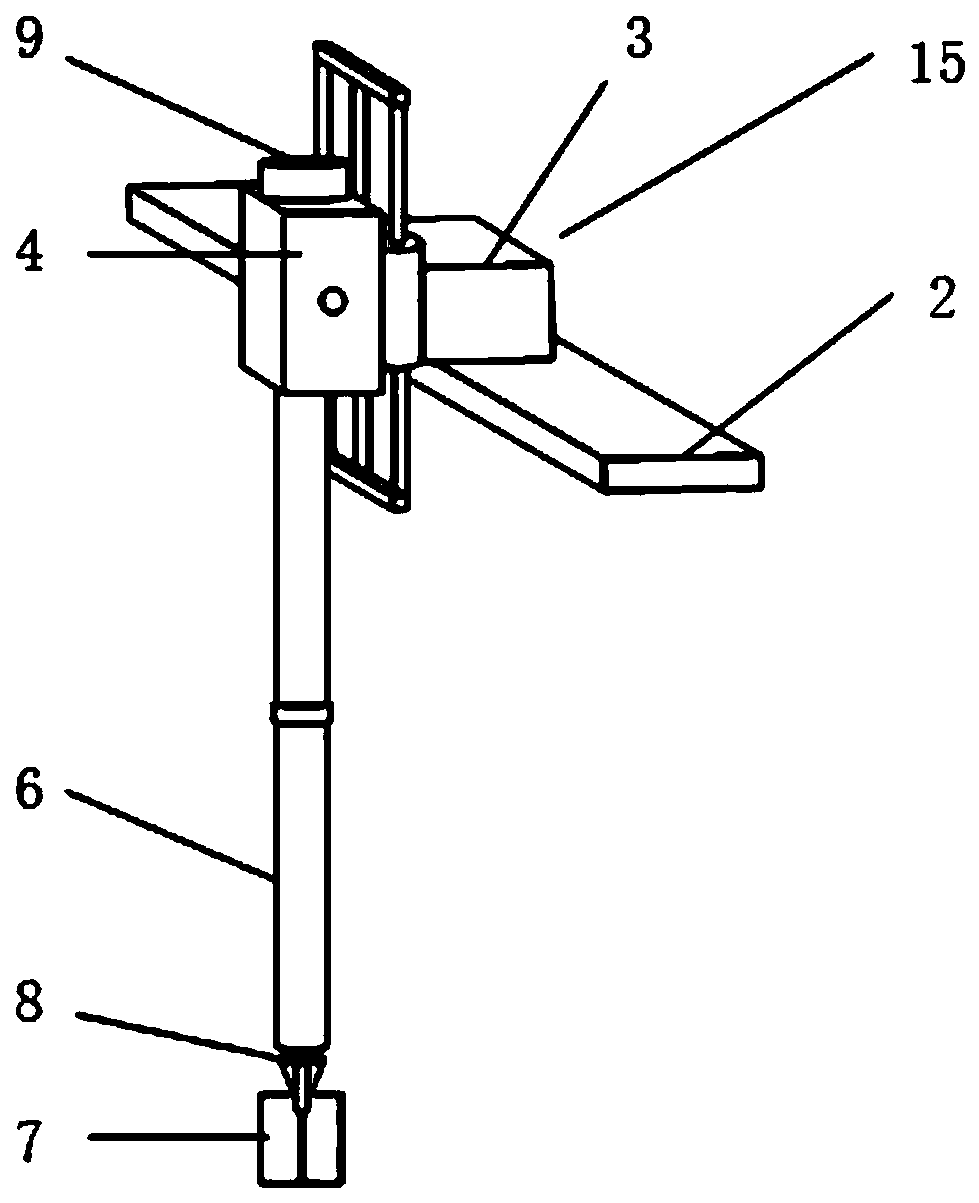

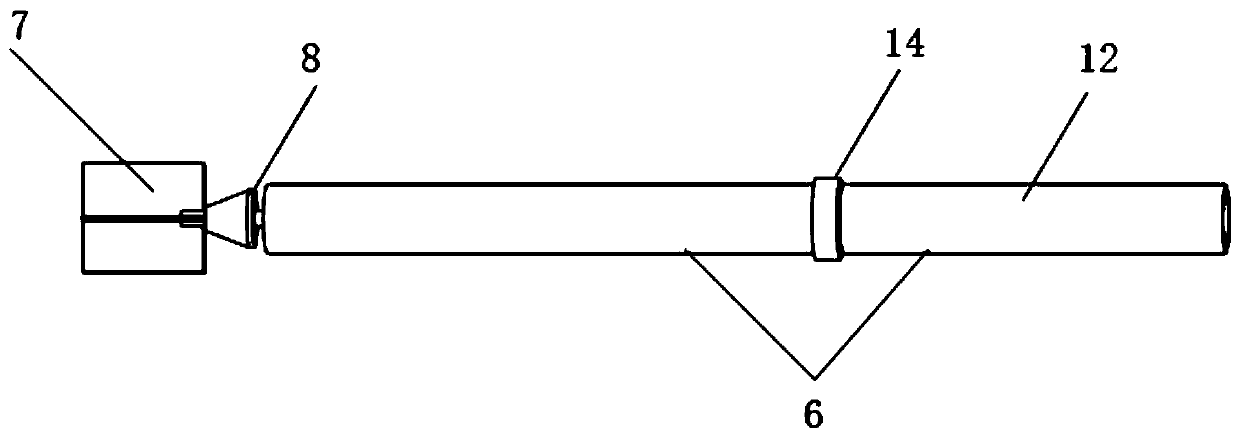

[0020] Such as figure 1 and figure 2 As shown, a kind of automatic cross-plate shearing instrument, described shearing instrument comprises host device 15 and described collection control device 10, and described host device comprises support frame 1, and described support frame 1 is rectangular parallelepiped frame, and frame is made of angle steel It is welded, the bottom surface and four sides of the support frame 1 are provided with plexiglass plates, a beam 2 is provided above the support frame 1, a lifting mechanism 3 is provided in the middle of the beam 2, and a lifting mechanism 3 is provided on the lifting mechanism 3. slide rail, the slide rail is placed vertically, and a torque output device 4 is provided on the slide rail, and the lifting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com