Method for spraying contamination on insulator surface

An insulator and pollution technology, which is used in the field of spray pollution test on the surface of power equipment, can solve the problems of equivalent salt density and equivalent gray density error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following description is a preferred embodiment of the present invention, it should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered Be the protection scope of the present invention.

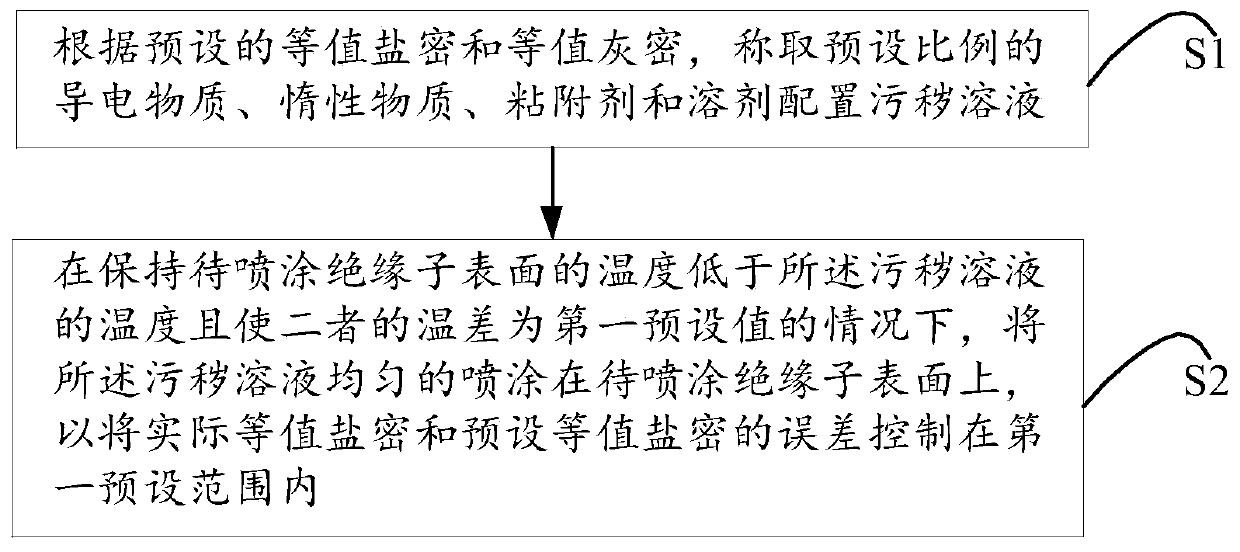

[0032] refer to figure 1 , the pollution spraying method of insulator provided by the present invention, comprises the following steps:

[0033] Step S1, according to the preset equivalent salt density, weigh the conductive substance, the inert substance, the adhesive and the solvent in the preset ratio to prepare the dirty solution.

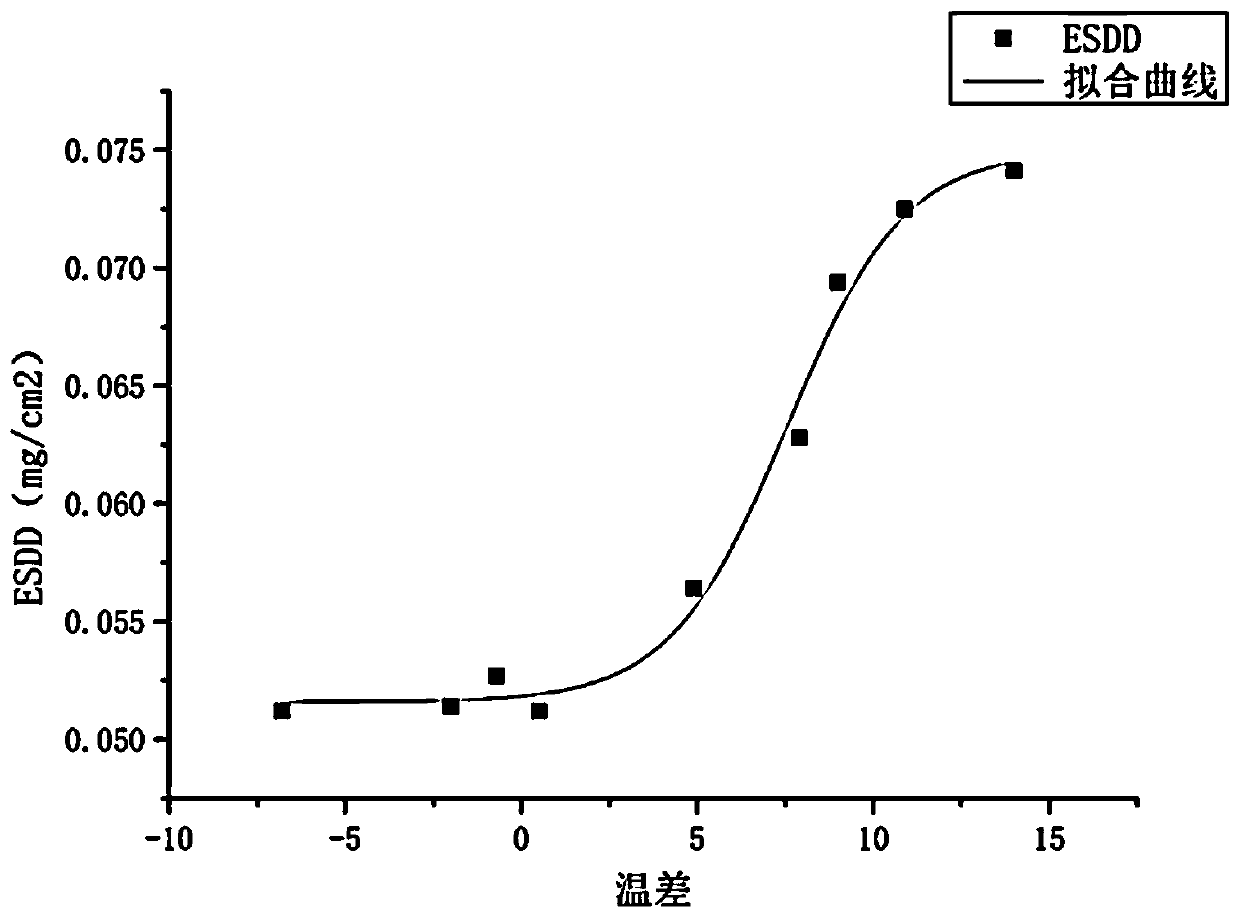

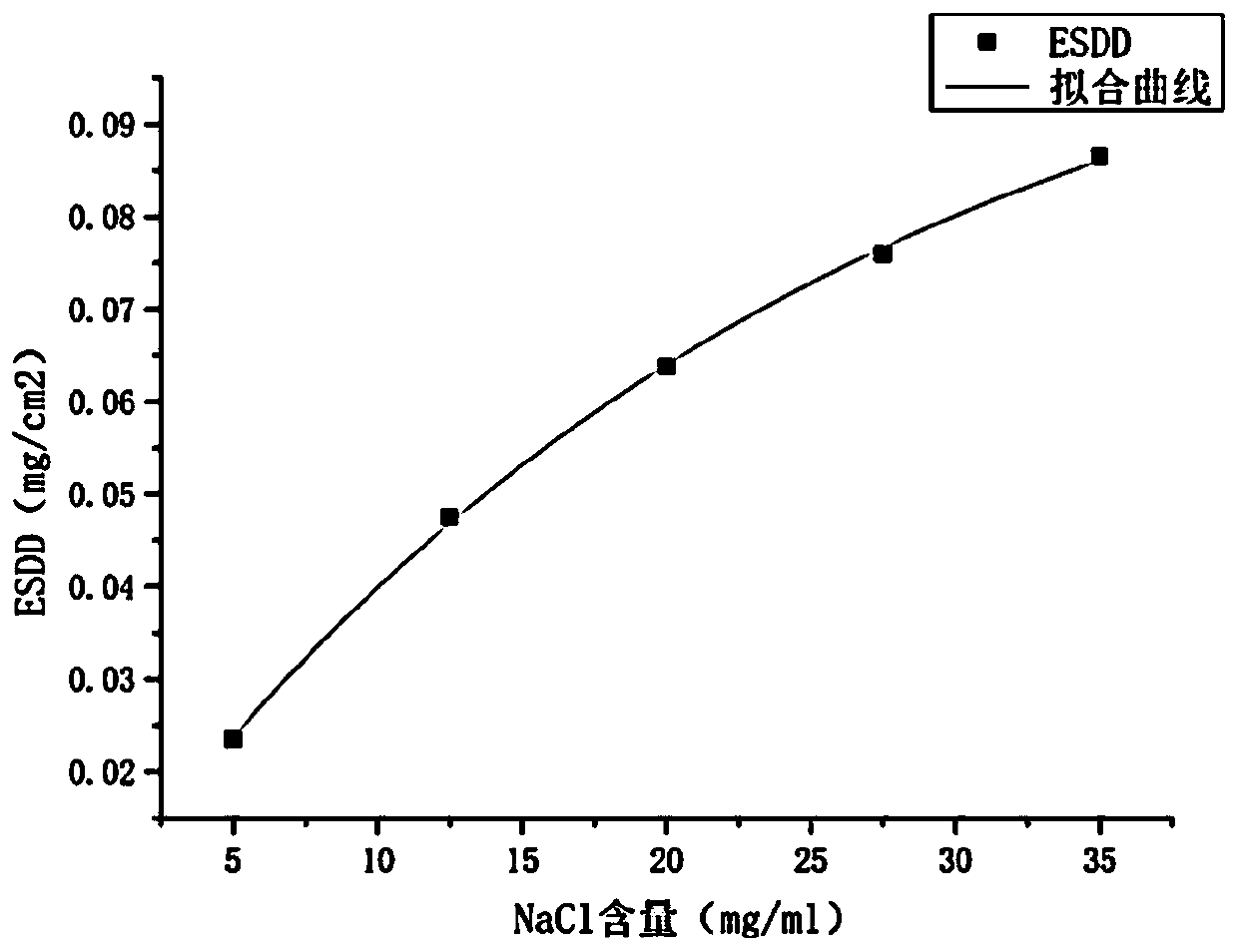

[0034] Specifically, the equivalent salt density (ESDD) is an important parameter to characterize the degree of contamination on the surface of an insulator. Use a certain amount of deionized water to clean the contamination on the surface of the insulator, and then measure th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap