A stopper mechanism that effectively triggers micro switches and protects electrical components

A technology of micro-switches and electrical components, applied in electrical components, electrical switches, circuits, etc., can solve the problems of difficulty in effectively triggering the micro-switch parts 9, damage to the contacts of the micro-switch, and inability to trigger the action stroke, etc. Improve mean time to maintenance, trigger effectiveness and reliability, increase effectiveness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

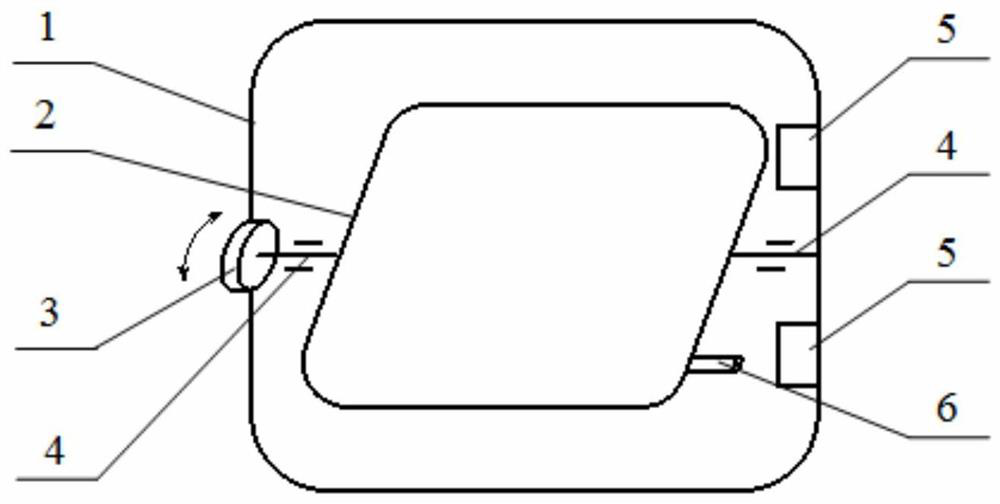

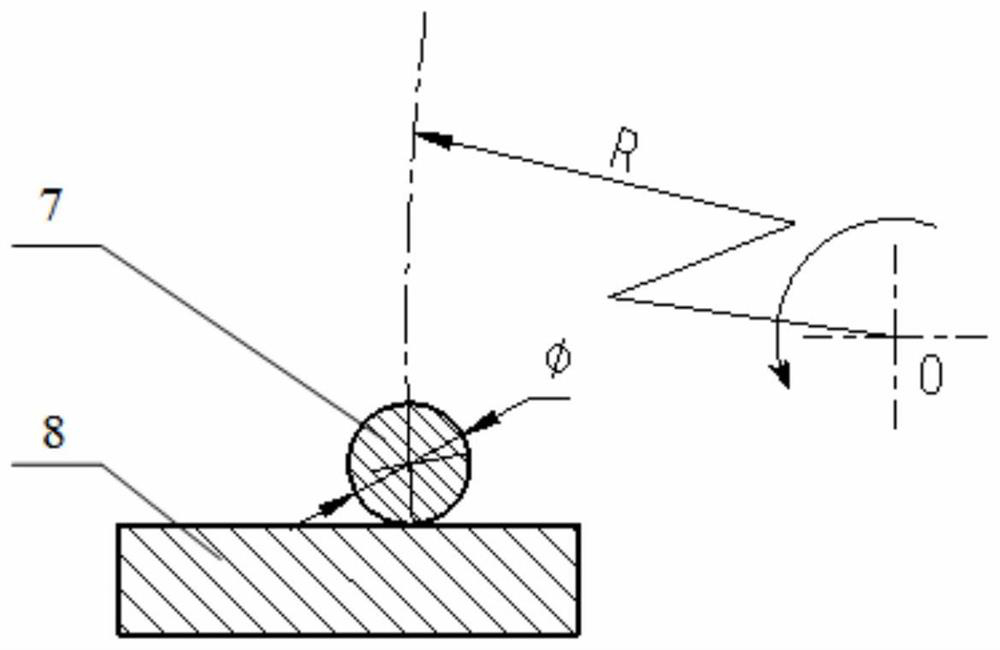

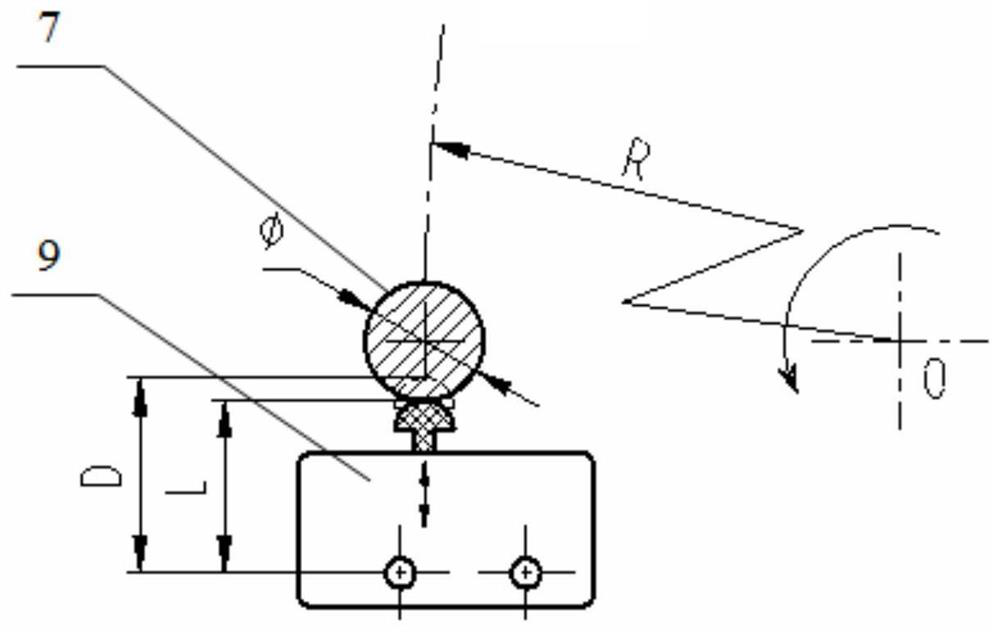

[0039] A stopper mechanism that effectively triggers micro switches and protects electrical components, including stopper pins and stoppers, combined below Figure 5 , Figure 6 and Figure 7 Detailed description of stop pins and stops:

[0040] ⑴. The stop pin is a cross-shaped trigger stop block in order to achieve effective trigger stop operation. The features of the parts are as follows: Figure 6 shown. This program requires that part 10 has a cross-shaped trigger stopper with upper and lower contact platforms to realize electrical triggering of one-way or two-way micro switches, such as Figure 6 Shown in 101 and 102. It is required that part 10 cross-shaped trigger stop block has left and right stop p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com