Process for jointing cables, apparatus for performing such a process and thermoplastic joint so manufactured

A thermoplastic and equipment technology, applied in the direction of connecting/terminating cable equipment, cable joints, cable installation, etc., can solve problems such as reconstruction and stability of cable joint insulation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

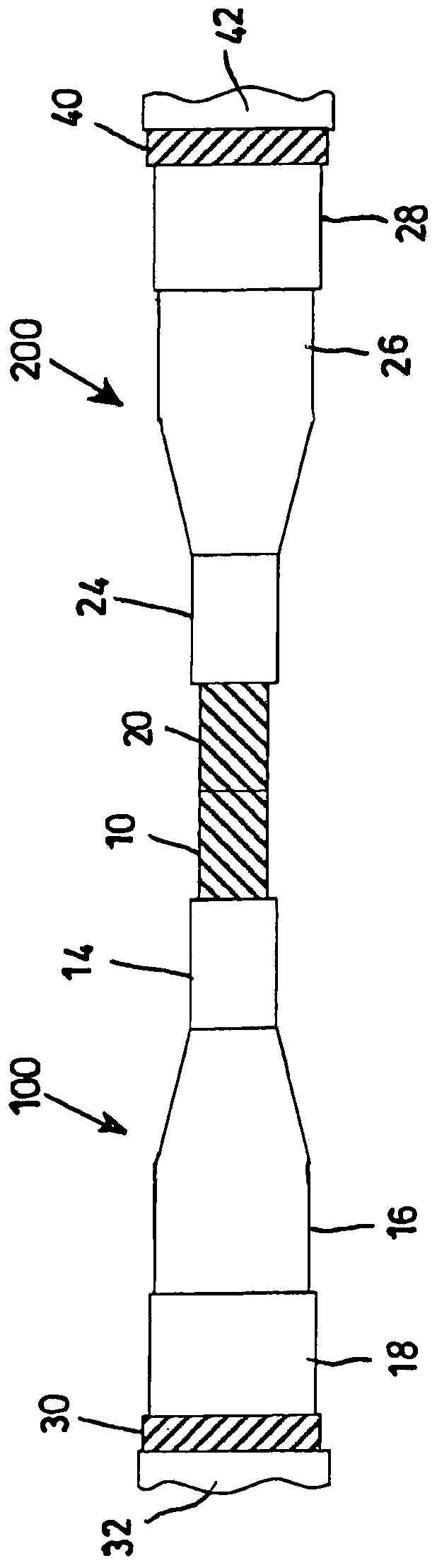

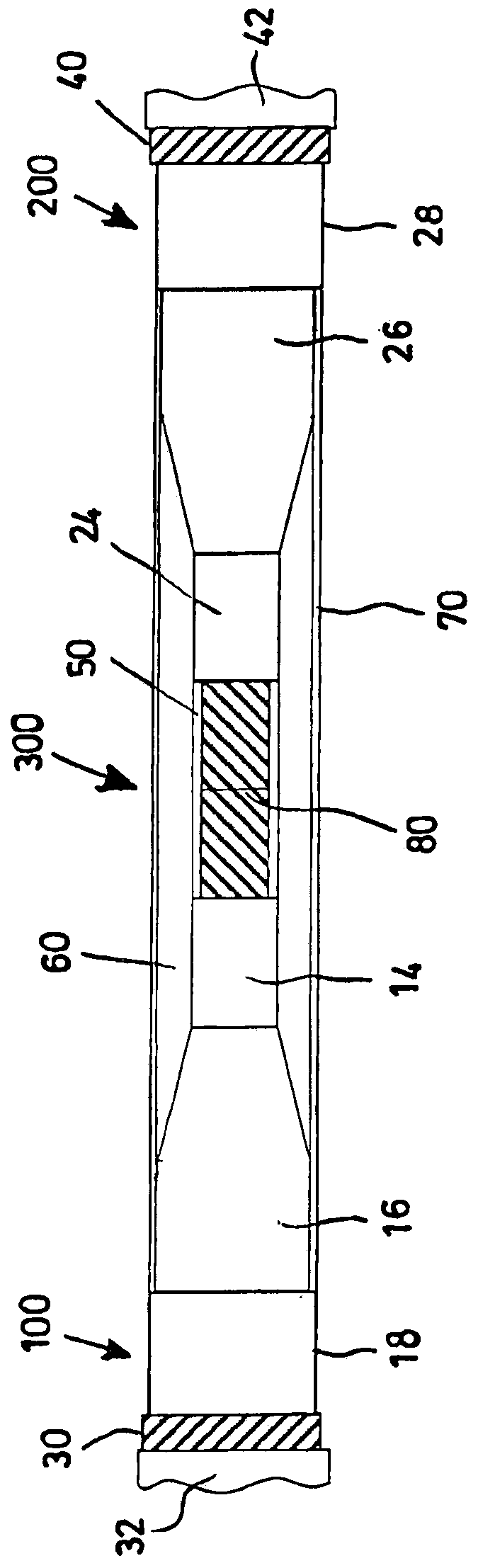

[0063] exist figure 1 In , a first power cable 100 and a second power cable 200 are schematically shown. The first power cable 100 and the second power cable 200 are arranged axially adjacent to each other and are exposed by removing parts of the upper layers (listed below) for subsequent joining together.

[0064] Each cable 100 , 200 comprises an electrical conductor 10 , 20 and an insulation system surrounding the respective electrical conductor 10 , 20 . The insulation system includes an inner thermoplastic semiconducting layer 14 , 24 , a thermoplastic insulating layer 16 , 26 and an outer thermoplastic semiconducting layer 18 , 28 . The inner thermoplastic semiconducting layer 14, 24 surrounds the respective electrical conductor 10, 20 of the power cable 100, 200 and is in direct contact with the electrical conductor. Each thermoplastic insulating layer 16, 26 surrounds and is in direct contact with a respective inner thermoplastic semiconducting layer 14, 24, and an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com