Lever type lifting, cleaning and removing device for top material plate in constructional engineering

A kind of construction engineering and lever-type technology, which is applied in the direction of construction, building structure, and on-site preparation of building components. It can solve the problems of high height of the top formwork and inconvenient manual disassembly, etc., and achieve increased friction and high self-locking characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

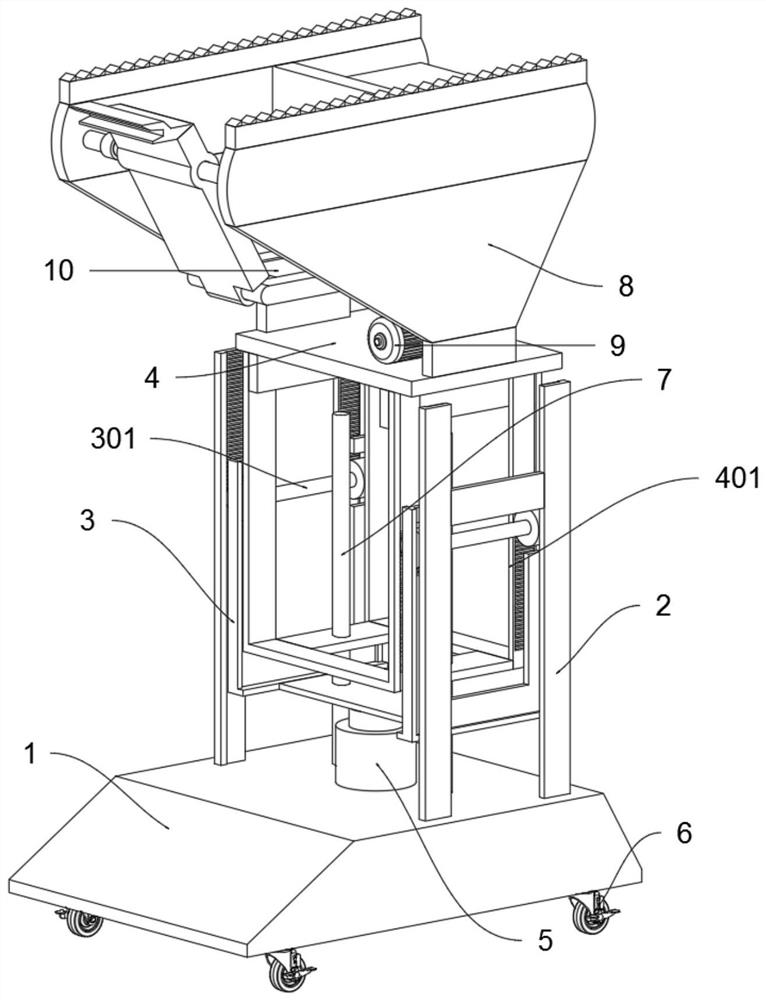

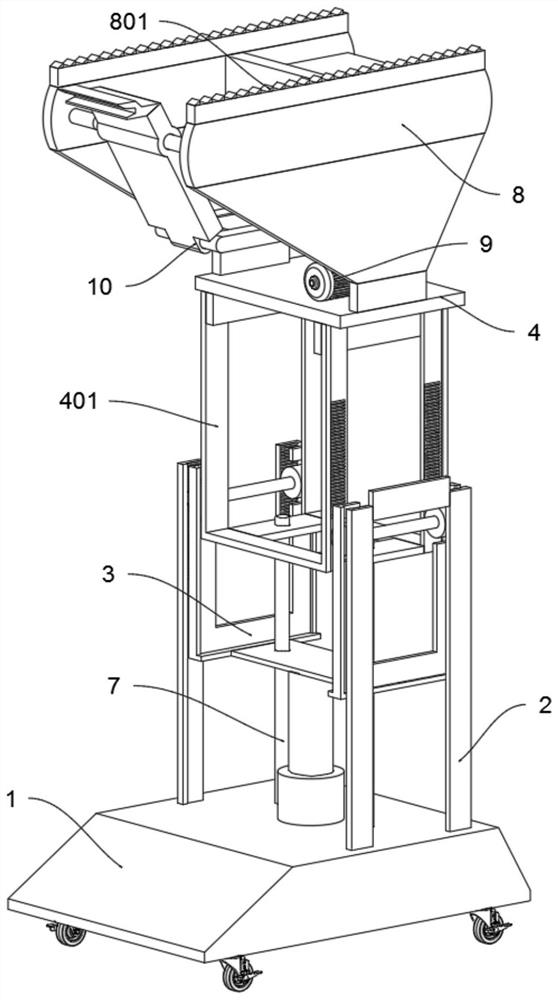

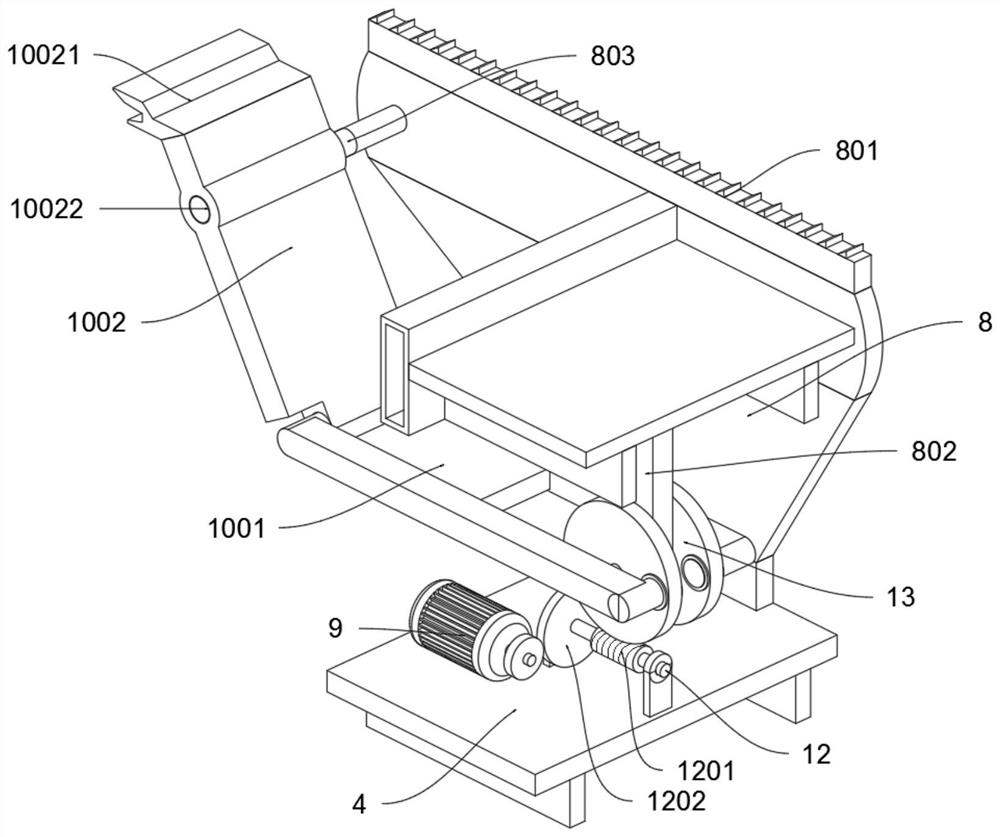

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034]The invention provides a lever-type tilting cleaning and removal device for the top material plate of construction engineering, which includes a base 1, an inner push frame 3, a lifting platform 4, a telescopic driving member 5, a moving wheel 6, an orientation guide rod 7, an upper positioning platform 8, The driving part 9, the lifting plate part 10, the lower transmission shaft 12, the double eccentric wheel 13; the upper surface of the base 1 is fixedly connected with four lifting columns 2 by welding, and the lifting columns 2 are perpendicular to the upper surface of the base 1; telescopic drive The part 5 is arranged in the middle of the upper surface of the base 1; the bottom surface of the inner push frame 3 is fixedly connected to the output shaft of the telescopic drive part 5, and the transmission wheel 301 of the inner push frame 3 is meshed with the inner rack on the lifting column 2; the lift table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com