Loom spindle balance block structure

A technology of balance weight and main shaft, which is applied in looms, textiles, textiles and papermaking, etc. It can solve the problems of vibrating fabric quality, rotation loss of balance, and affecting looms, so as to improve weaving quality and efficiency, weaken inertial force, and facilitate Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

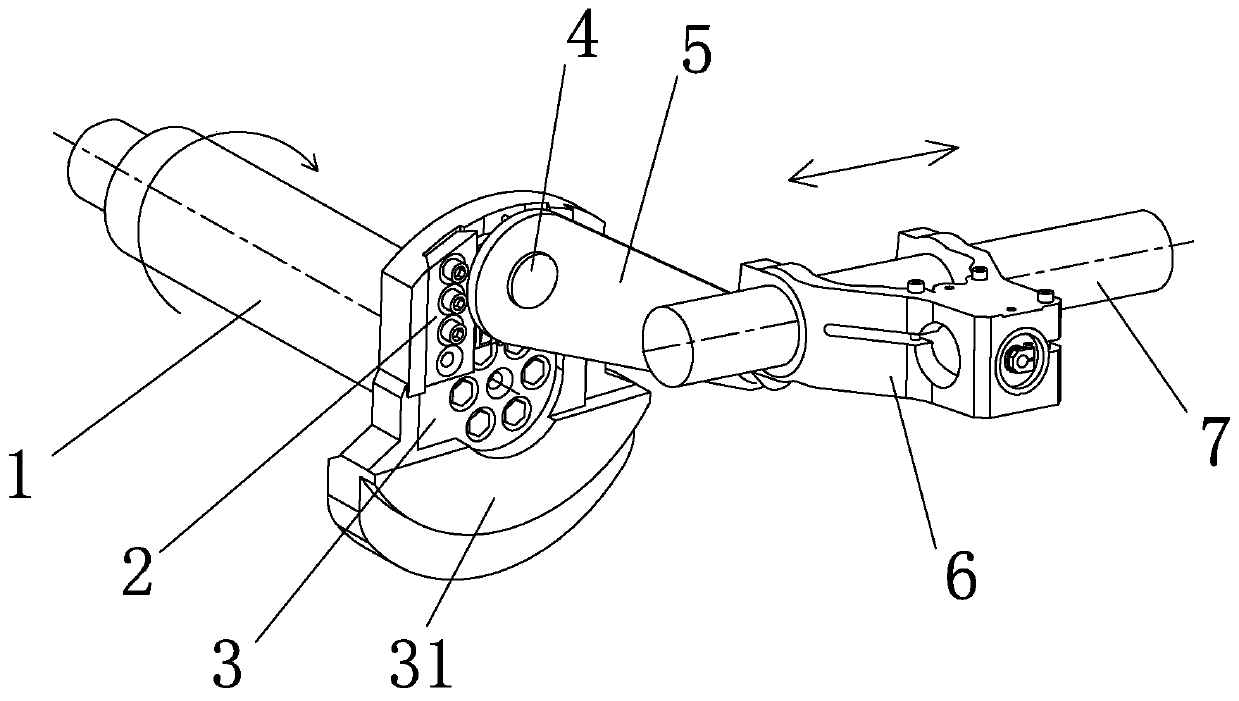

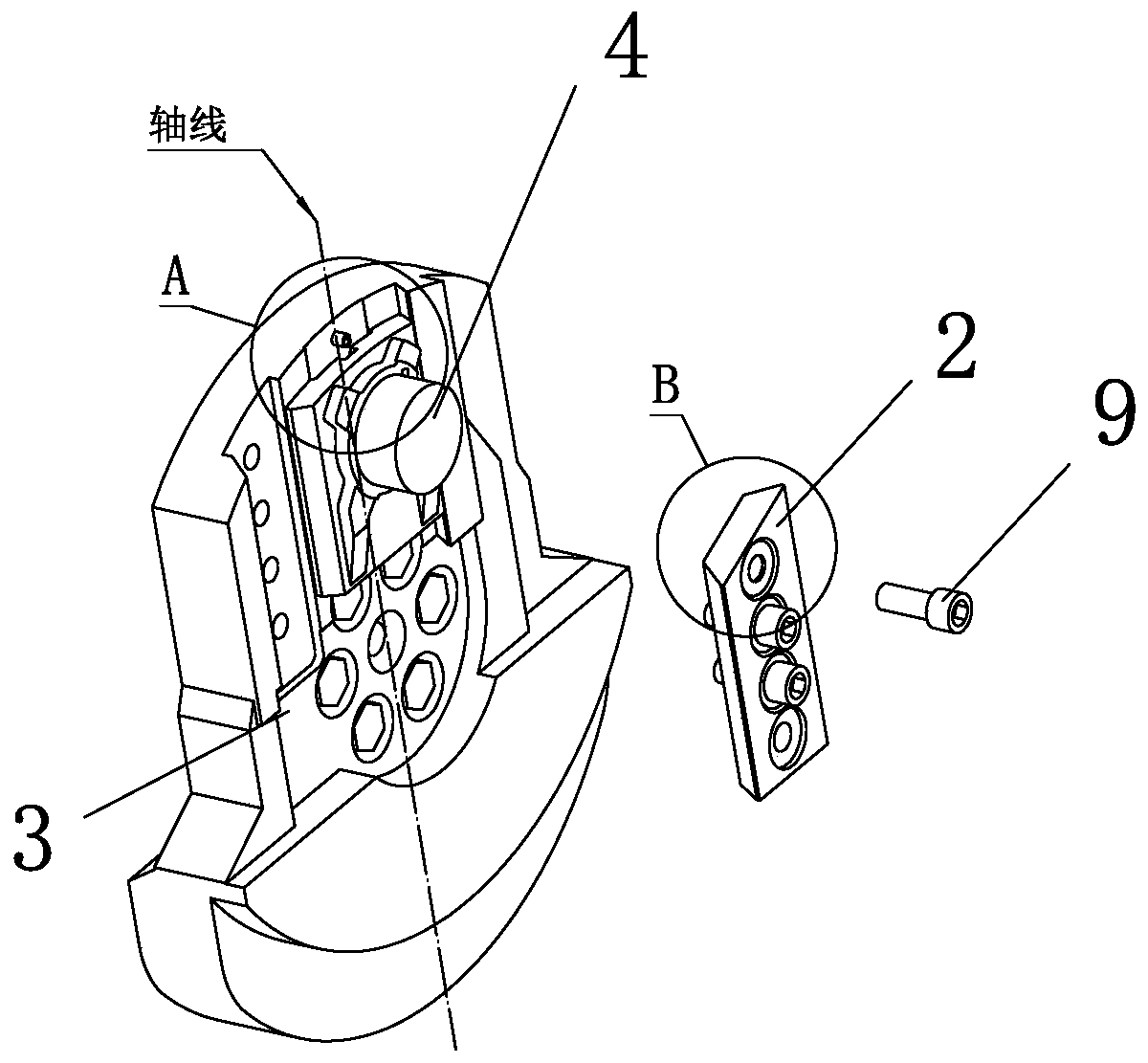

[0027] Such as figure 1 As shown, a main shaft balance weight structure of a loom includes a main shaft 1 and weft insertion mechanisms located at two ends of the main shaft 1 . Balance weights 3 are respectively fixedly arranged on the end faces of the two ends of the main shaft 1 , and the middle part of the main shaft 1 is fixedly connected with the balance weight 3 .

[0028] As a specific implementation, the balance weight 3 described in this embodiment is fixedly connected to the main shaft 1 through screws 9 .

