Four-jaw synchronous mechanical unlocking automatic pick-and-place device

An automatic pick-and-place and synchronous technology, which is applied in the field of cargo pick-and-place, can solve the problems of bulky and bulky structures, and achieve the effects of simple control methods, reduced possibilities, and improved mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments, features, and performance aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

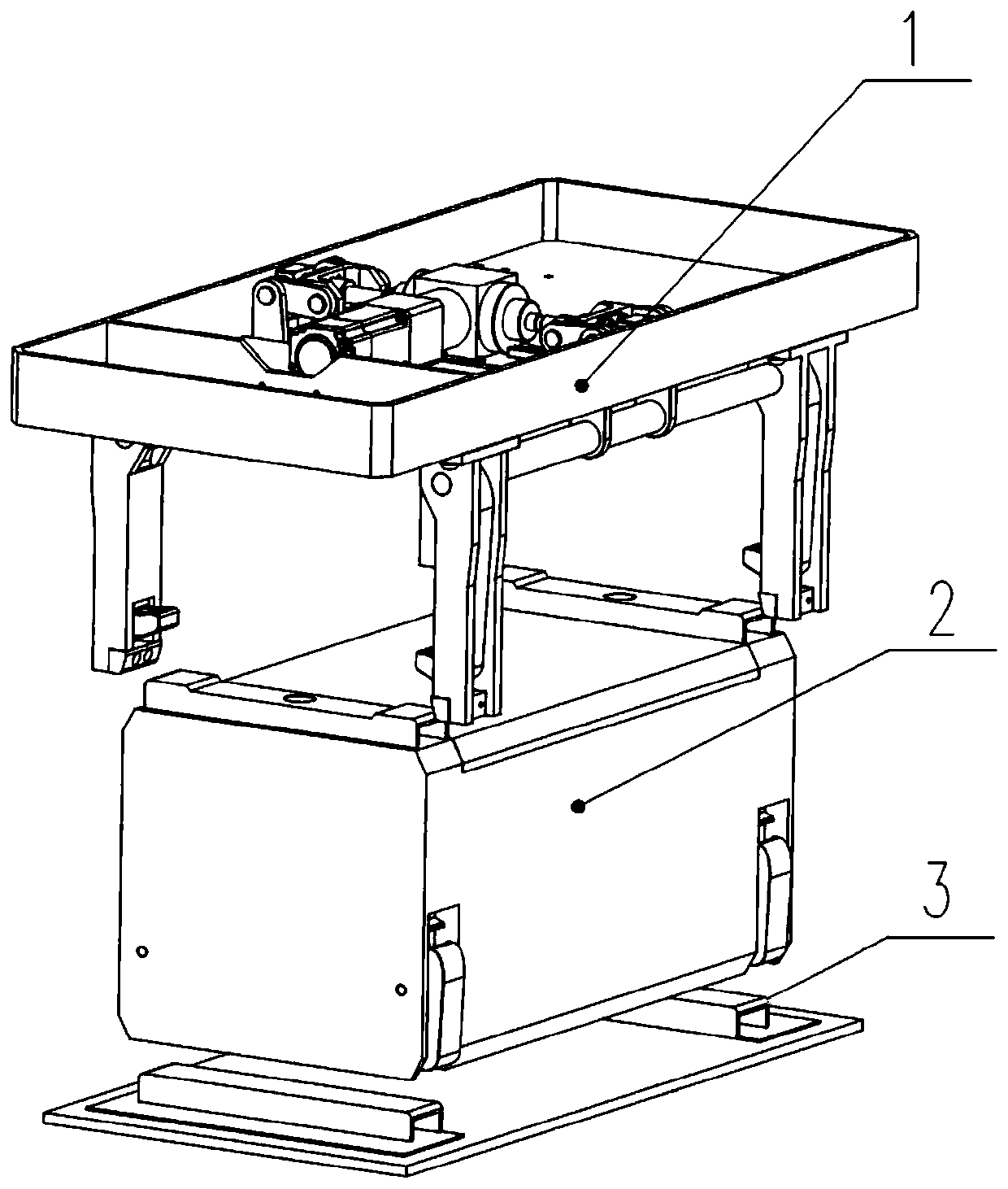

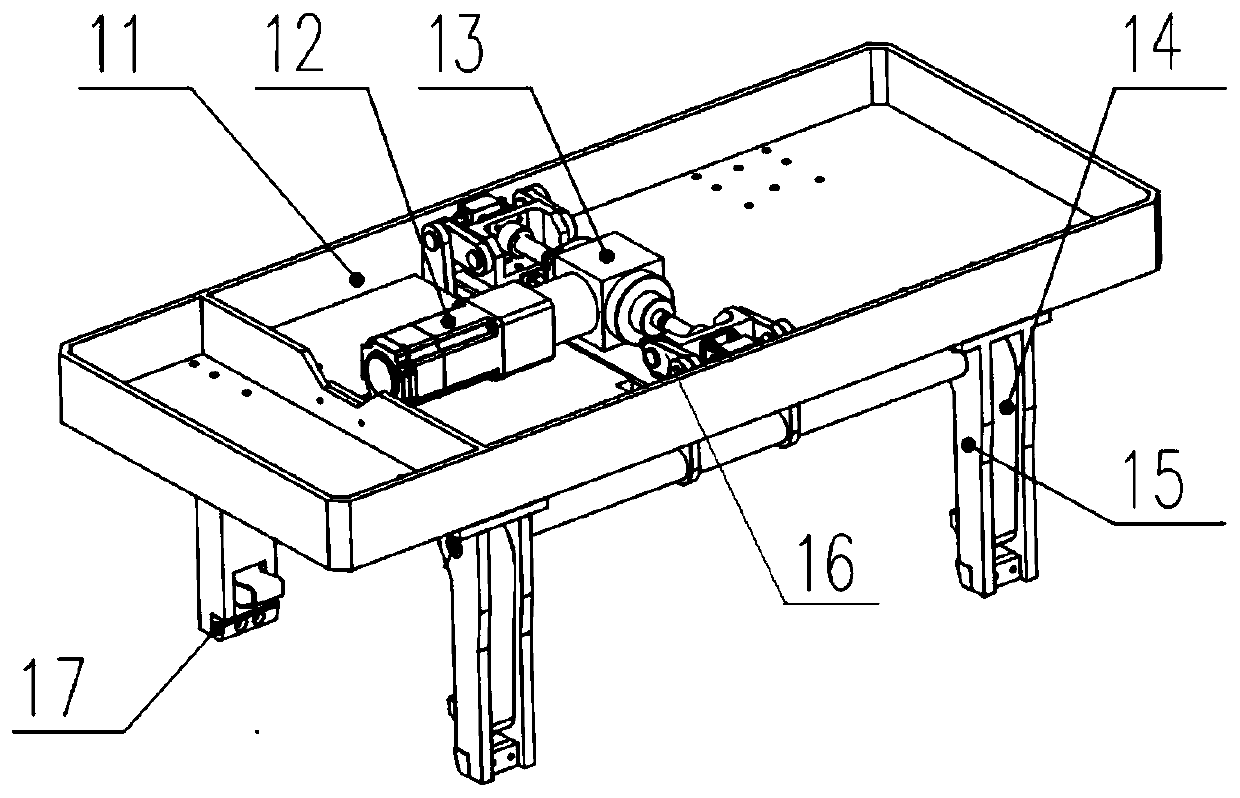

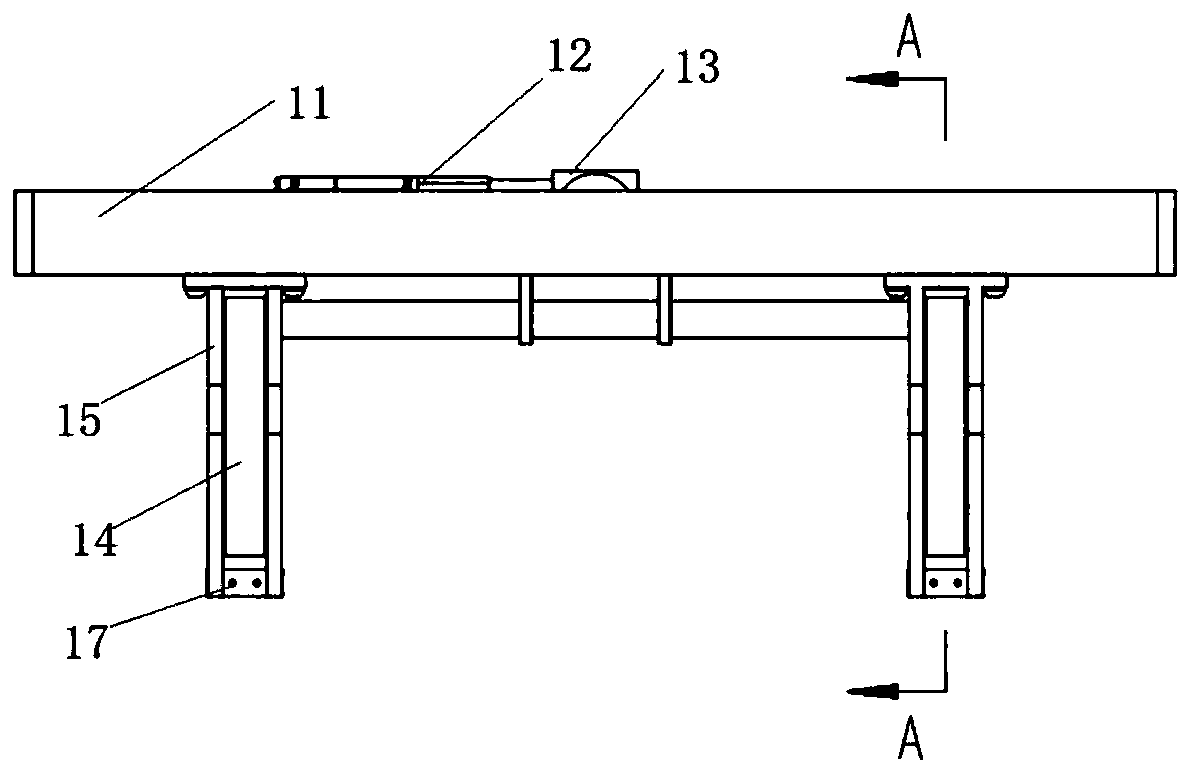

[0031] Such as figure 1 As shown, a four-claw synchronous mechanical unlocking automatic pick-and-place device includes a four-claw synchronous mechanical gripper 1 and a cargo storage box 2 . Such as figure 2 and 3 As shown, the four-claw synchronous mechanical gripper 1 includes a mounting frame 11, an input motor 12, a T-shaped double-output reducer 13, a connecting rod transmission 16, a hook claw 14, a fixed leg 15 and a wedge-shaped anti-collision block 17. Leg 15 is vertically fixed on the four corners of the bottom plate bottom of mounting frame 11 and is pressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com