Back-carried dust collector with stable suction force and transparent filter bag

A filter bag, vacuum cleaner technology, applied in suction filters, vacuum cleaners, suction hoses, etc., can solve the problems of reduced suction, waste of time, and discomfort on the back of cleaning personnel, so as to improve work efficiency and ensure the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

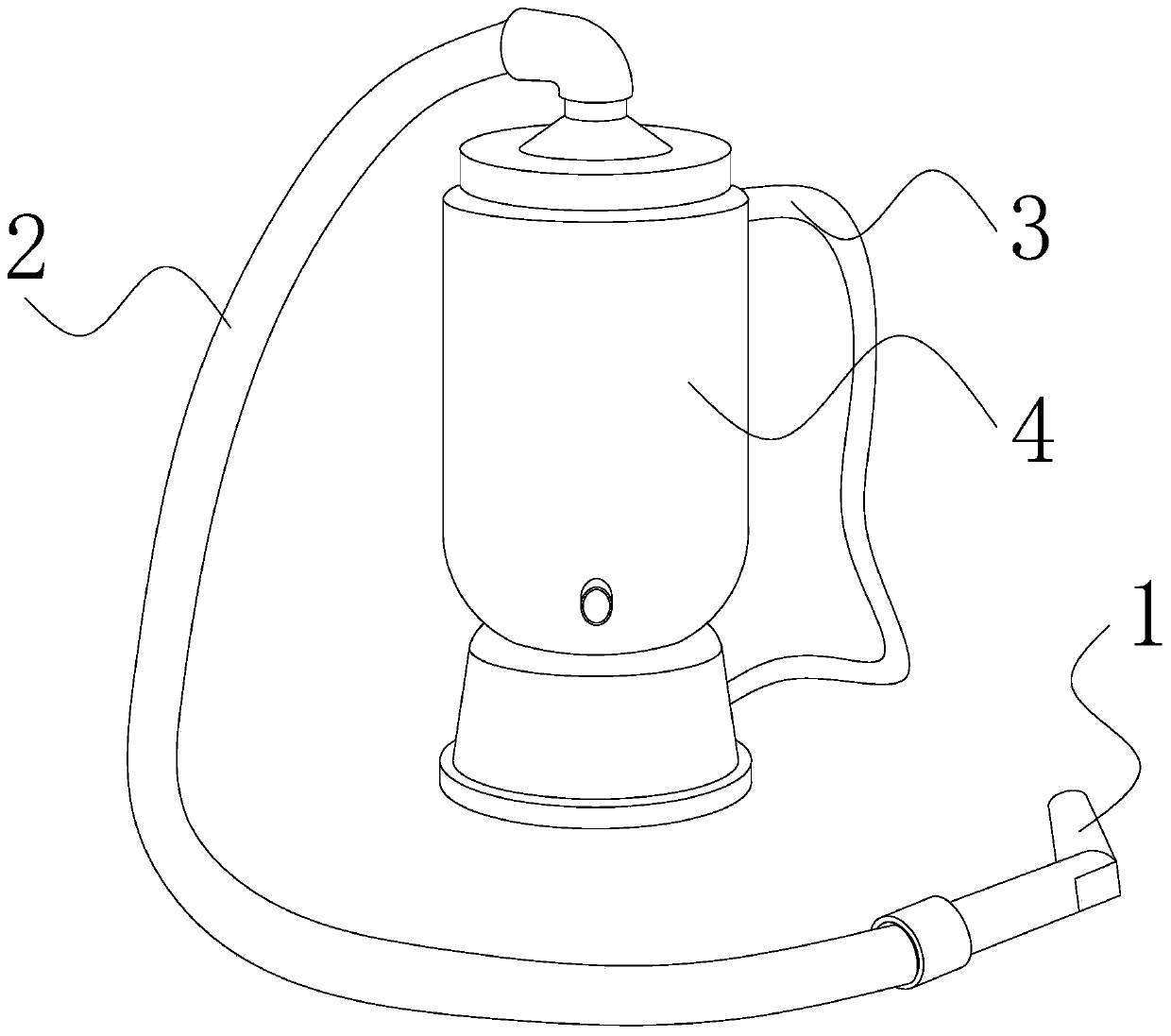

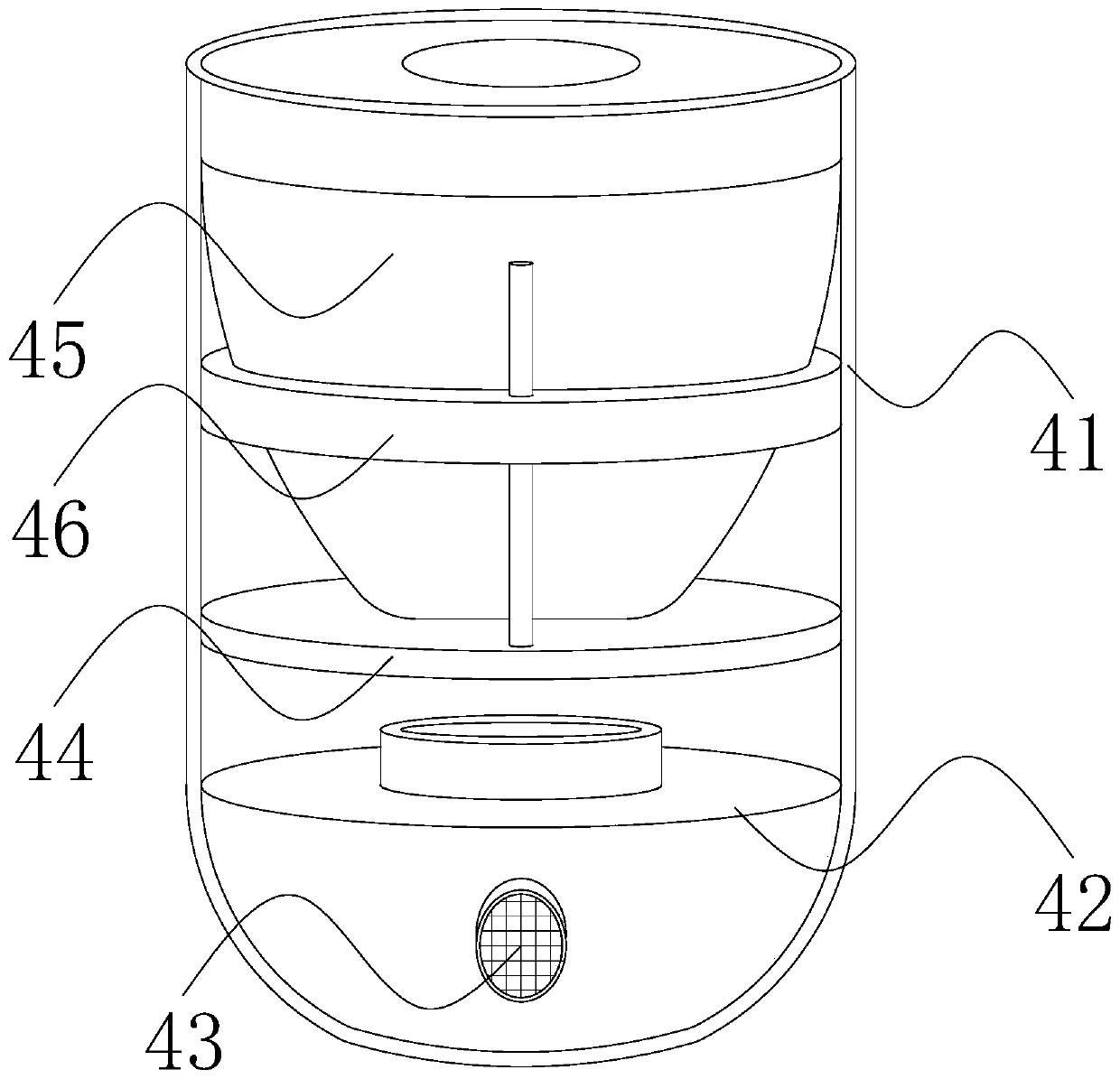

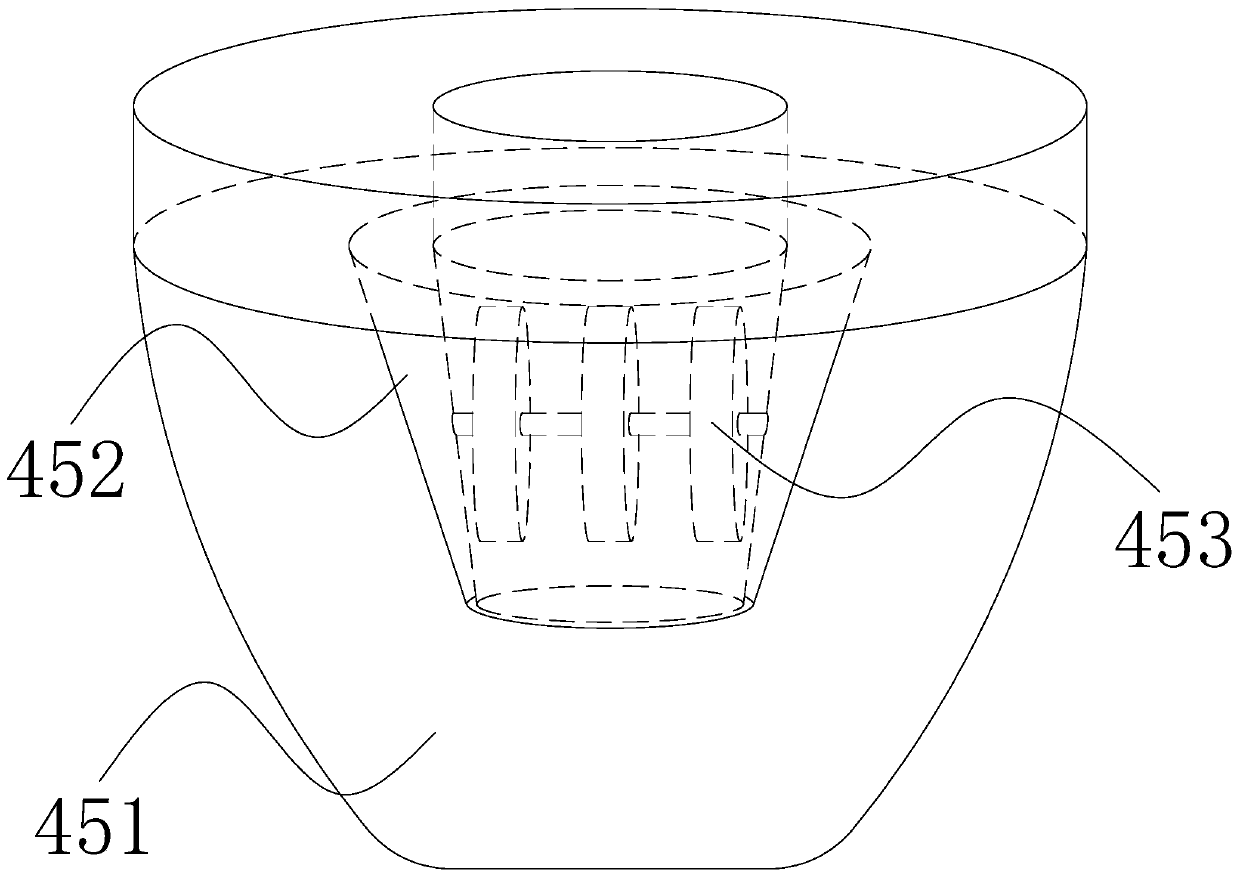

[0022] see Figure 1-Figure 9 , the present invention is a back-type vacuum cleaner with a stable suction filter bag, and its structure includes a dust suction port 1, a dust suction connecting pipe 2, a strap 3, a stable suction dust suction host 4, the dust suction port 1 and the dust suction connecting pipe The two ends are connected, the end of the dust suction connecting pipe 2 is fixedly installed on the top of the stable suction dust collection host 4, the strap 3 is fixedly installed on the stable suction dust collection host 4, and the stable suction dust collection host 4 is made of plastic Barrel-shaped shell 41, dust suction fan 42, air outlet 43, air inlet filter sheet 44, thorough dust filter bag 45, dust filter bag electrostatic attractor 46, the inner bottom of the plastic barrel-shaped shell 41 is fixedly equipped with a dust suction fan 42, The dust suction fan 42 is connected to the air outlet 43, the air inlet filter 44 is installed directly above the dust ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap