Rotary Masterbatch Cooling Device

A technology of cooling device and color masterbatch, which is applied in the direction of coating, etc., can solve problems such as the need to improve efficiency, and achieve the effects of avoiding long-term stacking contact, improving cooling effect, and alleviating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

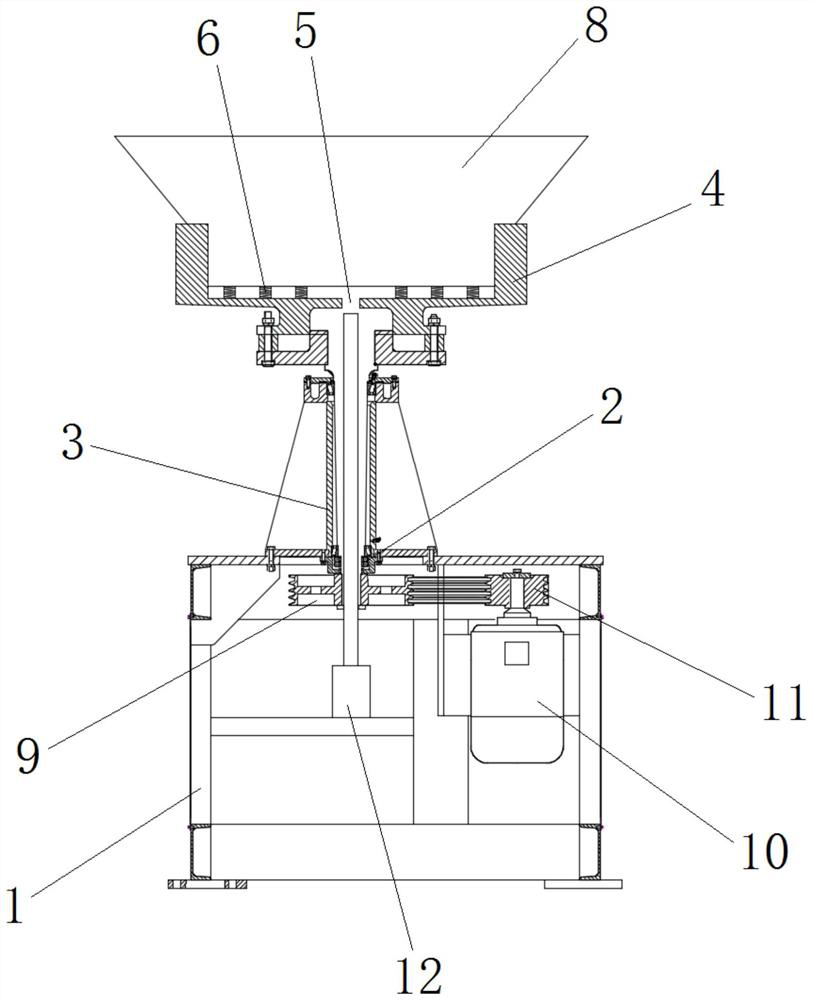

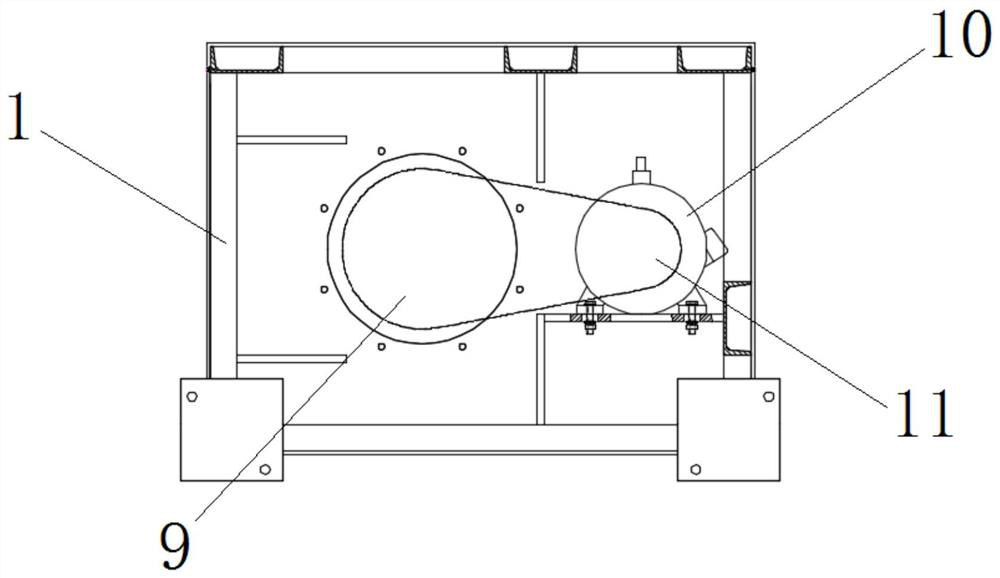

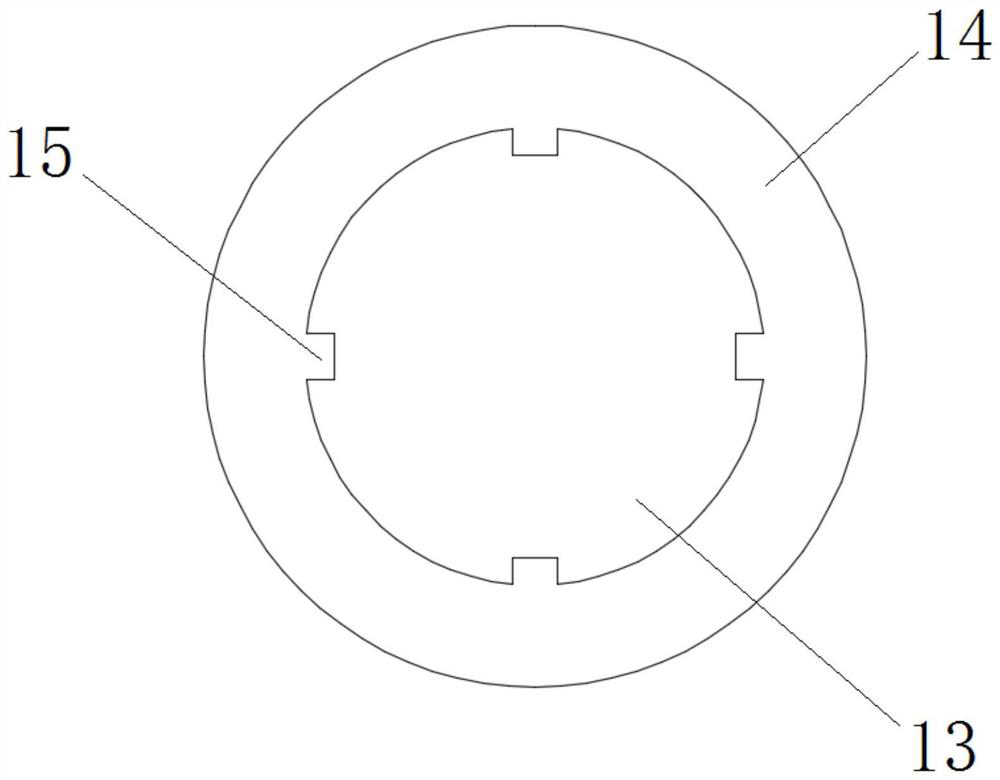

[0025] Rotary masterbatch cooling device, such as Figure 1~4 As shown, it includes box body 1, bearing 2, hollow shaft 3, cylinder body 4, through hole 5, spring 6, convex strip 7, container 8, driven gear 9, motor 10, driving gear 11, electric push rod 12, Cylindrical part 13, wide mouth part 14, strip groove 15, wherein box body 1 has an inner chamber, is connected with bearing 2 on the upper end of described box body 1, is connected with hollow shaft 3 on described bearing 2, so The axis of the hollow shaft 3 is vertical, and a cylinder 4 is fixedly connected to the top end of the hollow shaft 3, and a through hole 5 is opened in the center of the bottom surface of the cylinder 4, and the top end of the bottom surface of the cylinder 4 is fixedly connected to There are some springs 6, and some convex strips 7 are fixedly connected on the inner wall of the cylinder body 4; the container 8 includes a cylindrical portion 13 and a wide-mouth portion 14, and the wide-mouth port...

Embodiment 2

[0028] Rotary masterbatch cooling device, such as Figure 1~4As shown, it includes box body 1, bearing 2, hollow shaft 3, cylinder body 4, through hole 5, spring 6, convex strip 7, container 8, driven gear 9, motor 10, driving gear 11, electric push rod 12, Cylindrical part 13, wide mouth part 14, strip groove 15, wherein box body 1 has an inner chamber, is connected with bearing 2 on the upper end of described box body 1, is connected with hollow shaft 3 on described bearing 2, so The axis of the hollow shaft 3 is vertical, and a cylinder 4 is fixedly connected to the top end of the hollow shaft 3, and a through hole 5 is opened in the center of the bottom surface of the cylinder 4, and the top end of the bottom surface of the cylinder 4 is fixedly connected to There are some springs 6, and some convex strips 7 are fixedly connected on the inner wall of the cylinder body 4; the container 8 includes a cylindrical portion 13 and a wide-mouth portion 14, and the wide-mouth porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com