Base plate assembly of steam iron

A soleplate and iron technology, applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of unsatisfactory softening effect of clothes, achieve the effect of improving ironing effect, high utilization efficiency, and avoiding scratches on clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

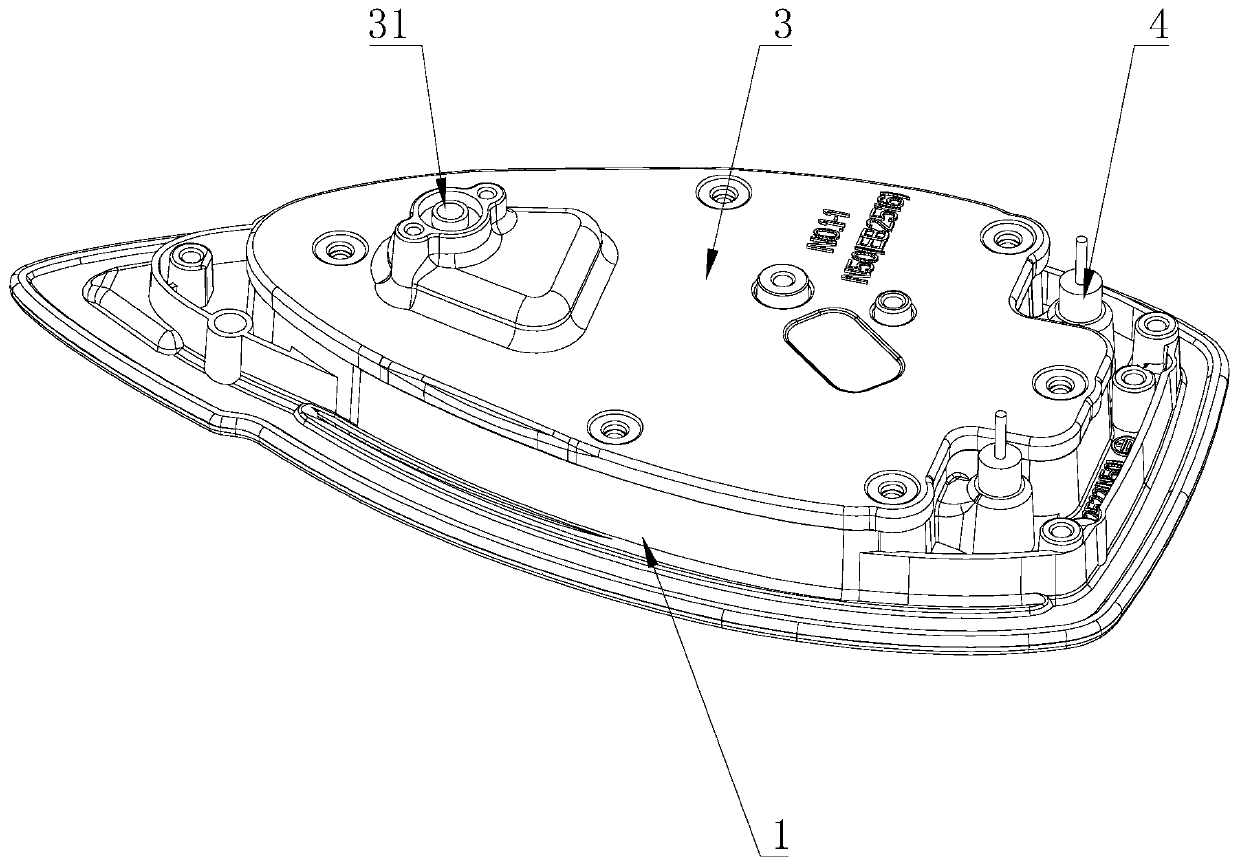

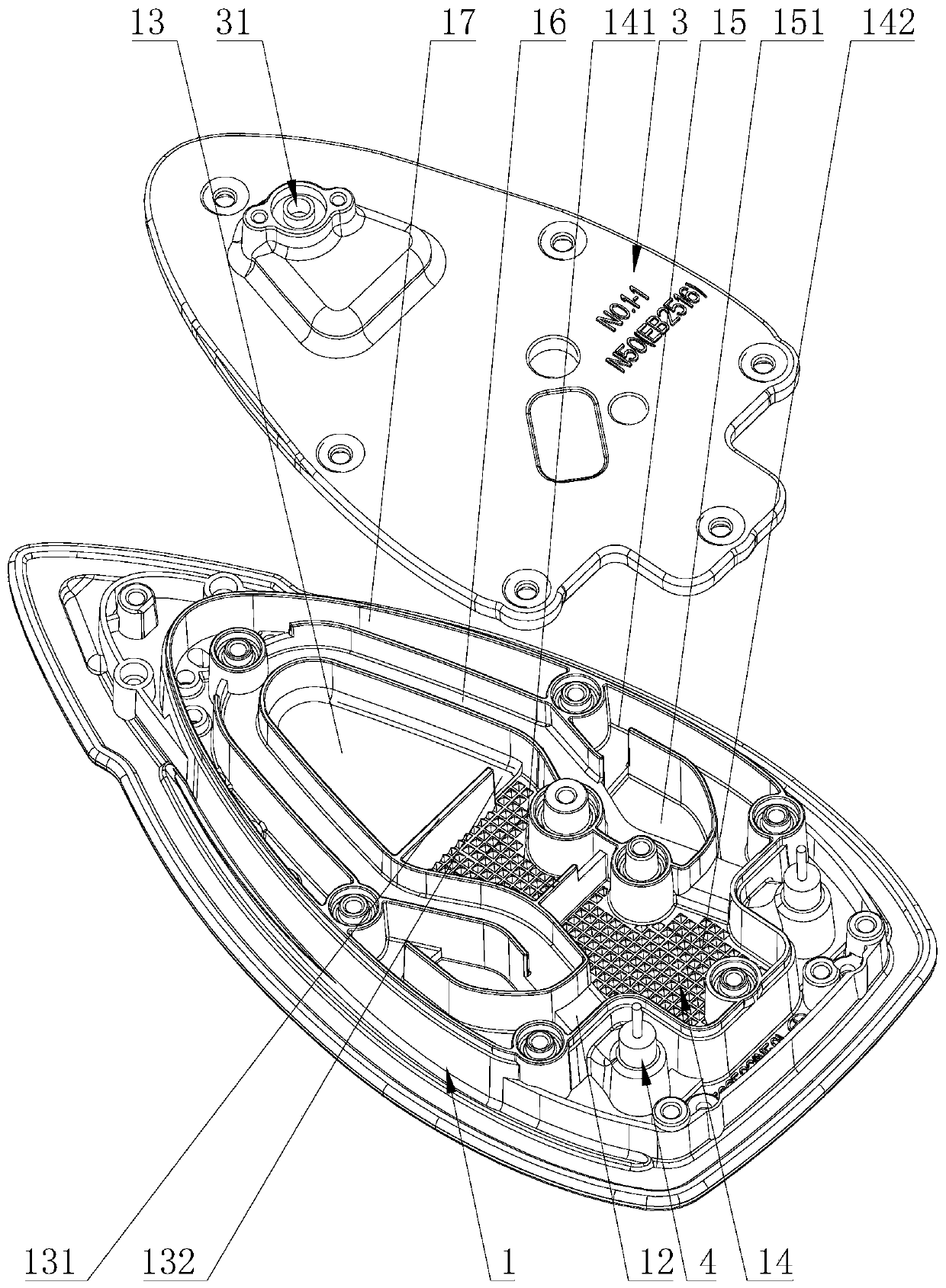

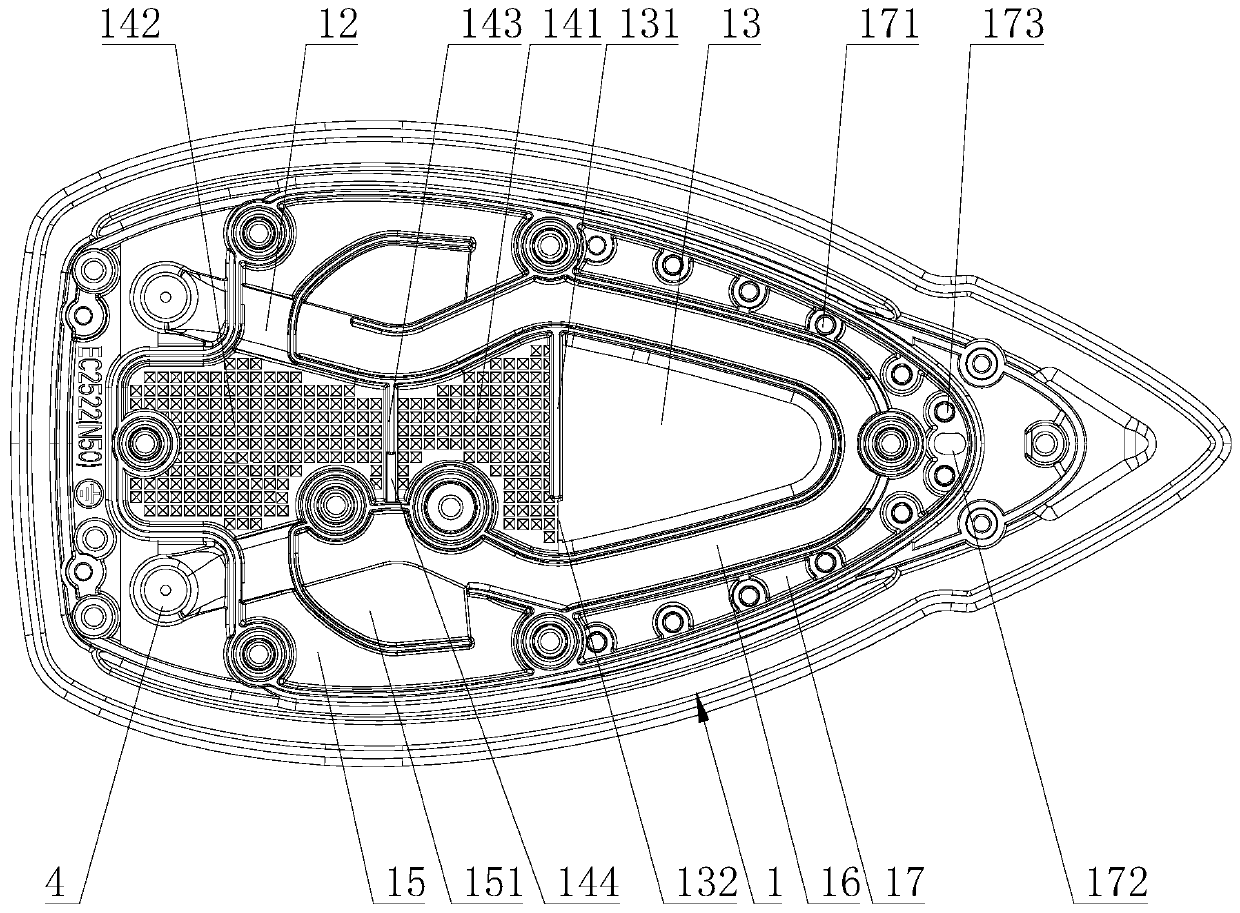

[0043] See attached figure 1 , attached figure 2 And attached Figure 5 , a soleplate assembly of a steam iron, comprising an iron soleplate 1 , an ironing panel 2 , a soleplate cover 3 and an electric heating tube 4 . The top of the soleplate 1 of the iron has a vaporization cavity 11 , the bottom plate cover 3 seals and covers the upper opening of the vaporization cavity 11 , and the soleplate cover 3 has a water filling hole 31 for replenishing liquid water into the vaporization cavity 11 .

[0044] See attached figure 2 And attached Figure 4 The electric heating tube 4 is fixed inside the soleplate 1 of the iron by die-casting, and mounting protrusions 12 symmetrically arranged on the left and right are formed on the top surface of the soleplate 1 . The joints at both ends of the electric heating tube 4 extend to the outside of the vaporization ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com