Detection structure and image molding device

An image forming and detection technology, which is applied to printing devices, typewriters, printing, etc., can solve the problems of complex paper position information detection structure, etc., and achieve the effect of reducing the number of structures, simple installation and matching structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

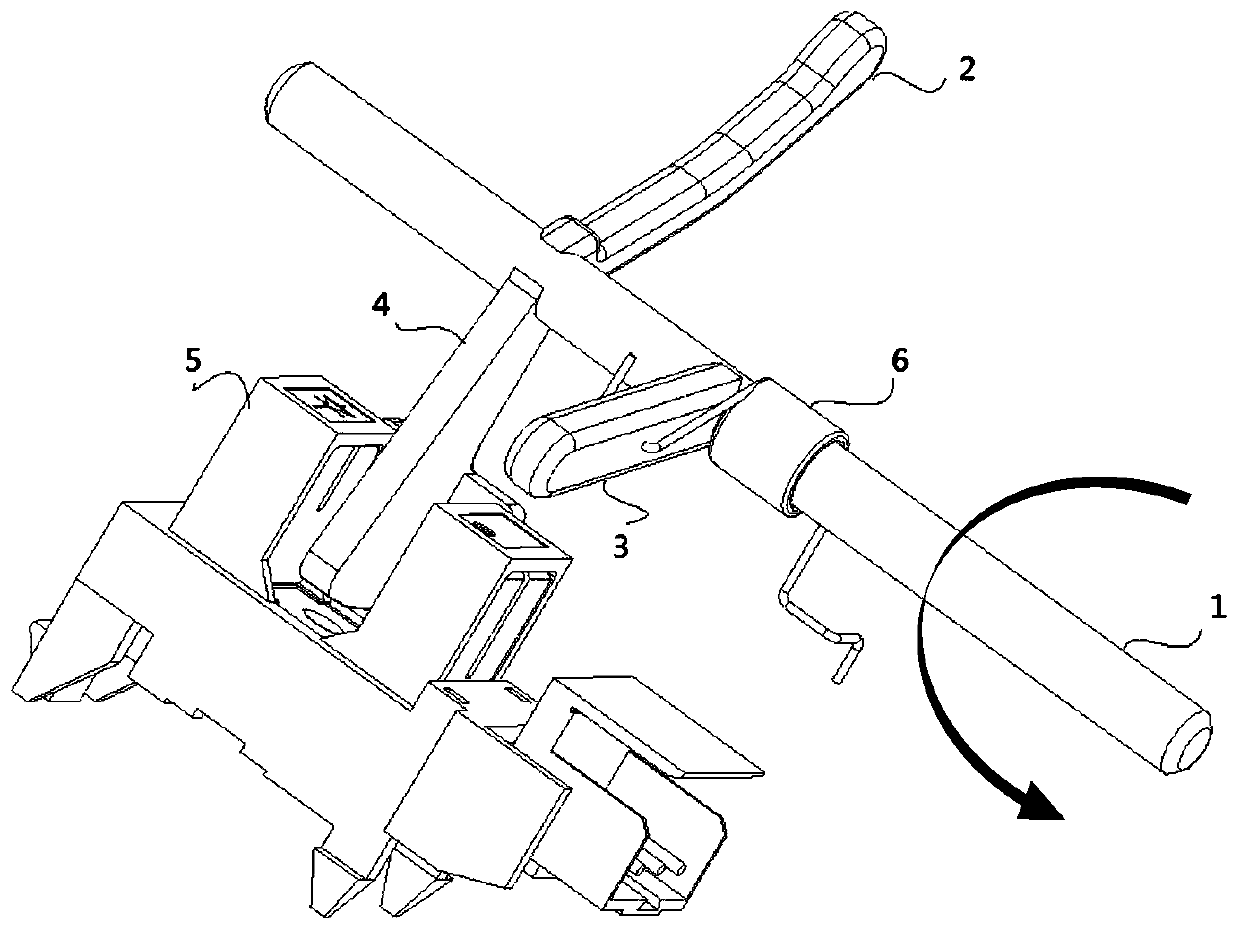

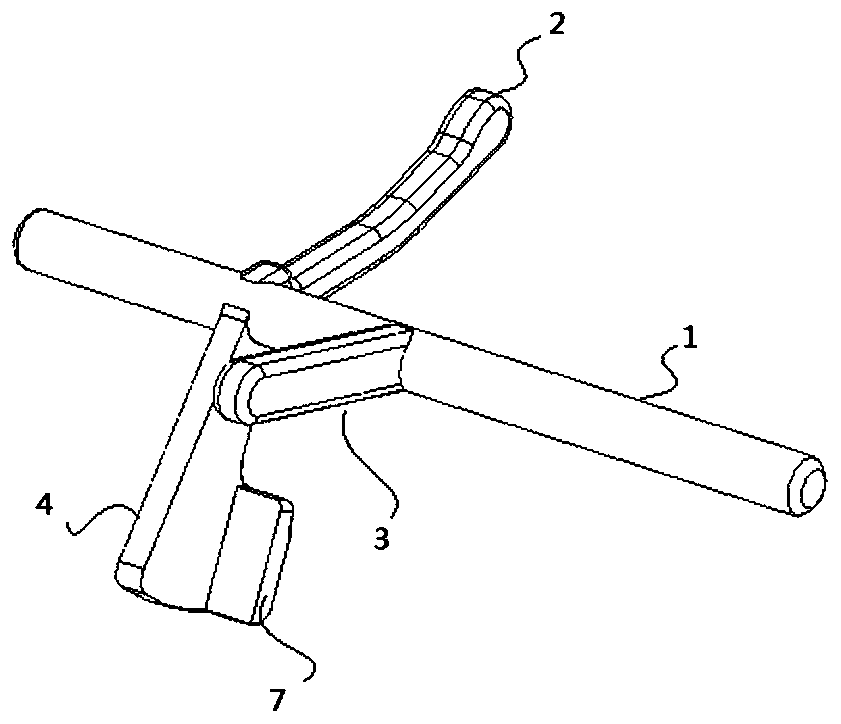

[0050] Such as figure 1As shown in -3, a detection structure provided for this embodiment includes a central axis 1, which is rotatably arranged on a paper board; a first detection arm 2 and a second detection arm 3, which are arranged at an angle On the peripheral surface of the central axis 1, and can be respectively arranged in the front printing path and the reverse printing path; the trigger arm 4, one end is arranged on the peripheral surface of the rotating shaft 1, and one end is correspondingly arranged with the sensing area of the sensor 5, printing The medium triggers the first detection arm 2 and the second detection arm 3 respectively in the front printing path and the reverse printing path, and drives the trigger arm 4 to rotate to realize the triggering of the sensor 5; the reset structure 6 is arranged on the central axis 1 , used to drive the axis 1 to rotate, and drive the trigger arm 4 to reset to a position not triggered by the printing medium.

[0051] ...

Embodiment 2

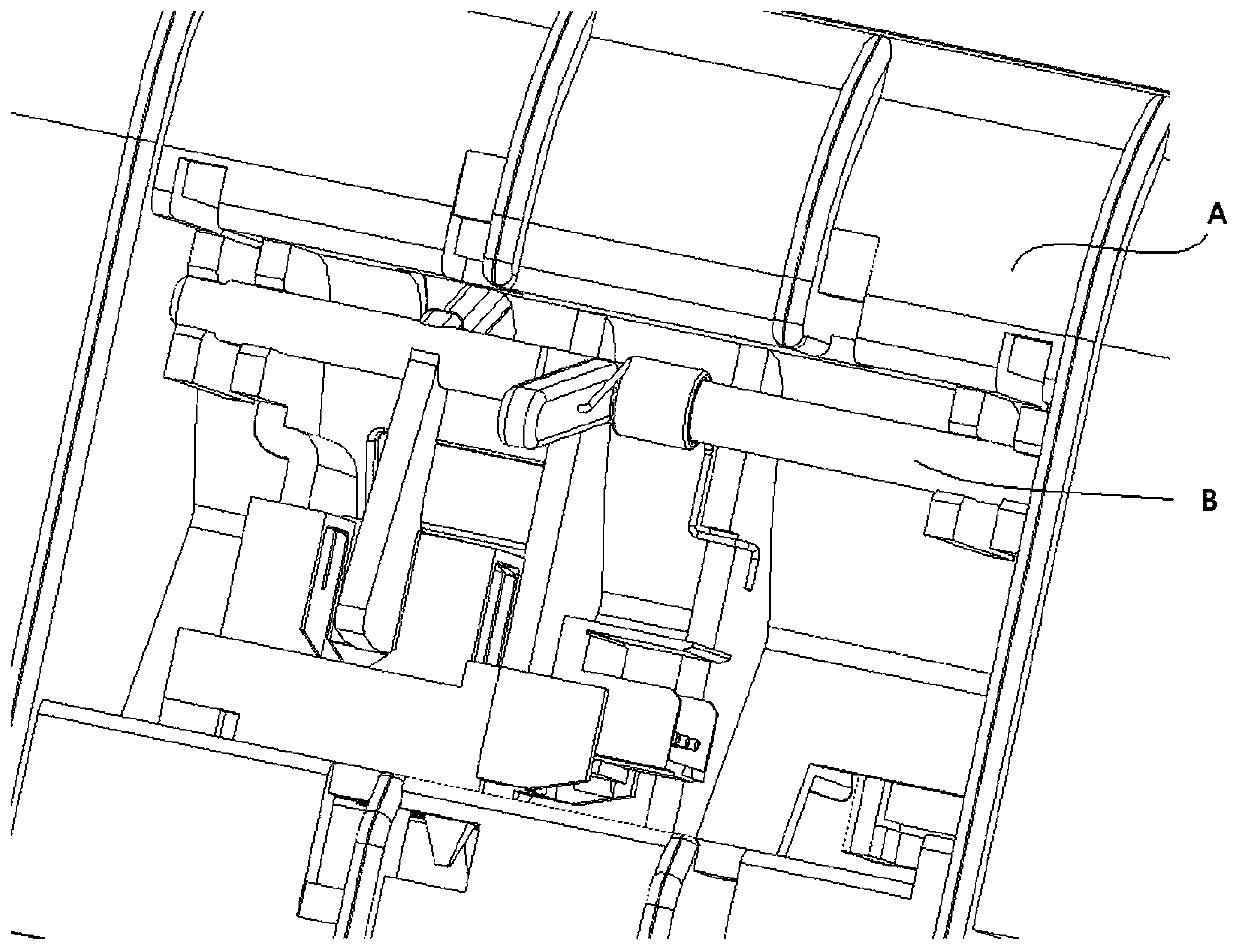

[0068] Such as Figure 4 As shown, an image forming device provided in this embodiment includes the detection structure described in Embodiment 1 above, and has all its technical advantages. Its working process is as follows:

[0069] The printing medium d coming out of the pick-up roller 8 enters the front printing channel e, and the head of the printing medium d triggers the detection structure in Embodiment 1, and finally hits it from position a to position c through position b to realize After the triggering of the sensor, the printing medium d enters the printing channel f on the reverse side, and before the head of the printing medium d touches the detection structure again, its tail end breaks away from the detection structure, and then repeats the printing detection on the front side process, and finally complete the detection of the position of the front and back printing media.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com