A piezoelectric ceramic driver preloading device

A technology of piezoelectric ceramics and drivers, applied in the field of piezoelectric ceramics, can solve problems such as loss of top tightening effect, input dead zone, large working thrust of piezoelectric ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The core of the present invention is to provide a piezoelectric ceramic driver pretensioning device, which can prevent the top tightening mechanism from loosening.

[0033] In order to enable those skilled in the art to better understand the technical solution of the present invention, the piezoelectric ceramic actuator pretensioning device of the present invention will be described in detail below with reference to the drawings and specific implementation methods.

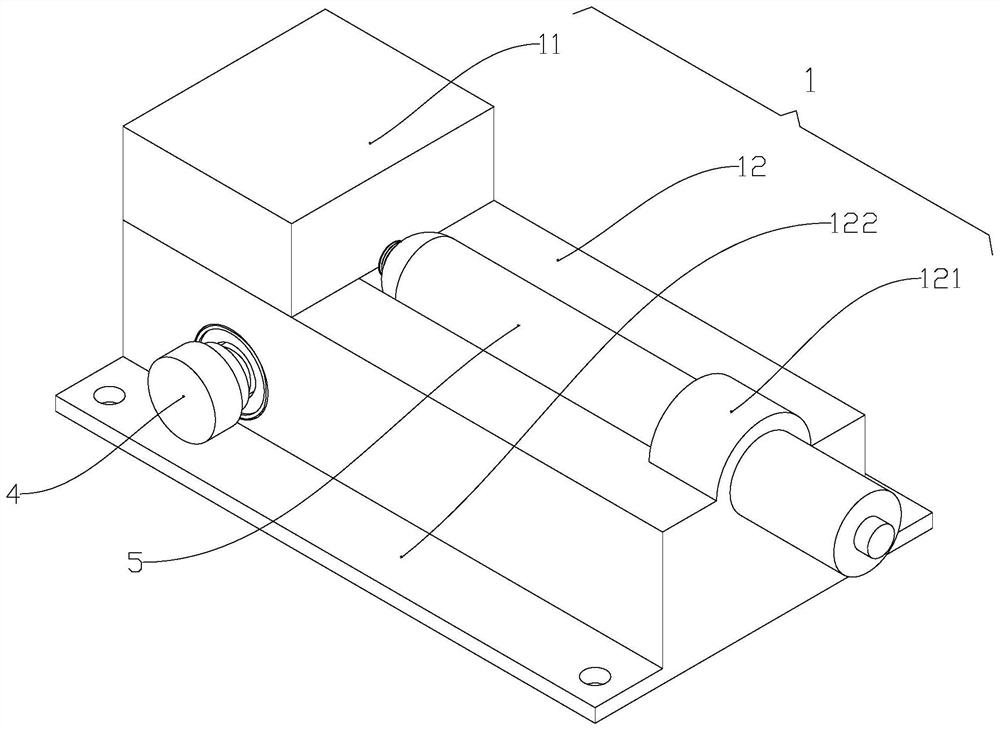

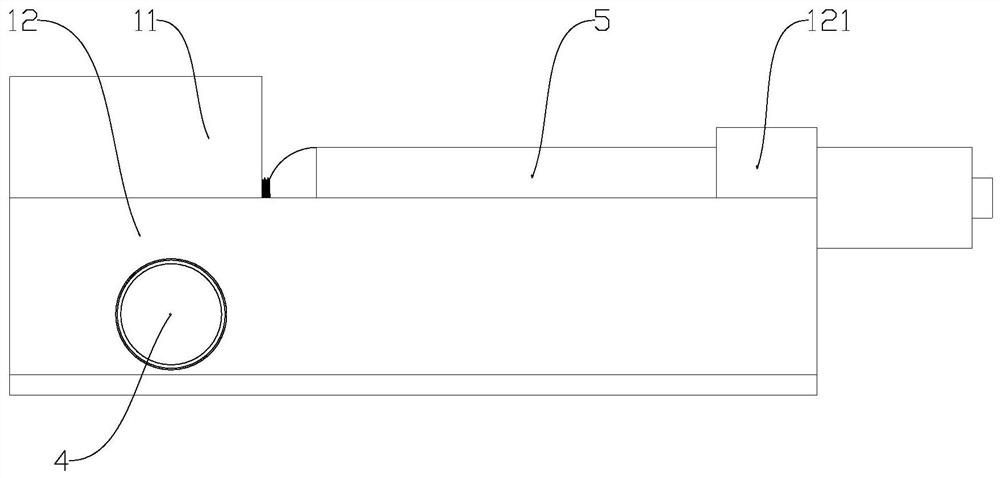

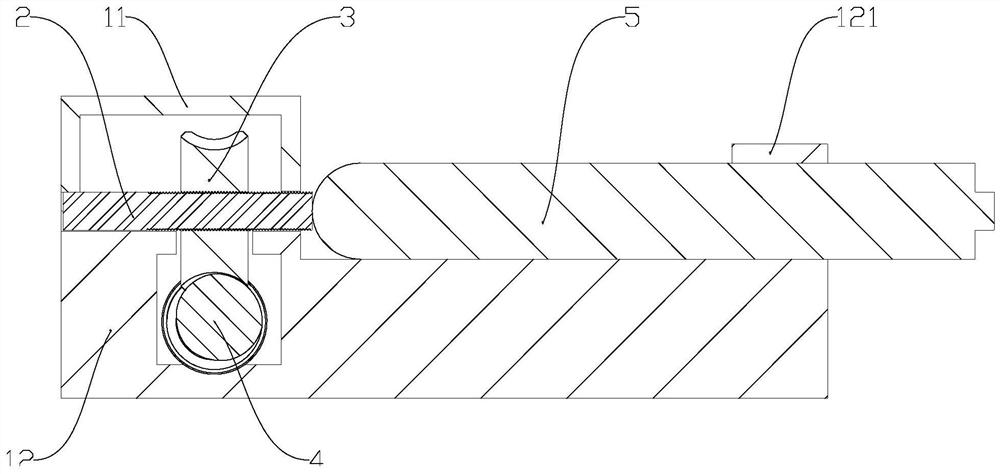

[0034] Such as Figure 1A As shown, it is an axonometric view of the piezoelectric ceramic driver pretensioner provided by the present invention; Figure 1B and Figure 1C Respectively, the front view and the front sectional view of the piezoelectric ceramic driver pretensioning device provided by the present invention; including structures such as a base 1, a threaded column 2, a worm wheel 3, and a worm 4, and the base 1 is a main support structure, such as Figure 2A and Figure 2B As shown, they are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com