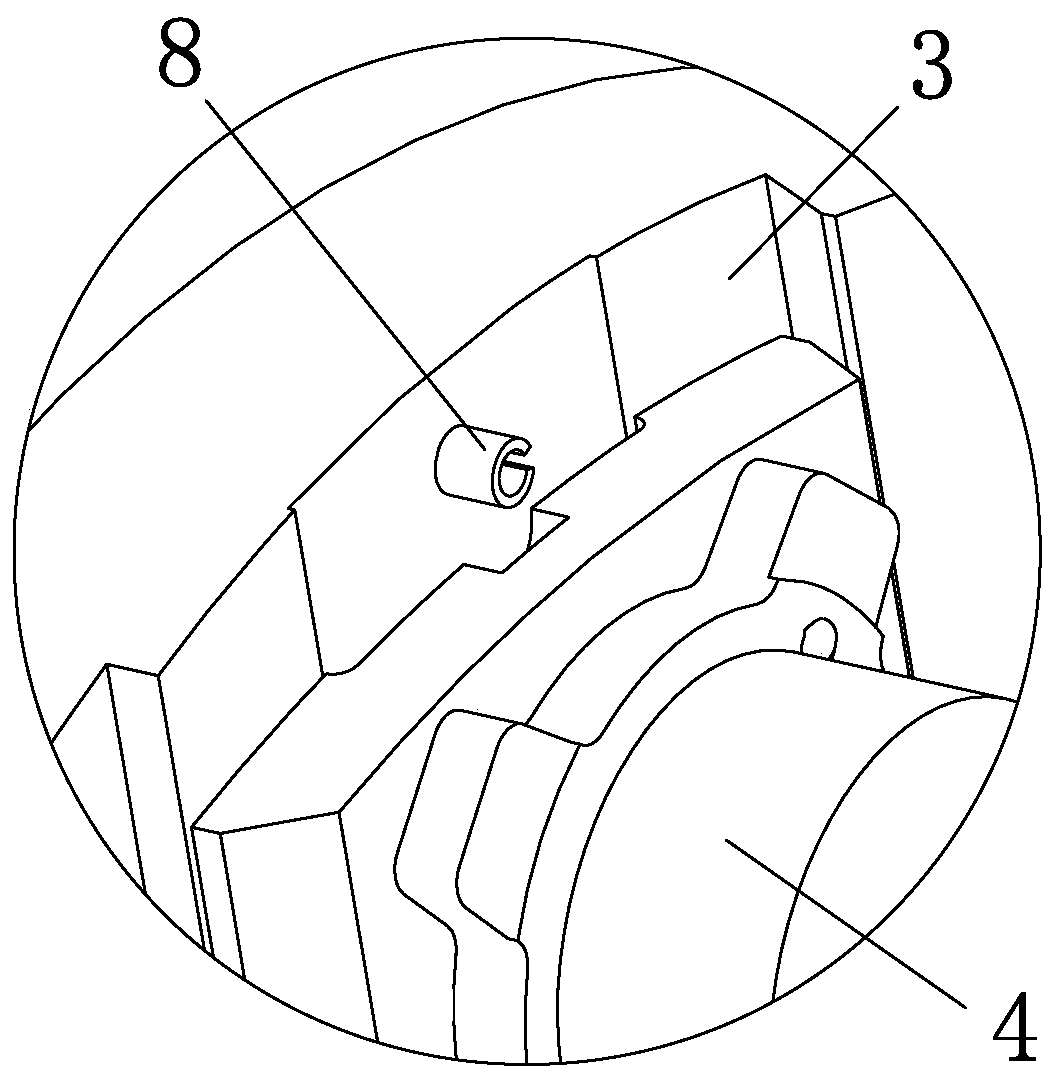

[0029] One end of the balance weight 3 is a counterweight 31 , the other end of the balance weight 3 is hinged to one end of the connecting rod 5 , and the other end of the connecting rod 5 is hinged to the weft insertion moving bracket 6 . The moving bracket 6 for weft insertion is arranged on the guide shaft 7 and can drive the weft insertion mechanism to reciprocate along the guide shaft 7 .

[0030] This patent does not involve the specific internal struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com